Borosilicate glass with high transmittance at far ultraviolet band and preparation method thereof

A borosilicate glass, high transmittance technology, applied in the field of glass manufacturing, can solve problems such as difficulty in meeting the requirements of airtight sealing, poor chemical stability against water, mismatched expansion coefficients, etc., and achieve excellent chemical resistance against water. , The effect of improving transmittance and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

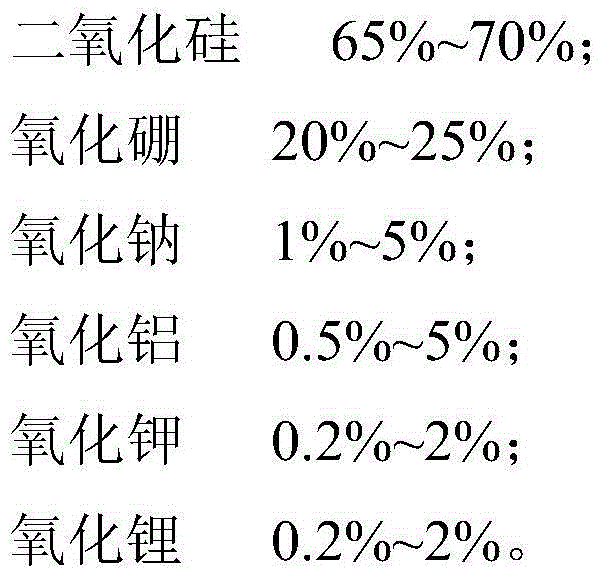

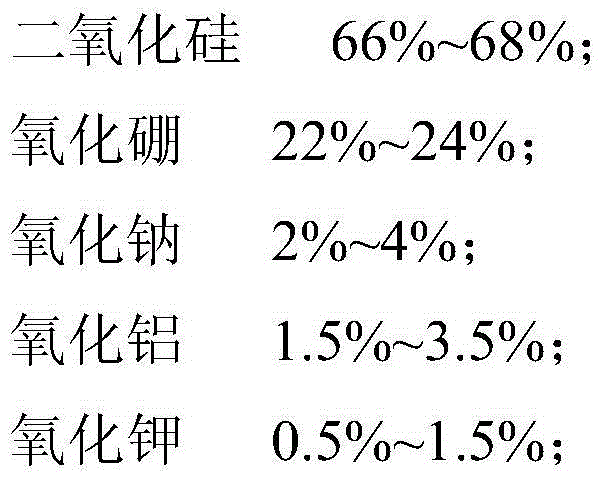

Method used

Image

Examples

Embodiment 1

[0036] Weighing step: weighing and mixing each raw material component according to the ratio set in Table 1 to form a mixture; wherein, the raw material of silica is prepared from quartz sand soaked in hydrochloric acid solution; specifically, Soak the quartz sand in hydrochloric acid solution for 4 hours, the iron content of the obtained quartz sand is less than 5ppm, then wash it with deionized water, and then transfer it to an oven at 120°C for 8 hours, which is the component used in this example. silica.

[0037] The raw material of the boron oxide is analytically pure H 3 BO 3 ; The raw material of alumina is analytically pure Al 2 o 3 ; The raw material of sodium oxide is analytically pure Na 2 CO 3 ; The raw material of potassium oxide is analytically pure K 2 CO 3 ; The raw material of lithium oxide is analytically pure Li 2 CO 3 .

[0038] During specific implementation, according to in table 1, the mass percentage composition of boron oxide, sodium oxide, a...

Embodiment 2

[0049] The procedure of Example 1 was repeated at the levels of components specified in Table 1 below. The test results are listed in Table 1.

Embodiment 3

[0051] The procedure of Example 1 was repeated at the levels of components specified in Table 1 below. The test results are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coefficient of expansion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com