Capsule dismantling method and apparatus

A technology for capsules and equipment, applied in the field of dismantling and equipment of capsules, can solve the problems of affecting the content of active ingredients of medicines, affecting the smoothness of filling process, and uneven density of medicinal powders, so as to avoid loss of medicinal materials, ensure medicinal purity, Fast separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

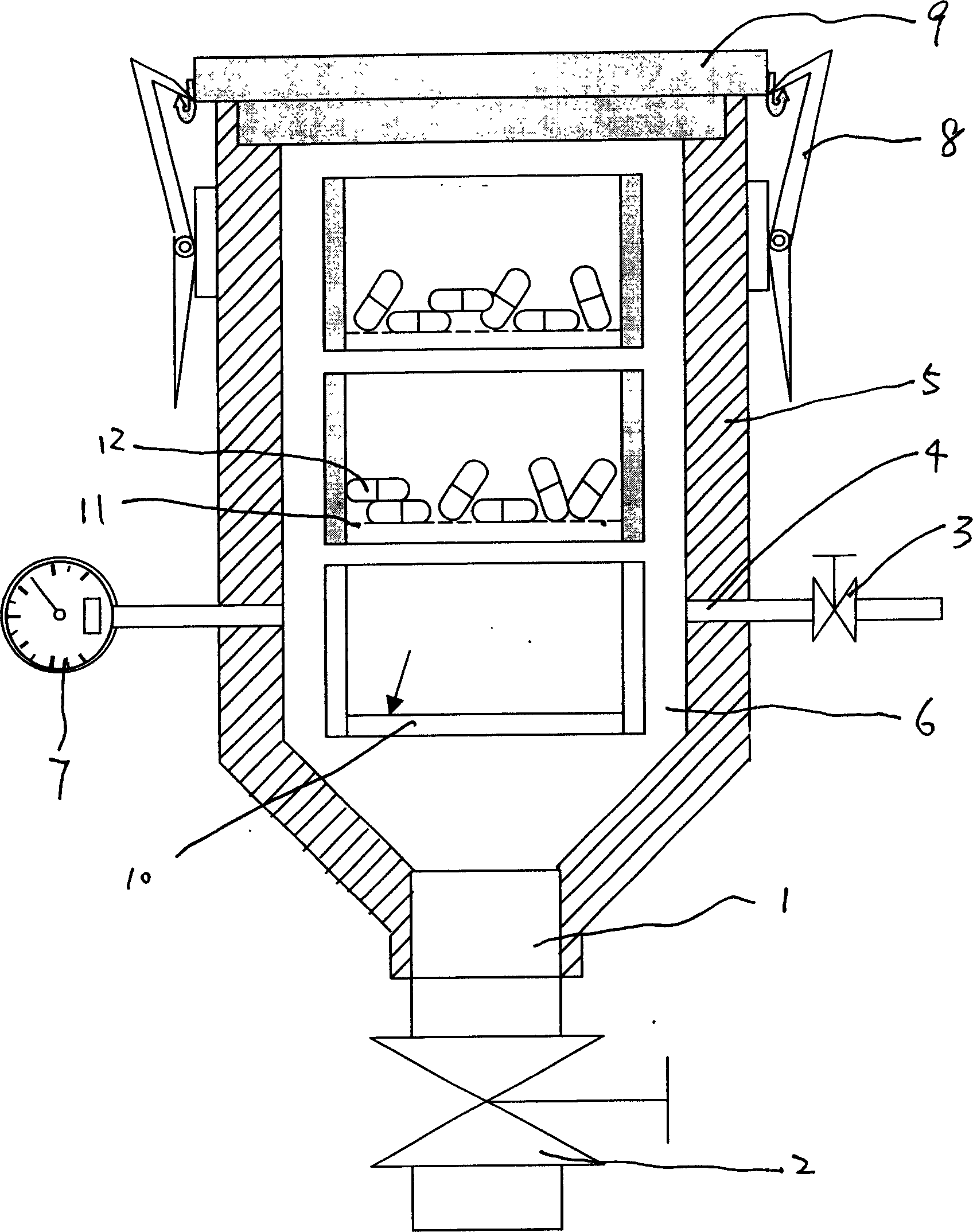

[0027] A capsule dismantling method, the capsule to be disassembled is put into a pressure container; the pressure container is filled with compressed air, so that the high-pressure compressed air enters the capsule from the gap between the capsule body and the capsule cap; and then quickly Reduce the pressure in the pressure vessel, so that the high-pressure air inside the capsule will expand rapidly due to the sudden pressure difference between the inside and outside, and the expansion force from the inside to the outside of the capsule will separate the capsule body and capsule cap. After filling the pressure vessel with compressed air, the high-pressure compressed air first flattens the capsule radially and enters the capsule from the gap between the capsule body and the capsule cap, so that the air pressure inside and outside the capsule is gradually balanced and maintained. With higher pressure. The crushed capsule body and capsule cap recover to the shape before being c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com