Photosensitive resin composition and photoresist

A technology of photosensitive resin and composition, applied in the field of photosensitive materials, can solve the problem that photosensitive resin cannot have high adhesion and developability, and achieve the effects of improving reactivity and curing rate, improving developability and solvent resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

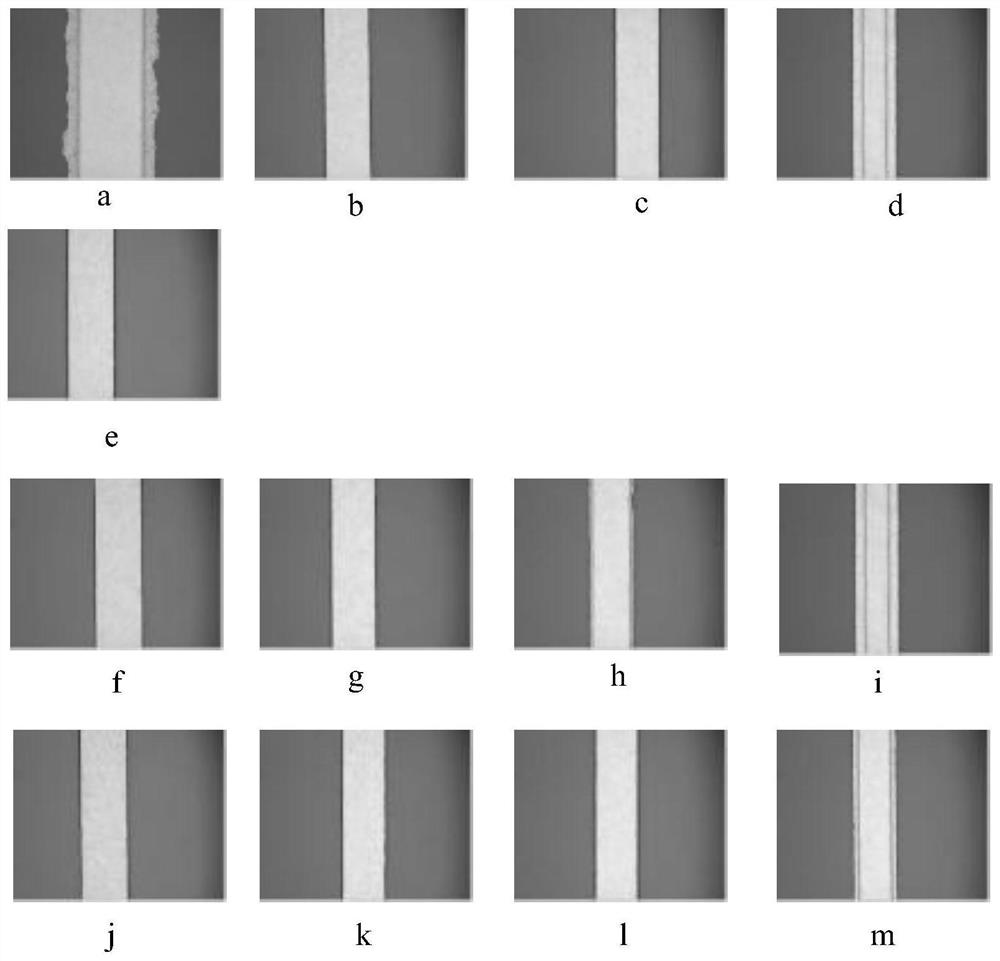

Image

Examples

Synthetic example

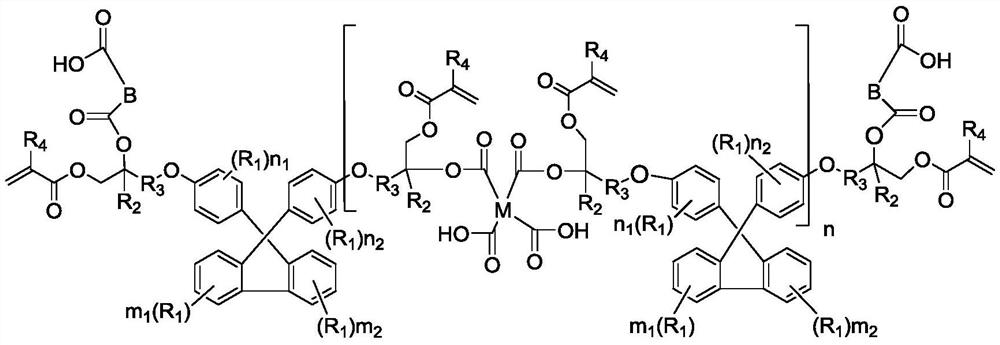

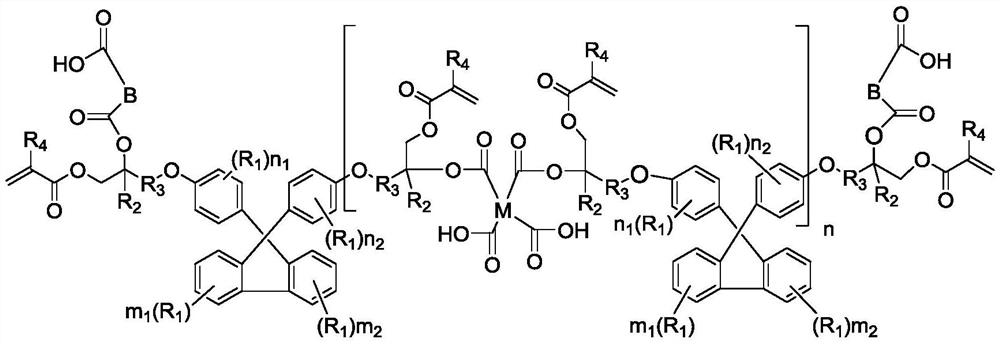

[0050] Synthesis example: Preparation of photosensitive resin

[0051] intermediate synthesis

[0052] Put 500g of intermediate I (9,9-bis[4-(2,3-epoxypropoxy)phenyl]fluorene) into a 2000ml four-necked flask, 160g of acrylic acid, and then add 0.5g of p-methoxyphenol And 5.6g tetraethyl ammonium bromide, then continue to add 400g PMA (propylene glycol methyl ether acetate, Propylene Glycol Methyl Ether Acetate), feed air bubbling in four-necked flask, start stirring, form reaction system, then The reaction system was gradually warmed up to 120°C, and reacted for 8 hours. During the reaction, the acid value was controlled centrally. After the acid value no longer changed, the reaction was completed, and the intermediate II (9,9-bis[4-(2-hydroxy- 3-acryloyloxypropoxy)phenyl]fluorene) product system, add PMA until the solid content reaches 55%, and then filter with an organic filter membrane with a pore size of 0.45 μm to obtain the PMA solution of the intermediate II.

[005...

Embodiment a-1

[0062] Add 1200g of the PMA solution of intermediate II to a 2000ml four-necked flask, continue to add 192.1g of 3,3',4,4'-biphenyltetracarboxylic dianhydride (BPDA), start stirring to form a reaction system, and pour into the four-necked flask Dry air was passed through the medium, and then the reaction system was heated to 105° C. and stirred for 12 hours. During this period, the reaction of the anhydride was detected by infrared, and the peak of the anhydride was no longer reduced. After adding 75 g of tetrahydrophthalic anhydride into the four-necked flask, the reaction was kept at 80° C. for 6 hours, during which time the consumption of the anhydride was detected by infrared. Then, add PMA to adjust the solid content of the system to 50%, cool down to about 70°C, and discharge. While hot, use a 0.8 μm membrane to filter out mechanical impurities to obtain photosensitive resin A1. The weight-average molecular weight of the resin obtained by GPC measurement is 6315, (the w...

Embodiment a-2

[0064] The formula is similar to that of Example a-1, the quality of the added 3,3',4,4'-biphenyltetracarboxylic dianhydride (BPDA) is adjusted to 208.1g, the preparation method is the same as that of Example a-1, and the obtained resin The weight average molecular weight is 6912, the acid value is 106mgKOH / g, named as photosensitive resin a-2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com