Patents

Literature

36results about How to "Realize Force Feedback Control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

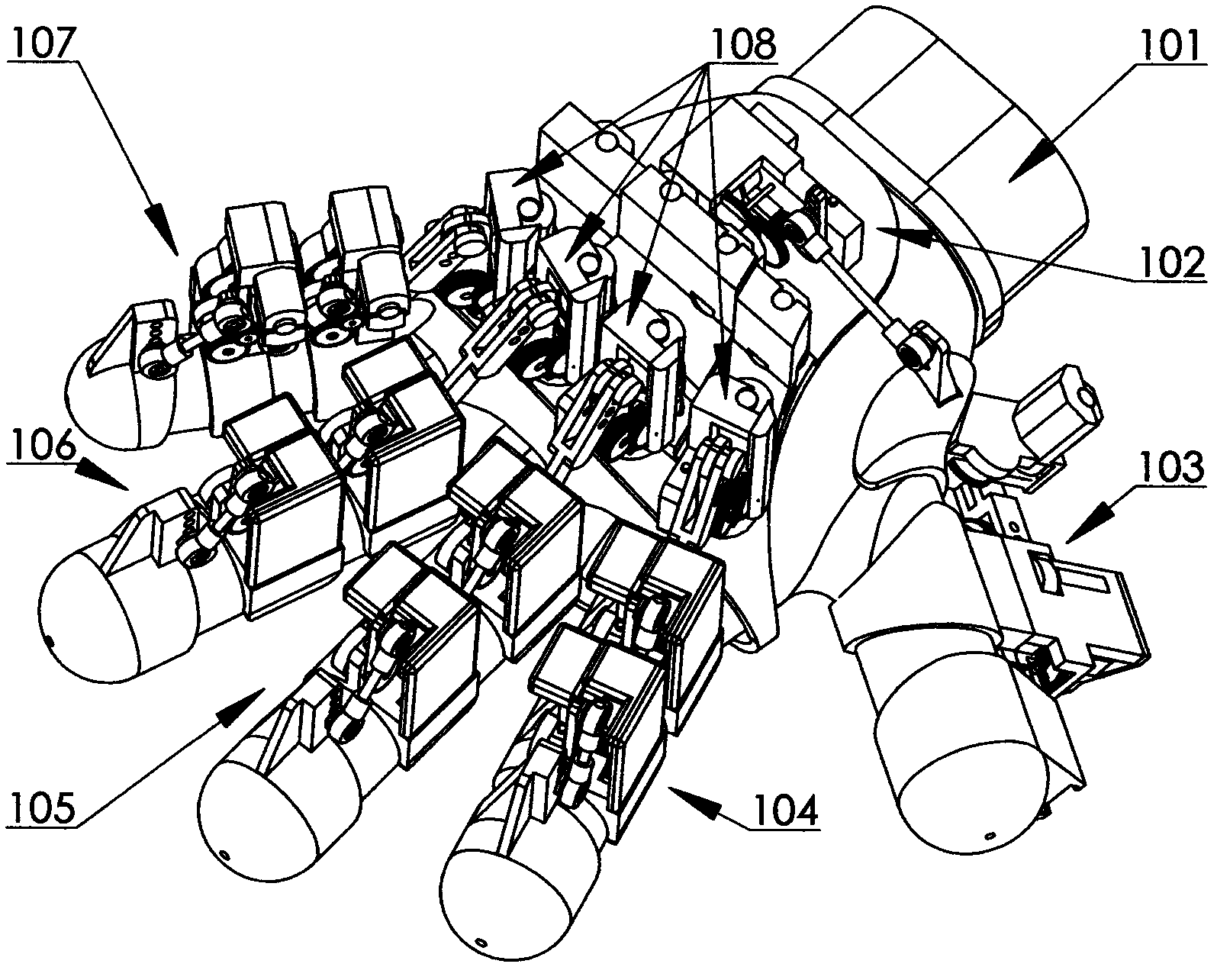

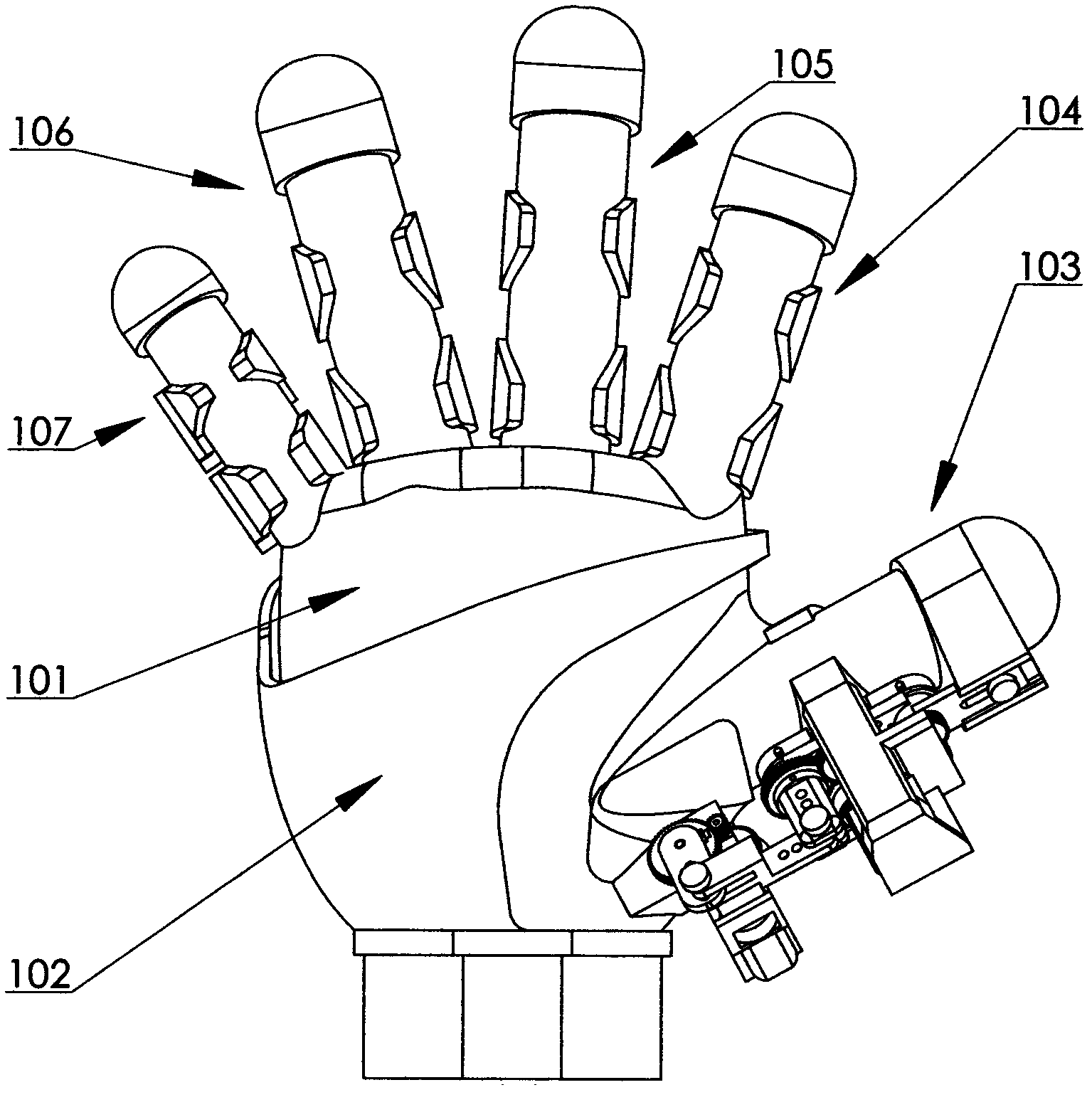

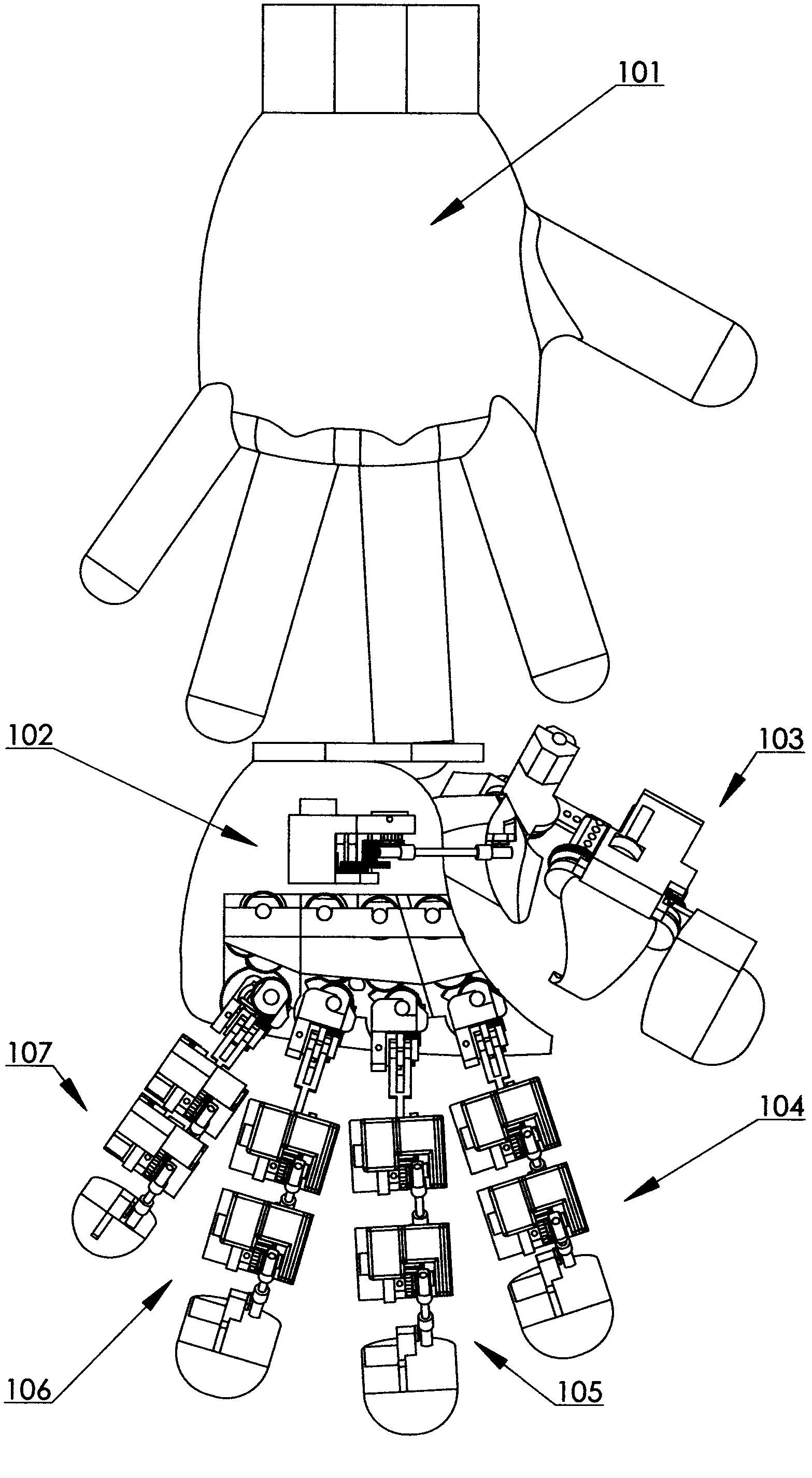

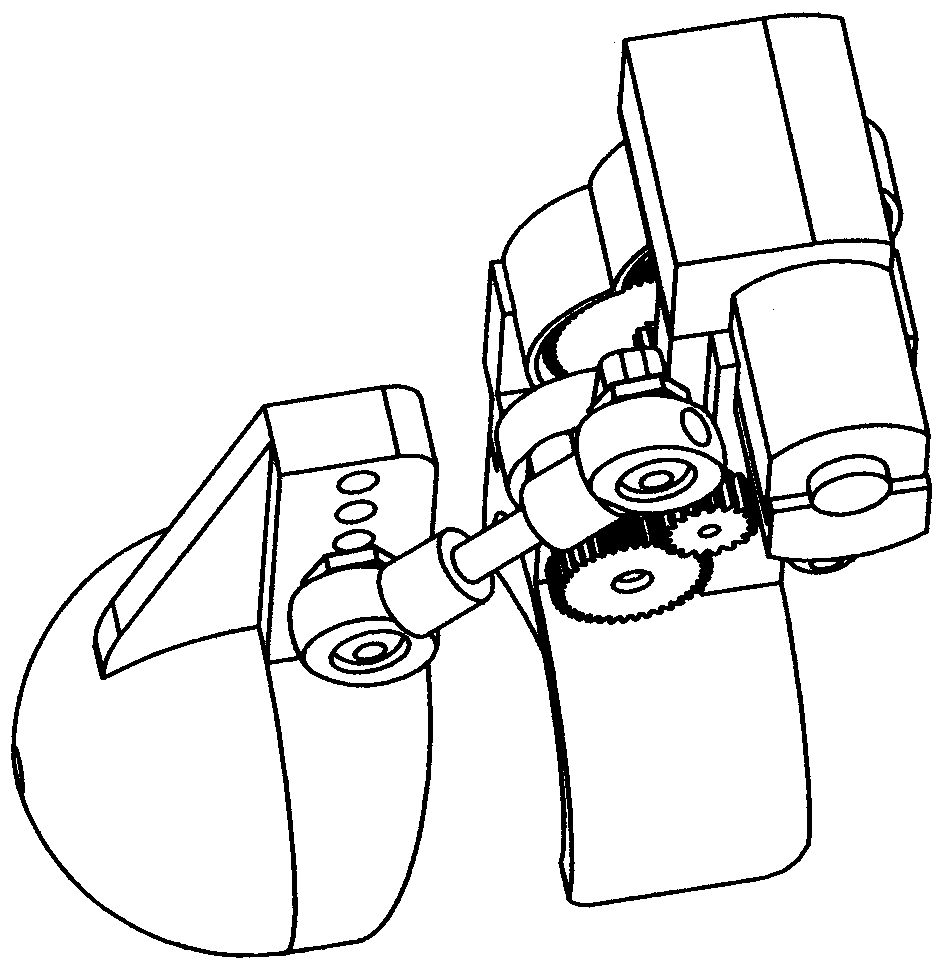

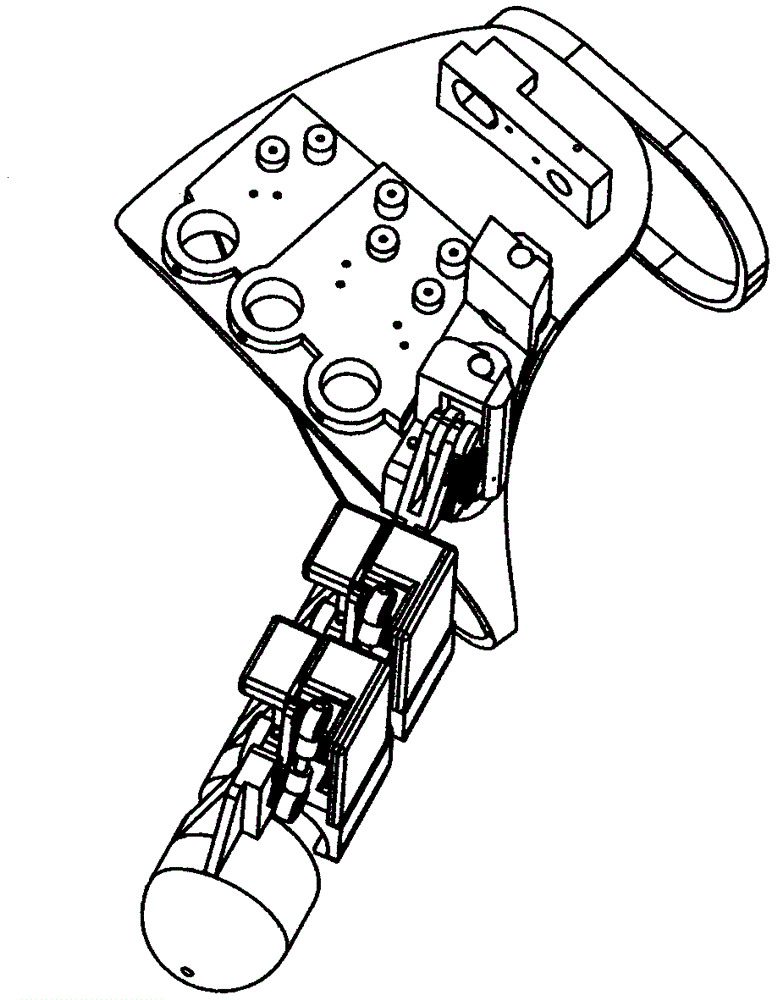

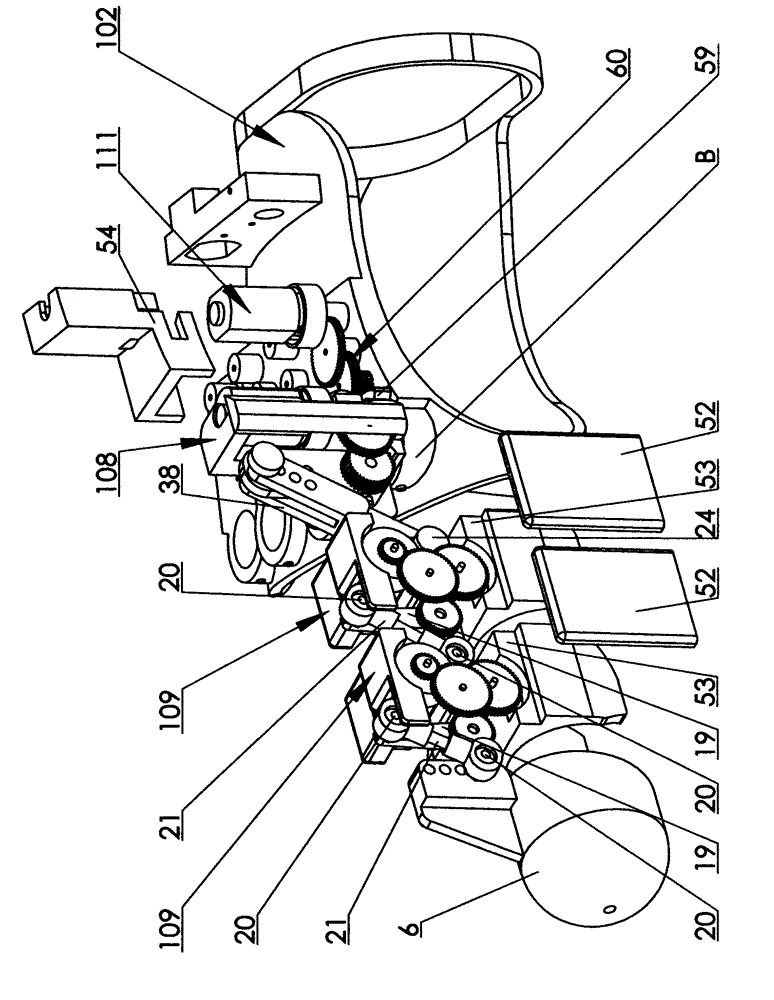

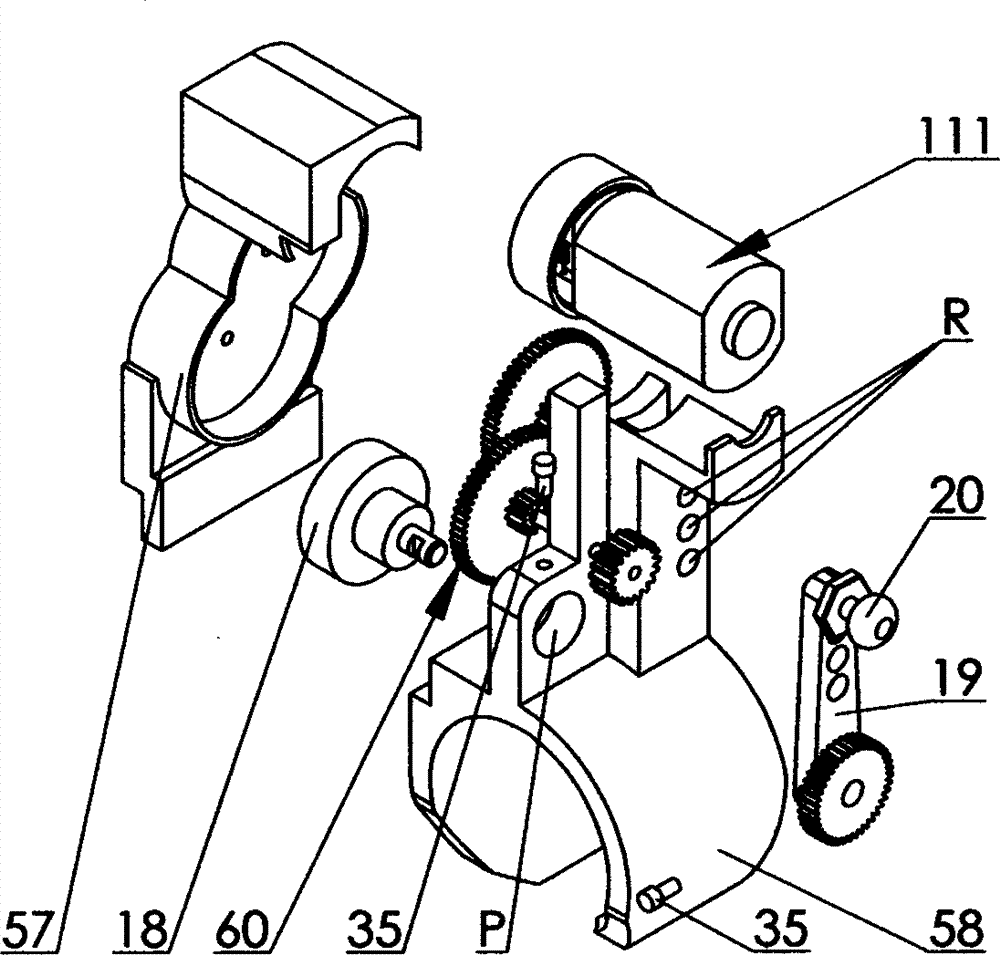

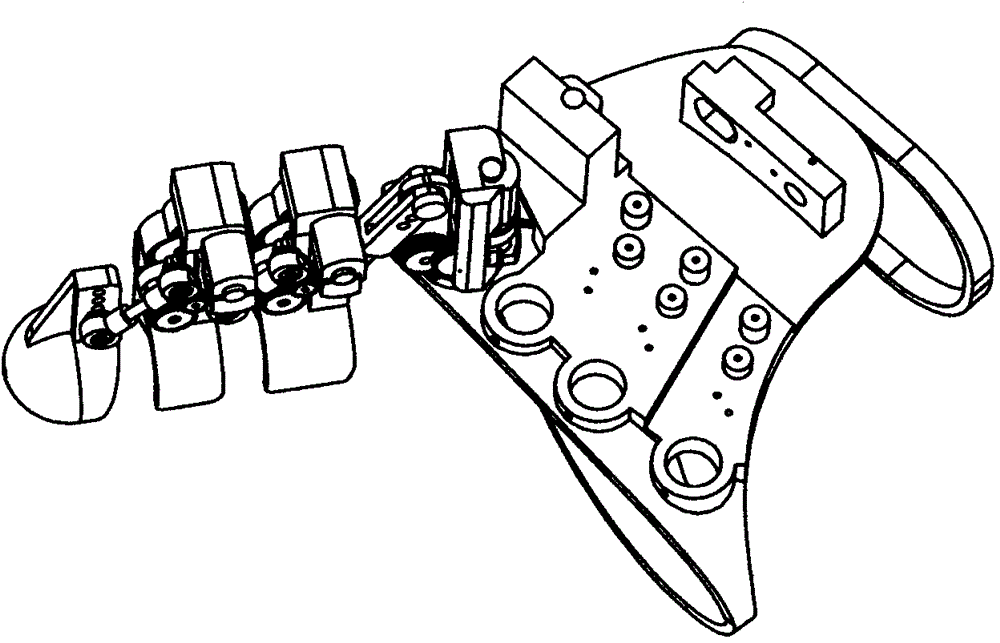

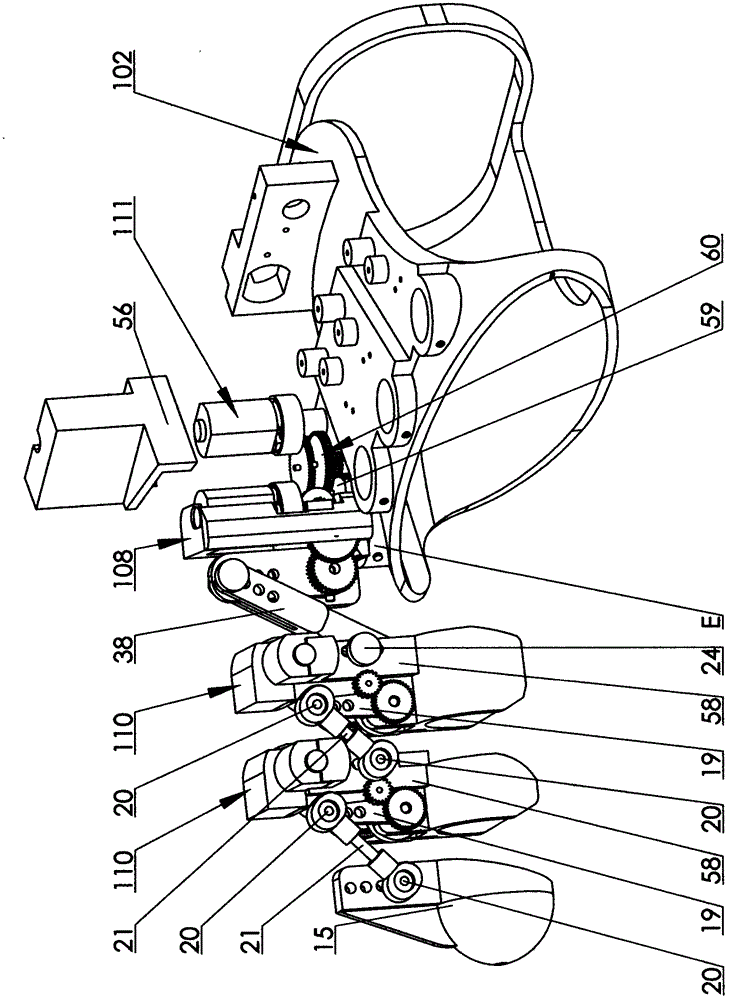

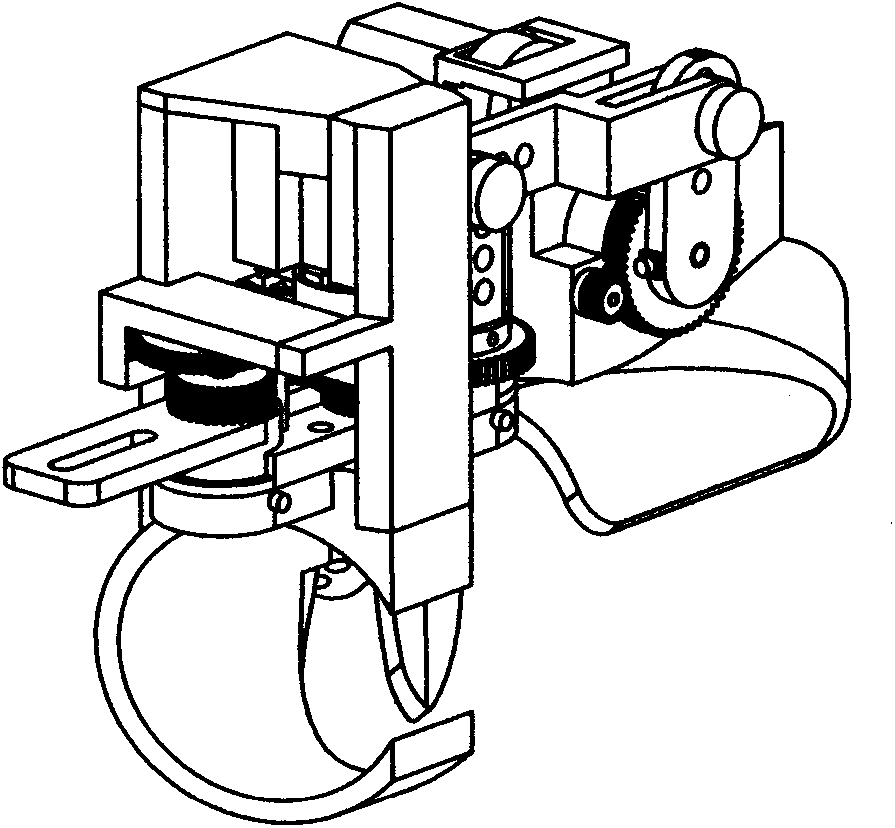

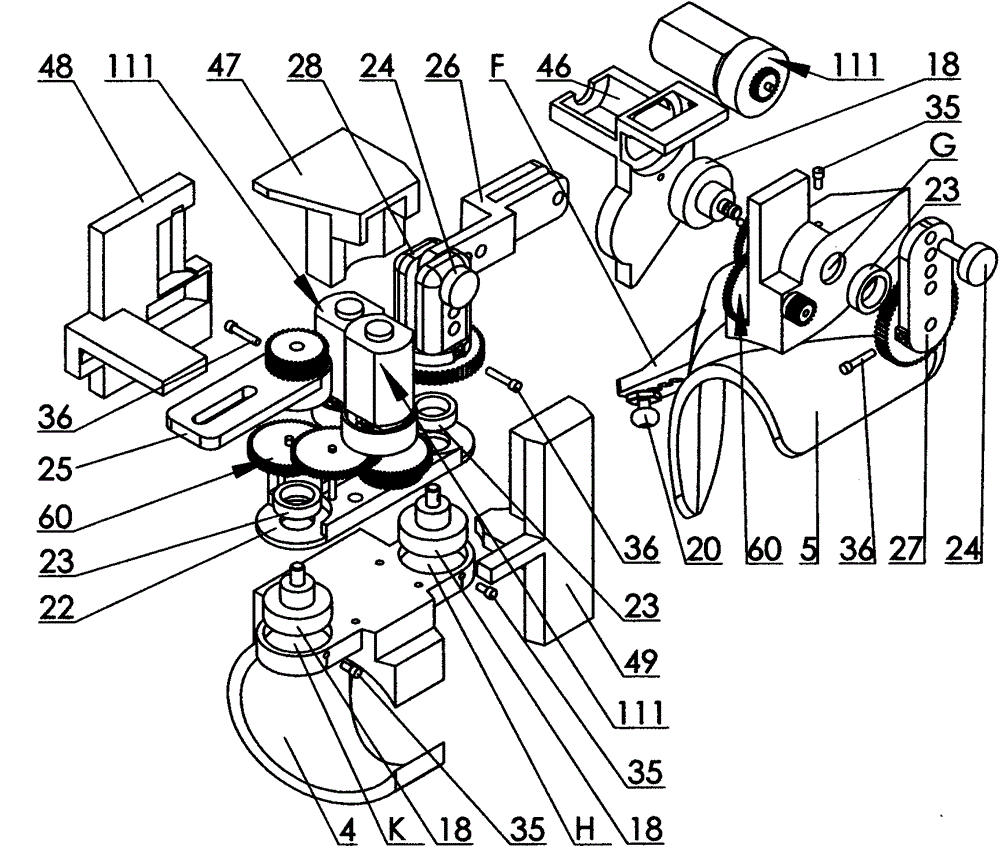

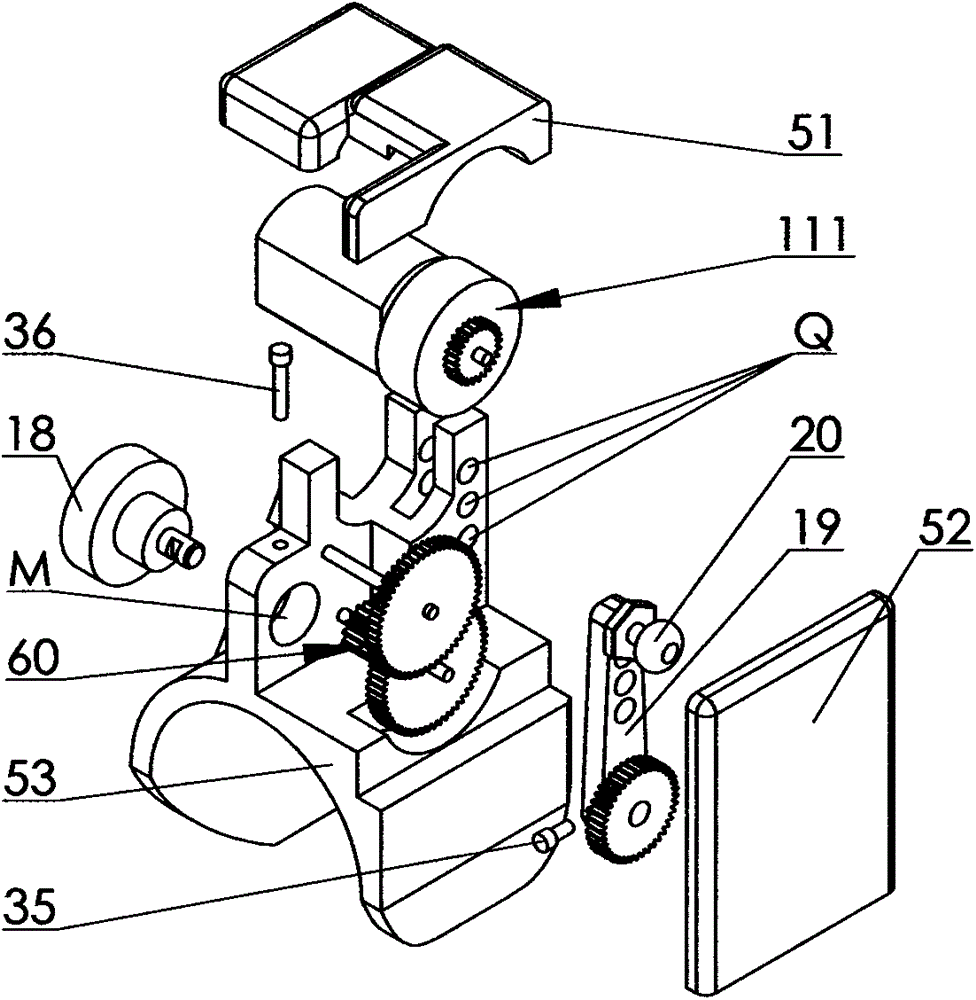

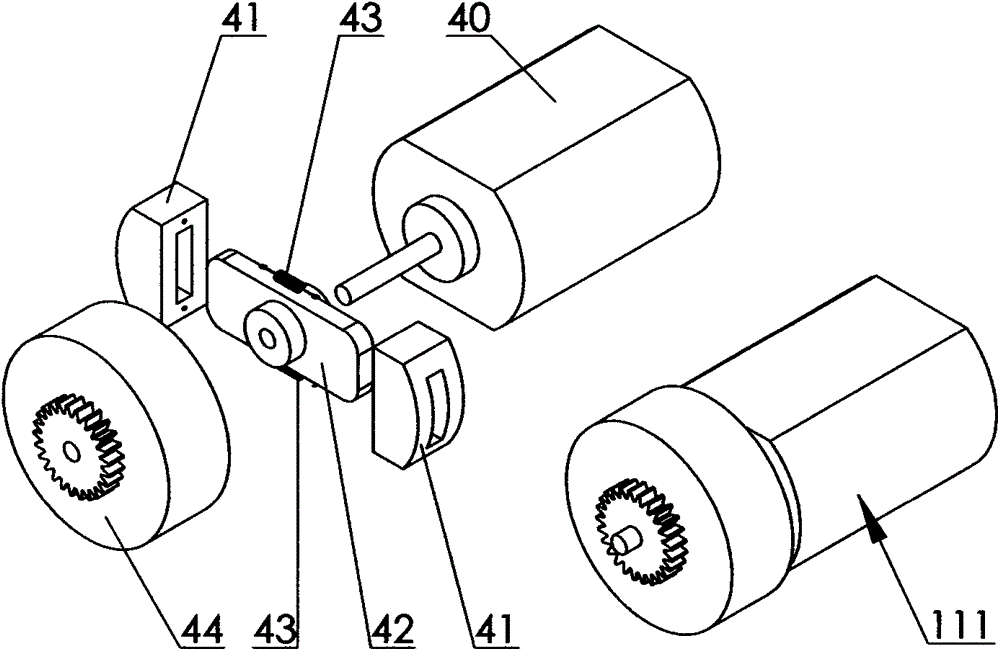

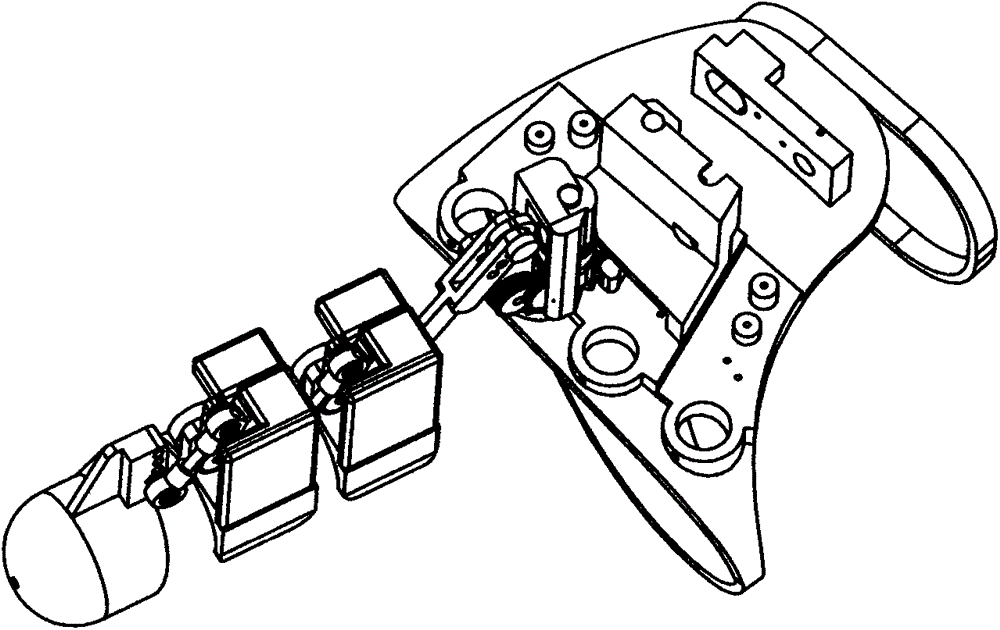

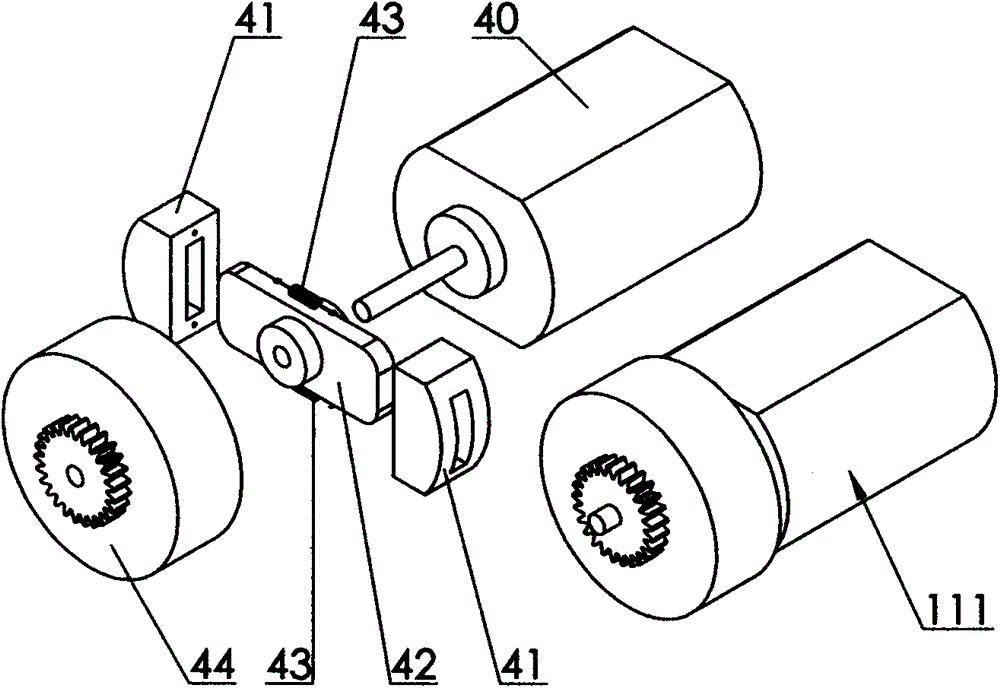

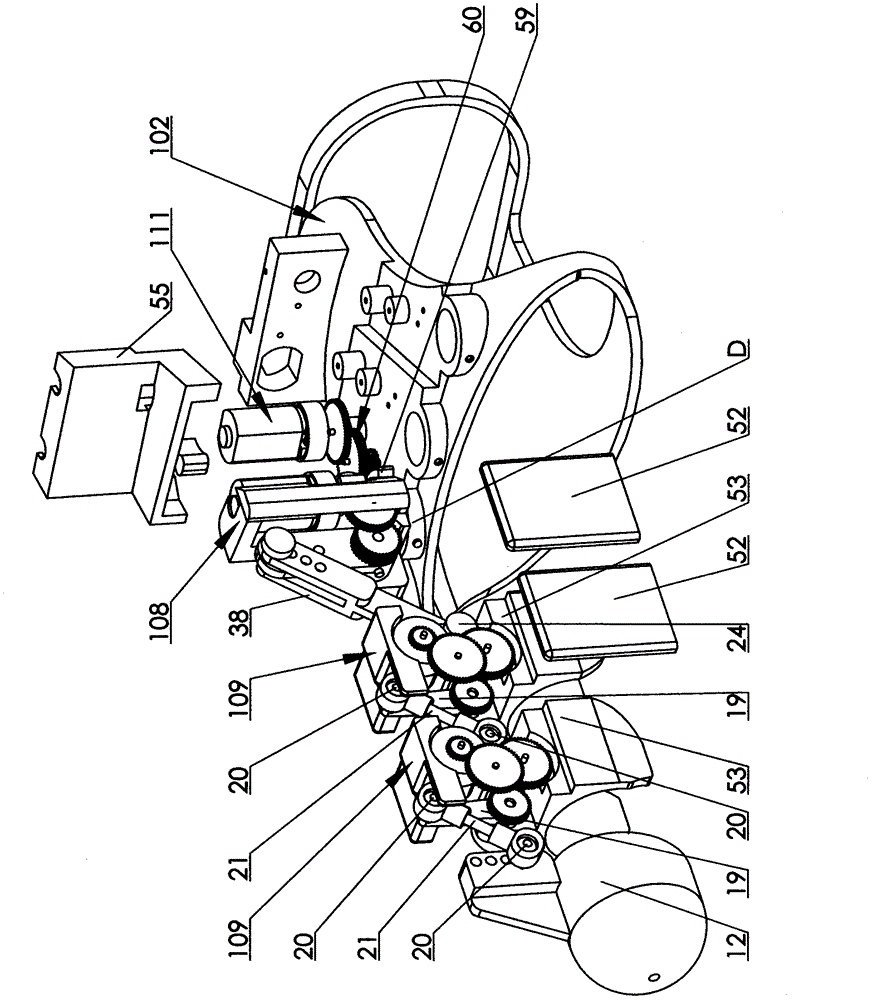

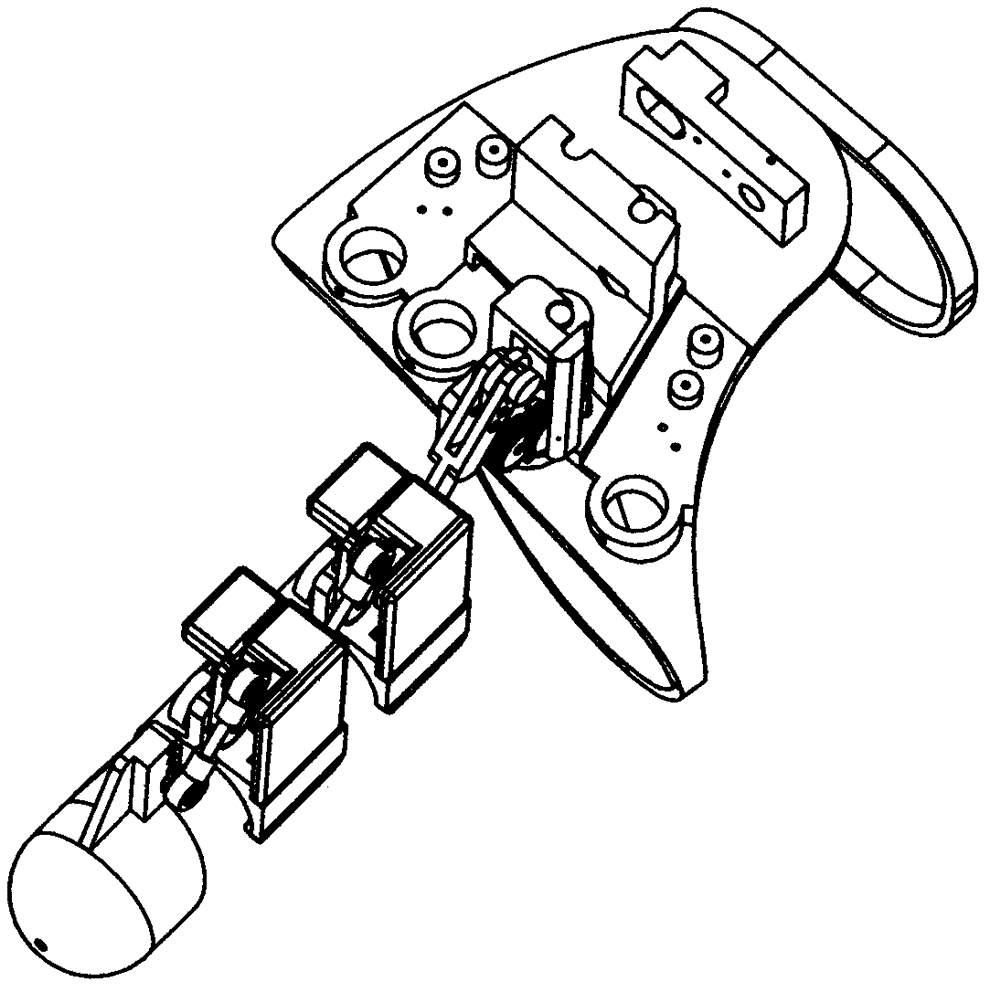

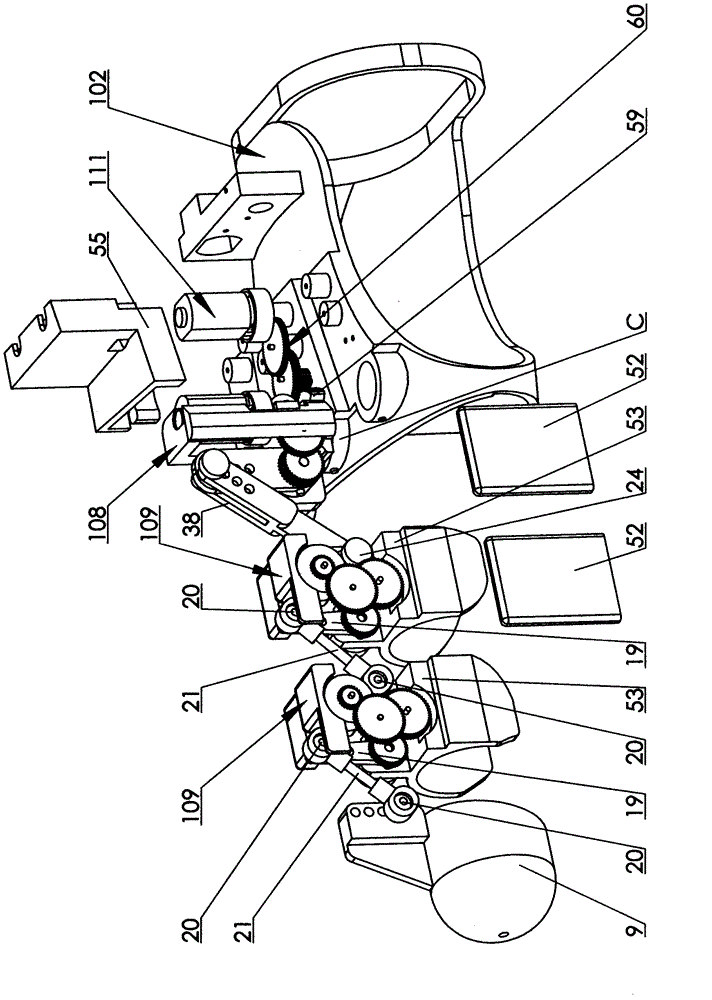

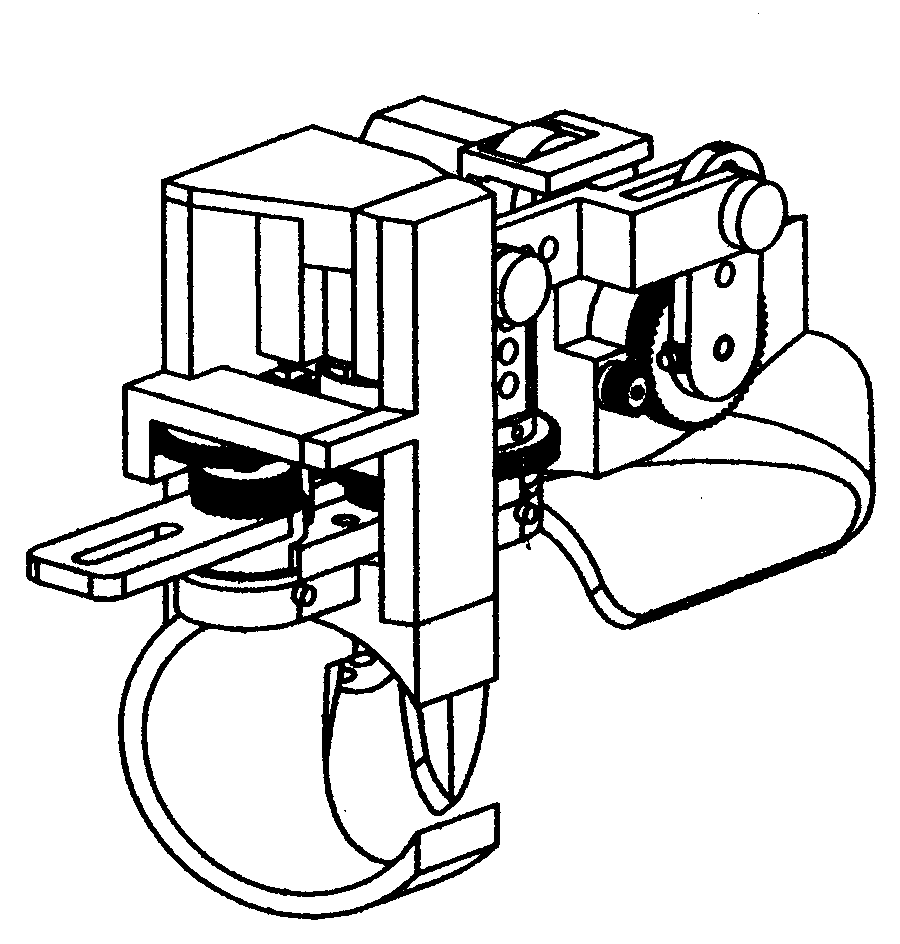

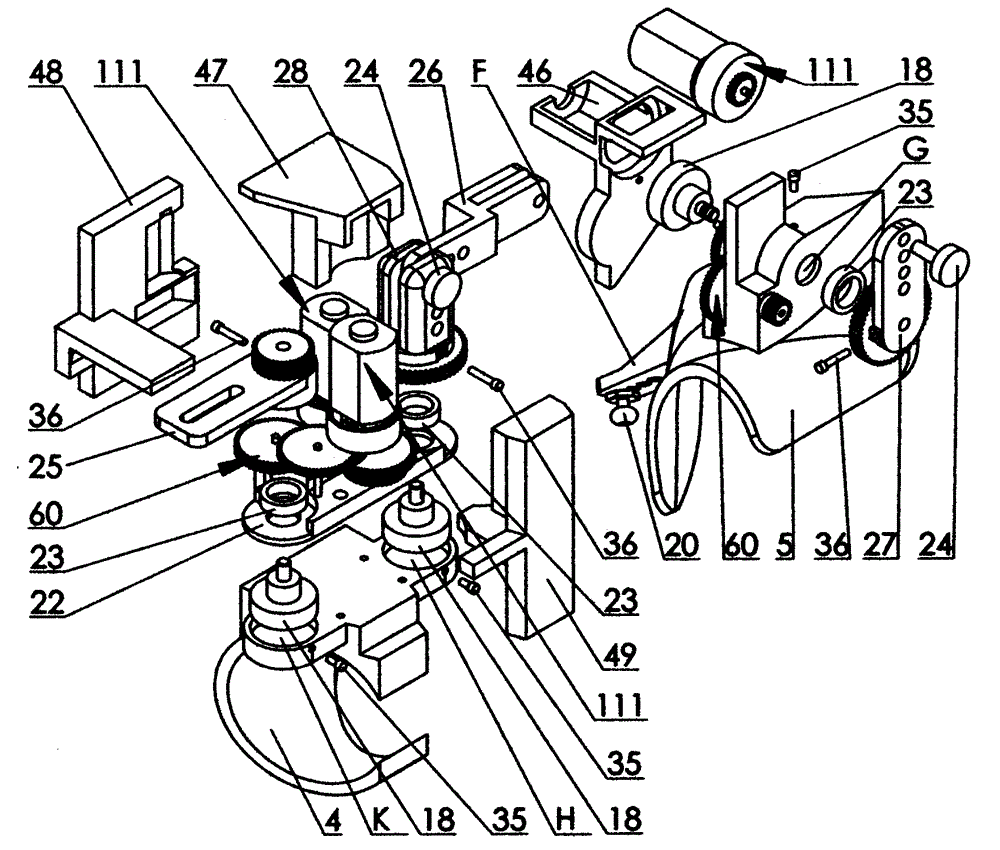

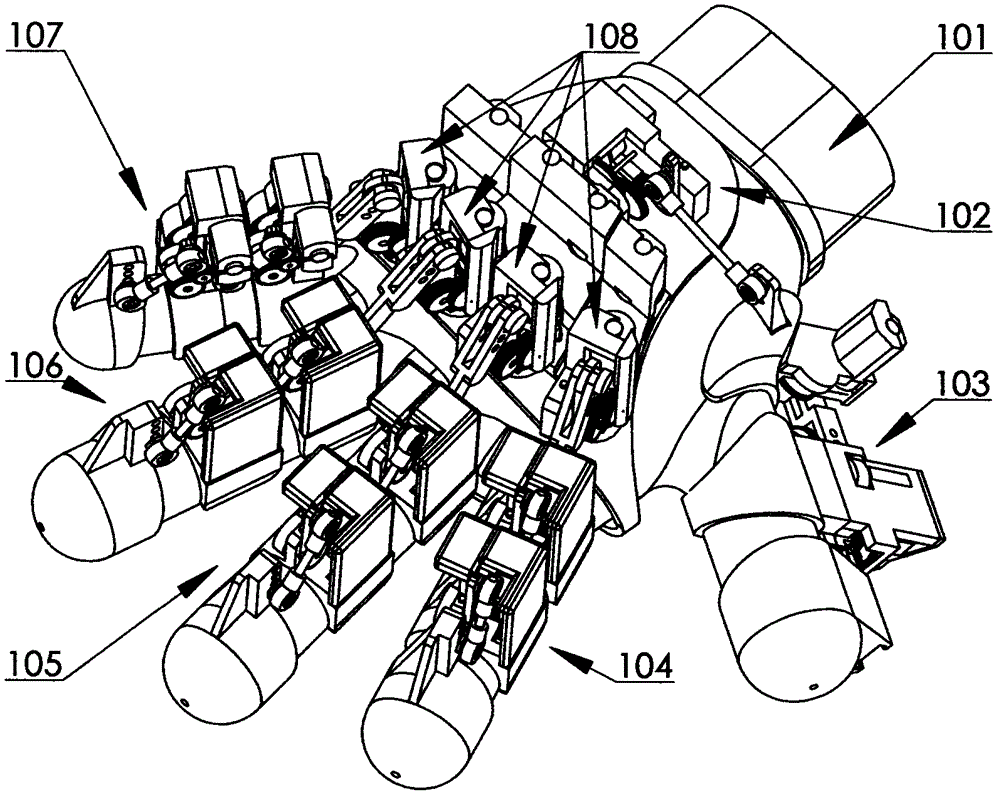

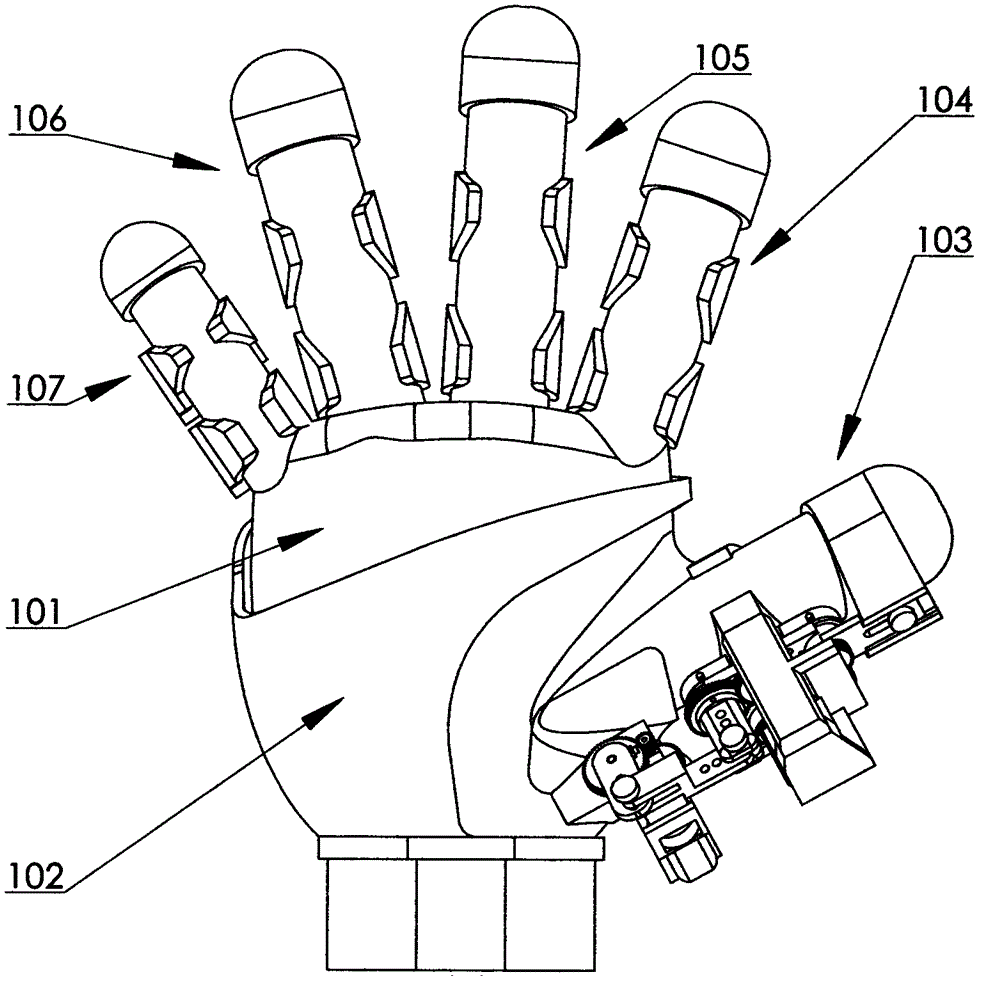

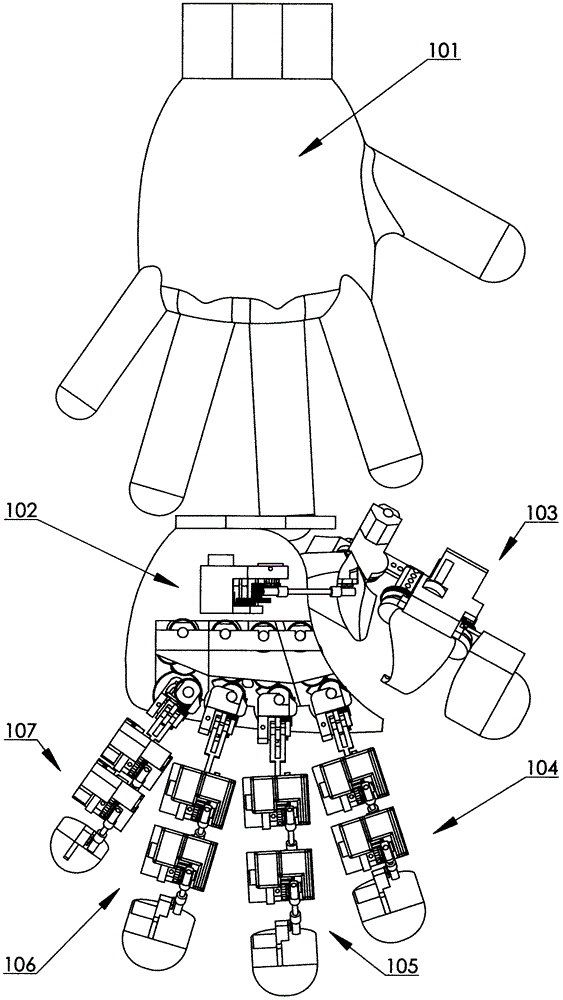

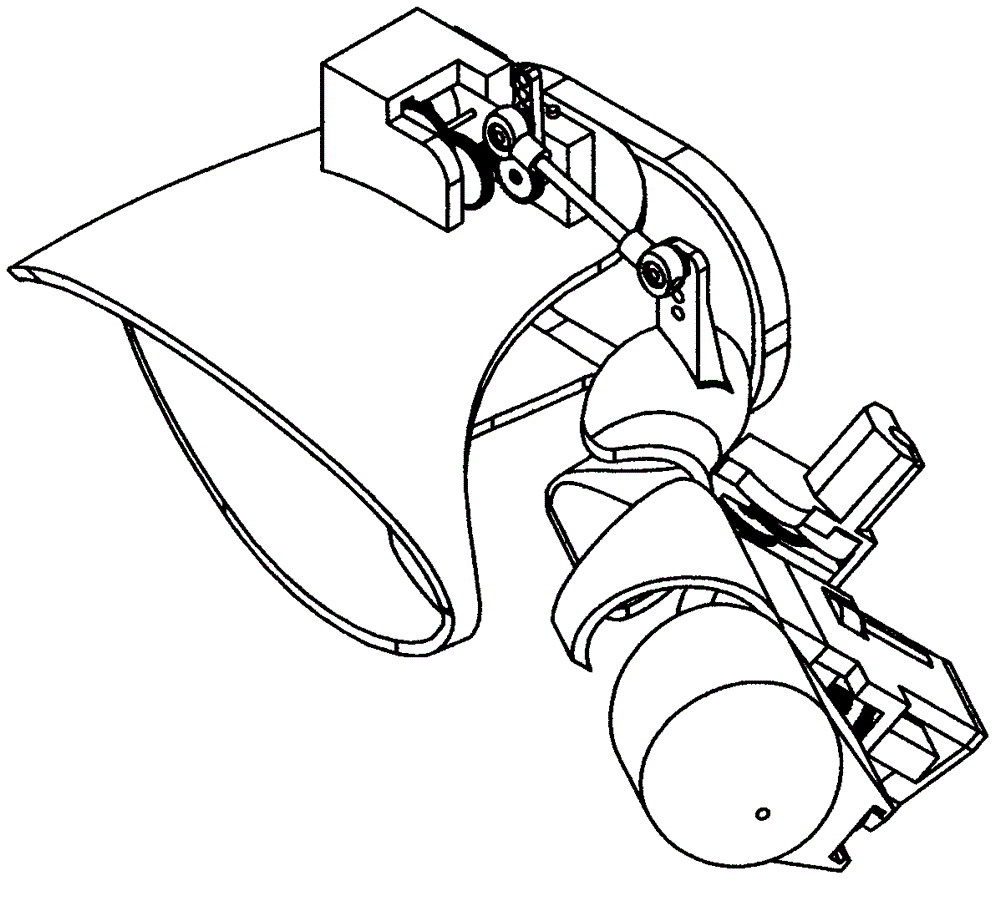

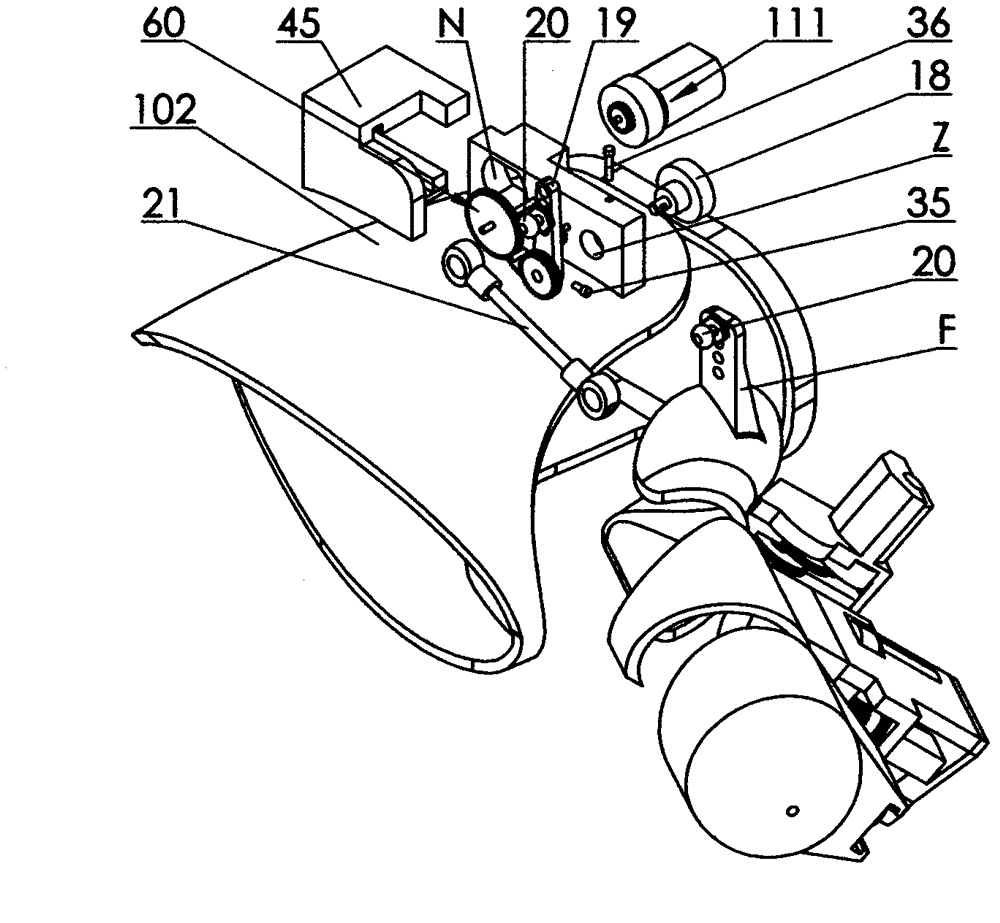

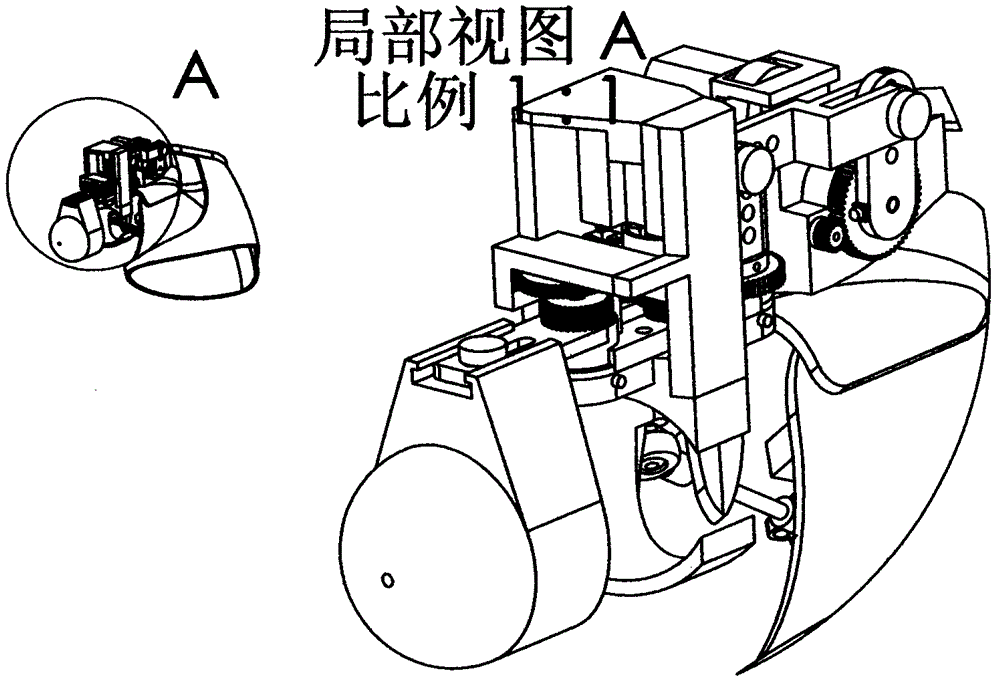

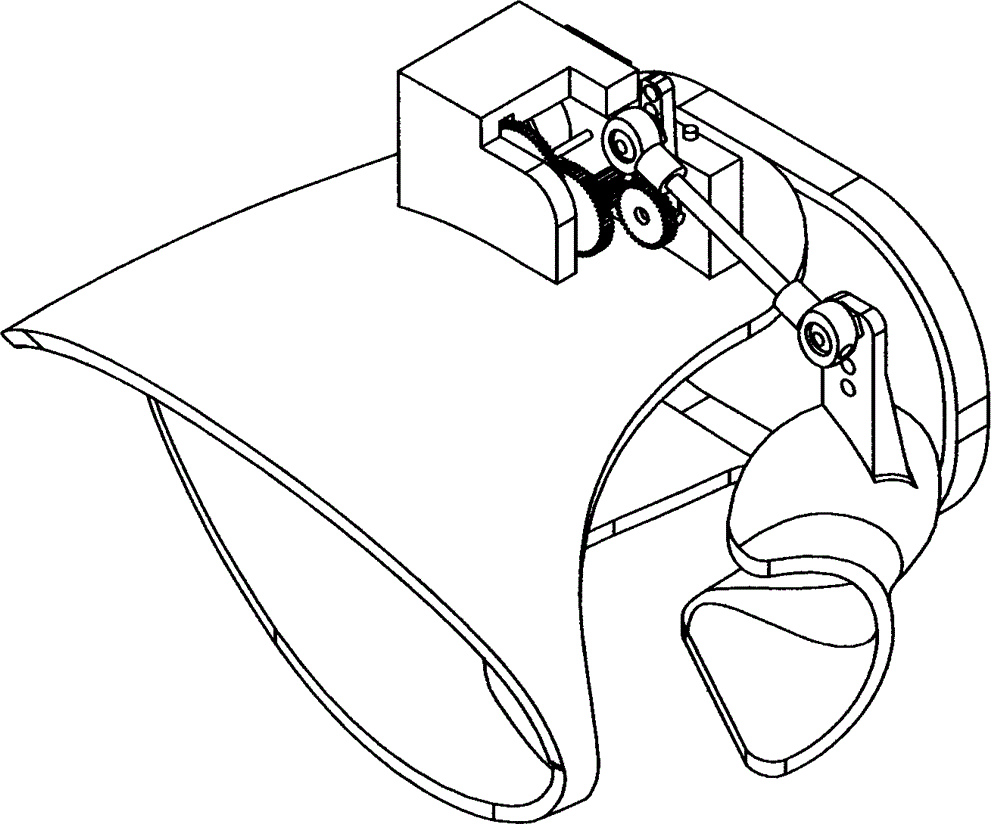

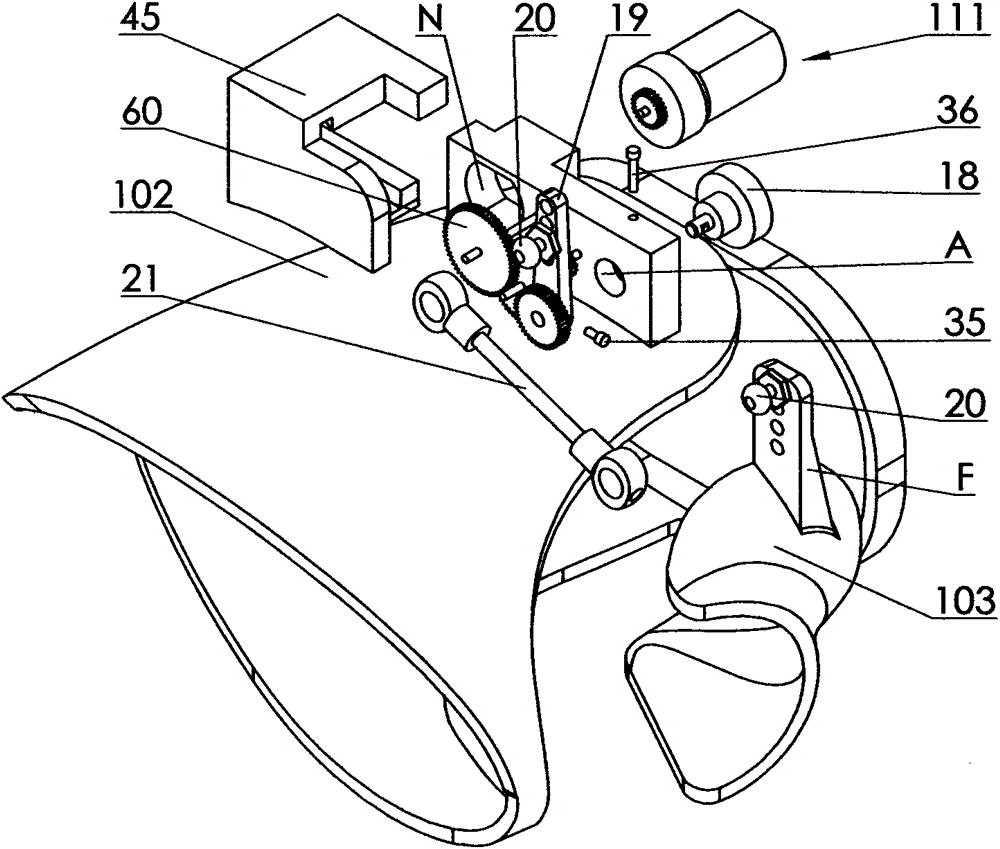

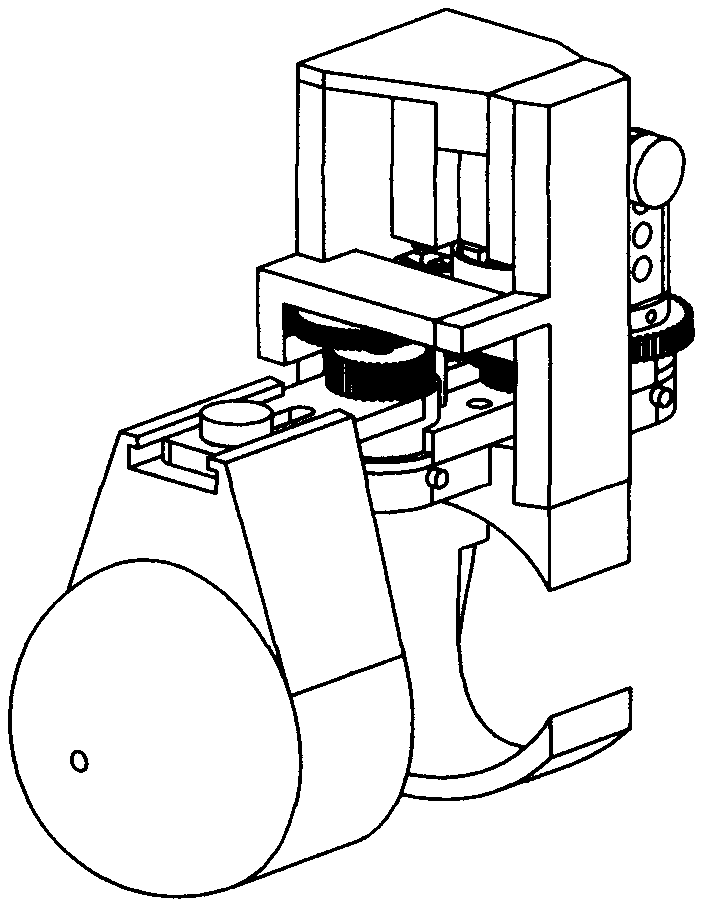

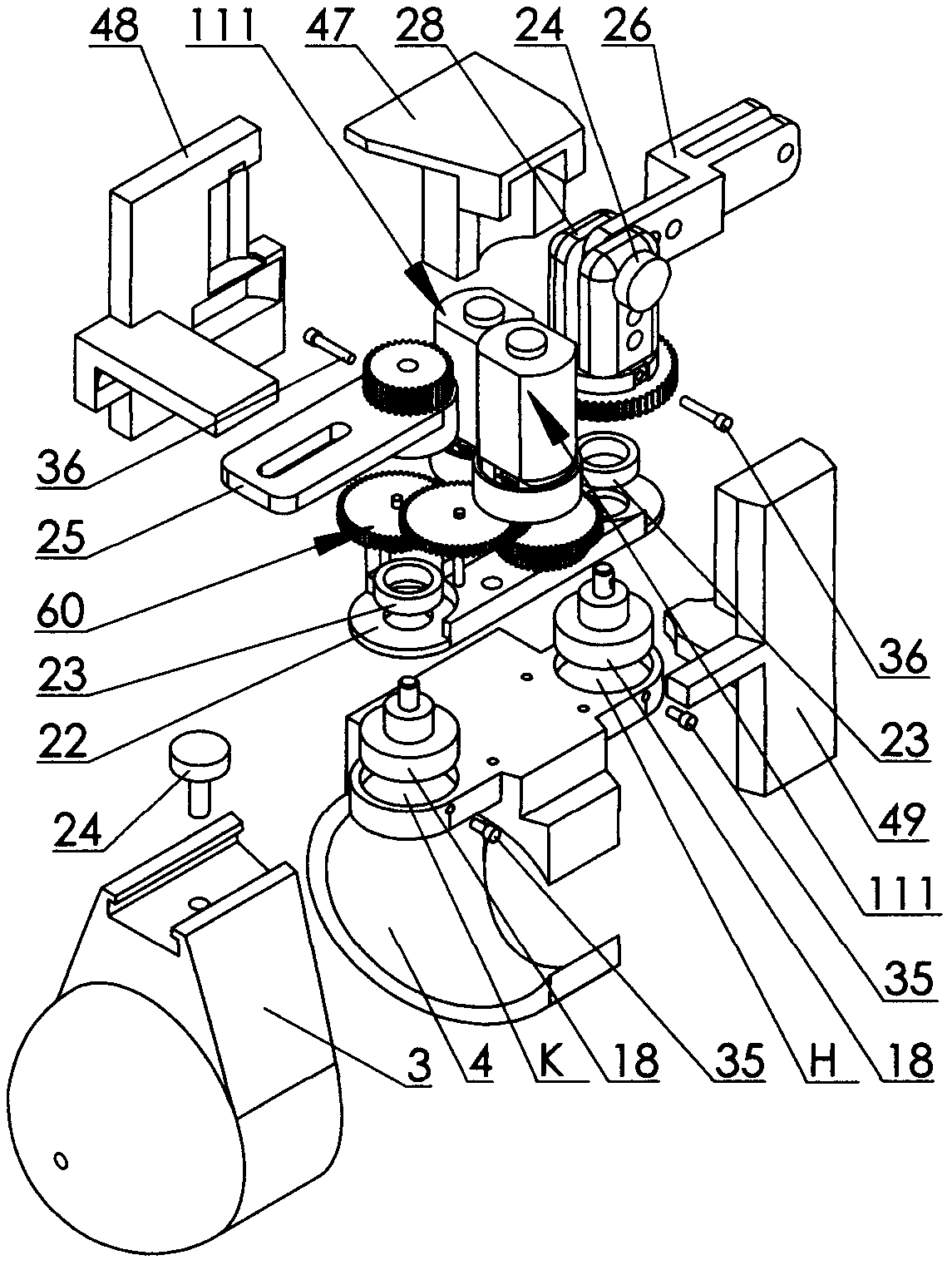

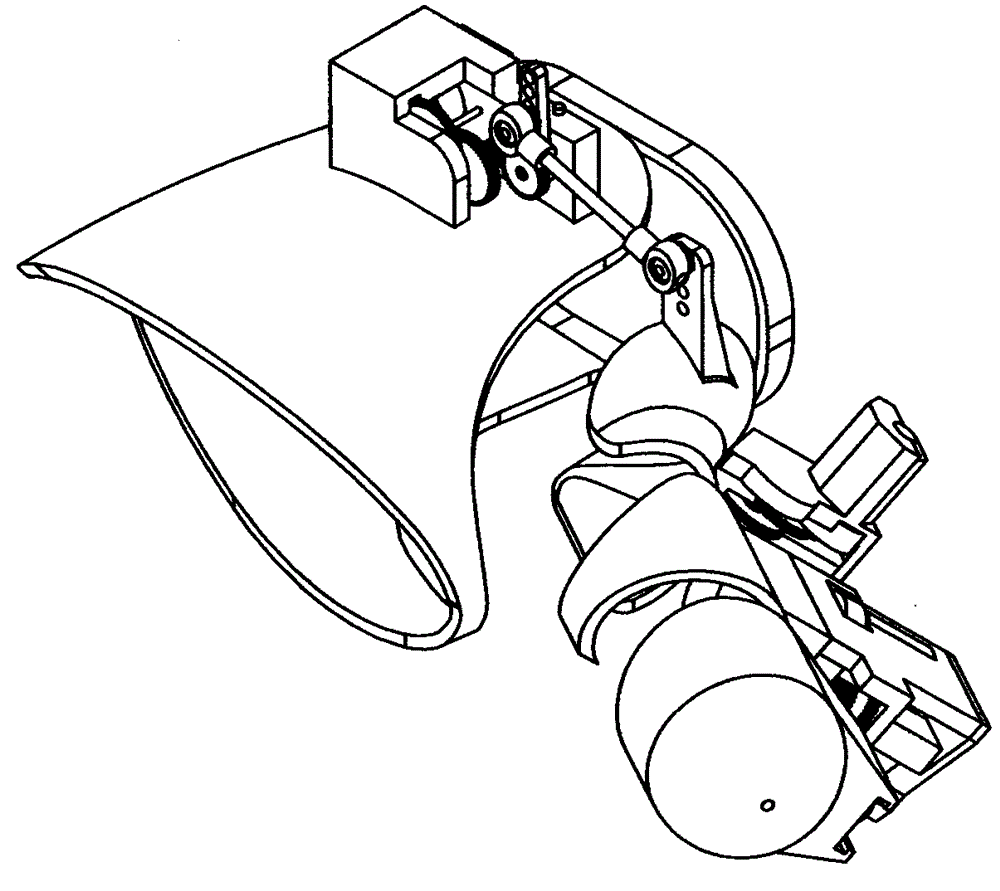

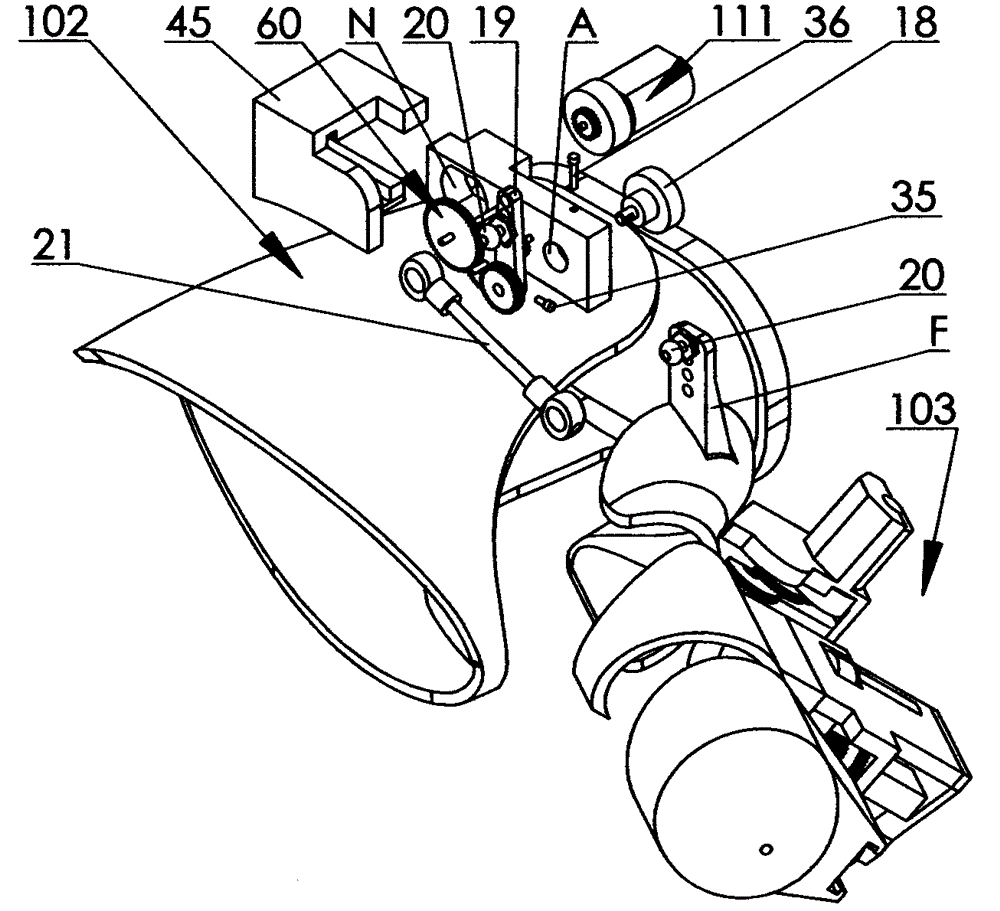

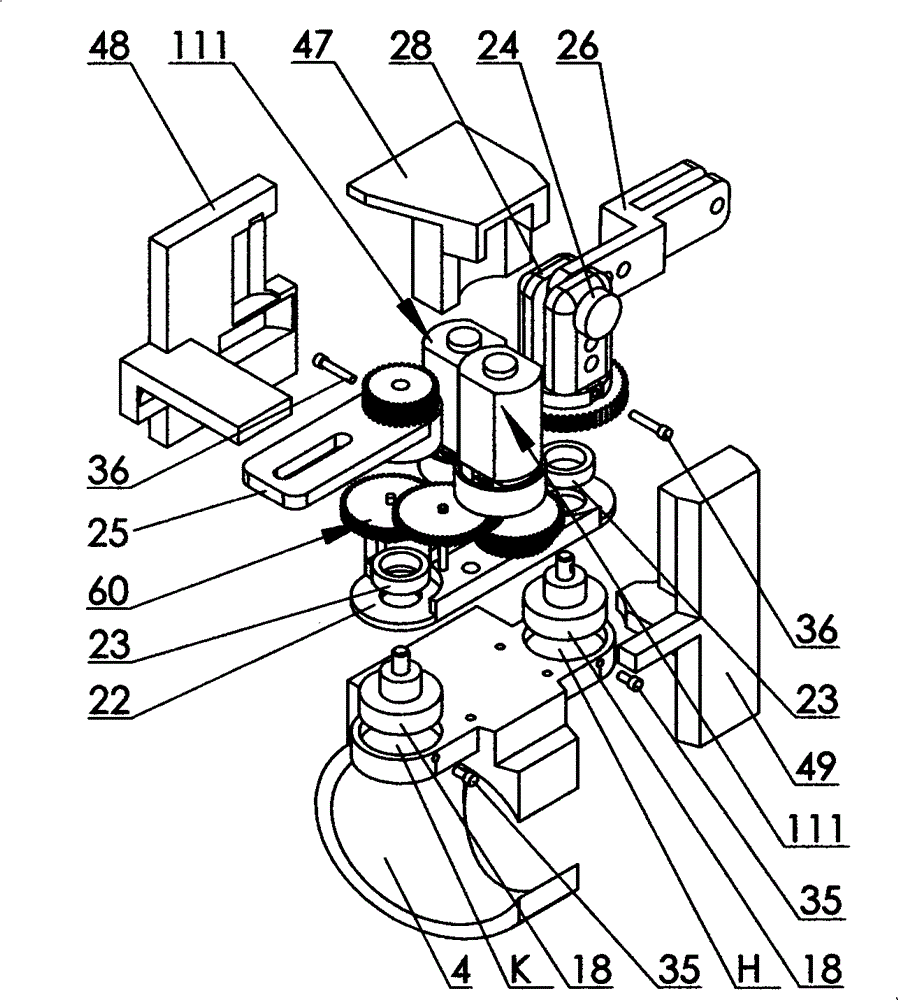

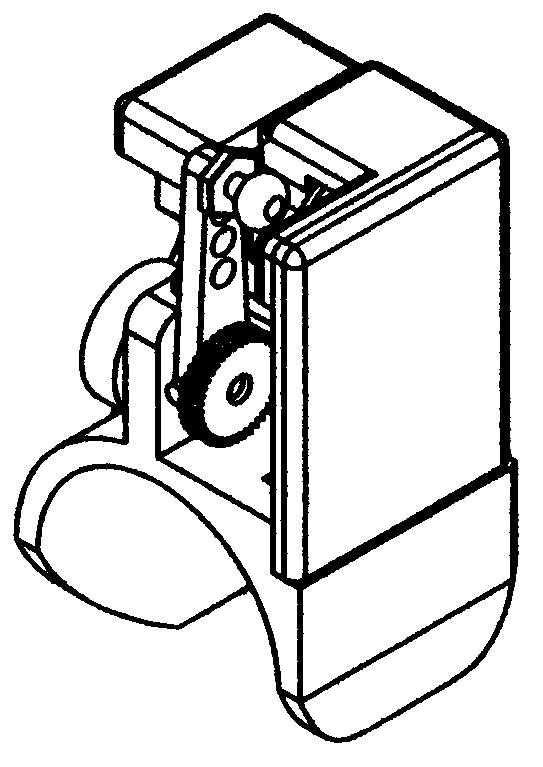

External-framework type bidirectional force feedback data glove

The invention provides to an external-framework type bidirectional force feedback data glove and relates to a force feedback data glove which is used for detecting human figure moving status and is provided with a bidirectional active drive to feed back force borne by an auxiliary hand. The external-framework type bidirectional force feedback data glove aims to resolve the problems that an existing force feedback data glove is separated in measurement mechanism and feedback mechanism, complex in system, tumid in structure, difficult to maintain, unachievable in bidirectional drive, expensive in price and the like. According to the external-framework type bidirectional force feedback data glove, a joint detection mechanism is connected with a force feedback mechanism into a whole, a unique connecting mode and an ingenious joint measurement point layout are used, five fingers of a user are enabled to keep the maximum flexibility when the force feedback data glove is used, the moving status of each joints of the fingers can be detected accurately, the movement of each finger joint of the controlled auxiliary hand is enabled to be coordinated with the movement of a corresponding finger joint of an operator, the force bearing conditions of the auxiliary hand in a specific working environment can be fed back to the operator, and the immediacy sense of a virtual reality or a remote operation is enhanced.

Owner:苏茂

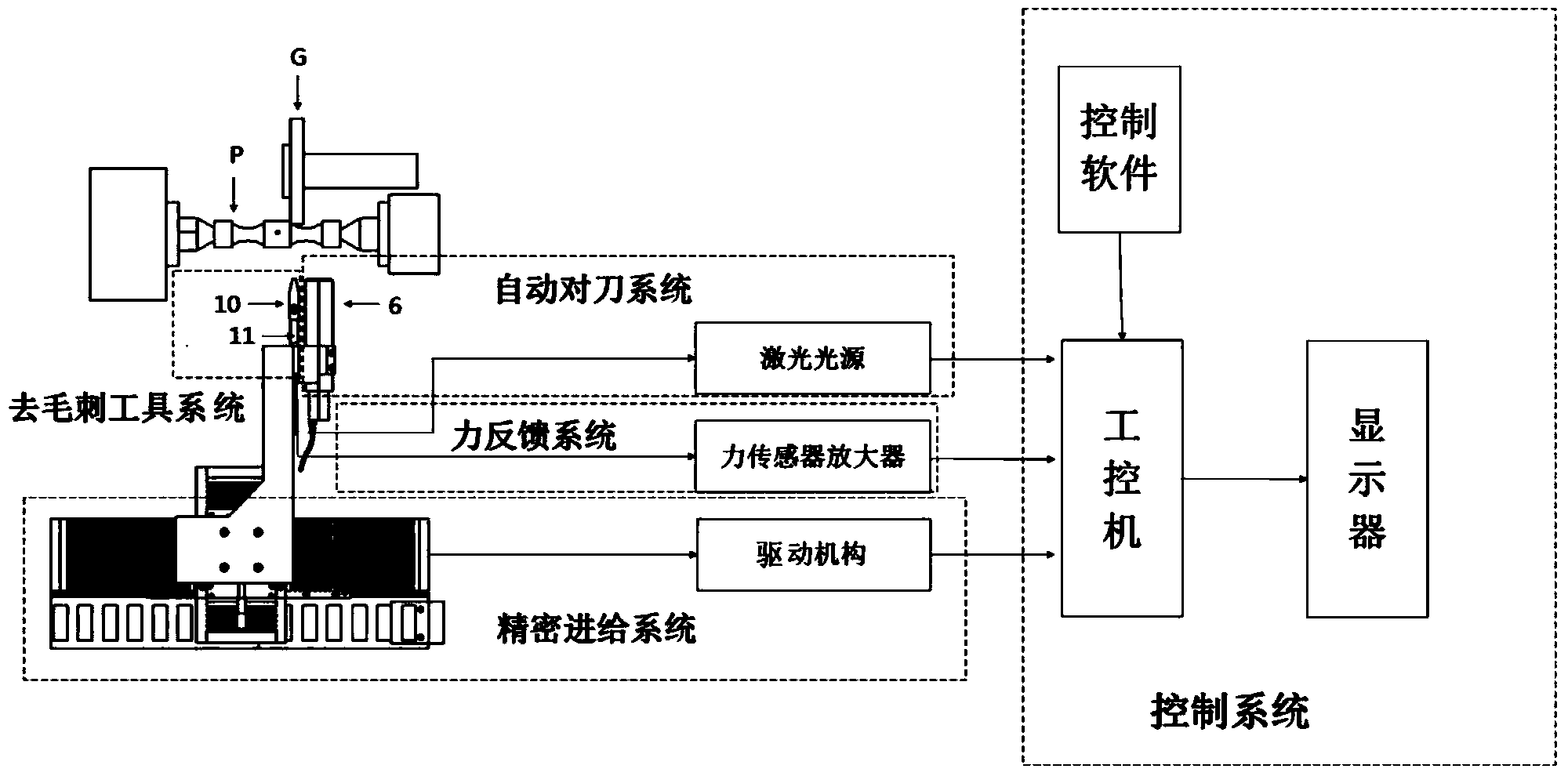

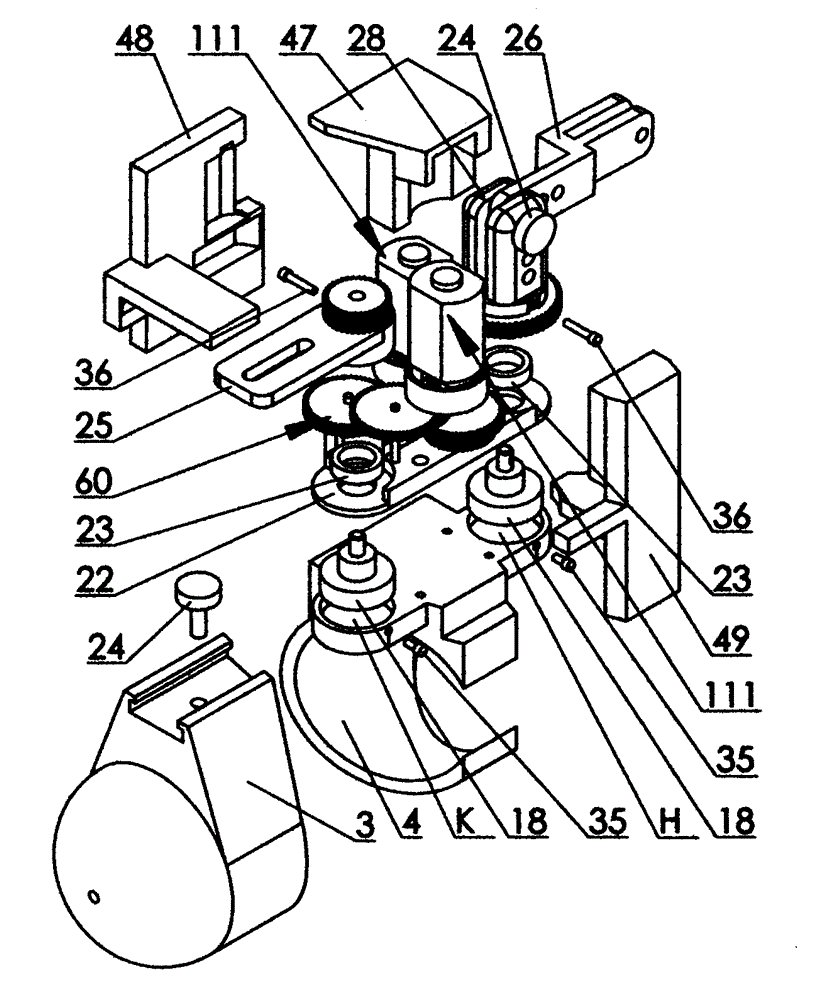

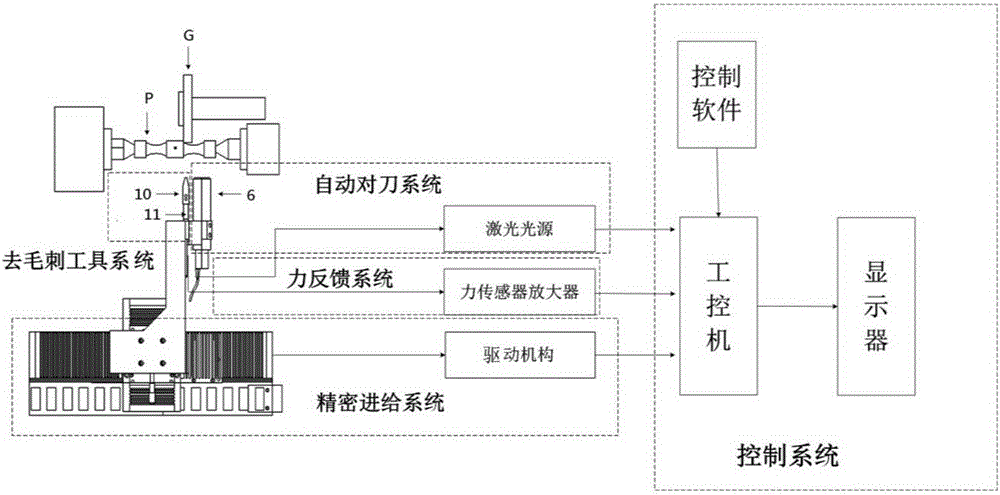

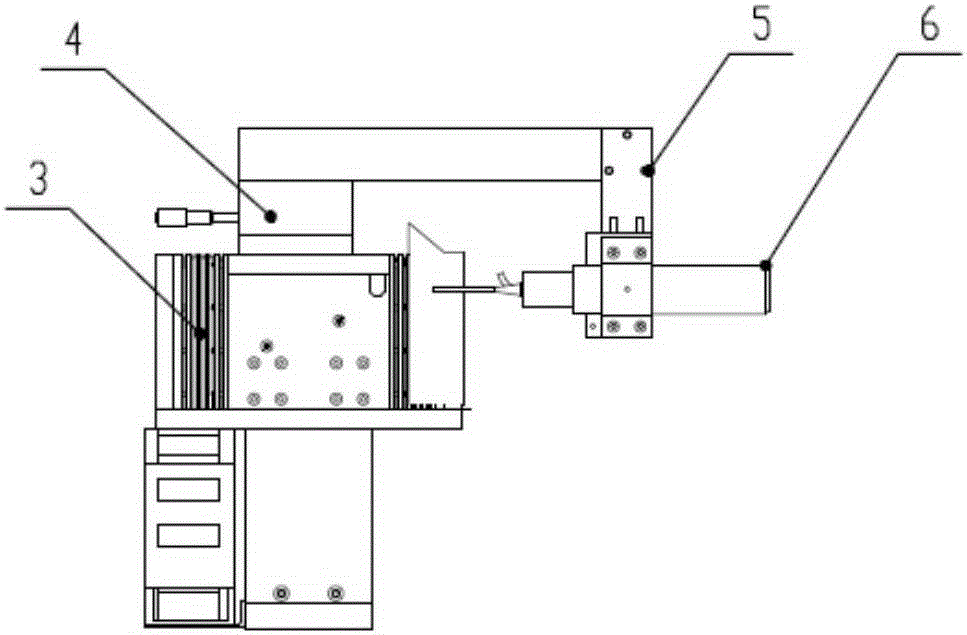

Automatic control device for online removing of tiny burrs on working edge of valve element of servo valve

ActiveCN104070183AGuaranteed stabilityGuaranteed accuracyAutomatic control devicesMeasurement/indication equipmentsAutomatic controlControl system

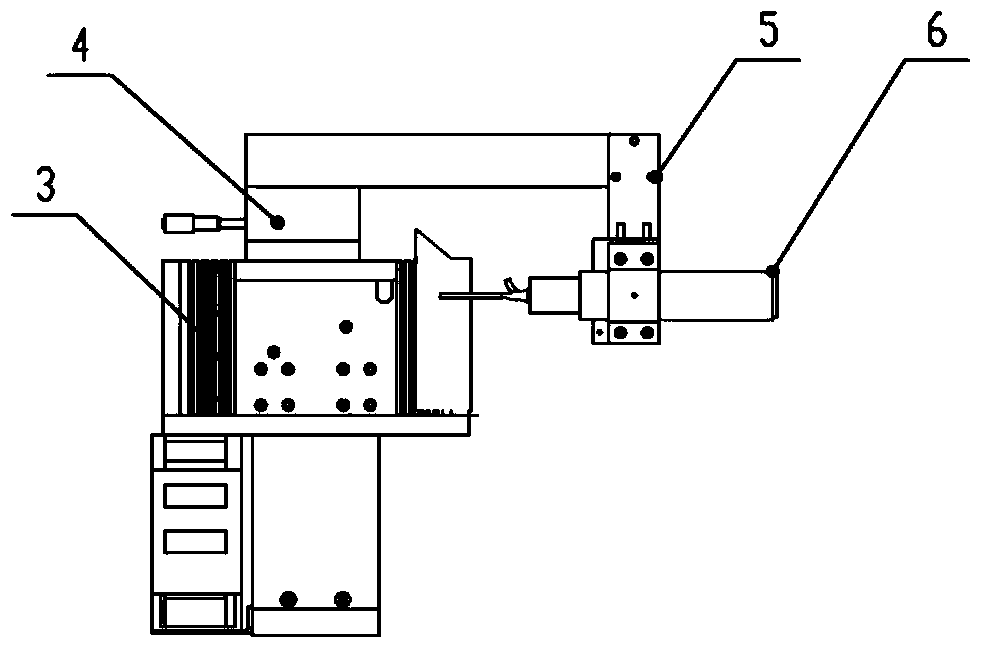

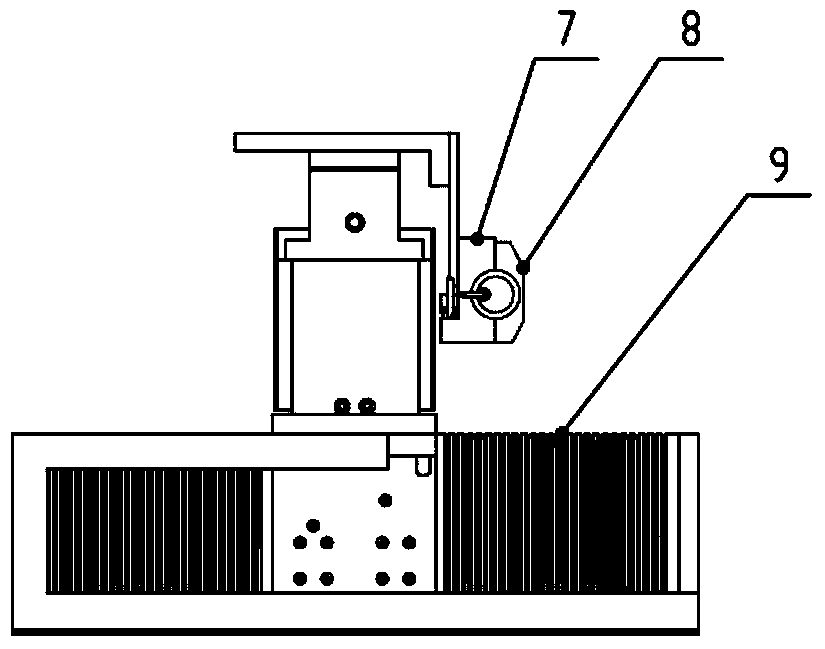

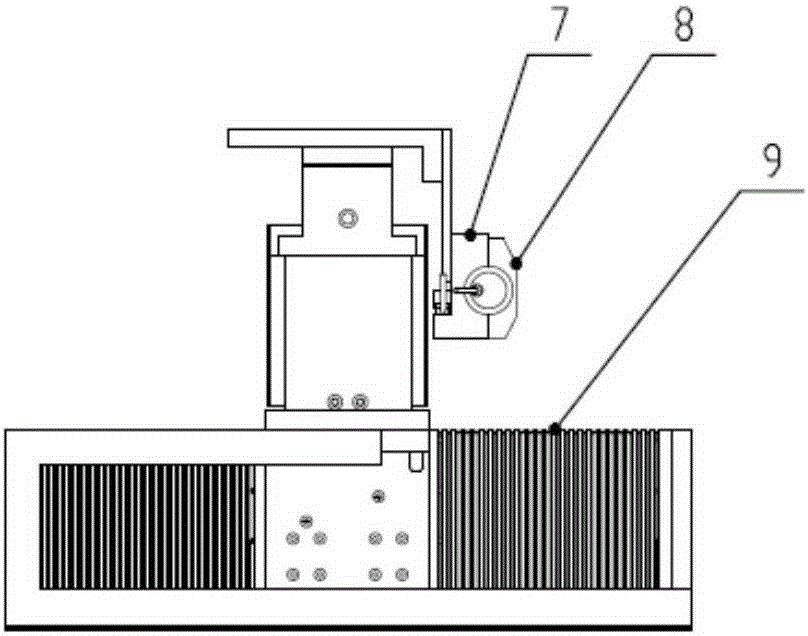

An automatic control device for online removing of tiny burrs on the working edge of a valve element of a servo valve comprises a deburring tool system, a precision feeding system, an automatic tool setting system, a force feedback system and a control system, wherein the deburring tool system mounted on a Z-axis lifting table comprises a deburring turning tool, a force sensor and a fixture, the precision feeding system used for controlling the feeding of the deburring tool system comprises an X-axis feeding mechanism, a Y-axis feeding mechanism and the Z-axis lifting table, the automatic tool setting system comprising a displacement sensor fixed on the fixture can achieve precise tool setting and complete radial runout measurement and working edge scanning detection of a workpiece, the force feedback system used for monitoring the degree of the deburring force in real time comprises a force sensor which is arranged below the deburring turning tool and connected with the fixture, and the control system used for monitoring the feeding movement, automatic tool setting, deburring, force feedback alarm retraction and online deburring effects of the automatic control device comprises an industrial personal computer connected with the precision feeding system, the force feedback system and the automatic tool setting system. The automatic control device for the online removing of the tiny burrs on the working edge of the valve element of the servo valve achieves the online automatic removing of the tiny burrs on the working edge and has the advantages of low rejection rates, high efficiency and low costs.

Owner:SHANGHAI JIAO TONG UNIV +1

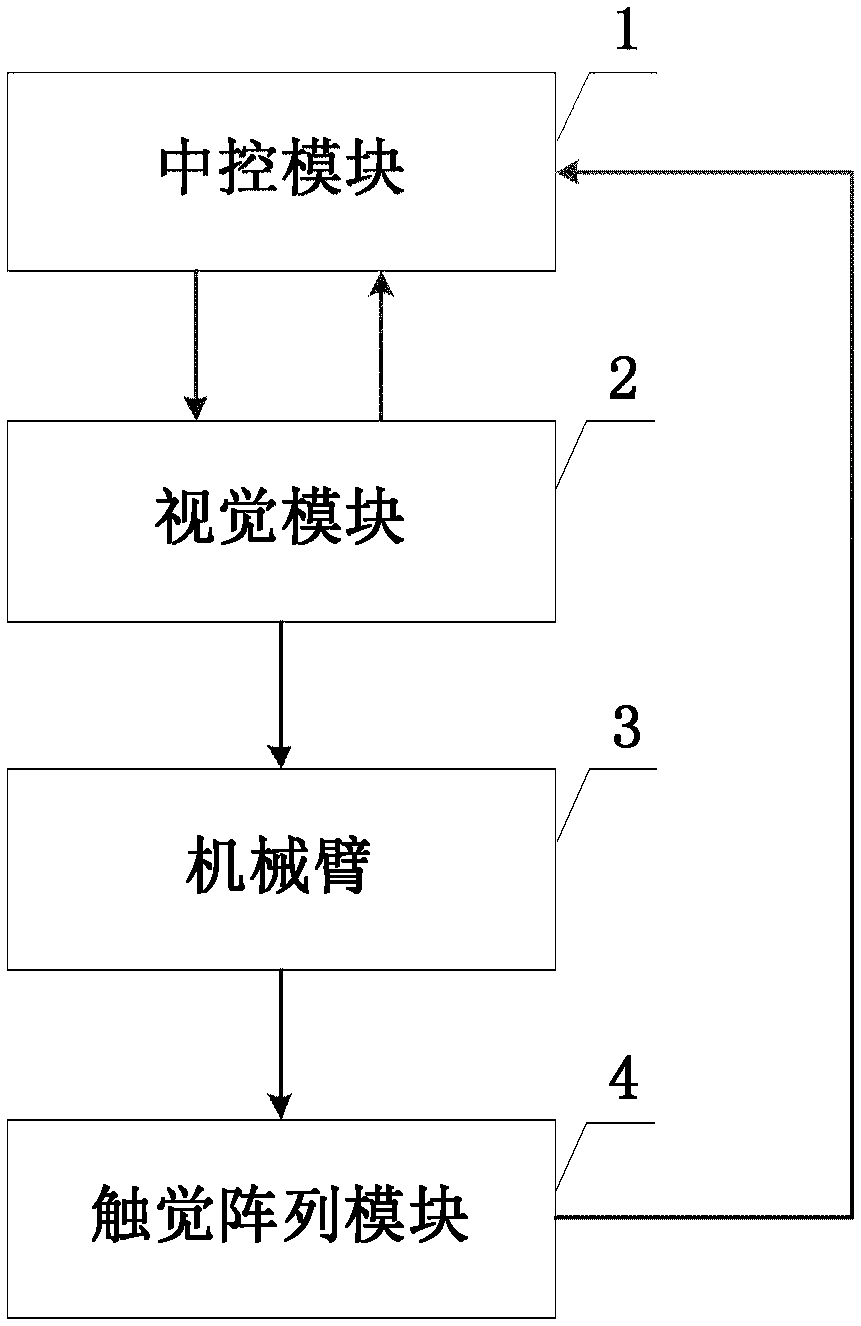

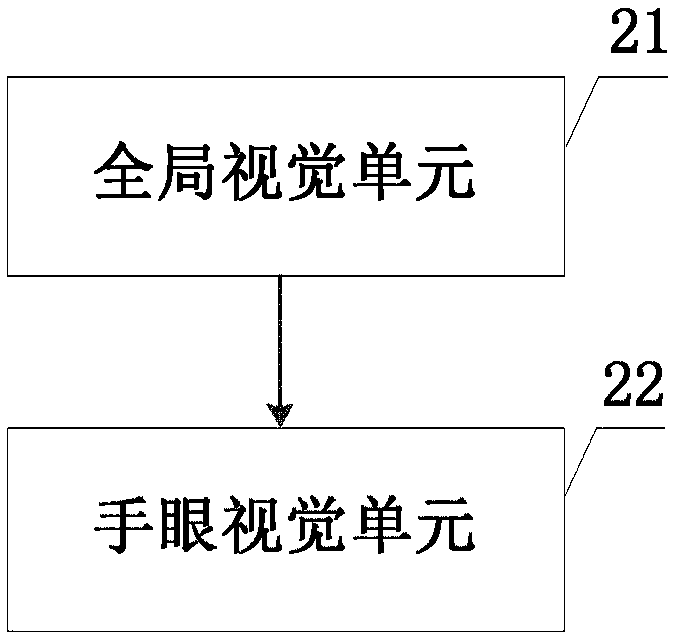

Mechanical arm system

InactiveCN108297083AImprove fine operabilityIncrease autonomyProgramme-controlled manipulatorVisual integrationComputer module

The invention provides a mechanical arm system which comprises a center control module, a visual module, a mechanical arm and a tactile array module. The center control module is used for producing aninstruction for operating a target; the visual module is used for receiving the instruction, recognizing the target, acquiring pose information of the target in real time, and outputting the pose information to the center control module so as to determine a track; the mechanical arm is used for moving according to the track until arriving at an operating position; and the tactile array module isused for touch type exploring the target when the mechanical arm touches the target at the operating position, feeding back touch information to the center control module in real time so as to realizerecognition, and feeding back force information during touching in real time at the same time until the center control module controls the mechanical arm to accomplish the operating of the target. According to a redundant mechanical arm tactile-visual integration system provided by the invention, the integration of a multisensory and the mechanical arm can be realized, and the characteristic of dexterous manipulation of the redundant mechanical arm is fully played to face diverse and complicated environments, so that the refine manipulation, the independence and the man-machine cooperation efficiency of the mechanical arm are improved.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

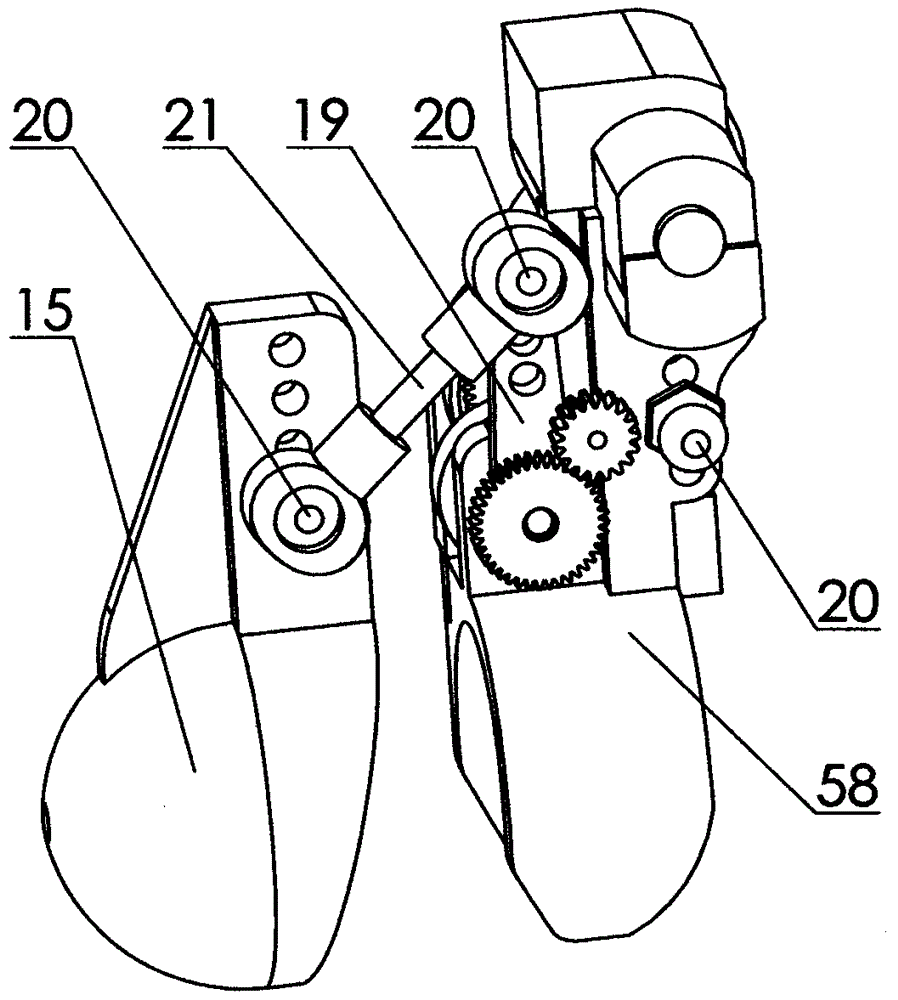

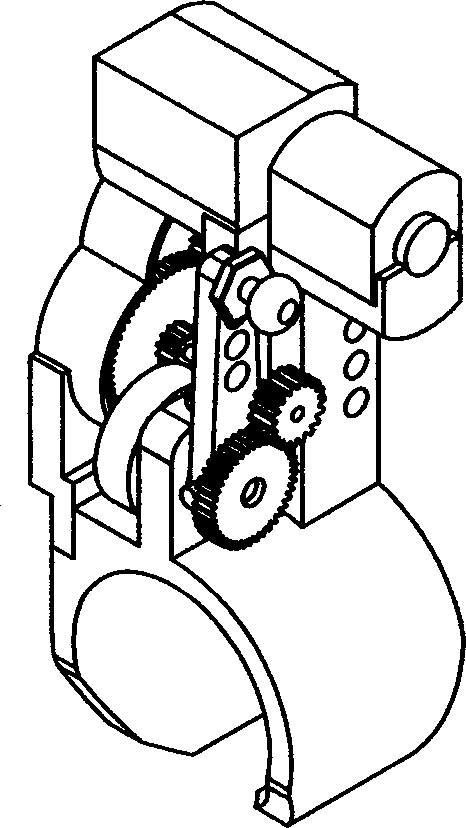

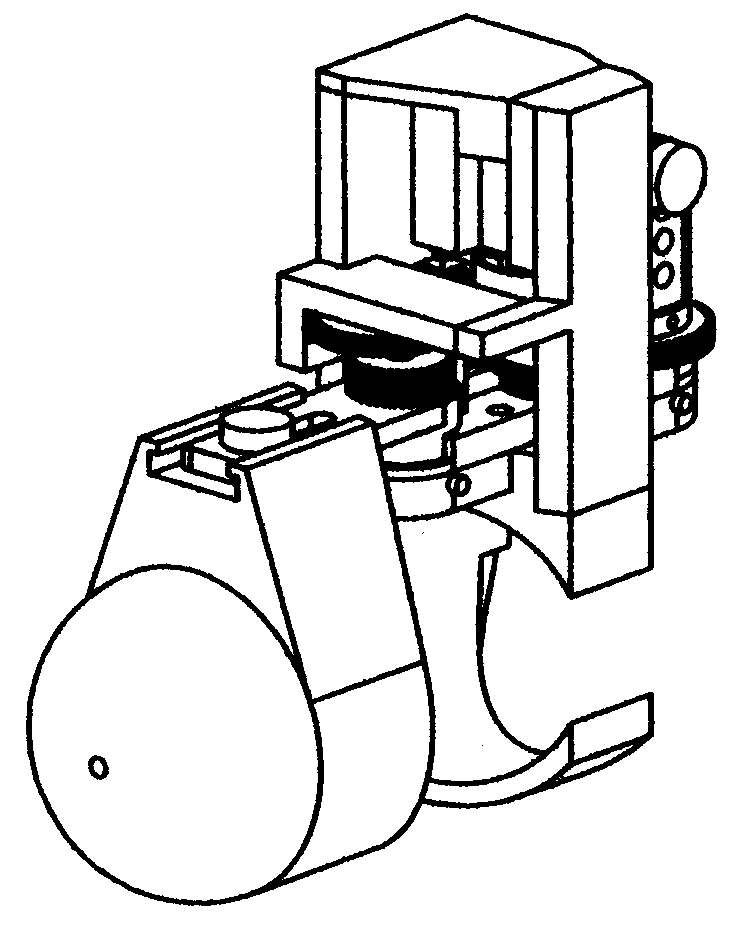

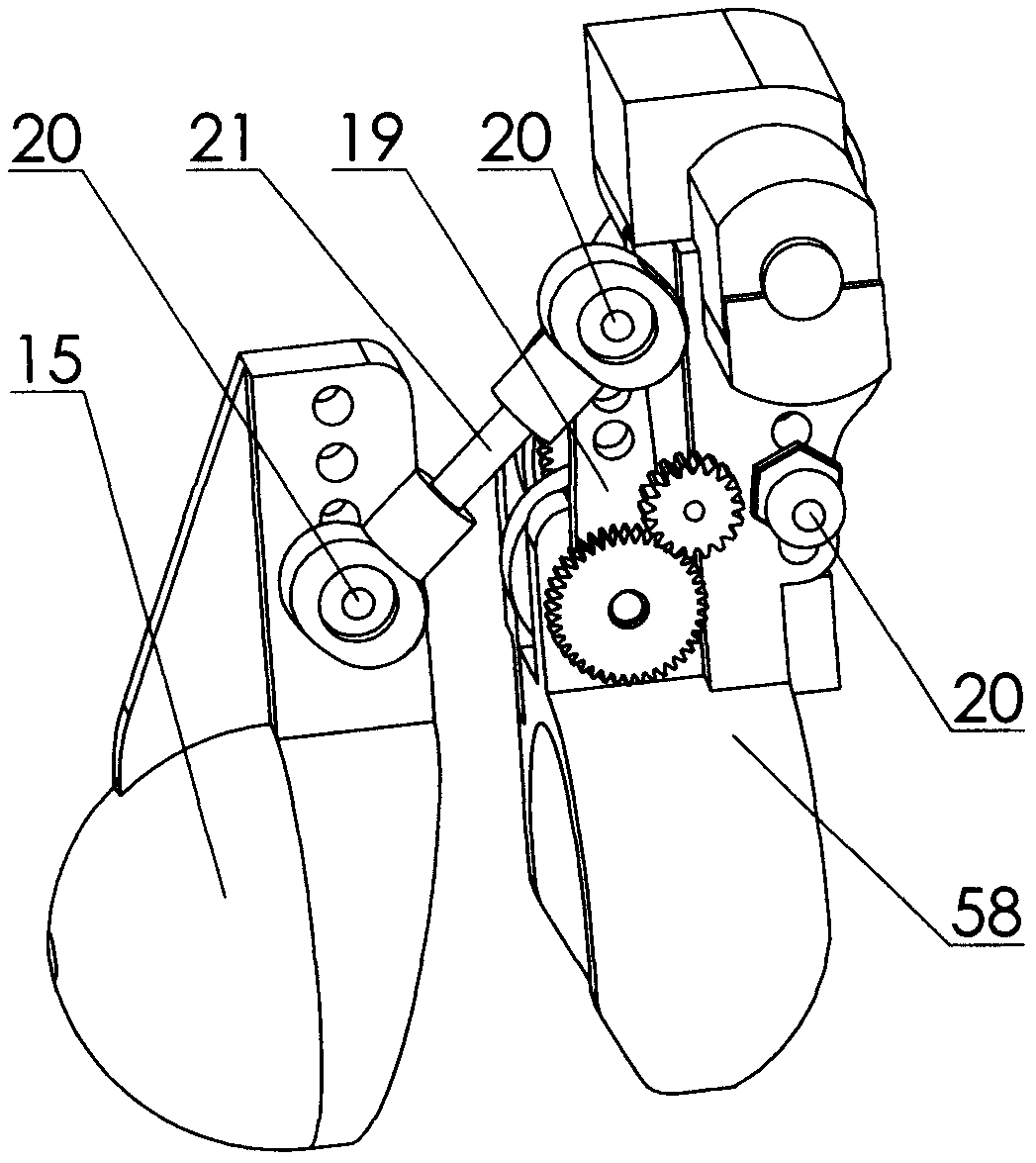

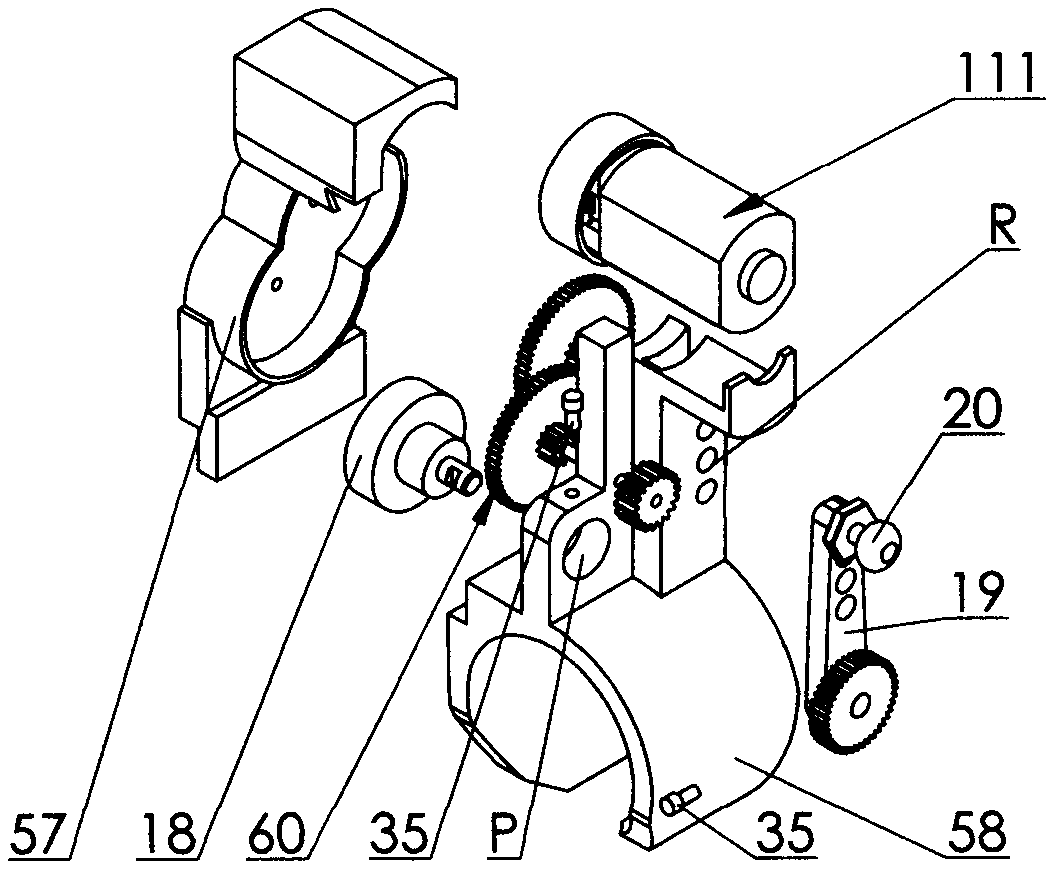

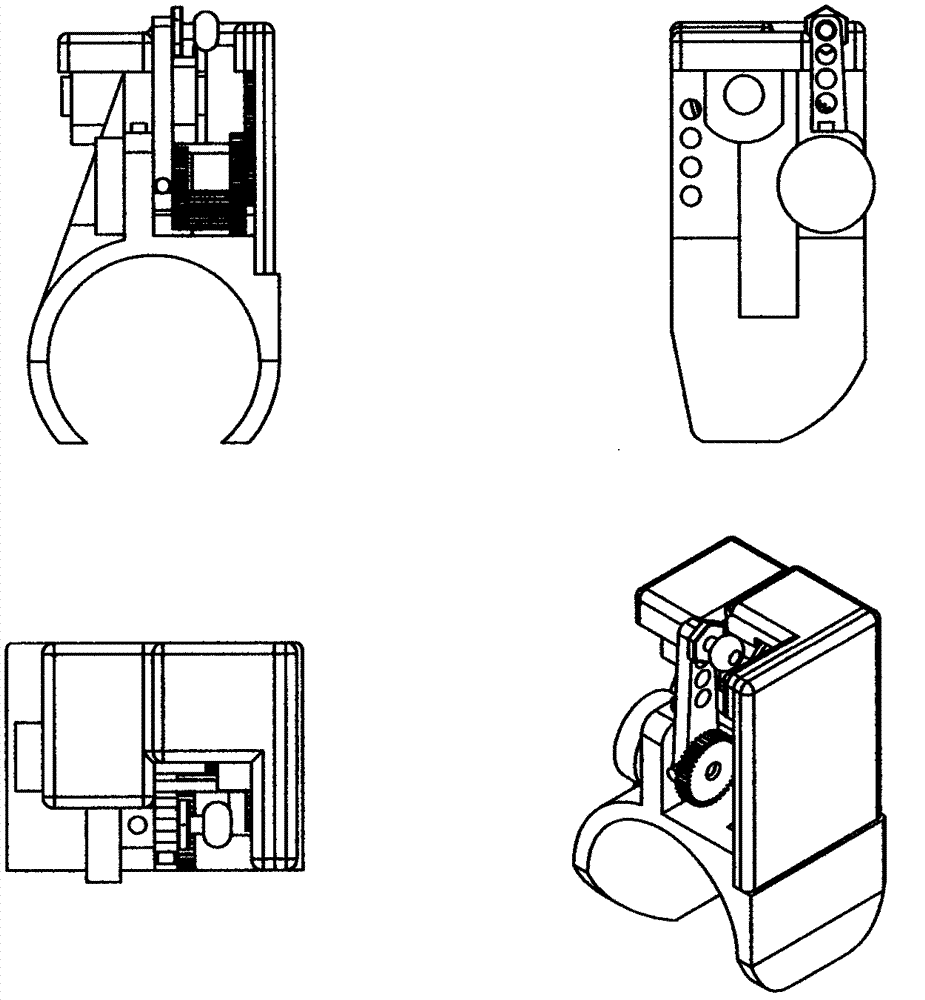

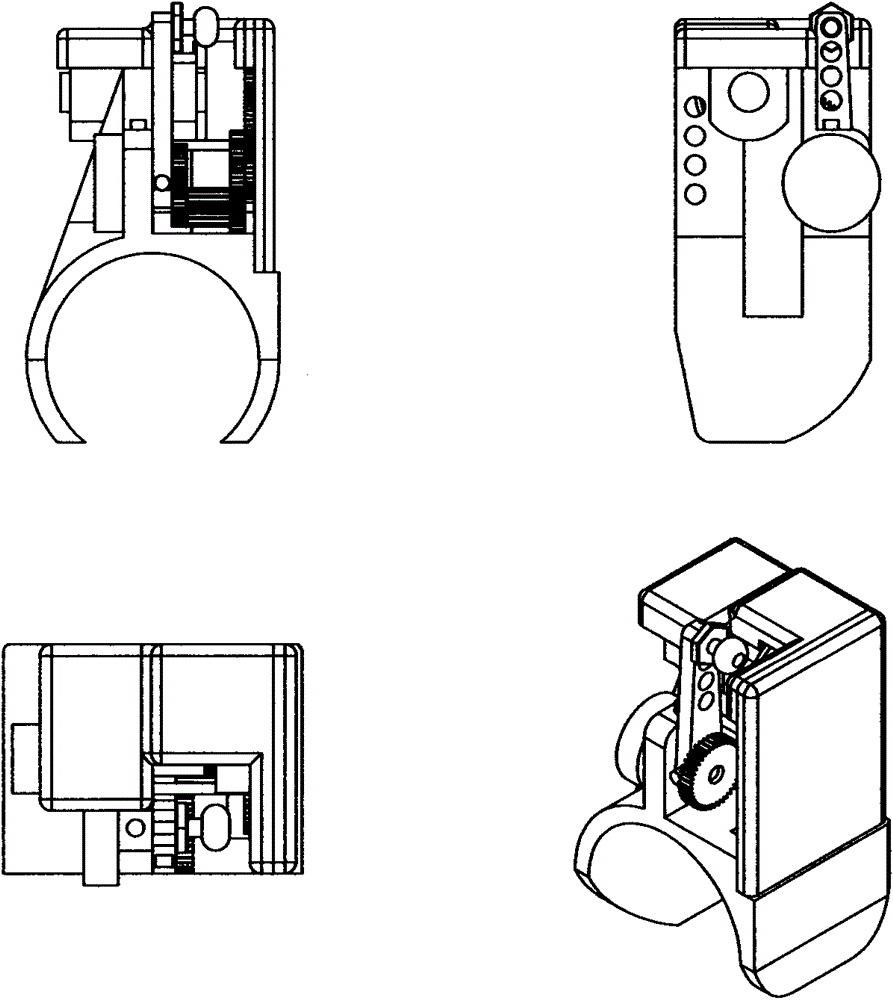

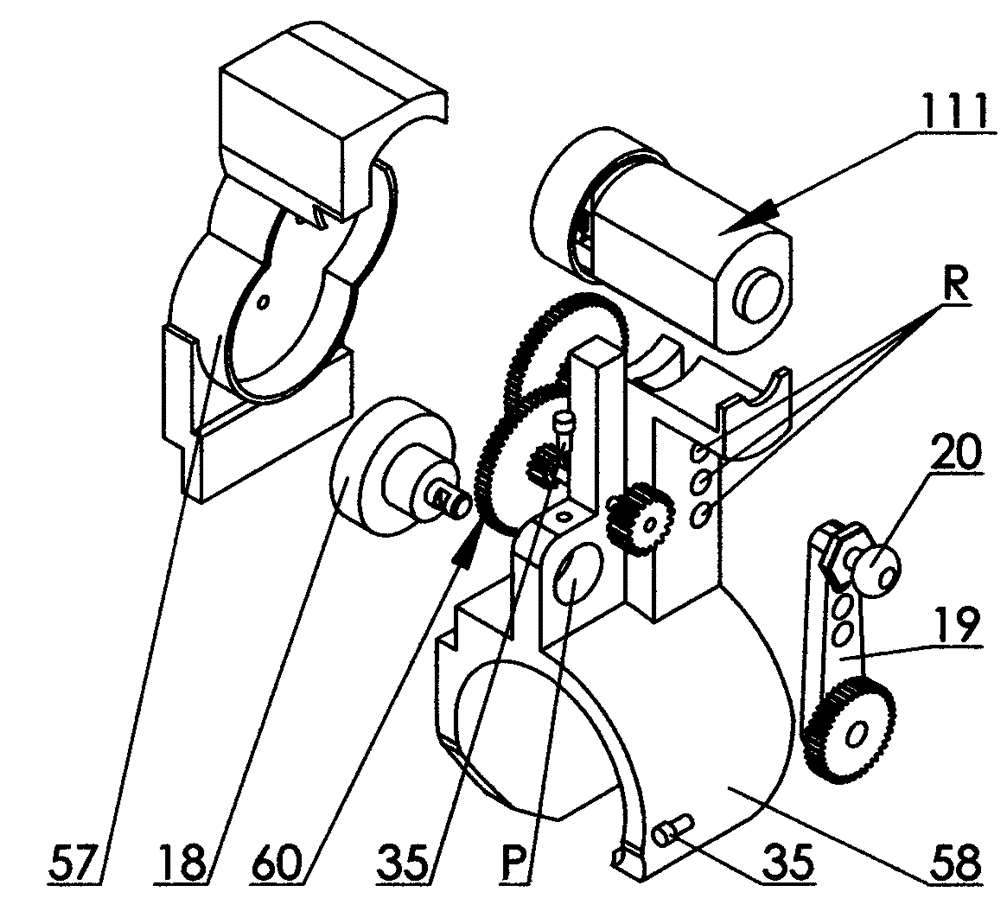

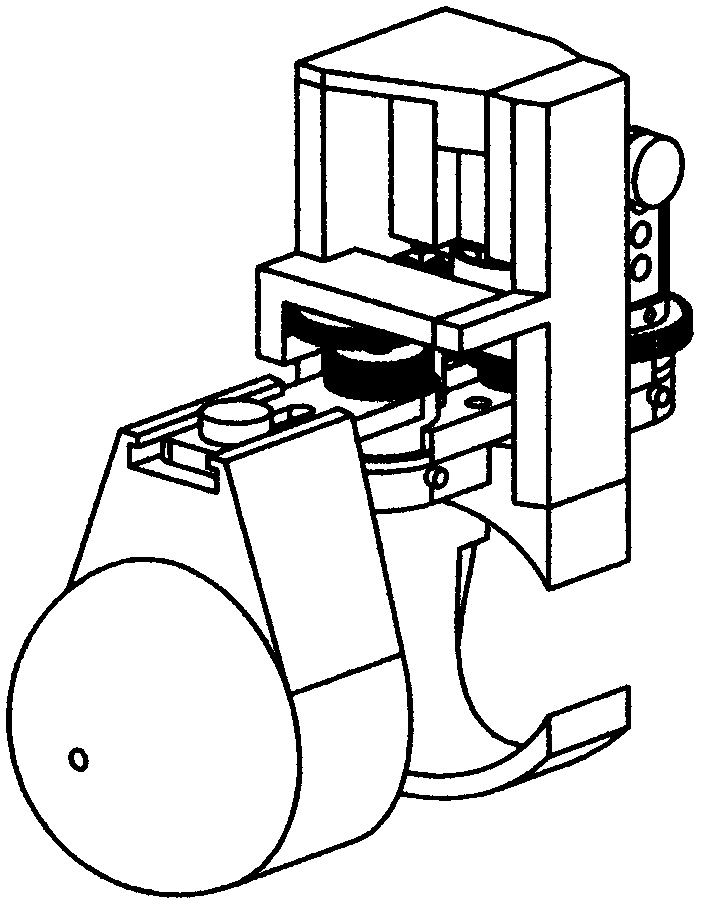

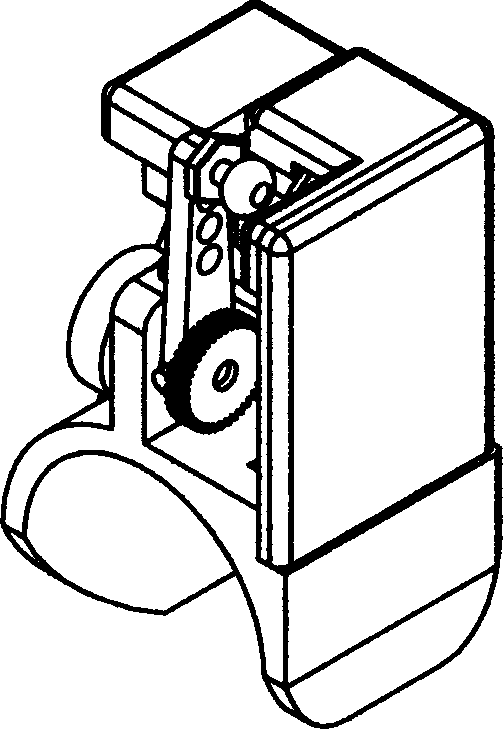

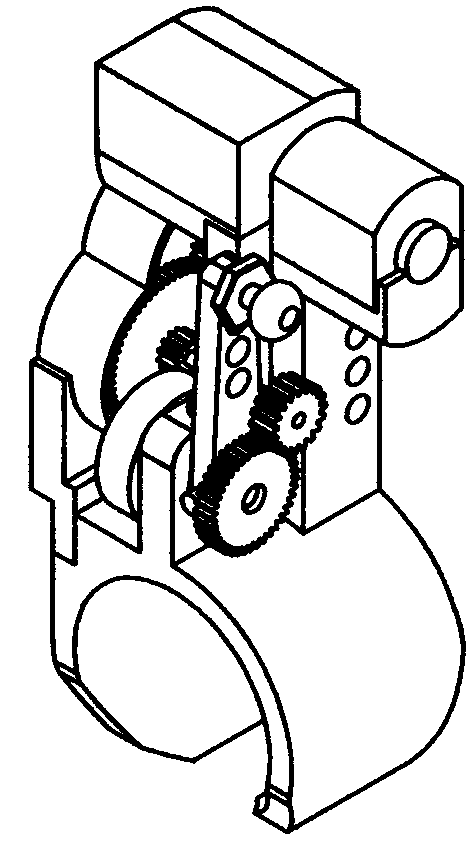

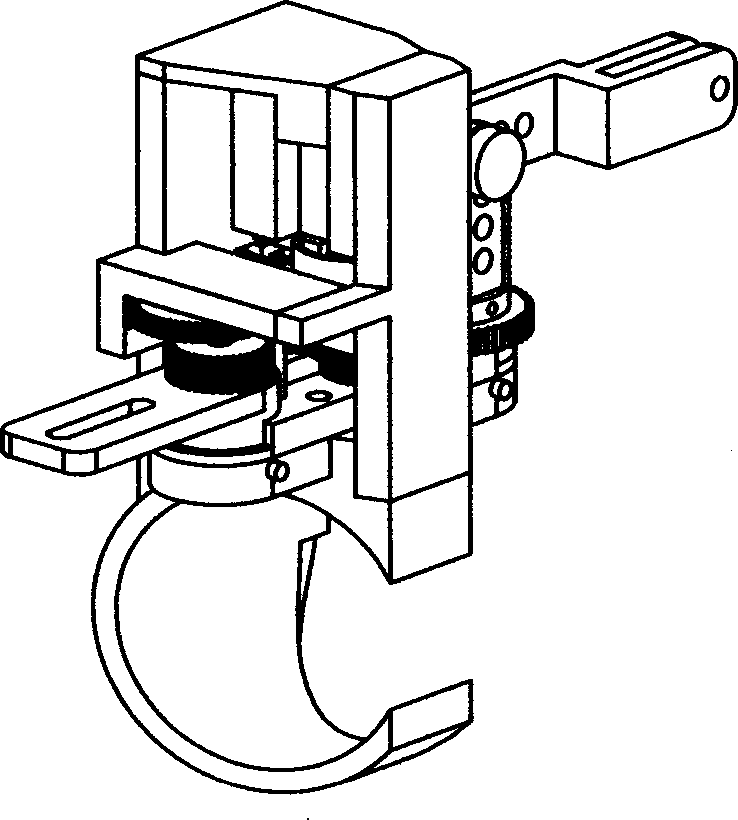

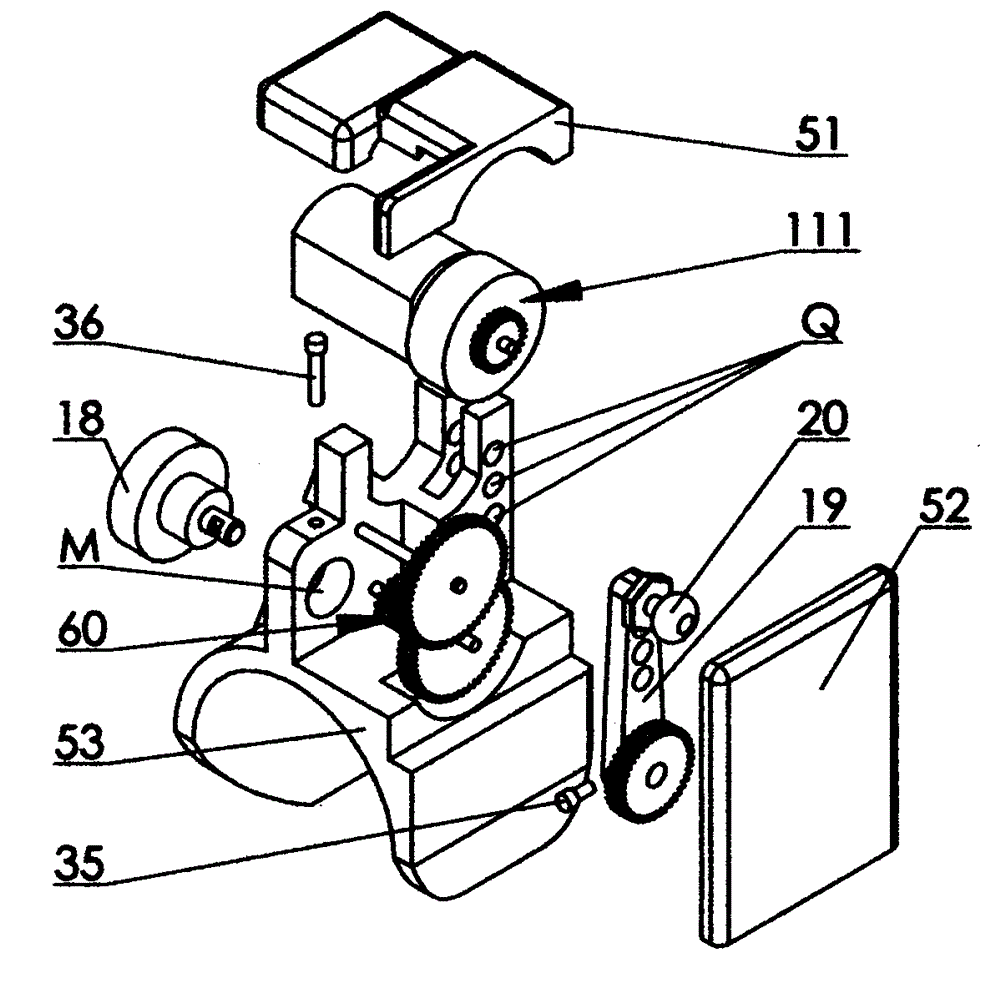

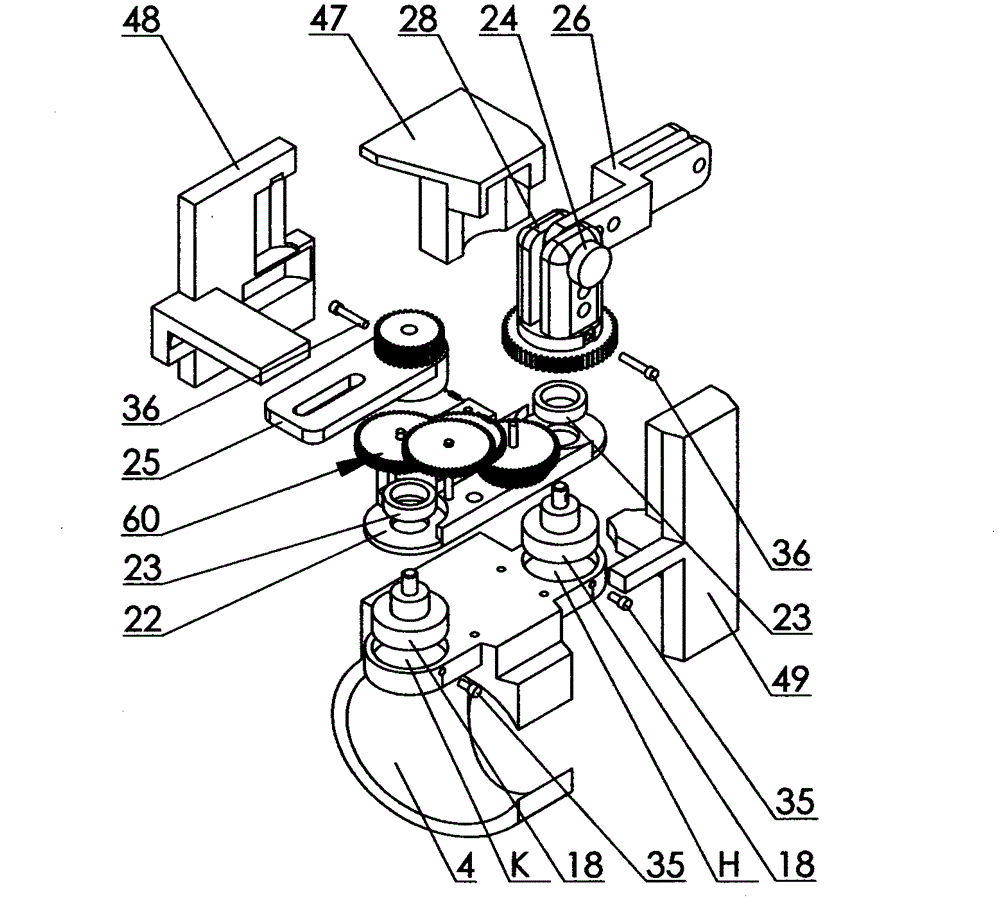

Far knuckle force feedback device

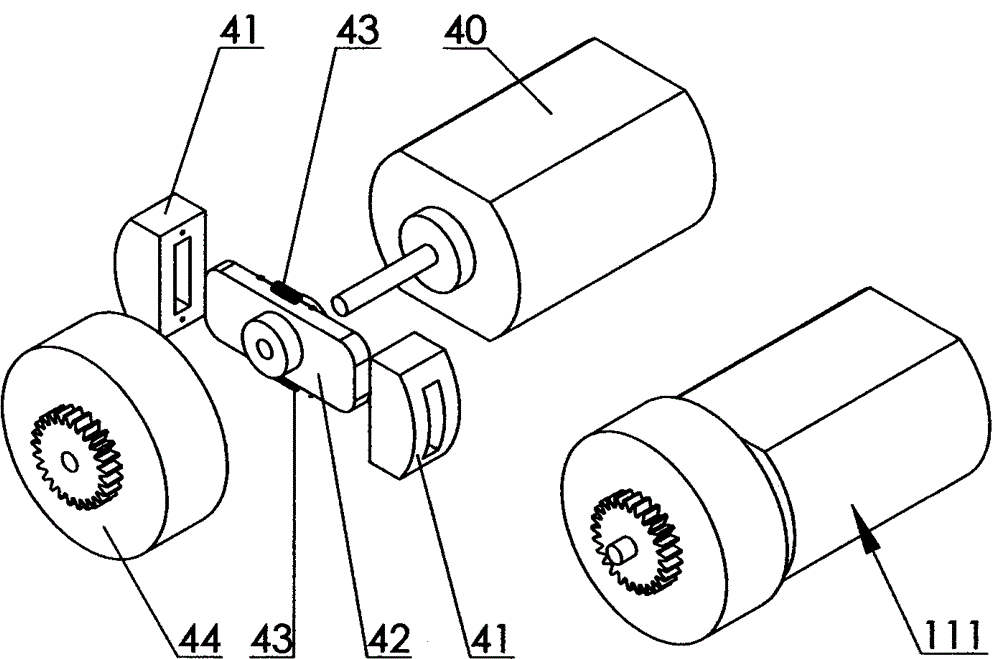

InactiveCN104635915ASmooth movementReduce resistanceInput/output for user-computer interactionGraph readingBack stressStress conditions

The invention relates to a device for detecting the motion state of fingers of a human hand and feeding back stress borne by the corresponding knuckles of the hand, in particular to a far knuckle force feedback device. The far knuckle force feedback device aims at solving the problems that a joint measuring mechanism and a force feedback mechanism of an existing force feedback device are separated, the system is complex, the structure is overstaffed, maintenance is difficult, bidirectional active driving cannot be achieved, and the price is high. A joint detecting mechanism and the force feedback mechanism are integrated, and are arranged through a unique connecting mode and ingenious knuckle measuring points, when an operator uses the device, the detected finger can be kept flexible to the maximum degree, the motion state can be precisely detected, the corresponding knuckle of a controlled human hand can move consistent with the corresponding knuckles of the operator in a cooperating mode, and the stressing condition of the hand in the specific work environment can be fed back to the operator so that the sense of immediacy of virtual reality or teleoperation can be enhanced.

Owner:苏茂

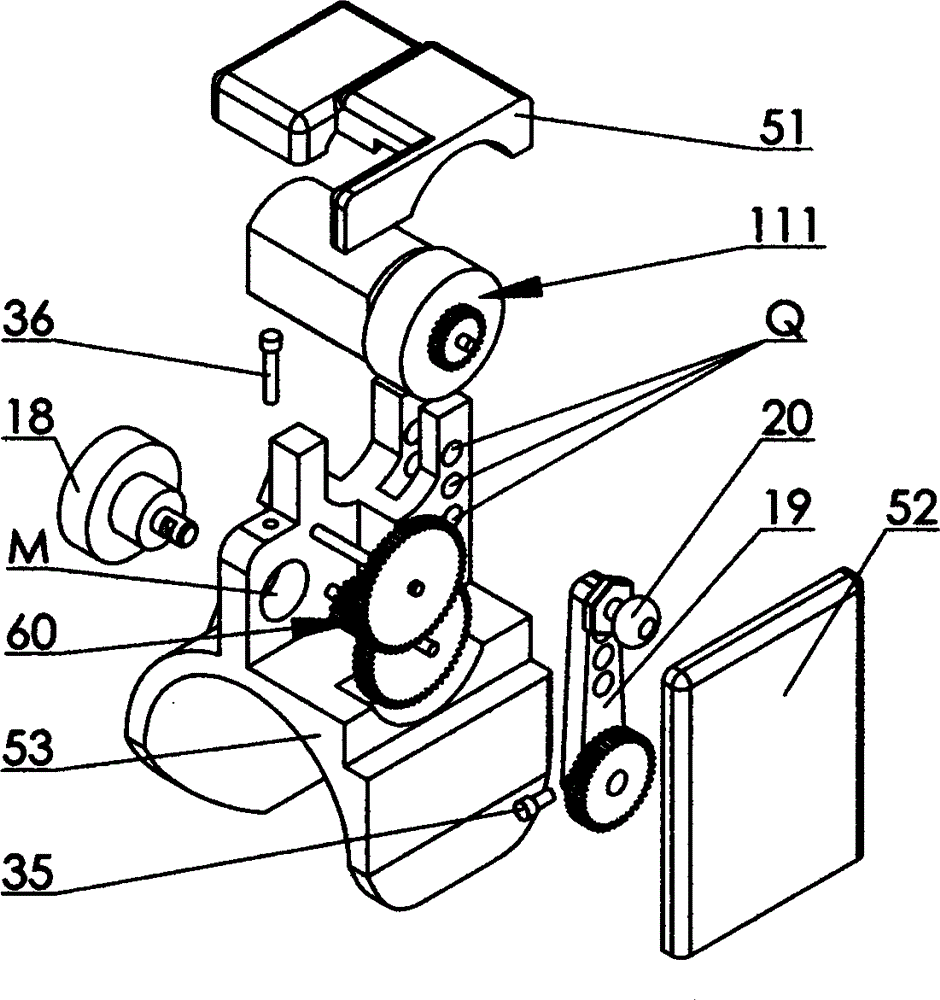

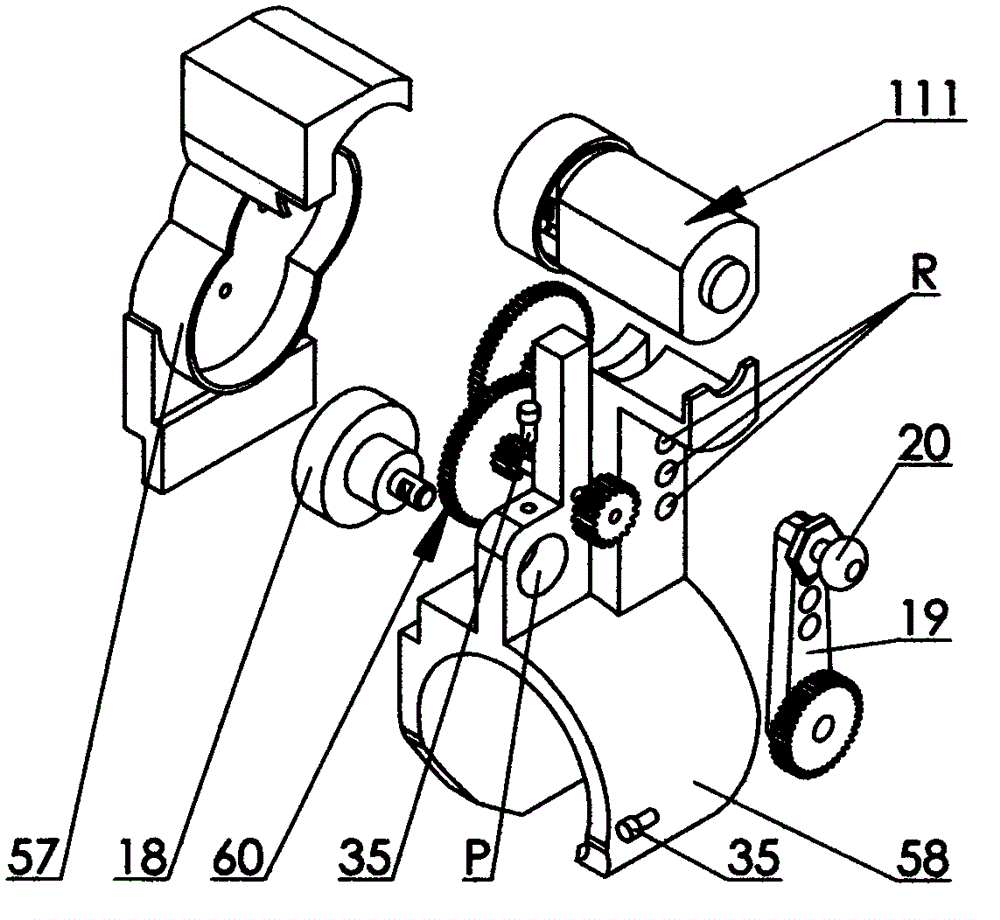

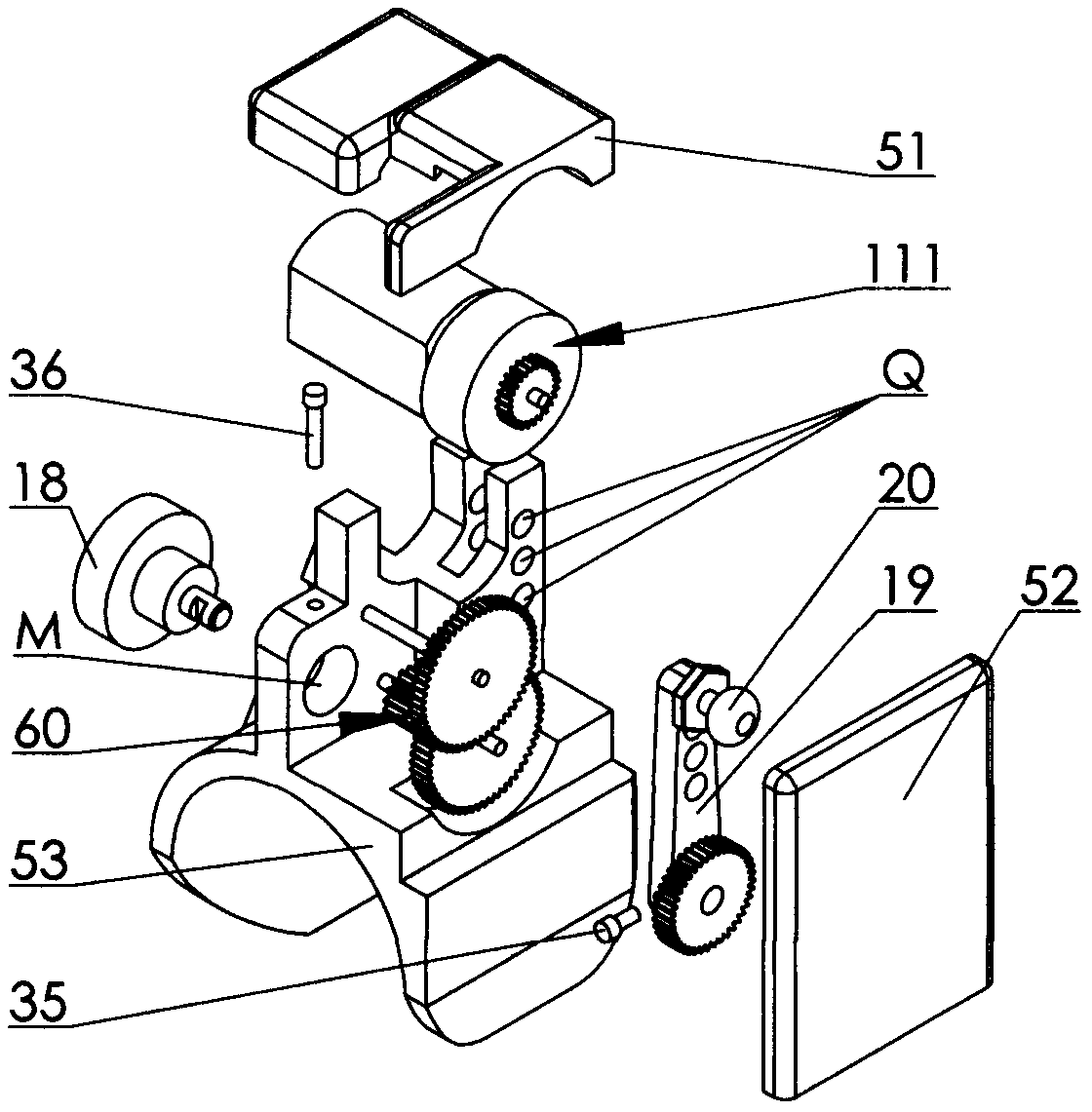

Index finger force feedback device

InactiveCN104635916ASmooth movementReduce resistanceInput/output for user-computer interactionGraph readingIndex fingerMeasurement point

The invention provides an index finger force feedback device and relates to a device which can detect the finger motion states of the hands and feedback force exerted on the corresponding finger joints of the slave hand. In order to overcome the defects that as an existing force feedback device joint measuring mechanism and a force feedback mechanism are separated, a system is complex, the structure is complex, maintenance is difficult, bi-directional active driving can not be achieved, and price is high, a joint detecting mechanism and a force feedback mechanism are integrated into one, a unique connecting mode and ingenious joint measurement point layout are adopted, and an operator can move the detected fingers flexibly to the maximum degree when using the device; moreover, the motion states can be detected accurately, so that the corresponding controlled finger joints of the slave hand and the corresponding finger joints of the operator coordinate and act congruously, and the force exerted on the slave hand in the specific working environment can be fed back to the operator to enhance the immediacy sense of virtual reality or teleoperation.

Owner:苏茂

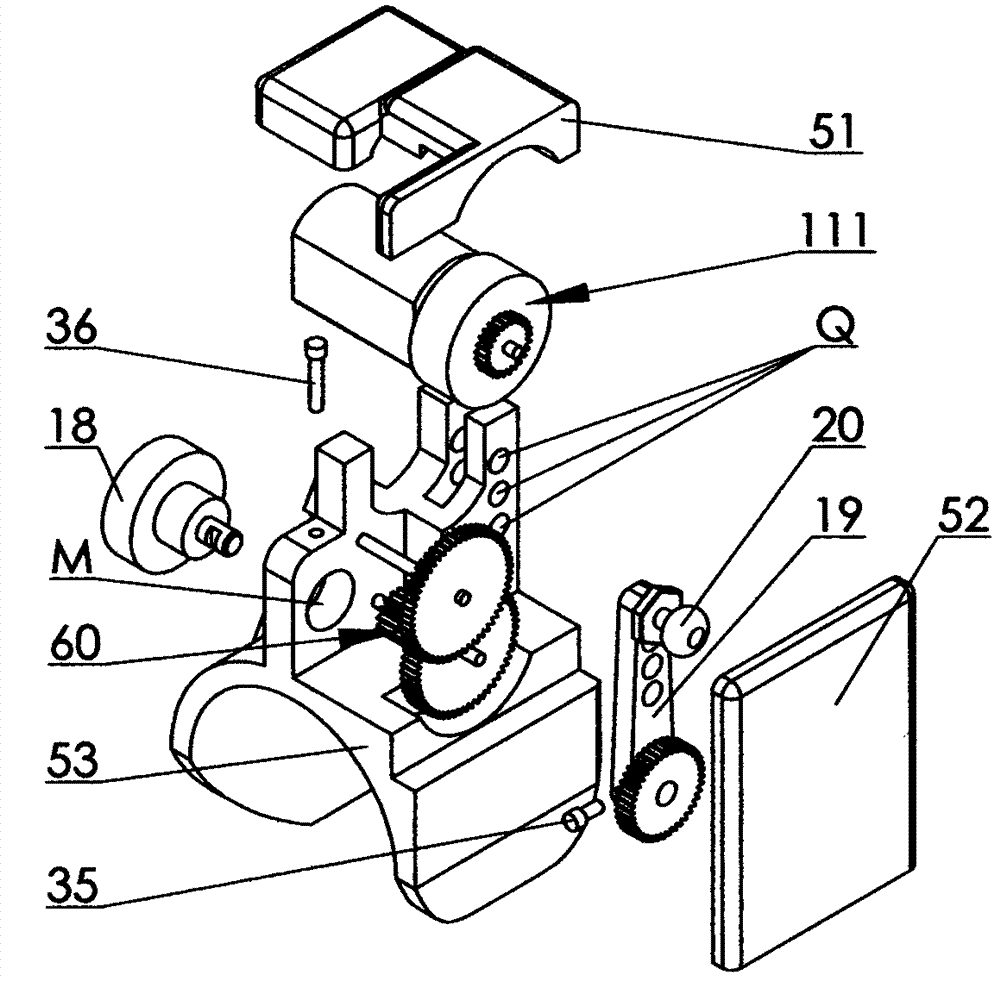

Human hand far knuckle joint force feedback unit

The invention discloses a human hand far knuckle joint force feedback unit, and relates to a device for detecting a human hand finger motion state and returning force stressed from a corresponding hand finger joint. The human hand far knuckle joint force feedback unit solves such defects as separation of a joint measurement mechanism and a force feedback mechanism, complex system, bloated structure, difficult maintenance, incapability of realizing two-way active driving and expensive cost in a traditional force feedback device; the joint measurement mechanism and the force feedback mechanism are integrated as a whole; and as a unique connecting mode and a skilful joint measurement point layout are adopted, when users use the equipment, detected fingers can keep the highest flexibility, the motion state can be precisely detected, the controlled hand finger joint and the corresponding operator finger joint can perform the same actions, and the hand stress condition in the specific working environment can be returned to operators so as to improve the immediacy sense of virtual reality or remote operation.

Owner:苏茂

Thumb far-end joint detection device for data glove

The invention discloses a thumb far-end joint detection device for a data glove and relates to a device for detecting the movement state of fingers of a hand and feeding back the force borne by corresponding finger joints of the hand. By the adoption of the thumb far-end joint detection device for the data glove, the defects that according to an existing force feedback device, a joint measurement mechanism and a force feedback mechanism are separated, a system is complicated, the structure is complicated, maintenance is difficult, bidirectional active driving cannot be achieved, and the price is high are overcome. A joint detection mechanism and a force feedback mechanism are integrated, and a unique connection way and ingenious joint measurement point arrangement are adopted, so that when an operator uses the device, the detected finger can be kept flexible to the maximum extent; the movement state can be accurately detected so that the corresponding finger joint of the controlled hand and the corresponding finger joint of the operator can move cooperatively and consistently, the stress condition of the hand in the specific working environment can be fed back to the operator, and accordingly virtual reality or the sense of immediacy of remote control is enhanced.

Owner:苏茂

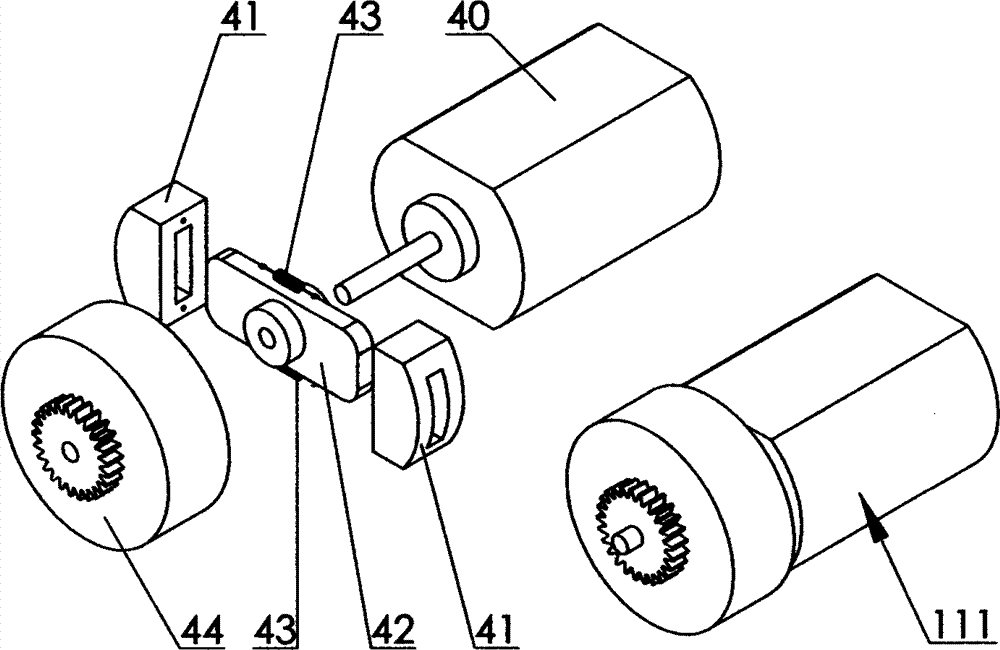

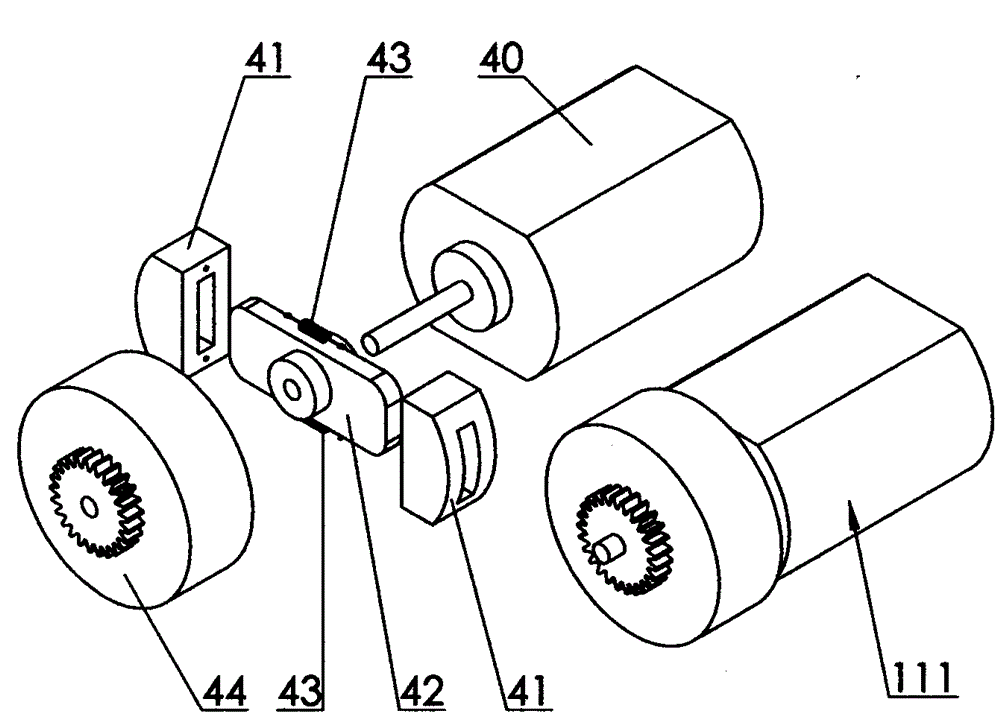

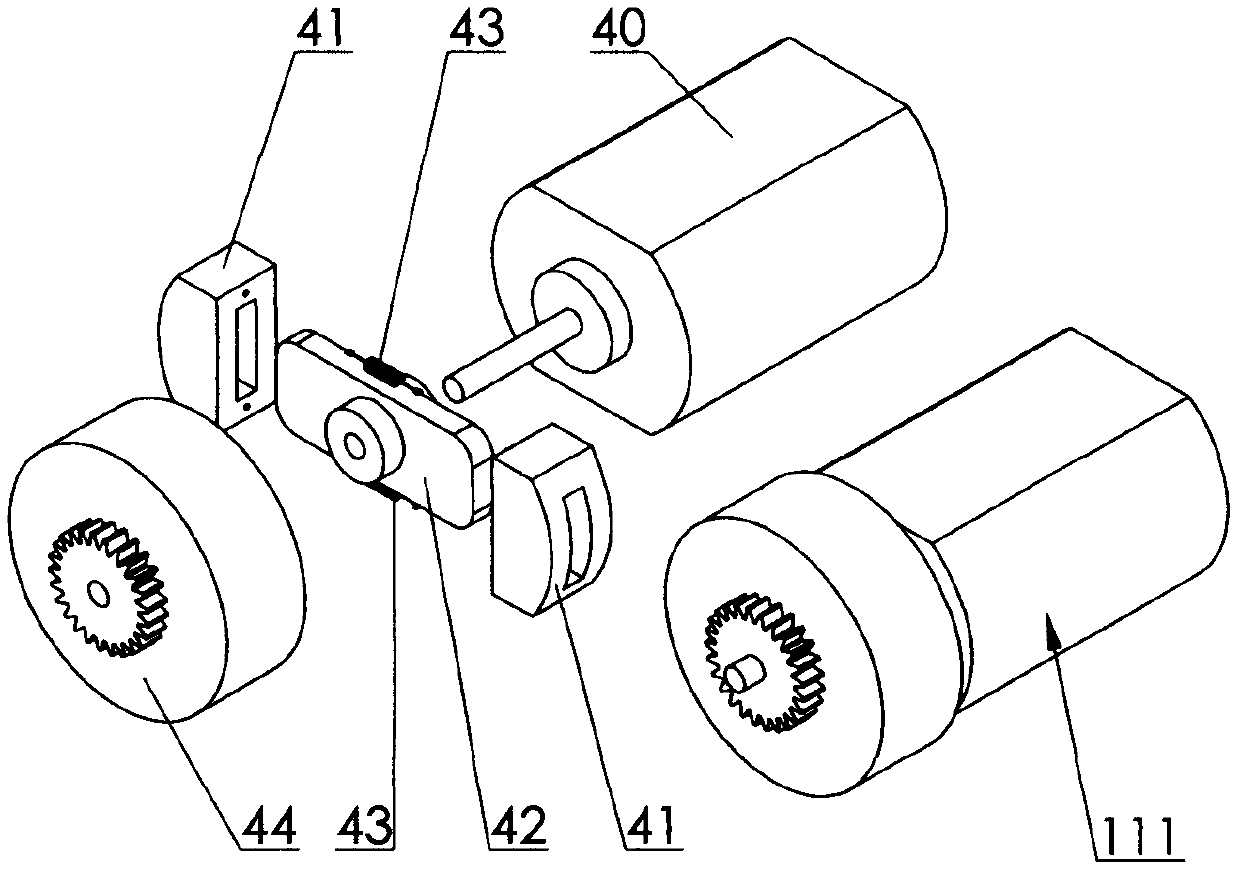

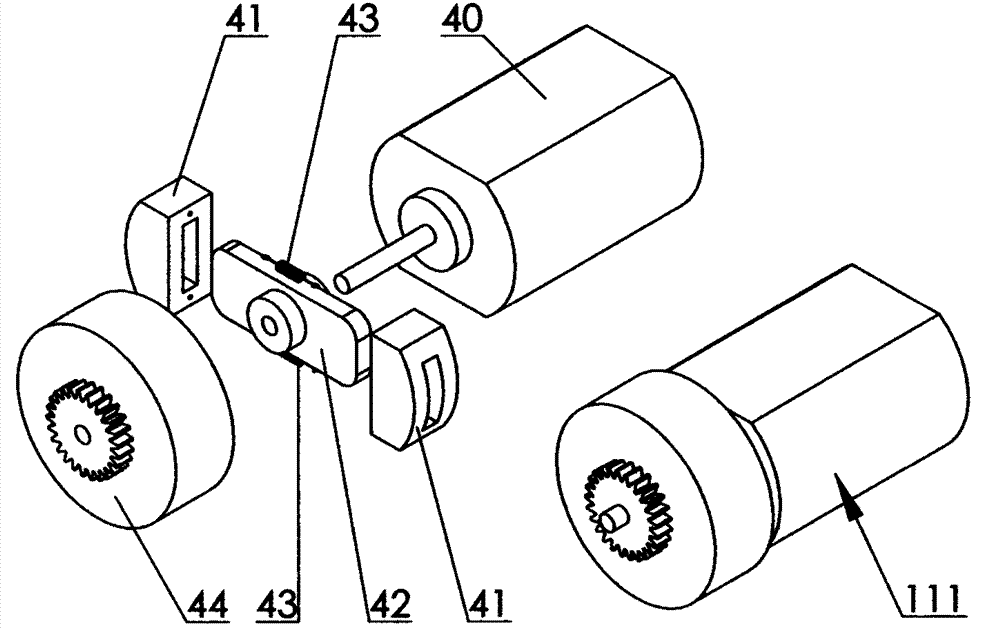

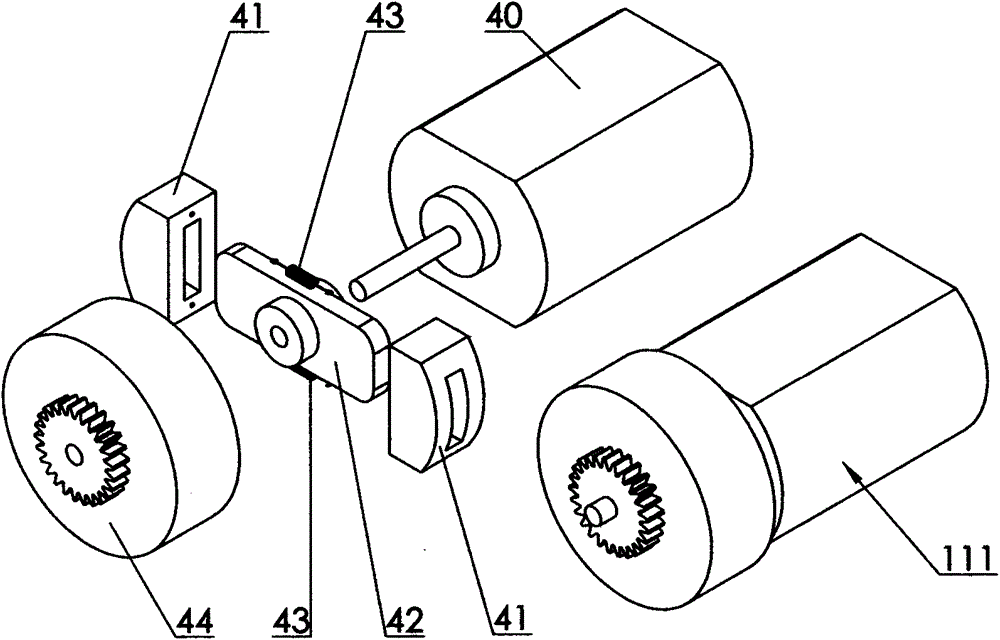

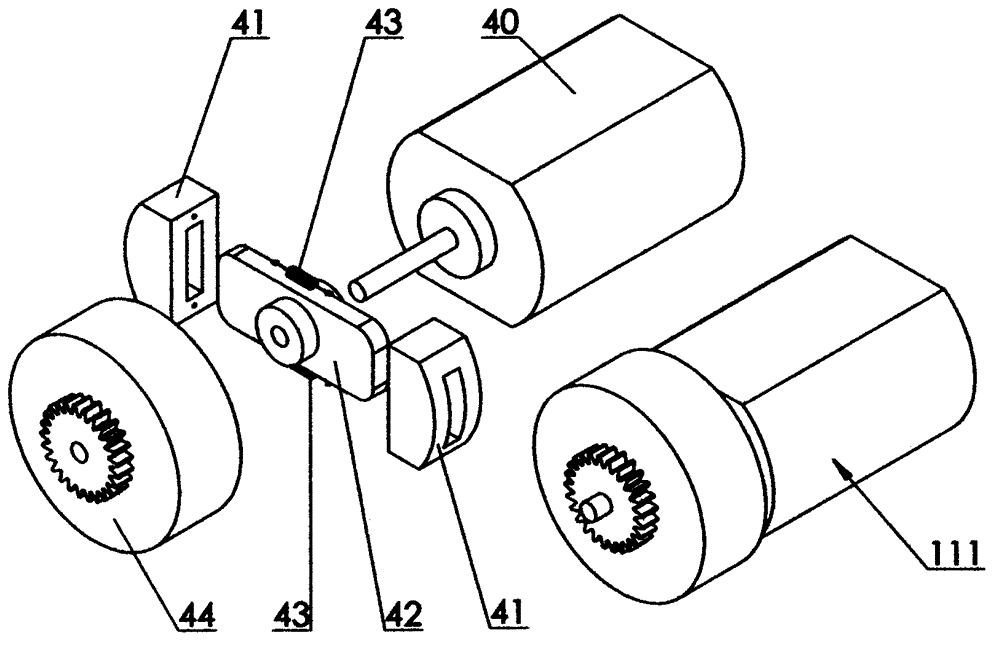

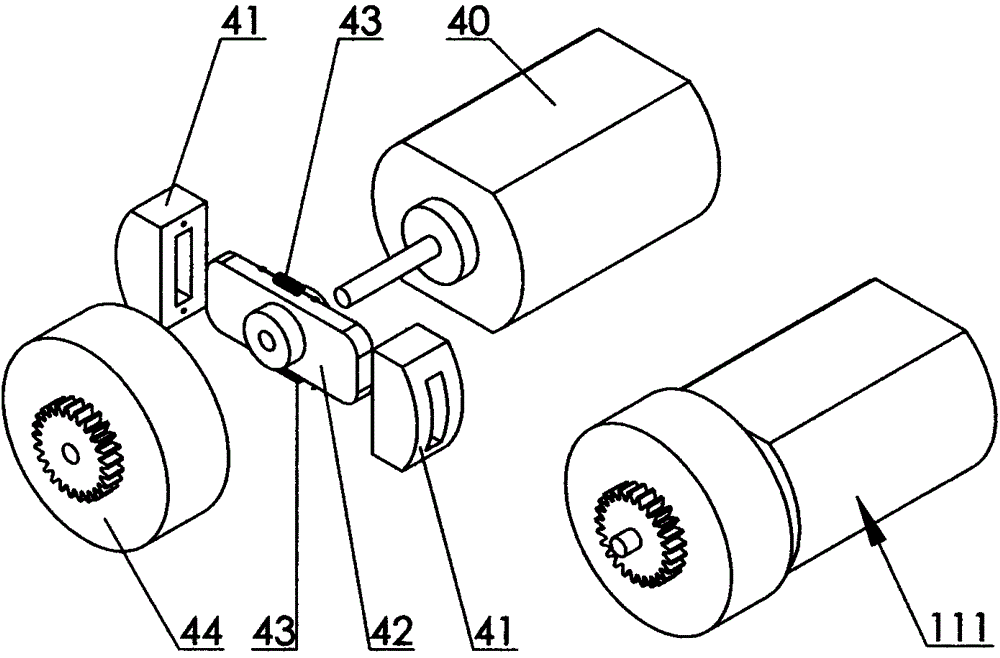

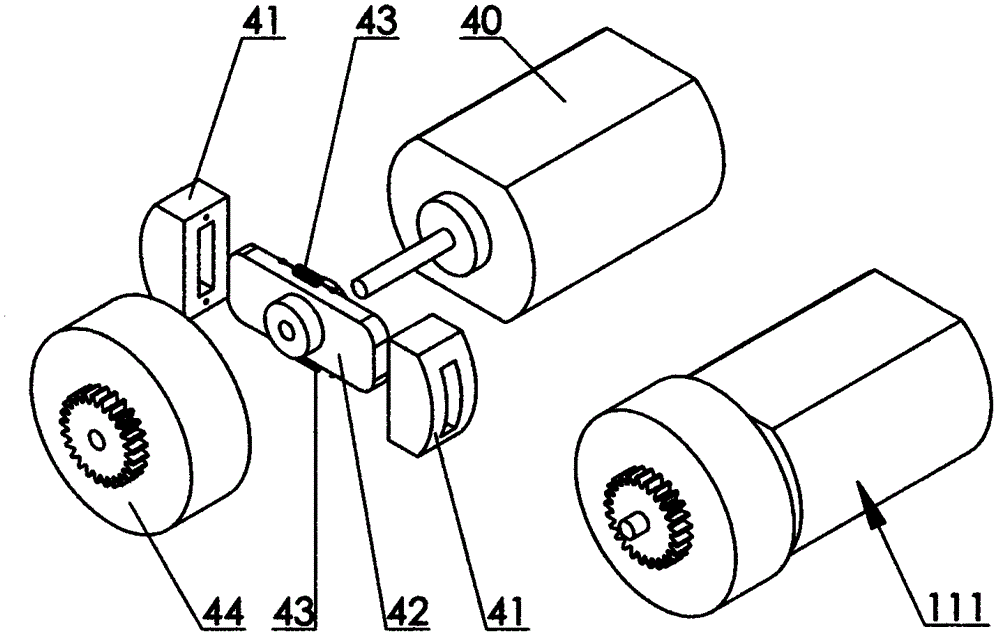

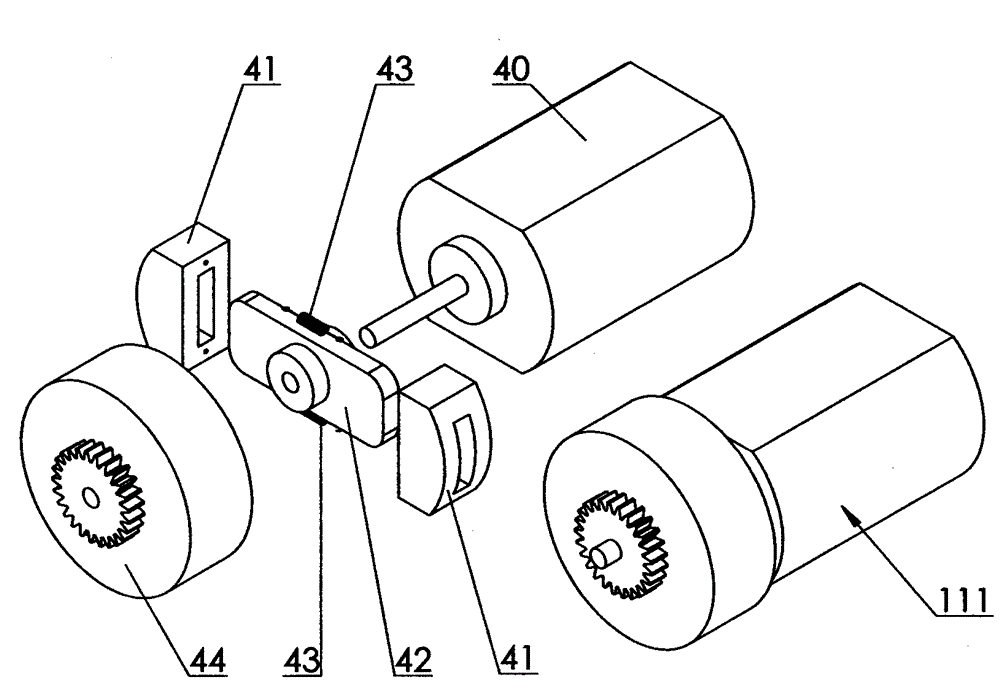

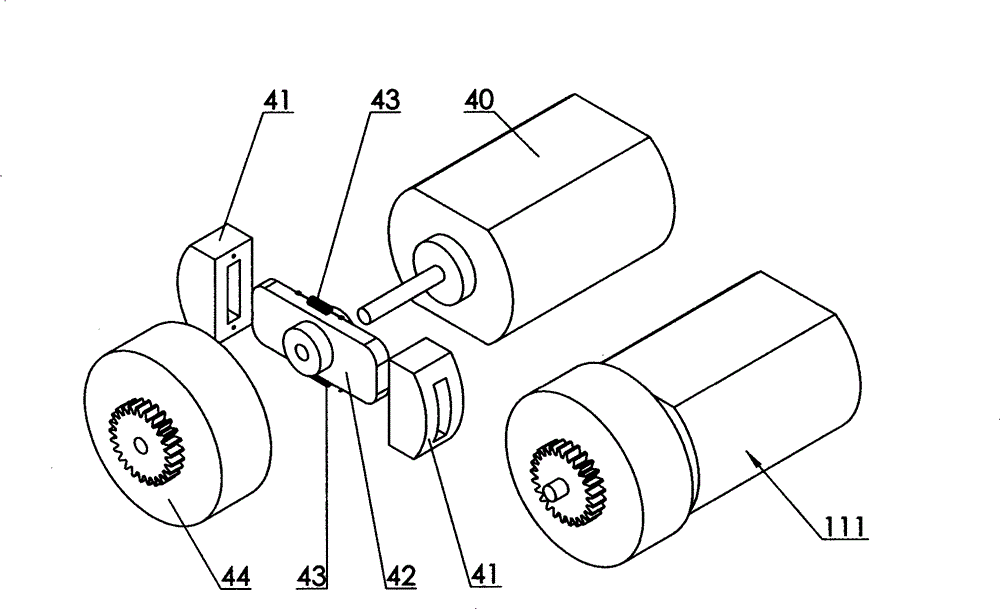

Flexible exoskeleton joint actuator capable of being clutched

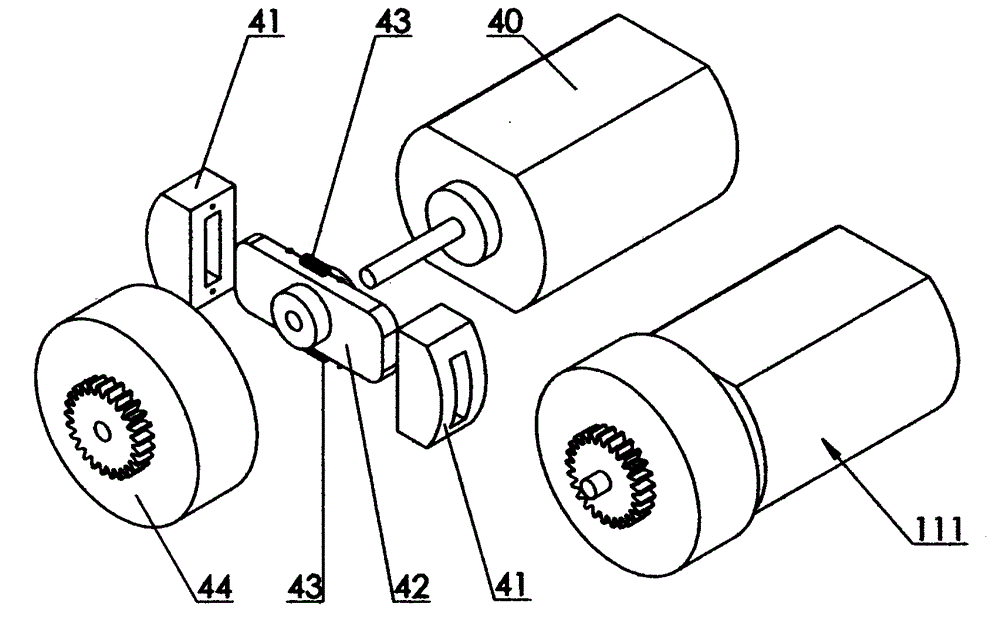

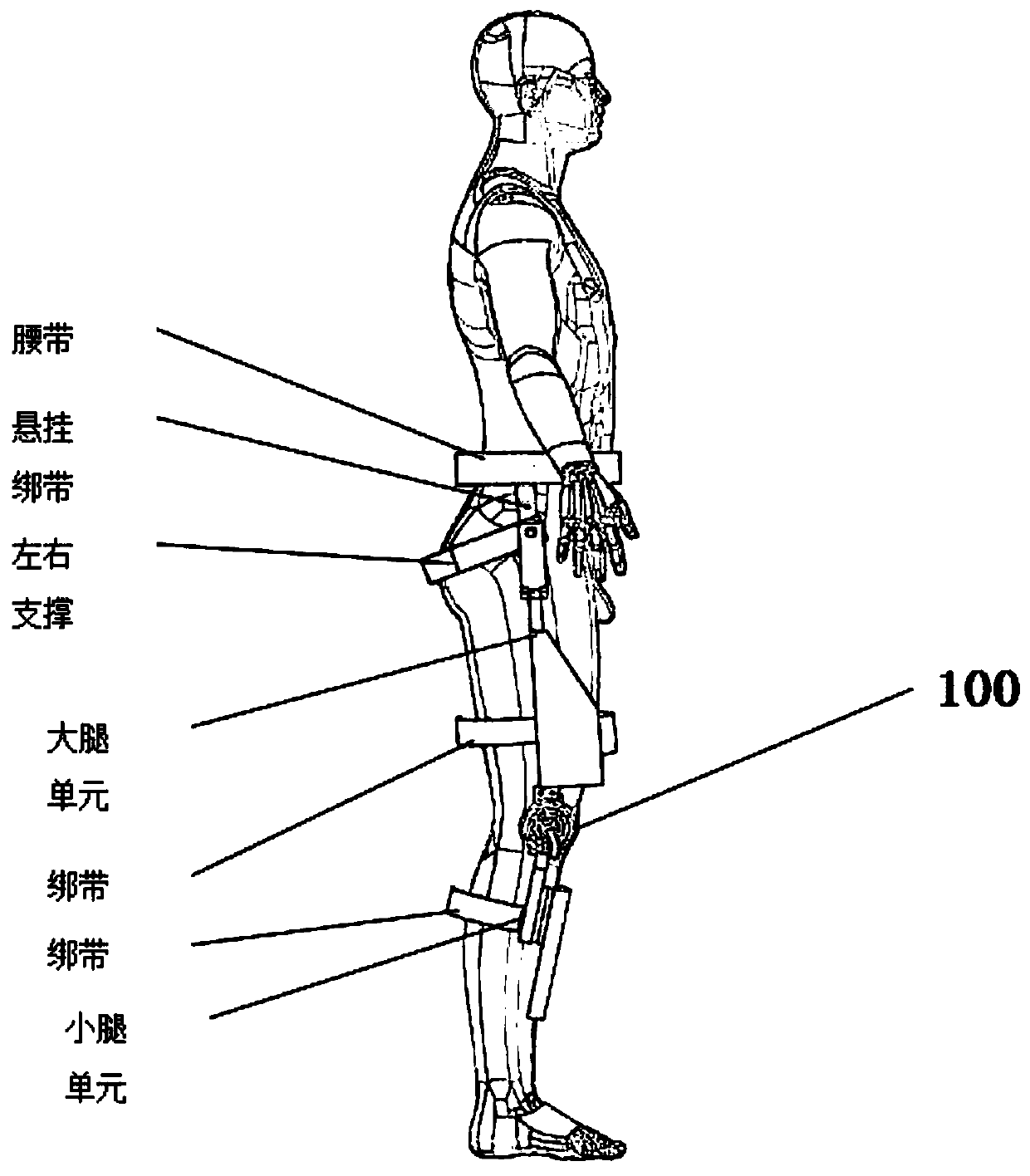

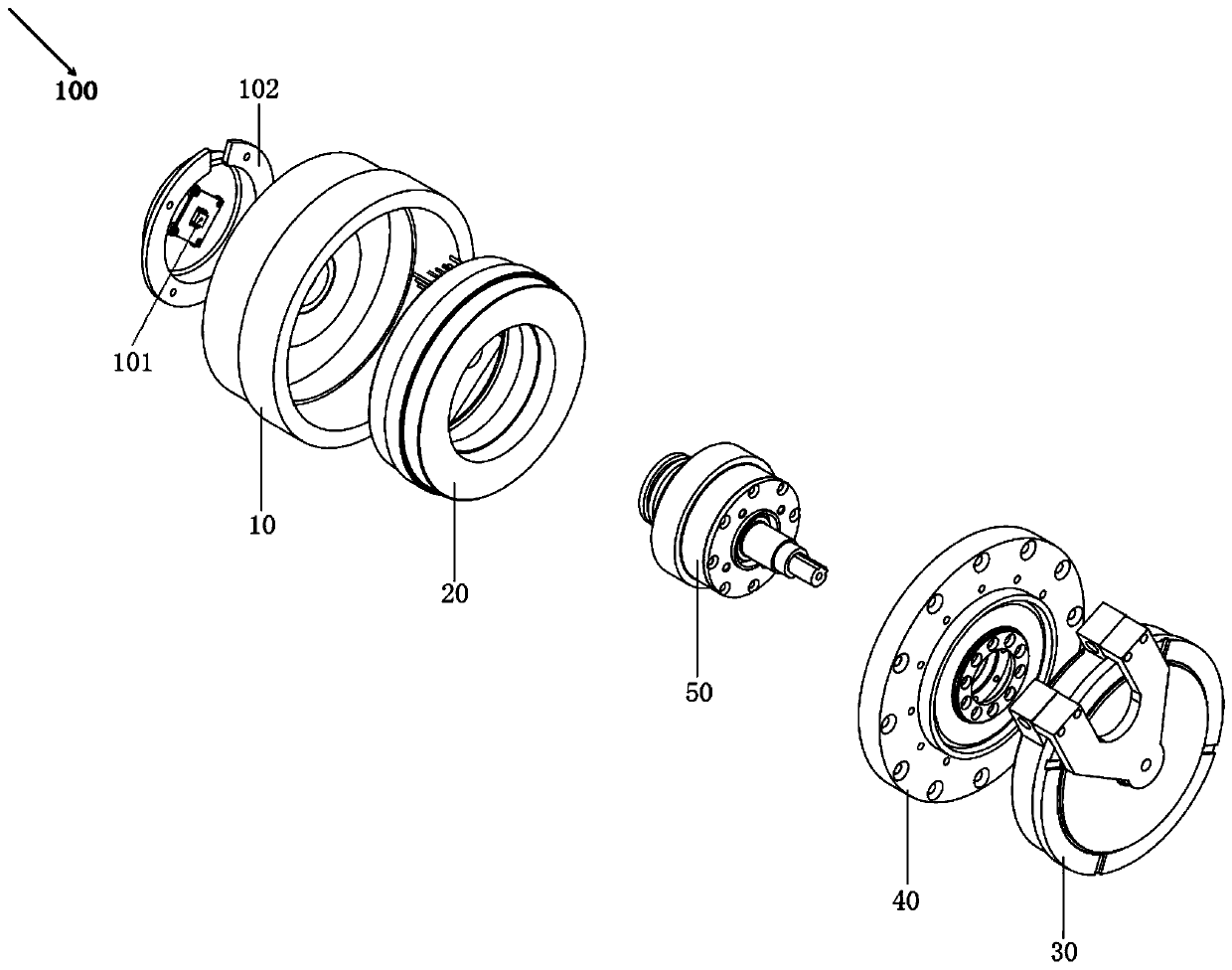

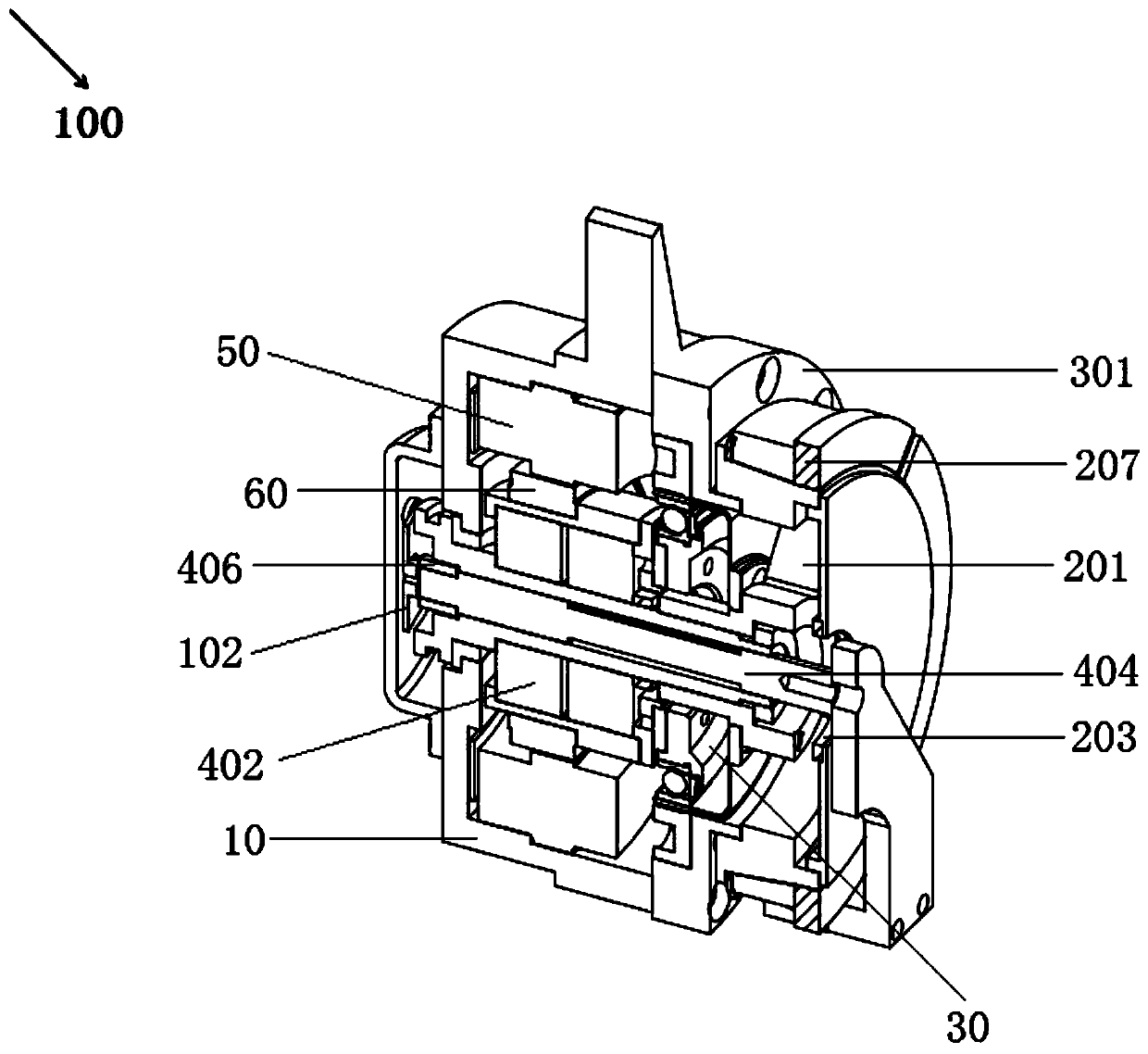

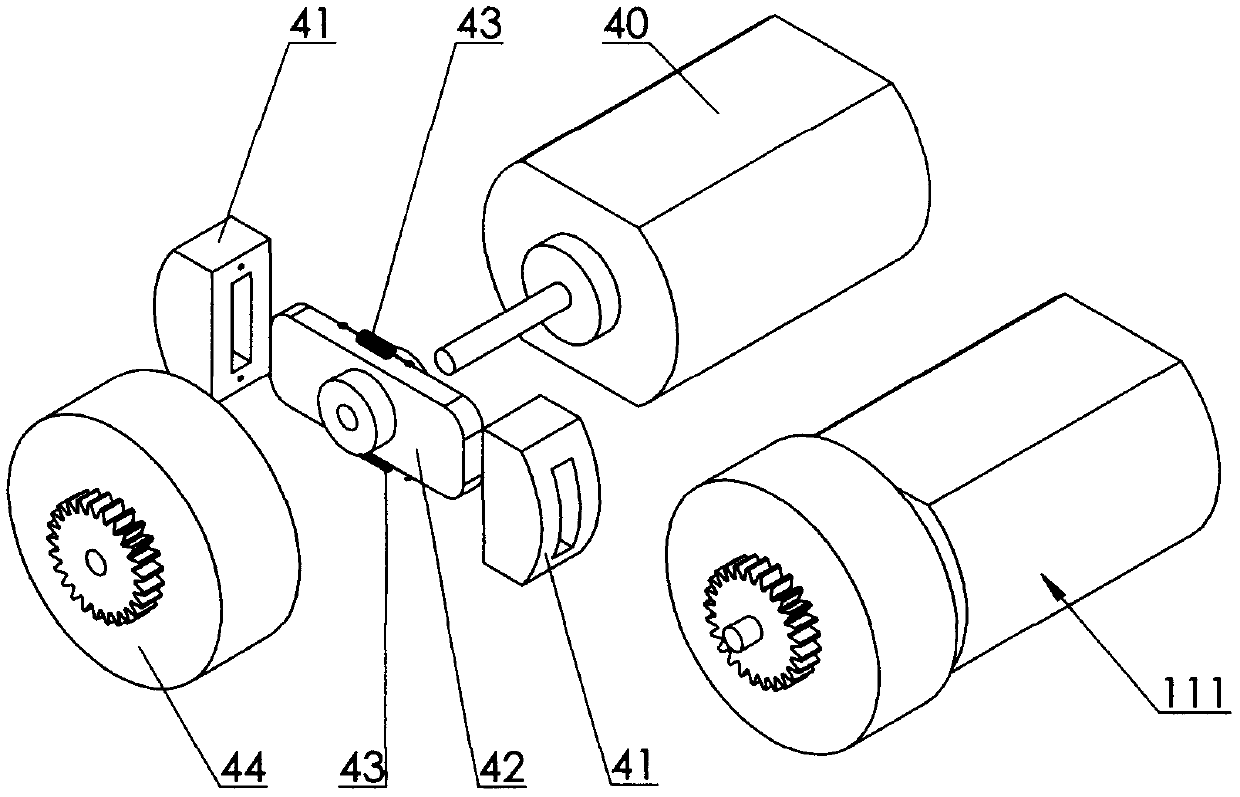

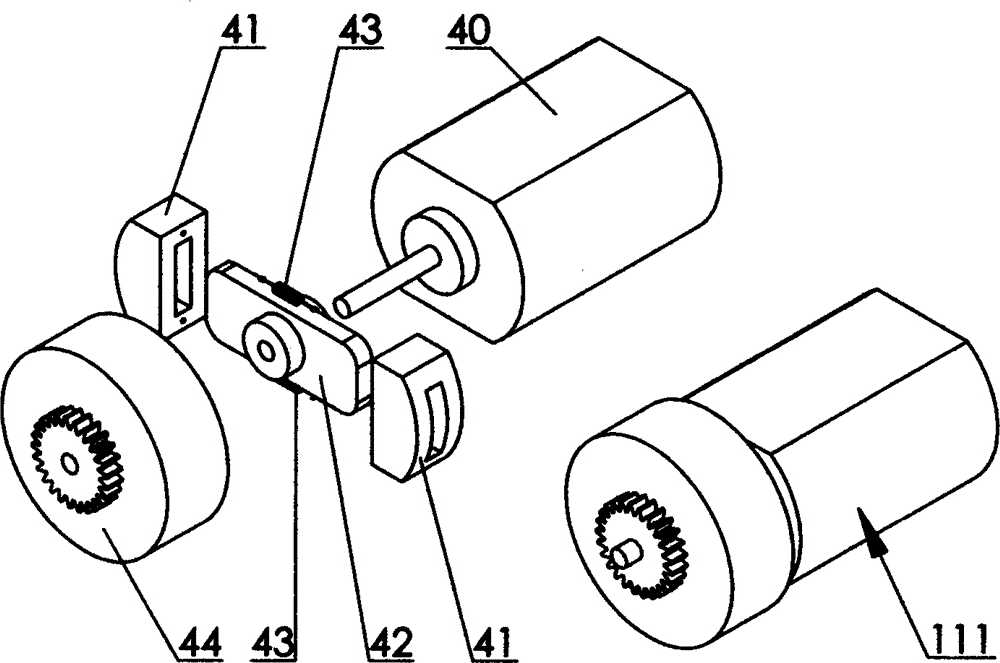

PendingCN110788840ARealize Force Feedback ControlReduce complexityProgramme-controlled manipulatorJointsElectric machineReduction drive

The invention provides a flexible exoskeleton joint actuator capable of being clutched. The flexible exoskeleton joint actuator is mounted between thighs and shanks of an orthotics exoskeleton which is in parallel connection to lower limbs of a human body, and is a structure for providing passive compliance and unilateral outgoing lines in a joint en-abled state. The flexible exoskeleton joint actuator comprises a motor base with a motor stator therein, a motor rotor arranged inside the motor stator, an output shaft and a speed reducer which are sequentially connected, and a rotary part whichpenetrates through the motor stator, the speed reducer and the output shaft, wherein the output shaft comprises an output disc, an outer ring corner feedback plate, a first magnetic ring, a pluralityof magnetic coding linear sensors, a shank locking connecting disc, a disc spring and a joint absolute rotation angle feedback rod; the speed reducer comprises a shank connecting disc, a speed reducerrigid wheel, a speed reducer flexible wheel and a speed reducer wave generator; and the rotary part comprises a rotor connector, a bearing group, a hollow centering shaft and a joint absolute motionfeedback shaft. The flexible exoskeleton joint actuator reduces complexity and weight of the structure, and improves integral safety and reliability.

Owner:FUDAN UNIV +1

Little finger force feedback device

The invention discloses a little finger force feedback device, and relates to a device capable of detecting the motion state of hand fingers and feeding back force borne by corresponding finger joints of a slave hand. The device solves the problems that according to an existing force feedback device, a joint measuring mechanism and a force feedback mechanism are separated, a system is complex in structure and bloated, maintenance is difficult, double-direction active driving cannot be achieved, and price is high. A joint detection mechanism and the force feedback mechanism are integrated, and the unique connecting mode and the ingenious joint measuring point layout are adopted, so that when an operator uses the device, the detected fingers can be kept flexible to be greatest extent; the motion state can be precisely detected, so that the motion of the corresponding finger joints of the controlled slave hand and the motion of the corresponding finger joints of the operator are coordinated consistently; and the stress condition of the slave hand in the specific working environment can be fed back to the operator, so that the virtual reality or the remote operation immediacy sense can be enhanced.

Owner:苏茂

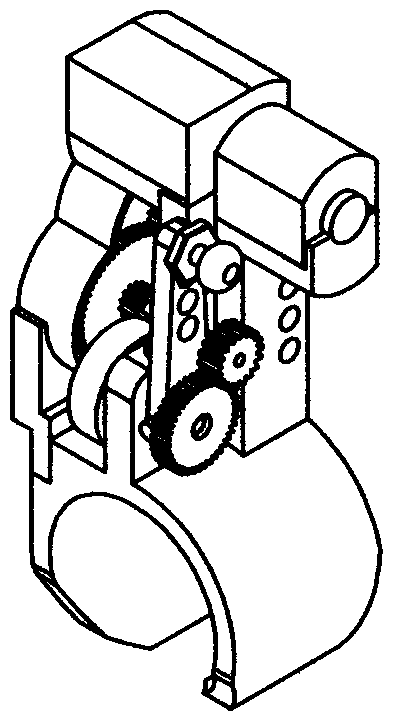

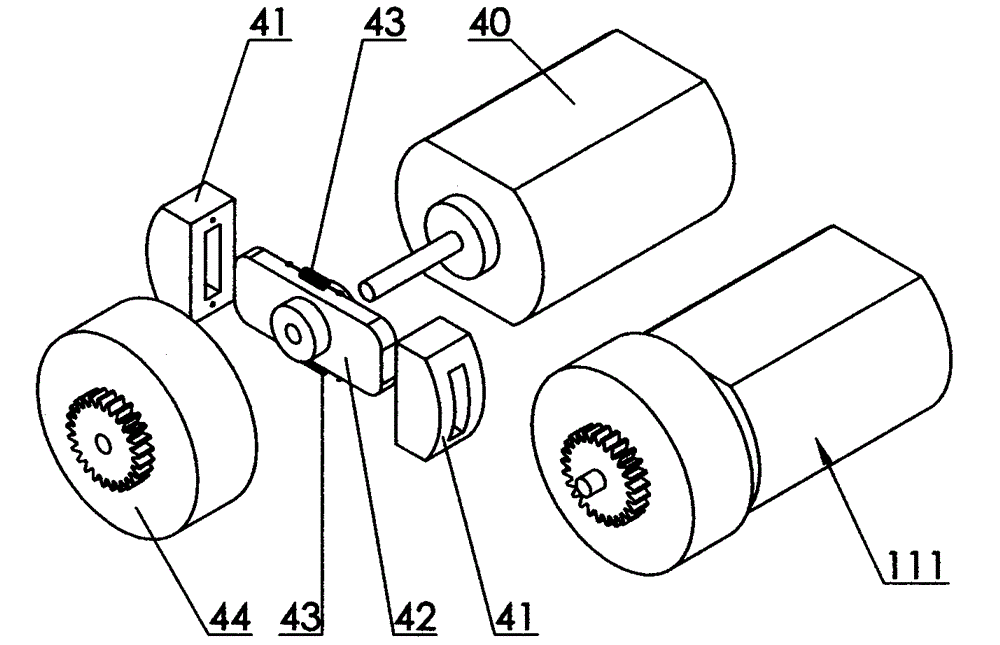

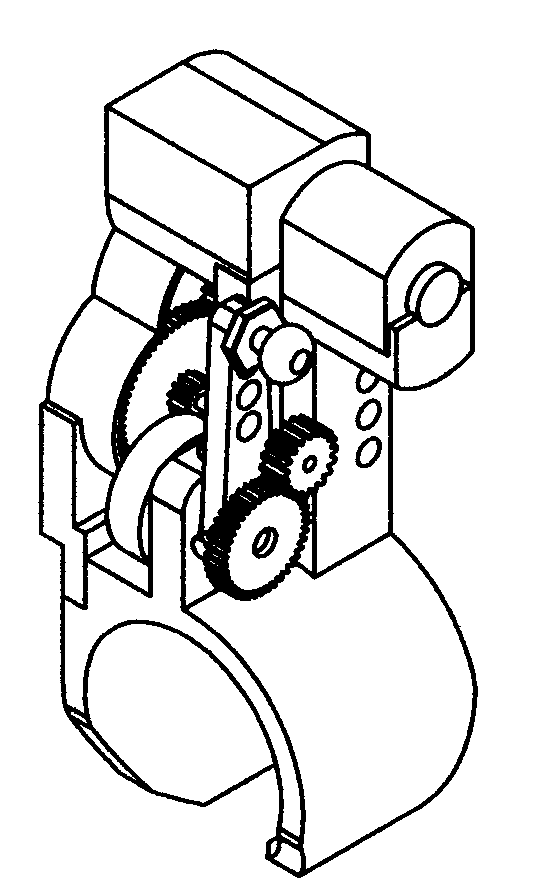

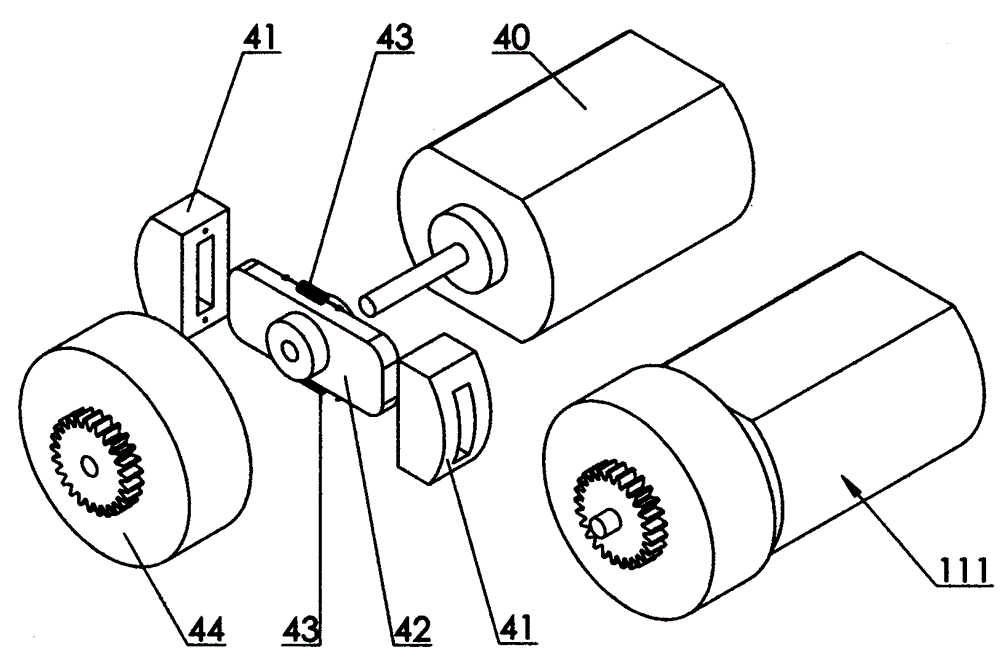

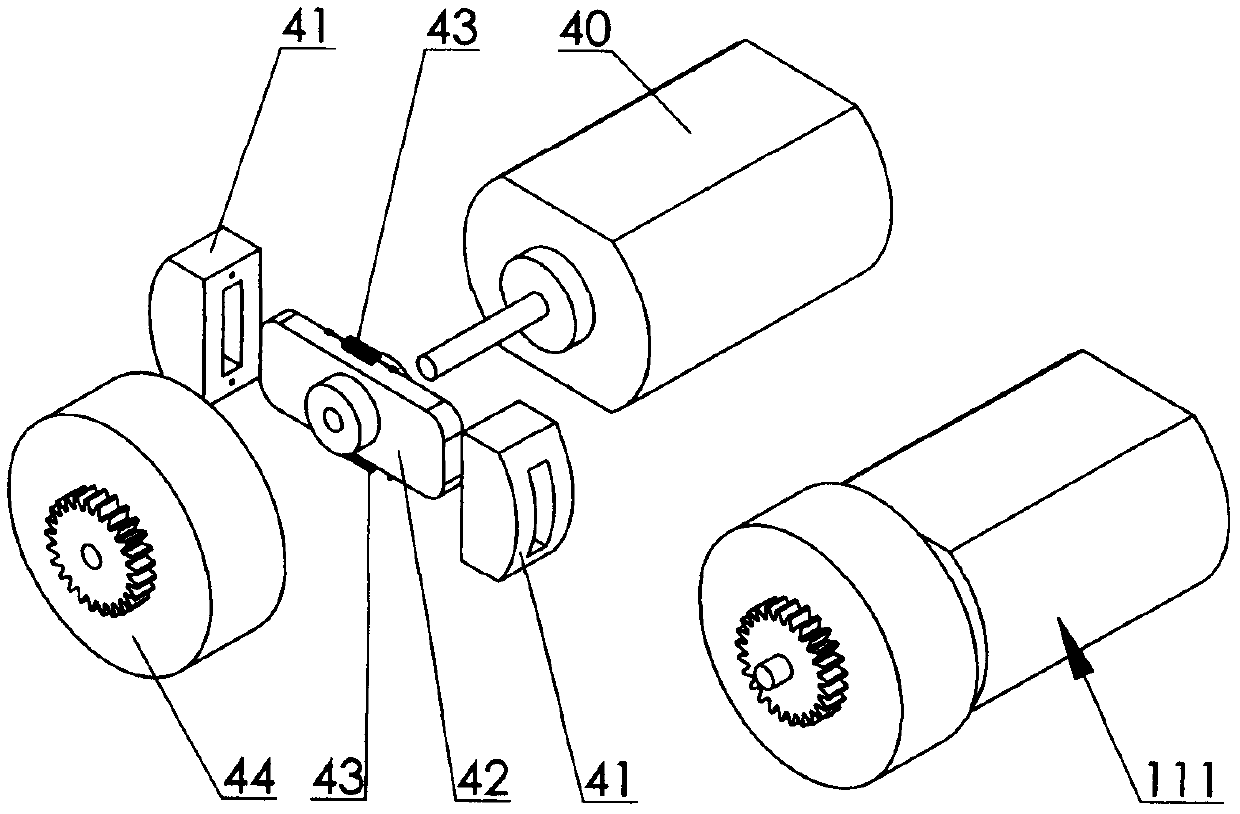

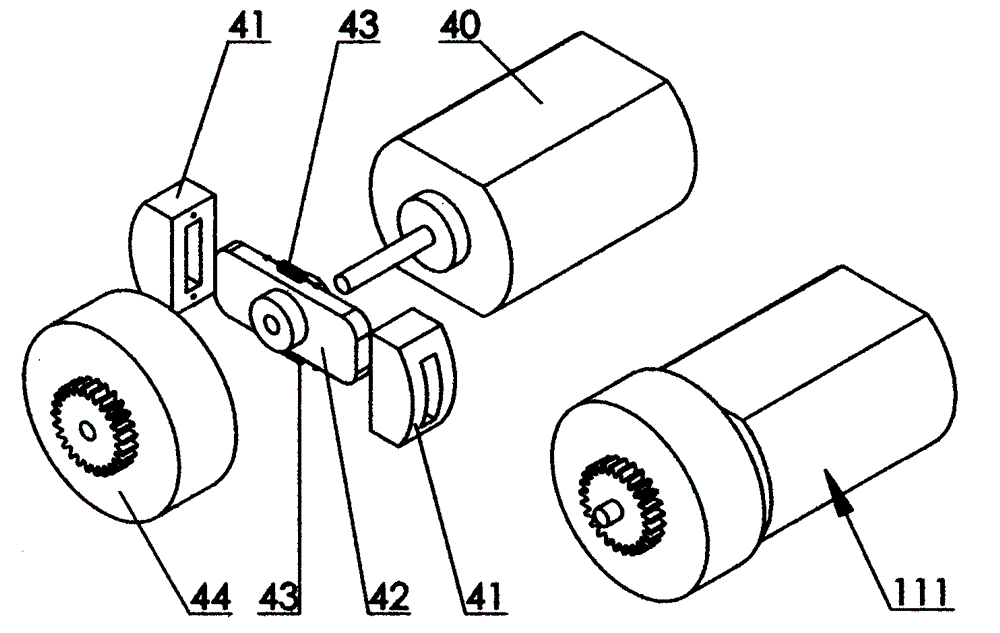

Thumb far knuckle driver

InactiveCN107756404ASmooth movementReduce resistanceProgramme-controlled manipulatorFinger jointWorking environment

The invention discloses a thumb far knuckle driver which relates to a micro device having a two-way torque feedback function. To solve the problems that a joint measuring mechanism and a force feedback mechanism of an existing force feedback device are separated, a system is complicated, a structure is complex, the maintenance is difficult and two-way active driving cannot be realized and the costis high, the joint detection mechanism and the force feedback mechanism are integrated, and by adopting a unique connecting mode and smart joint measuring point layout, when an operator uses the thumb far knuckle driver, detected fingers can be kept flexible to the full extent and motion states can be precisely detected, so that corresponding finger joints of a controlled slave hand can act withcorresponding finger joints of the operator synergistically, the stress situation of the slave hand in a specific working environment can be fed back to the operator, and the presence sensation of virtual reality or remote operation are improved.

Owner:苏茂

Automatic control equipment for online removal of tiny burrs on the working edge of the servo valve spool

ActiveCN104070183BGuaranteed stabilityGuaranteed accuracyAutomatic control devicesMeasurement/indication equipmentsAutomatic controlControl system

An automatic control device for online removing of tiny burrs on the working edge of a valve element of a servo valve comprises a deburring tool system, a precision feeding system, an automatic tool setting system, a force feedback system and a control system, wherein the deburring tool system mounted on a Z-axis lifting table comprises a deburring turning tool, a force sensor and a fixture, the precision feeding system used for controlling the feeding of the deburring tool system comprises an X-axis feeding mechanism, a Y-axis feeding mechanism and the Z-axis lifting table, the automatic tool setting system comprising a displacement sensor fixed on the fixture can achieve precise tool setting and complete radial runout measurement and working edge scanning detection of a workpiece, the force feedback system used for monitoring the degree of the deburring force in real time comprises a force sensor which is arranged below the deburring turning tool and connected with the fixture, and the control system used for monitoring the feeding movement, automatic tool setting, deburring, force feedback alarm retraction and online deburring effects of the automatic control device comprises an industrial personal computer connected with the precision feeding system, the force feedback system and the automatic tool setting system. The automatic control device for the online removing of the tiny burrs on the working edge of the valve element of the servo valve achieves the online automatic removing of the tiny burrs on the working edge and has the advantages of low rejection rates, high efficiency and low costs.

Owner:SHANGHAI JIAOTONG UNIV +1

Stress feedback unit for joints of third finger and middle finger

InactiveCN104742129ASmooth movementReduce resistanceInput/output for user-computer interactionProgramme-controlled manipulatorBack stressWorking environment

A stress feedback unit for joints of a third finger and a middle finger relates to a device used for detecting movement state of fingers of a human hand and capable of feeding back stress of the corresponding finger joints of the hand. The invention aims to make up defects that a joint detecting mechanism and a stress feedback mechanism of a prior stress feedback device are separated with each other and a prior system is complex in structure, difficult to maintain, incapable of bidirectional driving and high in cost and the like, integrates the joint detecting mechanism and the stress feedback mechanism, and adopts a unique connection way and a skillful joint detection point arrangement, so that to-be-detected fingers of a user can keep flexibility to the largest extent when the user is using the device. Besides, the movement state of the fingers can be detected precisely, so that finger joints of a slave hand corresponding to the finger joints of the user can move exactly as the finger joints of the user and stress of the hand in a specific working environment can be fed back to the user for enhancing sense of immediacy of virtual reality or for remote operation.

Owner:苏茂

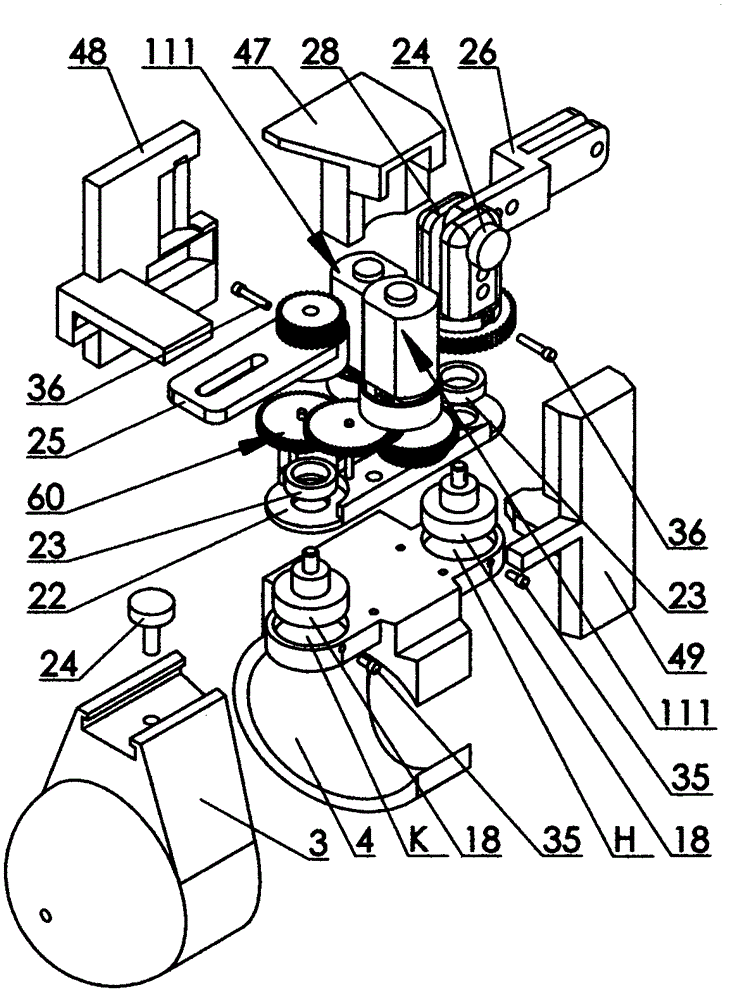

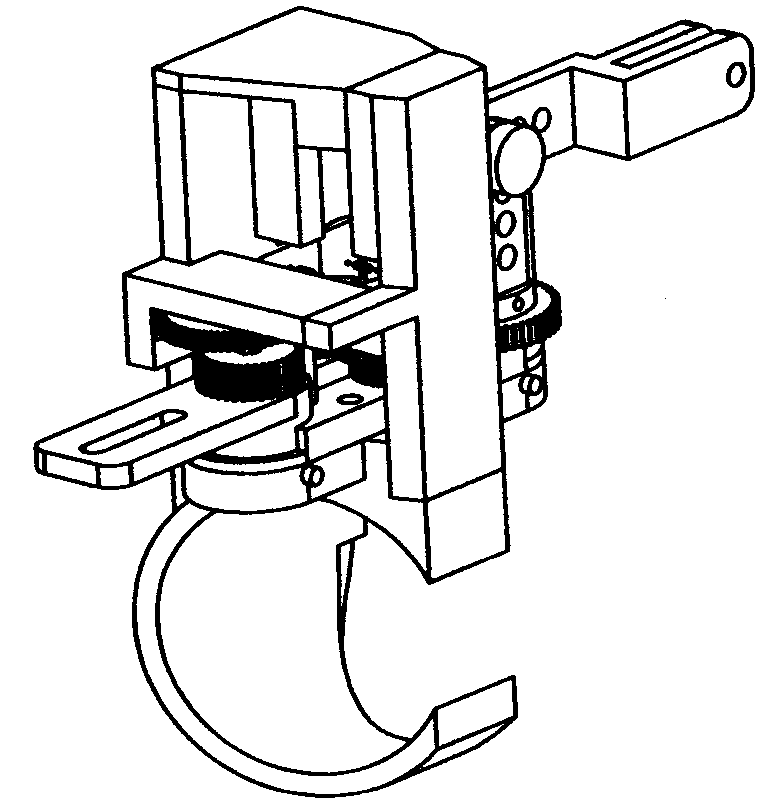

Thumb near-knuckle force feedback detection driving device

The invention relates to a device for detecting the human hand finger motion state and feeding back the force borne by the corresponding finger knuckle of a slave manipulator, in particular to a thumb near-knuckle force feedback detection driving device. The device aims at overcoming the defects that according to an existing force feedback device, a knuckle measuring mechanism and a force feedback mechanism are separated, the system is complex, the structure is complex, maintenance is difficult, bi-directional active driving cannot be achieved, and the cost is high. A knuckle detection mechanism and a force feedback mechanism are integrated, a unique connection way and a skillful knuckle measurement point layout are adopted, the finger to be detected can be kept flexible to the greatest degree when an operator uses the device, the motion state can be accurately detected, the controlled corresponding finger knuckle of the slave manipulator and the corresponding finger knuckle of the operator move coordinately and consistently, the stress condition of the slave manipulator in the specific working environment can be fed back to the operator, and therefore the virtual reality or remote operation immediacy sense is strengthened.

Owner:苏茂

Minitype finger joint force feedback unit

The invention discloses a minitype finger joint force feedback unit and relates to a device capable of detecting human finger motion states and feeding force applied on the corresponding human finger joints of a manipulator back. In order to solve the problem that a joint measuring mechanism and a force feedback mechanism of an existing force feedback device are separated, the system is complicated and bloated in the structure and difficulty to maintain and overcome the defect that bidirectional active driving cannot be realized and price is high, the joint detecting mechanism and the force feedback mechanism are integrated, and joint measuring points are arranged in the unique and ingenious connection mode. Accordingly, when operating the equipment, operators can keep most flexibly use the detected fingers, motion states can be accurately detected, the finger joints of the manipulator can be controlled to be coordinative to the corresponding finger joints of the operators, and stress conditions of the manipulator in the specific operating environment can be fed back to the operators so as to enhance field feeling of virtual or remote operation.

Owner:苏茂

Ring finger force feedback device

The invention discloses a ring finger force feedback device, and relates to a device which is used for detecting the finger motion state of the hand of a person and can feed back force borne by a corresponding finger joint of the hand. The ring finger force feedback device overcomes the shortcomings that a joint measurement mechanism and a force feedback mechanism of an existing force feedback device are separated, a system is complex, the structure is bloated, maintenance is difficult, bothway initiative driving cannot be achieved, and the price is expensive. A joint measurement mechanism and a force feedback mechanism are integrated together, and a unique connecting mode and the ingenious joint measurement point layout are adopted, so that when an operator uses the device, the detected finger can keep flexible to the maximum degree, the motion state can be accurately detected, a corresponding finger joint of the controlled driven hand and the corresponding finger joint of the operator move unanimously, the stress condition of the driven hand in the specific working environment can be fed back to the operator, and therefore the immediacy sense of the virtual reality or remote control is improved.

Owner:苏茂

Middle finger force feedback device

The invention discloses a middle finger force feedback device, and relates to a device for detecting a human hand finger motion state and returning force stressed by a corresponding hand finger joint. The invention aims to solve such defects as separation of a joint measurement mechanism and a force feedback mechanism, complex system, clunky structure, difficult maintenance, incapability of realizing two-way active driving and high cost in a traditional force feedback device; the joint measurement mechanism and the force feedback mechanism are integrated as a whole, and an unique connecting mode and a skilful joint measurement point layout is adopted; and when operators use the equipment, a detected finger can keep the flexibility to the greatest extent, and the motion state can be precisely detected, so that the controlled corresponding hand finger joint and the corresponding finger joint of the operators can cooperate, and the specific hand stress condition in the working environment can be returned to the operators so as to improve the immediacy sense of virtual reality or remote control.

Owner:苏茂

Data glove thumb near-end joint detection apparatus

InactiveCN105892622ASmooth movementReduce resistanceInput/output for user-computer interactionGraph readingStress conditionsProximal point

The invention discloses a data glove thumb near-end joint detection apparatus, relates to an apparatus for detecting a movement state of a finger of a human hand and feeding back force on a corresponding finger joint of a slave hand, and aims to overcome the shortcomings of separation of a joint measurement mechanism from a force feedback mechanism, complicated system, swollen structure, difficult maintenance, incapability of realizing bidirectional active driving, high price and the like of an existing force feedback apparatus. According to the data glove thumb near-end joint detection apparatus, the joint detection mechanism and the force feedback mechanism are integrated, and a unique connection mode and a skillful joint measurement point layout are adopted, so that when the apparatus is used by an operator, a detected finger can be kept flexible to the maximum extent; the movement state of the finger can be accurately detected, so that the corresponding finger joint of the controlled slave hand can act cooperatively and consistently with that of the operator; and a stress condition of the slave hand in a specific working environment can be fed back to the operator for enhancing the presence of virtual reality or teleoperation.

Owner:苏茂

Little finger joint force feedback device

The invention discloses a little finger joint force feedback device, and relates to a device which is used for detecting the finger motion state of the hand of a person and can feed back force borne by a joint of the corresponding finger of the hand. The little finger joint force feedback device overcomes the shortcomings that a joint measurement mechanism and a force feedback mechanism of an existing force feedback device are separated, a system is complex, the structure is bloated, maintenance is difficult, bothway initiative driving cannot be achieved, and the price is expensive. A joint measurement mechanism and a force feedback mechanism are integrated together, and a unique connecting mode and the ingenious joint measurement point layout are adopted, so that when an operator uses the device, the detected finger can keep flexible to the maximum degree, the motion state can be accurately detected, a corresponding finger joint of the controlled driven hand and the corresponding finger joint of the operator move unanimously, the stress condition of the driven hand in the specific working environment can be fed back to the operator, and therefore the immediacy sense of the virtual reality or remote control is improved.

Owner:苏茂

Outer frame two-way force feedback data glove

The invention provides to an external-framework type bidirectional force feedback data glove and relates to a force feedback data glove which is used for detecting human figure moving status and is provided with a bidirectional active drive to feed back force borne by an auxiliary hand. The external-framework type bidirectional force feedback data glove aims to resolve the problems that an existing force feedback data glove is separated in measurement mechanism and feedback mechanism, complex in system, tumid in structure, difficult to maintain, unachievable in bidirectional drive, expensive in price and the like. According to the external-framework type bidirectional force feedback data glove, a joint detection mechanism is connected with a force feedback mechanism into a whole, a unique connecting mode and an ingenious joint measurement point layout are used, five fingers of a user are enabled to keep the maximum flexibility when the force feedback data glove is used, the moving status of each joints of the fingers can be detected accurately, the movement of each finger joint of the controlled auxiliary hand is enabled to be coordinated with the movement of a corresponding finger joint of an operator, the force bearing conditions of the auxiliary hand in a specific working environment can be fed back to the operator, and the immediacy sense of a virtual reality or a remote operation is enhanced.

Owner:苏茂

Mechanism for detecting and driving distal thumb joint of human hand

The invention provides a mechanism for detecting and driving a distal thumb joint of a human hand, relates to a device for detecting the motion state of the distal thumb joint of the human hand and feeding back force on the distal thumb joint of the human hand, and aims to overcome the defects that a joint measurement mechanism is separated from a force feedback mechanism of a conventional force feedback device, the conventional force feedback device is complex in system, bloated in structure and difficult to maintain, two-way active driving cannot be achieved, and the price is high. According to the mechanism provided by the invention, a joint measurement mechanism and a force feedback mechanism are integrated, and a unique connection mode and the ingenious layout of joint measurement points are adopted, so that the flexibility of the detected thumb can be kept to the greatest extent when the mechanism is used by an operator. Meanwhile, the motion state can be precisely detected, so that corresponding thumb joints of a controlled slave manipulator can collaboratively act with those of the operator, the force condition of the slave manipulator in a specific working environment can be fed back to the operator, and then the presence of virtual reality or teleoperation can be enhanced.

Owner:钦州市科海奇科技有限公司

Thumb force feedback detection driving device

InactiveCN104669231ASmooth movementWith two-way force feedback functionManipulatorMeasurement pointFinger joint

The invention discloses a thumb force feedback detection driving device, and relates to a device capable of detecting the motion state of fingers and feeding back forces borne by corresponding finger joints of a slave hand. The device solves the problems that according to an existing force feedback device, a joint measuring mechanism and a force feedback mechanism are separated, a system is complex in structure and bloated, maintenance is difficult, bidirectional active driving cannot be achieved, and the price is high. According to the device provided by the invention, a joint detection mechanism and a force feedback mechanism are integrated, and a unique connecting manner and an ingenious joint measuring point layout are adopted, so that when an operator uses the device, detected fingers can be kept flexible to the greatest extent, the motion state can be precisely detected, and the motion of the corresponding finger joints of the controlled slave hand and the motion of the corresponding finger joints of the operator are coordinated consistently; and the force bearing conditions of the slave hand in the specific working environment can be fed back to the operator, so that the virtual reality or the remote operation immediacy sense can be enhanced.

Owner:苏茂

Thumb palm knuckle force feedback detection driving device

The invention relates to a device for detection finger movement state of a human hand and having a function of feeding back force received by corresponding finger joints of a slave hand, in particular to a thumb palm knuckle force feedback detection driving device, and aims to solve the problem that an existing force feedback device is provided with a joint measuring mechanism and a force feedback mechanism which are separated, is complex in system, complicated in structure and difficult to maintain, cannot realize bidirectional active driving and is high in cost. The device integrates a joint detection mechanism with a force feedback mechanism, and an unique connecting mode and ingenious joint measuring point layout are adopted, so that when an operator uses the device, detected fingers can maintain flexibility to greatest extent; movement state can be detected accurately, so that corresponding finger joints of a controlled slave hand and corresponding finger joints of the operator can act coordinately, and stress condition of the slave hand in specific working environment can be fed back to the operator to enhance sense of immediacy of virtual reality or remote operation.

Owner:苏茂

Thumb portion double-knuckle driver

The invention discloses a thumb portion double-knuckle driver and relates to a device for detecting the movement state of a distal knuckle of a hand thumb and feeding back force borne by a distal knuckle of a slave hand thumb. In order to overcome the defects that a knuckle measurement mechanism and a force feedback mechanism of an existing force feedback device are separated, the system is complex, the structure is not simple, maintenance is difficult, bidirectional active driving cannot be achieved and the price is high, a knuckle detection mechanism and a force feedback mechanism are integrated into a whole, the unique connection mode and the ingenious knuckle measurement point layout are adopted, when an operator uses the device, a detected finger can keep flexible to the greatest extent, the movement state can be detected accurately, the knuckle of a controlled slave hand can keep collaborative and consistent action with the corresponding knuckle of the operator, the borne force condition of the slave hand in the specific working environment can be fed back to the operator, and the virtual reality or teleoperation immediacy sense is enhanced.

Owner:苏茂

Human hand distal knuckle detecting and driving mechanism

The human hand far knuckle detection drive mechanism relates to a device that detects the movement state of the human hand far knuckle and has the force feedback from the hand far knuckle joint. The present invention aims to solve the shortcomings of the existing force feedback device, such as the separation of the joint measurement mechanism and the force feedback mechanism, the complex structure of the system, the difficulty in maintenance, the inability to realize two-way active driving, and the high price. The joint detection mechanism and the force feedback mechanism are integrated into the It adopts a unique connection method and ingenious layout of joint measurement points, so that when the operator uses the device, the finger to be detected can maintain maximum flexibility, and the motion state can be accurately detected, so that the controlled slave The far knuckle joints of the hand can act in unison with the corresponding finger far knuckle joints of the operator, and can feed back the force of the hand in a specific working environment to the operator, so as to enhance the sense of presence in virtual reality or teleoperation .

Owner:钦州市科海奇科技有限公司

Human hand little finger joint detecting and driving mechanism

The invention discloses a human hand little finger joint detecting and driving mechanism, and relates to a device used for detecting the motion state of a human hand little finger and feeding back the force applied to little finger joints of a slave hand. The human hand little finger joint detecting and driving mechanism aims at overcoming the defects that an existing force feedback device joint measuring mechanism is separated from a force feedback mechanism, a system is complicated, the structure is bloated, maintenance is hard, bidirectional active driving cannot be achieved, and the cost is high. A joint detecting mechanism is integrated with a force feedback mechanism; further, a unique connection mode and an ingenious joint measuring point layout are adopted; an operator can keep the most flexibility of detected fingers when the mechanism is used, the motion state can be accurately detected, and the little finger joints of the controlled slave hand and corresponding little finger joints of the operator can be consistent in action; and furthermore the stress situation of the slave hand in a specific working environment can be fed back to the operator, so that the sense of immediacy for virtual reality or remote operation is enhanced.

Owner:钦州市科海奇科技有限公司

Index finger distal knuckle driver

The invention discloses an index finger distal knuckle driver and relates to a device for detecting the movement state of a distal knuckle of a hand and feeding back force borne by a distal knuckle ofa slave hand. In order to overcome the defects that a knuckle measurement mechanism and a force feedback mechanism of an existing force feedback device are separated, the system is complex, the structure is not simple, maintenance is difficult, bidirectional active driving cannot be achieved and the price is high, a knuckle detection mechanism and a force feedback mechanism are integrated into awhole, the unique connection mode and the ingenious knuckle measurement point layout are adopted, when an operator uses the device, a detected finger can keep flexible to the greatest extent, the movement state can be detected accurately, the distal knuckle of the controlled slave hand can keep collaborative and consistent action with the distal knuckle of the corresponding finger of the operator,the borne force condition of the slave hand in the specific working environment can be fed back to the operator, and the virtual reality or teleoperation immediacy sense is enhanced.

Owner:苏茂

Thumb carpometacarpal joint force feedback device

InactiveCN105881562ASmooth movementWith two-way force feedback functionManipulatorStress conditionsMeasurement point

The invention discloses a thumb carpometacarpal joint force feedback device and relates to a device for detecting human hand finger movement states and feeding back force exerting on corresponding finger joints of a slave hand. In order to solve the problems that a joint detecting mechanism and a force feedback mechanism of an existing force feedback device are separated, the system is complex, the structure is cumbersome, maintenance is difficult, two-directional active drive cannot be achieved and the price is high, the joint detecting mechanism and the force feedback mechanism are integrated into a whole, and a unique connection way and an ingenious joint measurement point layout are adopted, so that when an operator uses the device, the detected finger can keep flexible to the greatest degree, all movement states can be precisely detected, the corresponding finger joints of the controlled slave hand and corresponding finger joints of the operator can act synergistically and consistently, the stress condition of the slave hand in the specific working environment can be fed back to the operator, and therefore virtual reality or telepresence of remote operation is enhanced.

Owner:苏茂

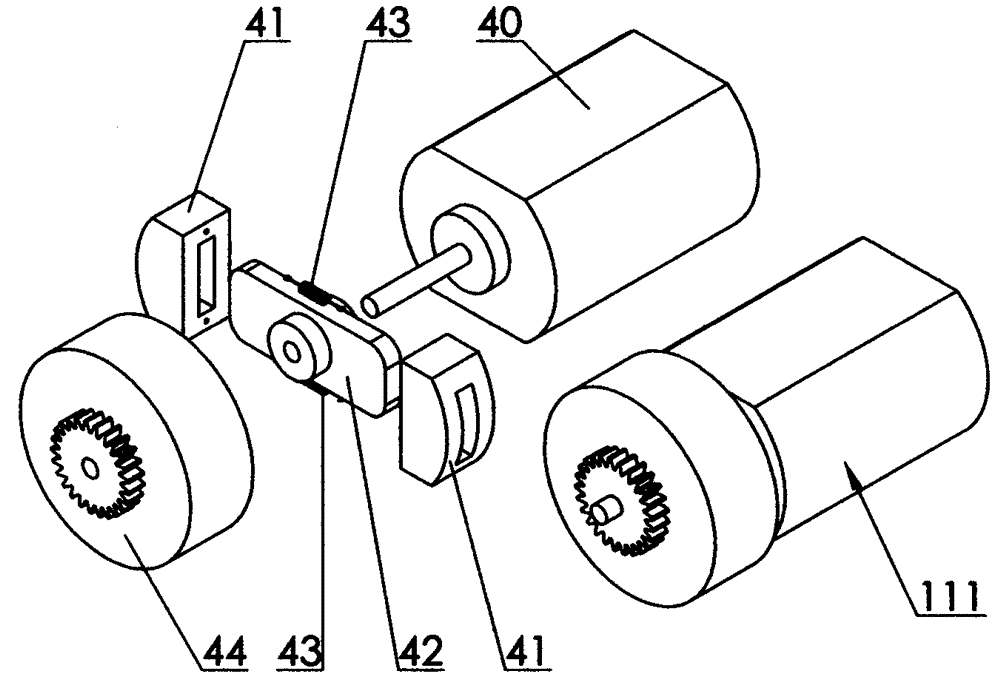

Device for bidirectional knuckle detection driving

InactiveCN104635912ASmooth movementReduce resistanceInput/output for user-computer interactionGraph readingKnuckleEngineering

The invention relates to a device which is used for detecting the motion state of the fingers of a human hand and has the function of feeding back force borne by corresponding finger knuckles of the human hand, in particular to a device for bidirectional knuckle detection driving. The device aims at solving the problems that a knuckle measuring mechanism and a force feedback mechanism of an existing force feedback device are separated, the system is complex, the structure is overstaffed, maintenance is difficult, bidirectional active driving cannot be achieved, and the price is high. A knuckle detecting mechanism and a force feedback mechanism are integrated, and are arranged through a unique connecting mode and ingenious knuckle measuring points, when an operator uses the device, the detected finger can be kept flexible to the maximum degree, the motion state can be precisely detected, the corresponding finger knuckle of the controlled human hand can move consistently with the corresponding finger knuckles of the operator in a cooperating mode, and the stressing condition of the human hand in the specific work environment can be fed back to the operator so that the sense of immediacy of virtual reality or teleoperation can be enhanced.

Owner:苏茂

Far knuckle unit of data glove

The invention discloses a far knuckle unit of a data glove, and relates to a device detecting motion states of human hand fingers and feeding back forces applied on corresponding finger joints of a slave hand. In order to overcome the shortcomings that an existing knuckle detection mechanism of a force feedback device is separated from a force feedback mechanism, system is complicated, structure is bulky, maintenance is difficult, bi-directional active driving cannot be achieved and cost is high, the knuckle detection mechanism is integrated with the force feedback mechanism, a unique connection method and a smart knuckle detecting point layout are adopted, the maximum flexibility of fingers to be detected can be maintained when an operator uses the far knuckle unit of the data glove, and the motion states can be accurately detected, so that the corresponding finger joints of the slave hand under control move consistently with the corresponding finger joints of the operator, and force bearing situation of the slave hand in a specific work environment can be fed back to the operator to enhance the sense of immediacy of virtual reality or teleoperation.

Owner:苏茂

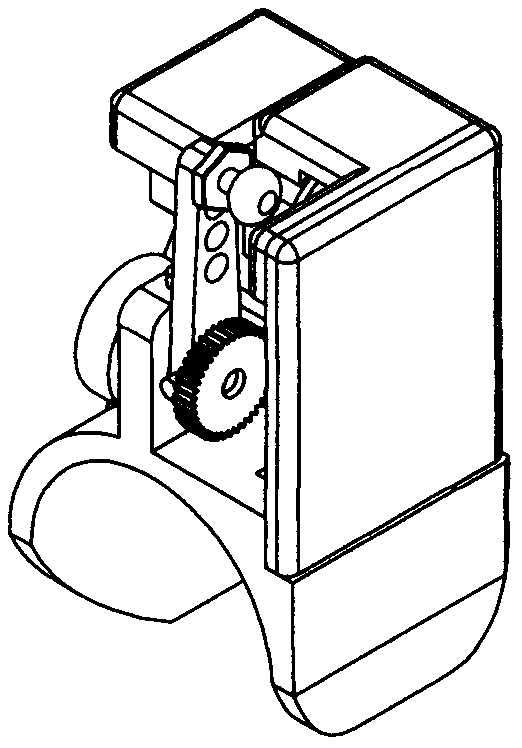

Thumb two-head joint detecting device

InactiveCN105881561ARealize Force Feedback ControlSmooth movementManipulatorStress conditionsMeasurement point

The invention discloses a thumb two-head joint detecting device and relates to a device for detecting human hand finger movement states and feeding back force exerting on corresponding finger joints of a slave hand. In order to solve the problems that a joint measuring mechanism and a force feedback mechanism of an existing force feedback device are separated, the system is complex, the structure is cumbersome, maintenance is difficult, two-directional active drive cannot be achieved and the price is high, the joint measuring mechanism and the force feedback mechanism are integrated into a whole, and a unique connection way and an ingenious joint measurement point layout are adopted, so that when an operator uses the device, the detected finger can keep flexible to the greatest degree, all movement states can be precisely detected, the corresponding finger joints of the controlled slave hand and corresponding finger joints of the operator can act synergistically and consistently, the stress condition of the slave hand in the specific working environment can be fed back to the operator, and therefore virtual reality or telepresence of remote operation is enhanced.

Owner:苏茂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com