Thumb force feedback detection driving device

A driving device and force feedback technology, applied in the field of data gloves, can solve the problems of expensive force feedback data gloves, difficult maintenance, and complex systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

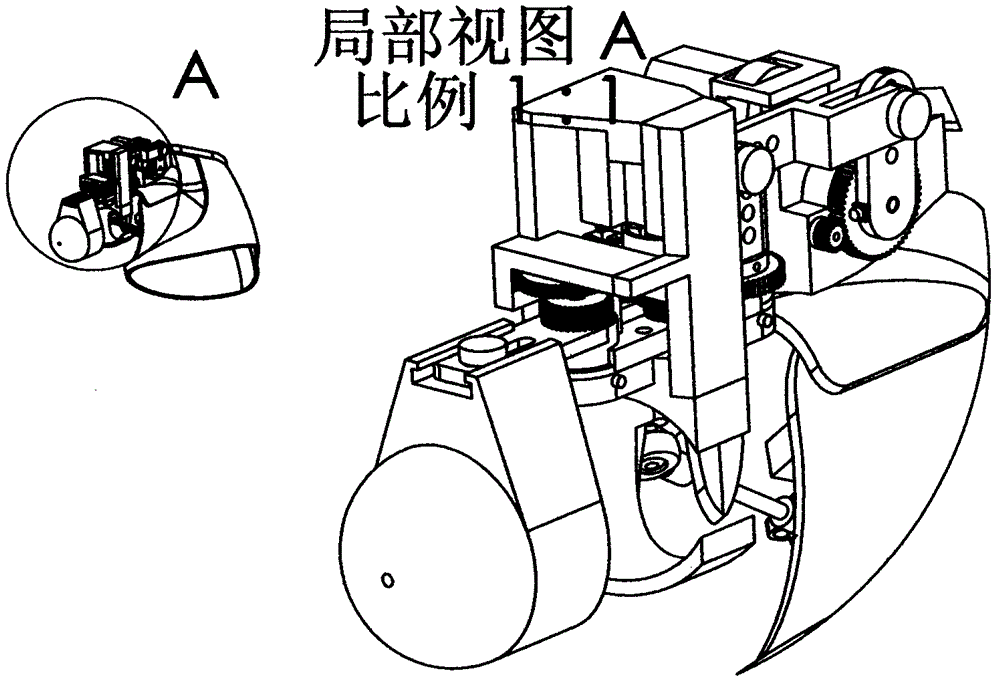

[0015] Specific implementation mode one: Figure 5 As shown, the thumb force feedback detection driving device includes a driving part 111, and the driving part 111 includes a micro motor 40 and a clutch, and the clutch is composed of a clutch friction plate 41, a friction plate slide bar 42, a return tension spring 43, The clutch cover 44 is composed of the friction plate sliding rod 42 and the shaft of the micro motor 40, and the two clutch friction plates 41 are inserted into the two ends of the friction plate sliding bar 42 respectively, and a return tension spring is connected between the two clutch friction plates 41 43. The clutch cover 44 is inserted into the shaft of the micro motor 40, and the clutch cover 44 is in sliding contact with the shaft of the micro motor 40, and the clutch cover 44 is provided with transmission gears. Action implementation process: when the rotation speed of the micro motor 40 is higher than a certain value, the two clutch friction plates 4...

specific Embodiment approach 2

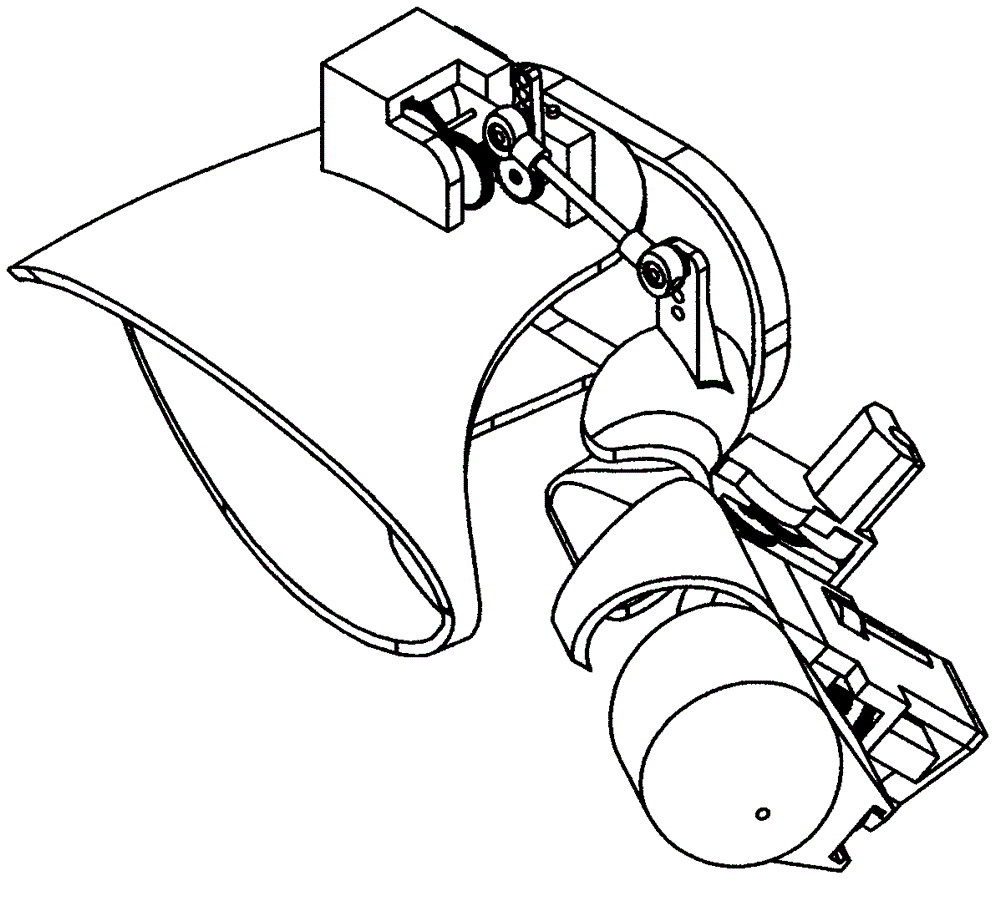

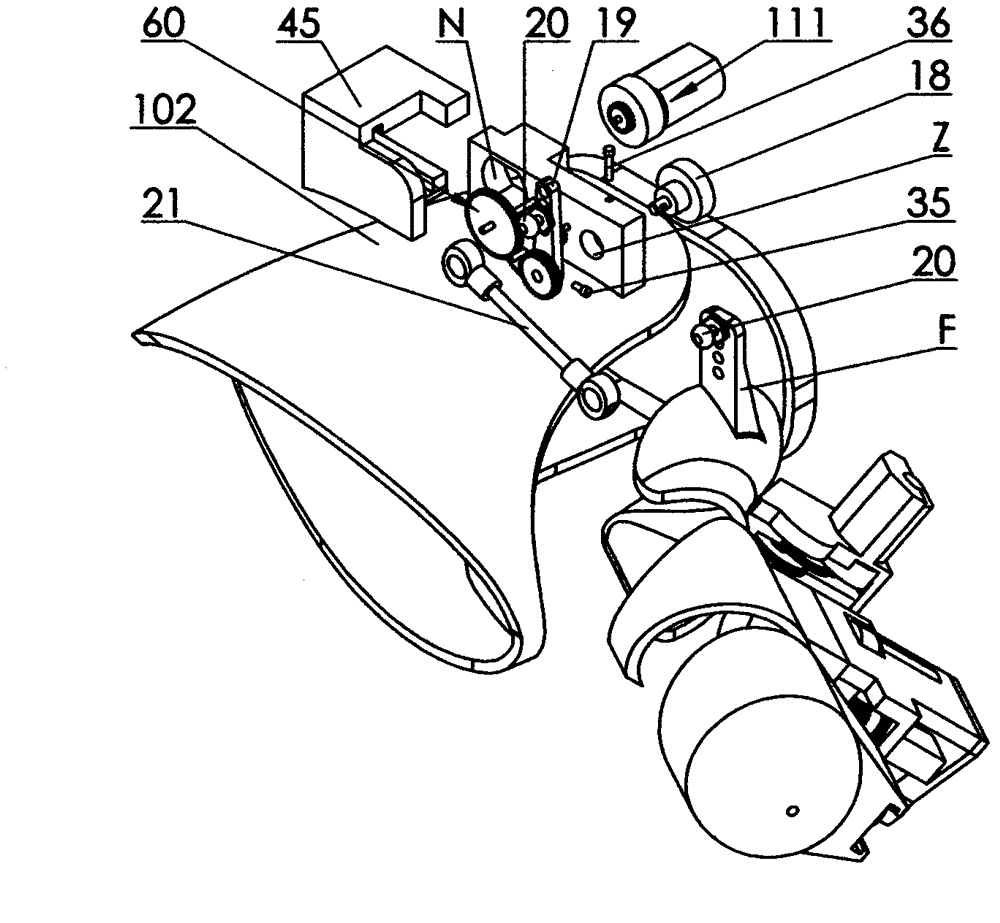

[0016] Specific implementation mode two: as figure 1 , figure 2 and Figure 5 As shown, the thumb force feedback detection driving device includes a palm base 102, a thumb far knuckle base 3, a thumb proximal knuckle base 4, a thumb metacarpophalangeal base 5, a driving part 111, an angle sensor 18, a rocker Arm 19, ball head 20, connecting rod 21 and reduction gear set 60. The thumb metacarpophalangine base 5 is fixed on the thumb metacarpophalangine of the human hand, the thumb metacarpophalangine base 5 adopts a "C" shape to surround the thumb metacarpophalangine, and the opening faces the side where the thumb is connected to the palm surface , the thumb metacarpophalangine base 5 is located at the back of the thumb metacarpophalangine with a rocker F, and the rocker F of the thumb metacarpophalangine base 5 is connected with the rocker 19 through the ball head 20 and the ball head buckle The spherical hinge that rod 21 cooperates is connected, and the axle of described...

specific Embodiment approach 3

[0017] Specific implementation mode three: as figure 1 , image 3 , Figure 4 and Figure 5As shown, the thumb proximal knuckle base 4 is fixed on the thumb proximal knuckle part of the human hand, the thumb proximal knuckle base 4 half surrounds the thumb proximal knuckle, and the cross section surrounding the junction is "C" shape, with an opening Facing the front side of the palm, there are two hole seats H and K at the position of the base on the outer side of the proximal knuckle of the thumb, and the positions of the two hole seats correspond to the metacarpophalangeal joint (MP) and interphalangeal joint of the thumb respectively (DIP). Thumb proximal knuckle base 4 and thumb metacarpophalangeal base 5 are hinged by rocking arm 28, connecting rod 26, rocking arm 27, and the bottom of said rocking arm 28 (embedded bearing 23) and the shaft of angle sensor 18 are passed through screw 36, the angle sensor 18 is fixed in the hole seat H of the thumb proximal knuckle bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com