Automatic control equipment for online removal of tiny burrs on the working edge of the servo valve spool

A working edge and servo valve technology, applied in metal processing equipment, turning equipment, turning equipment, etc., can solve the problems of easily destroying the integrity of the working edge, high rejection rate, low efficiency, etc., and achieve online automatic detection, The effect of removing difficulty and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] At present, the method of removing the tiny burrs generated during the grinding process is to install them off-line on a motor-driven rotating device after processing to rotate the workpiece, and then use a hard alloy strip that is ground flat and a metallographic sandpaper wrapped The razor blade is repeatedly extruded along the outer circle and the end surface respectively. This method is very inefficient and easily destroys the integrity of the working edge, resulting in a high scrap rate.

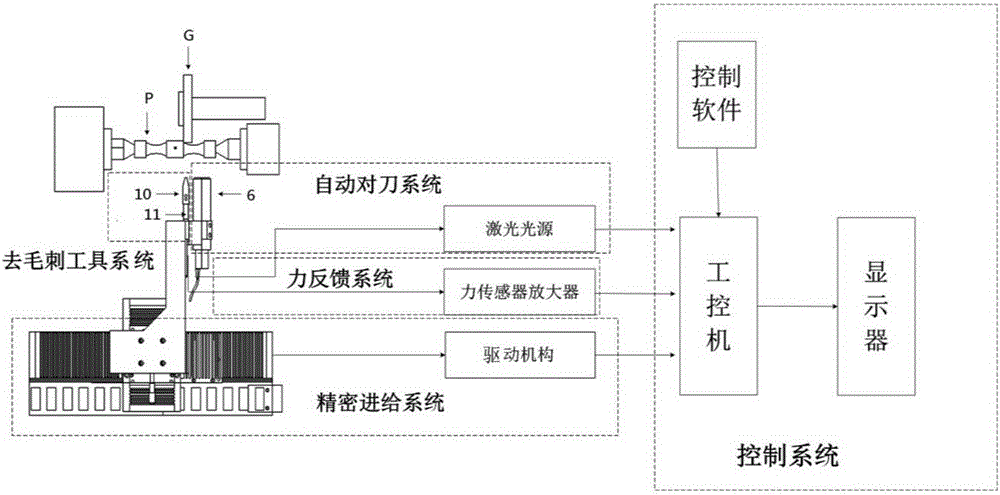

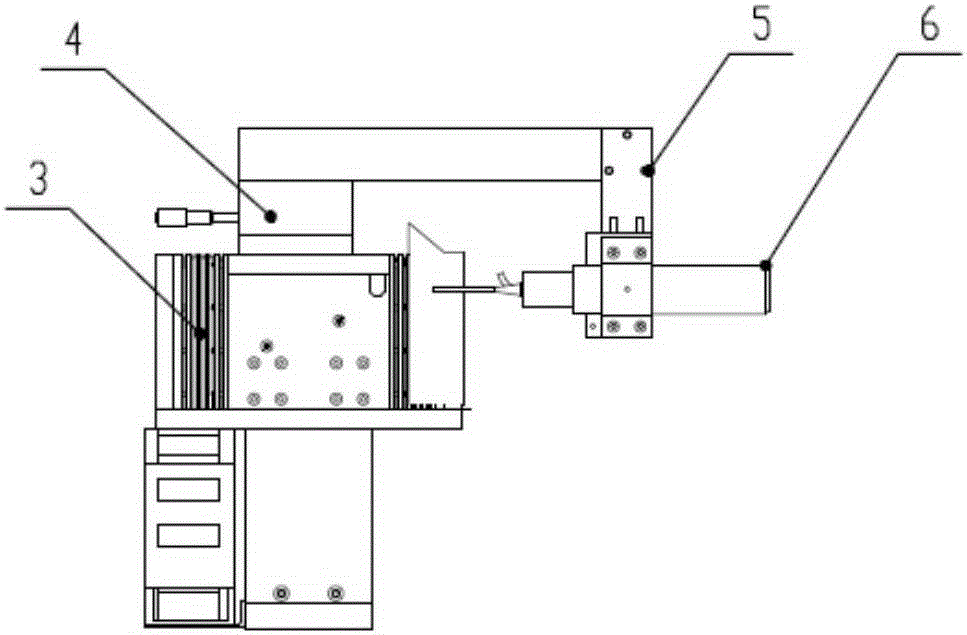

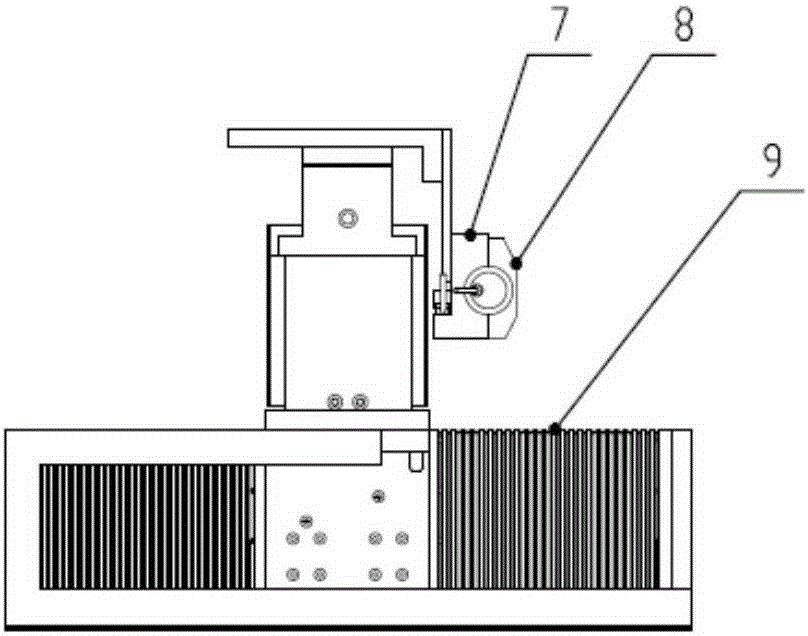

[0027] The present invention is used for online automatic deburring of the working side of the spool of the servo valve, please refer to figure 1 , in the production process, the working edge of the servo valve spool workpiece P is finally processed by grinding with the grinding wheel G of the precision grinder, and tiny burrs will be produced on the surface of the working edge in the processing process. The automatic control device of the present invention is installed on the gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com