Wall element and its manufacturing method

A wall and on-site manufacturing technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of production, transportation and installation plus difficulties, and achieve the effect of simple operation, great flexibility and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

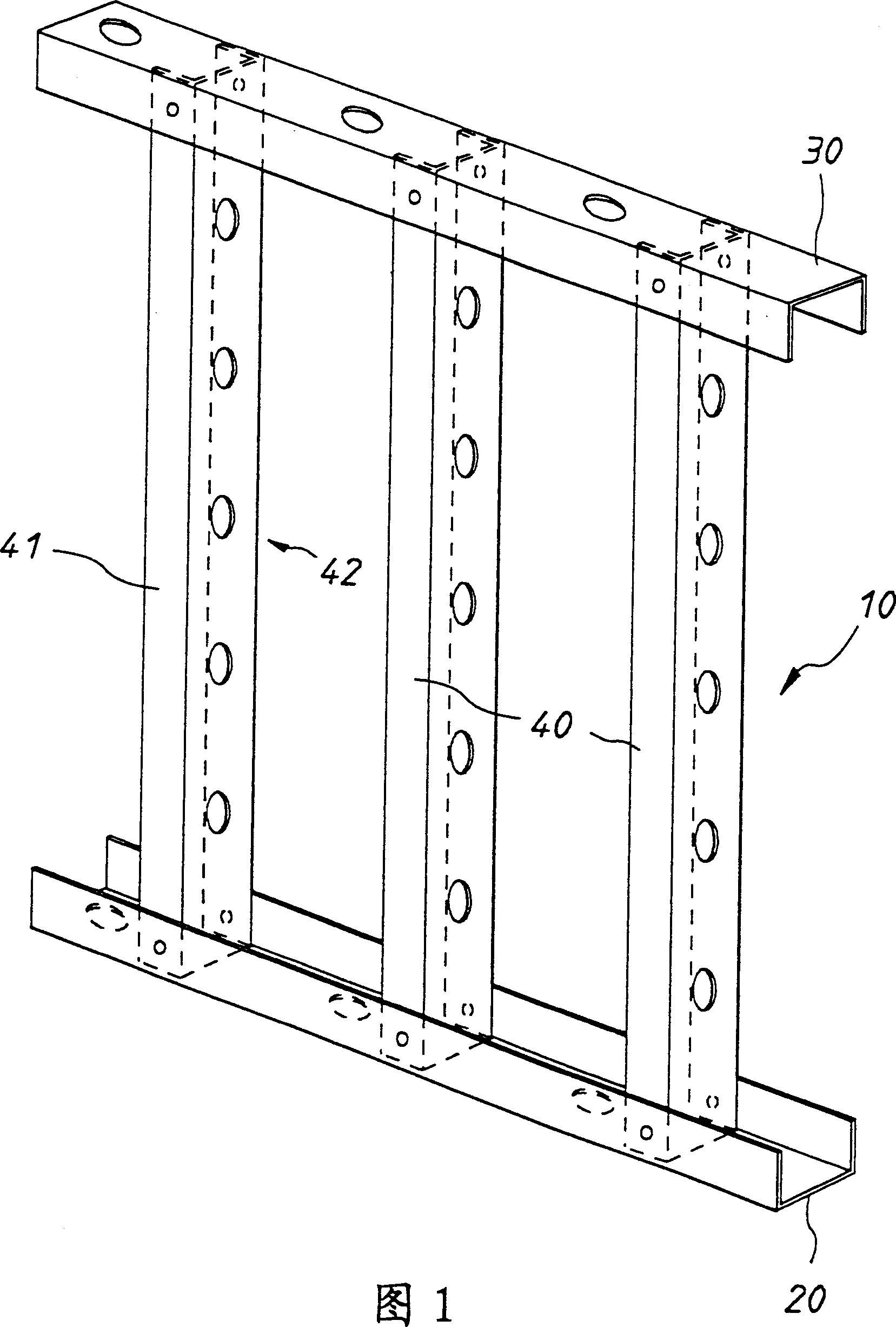

[0033] Referring first to Figure 1, the first step in the method of the present invention is to provide a frame for the desired wall, floor or ceiling. The frame 10 is preferably constructed of a common thin-walled load-bearing steel framework. In this example, the frame 10 includes a lower rail 20 , an upper rail 30 coupled by substantially vertically oriented, spaced apart studs 40 .

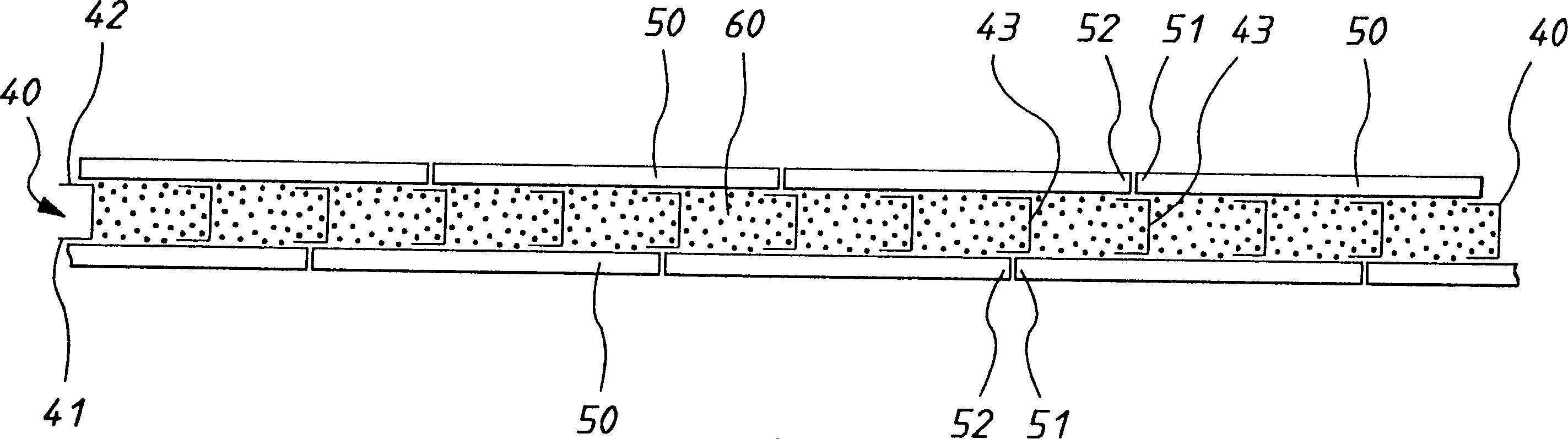

[0034] Preferably, the minimum thickness of the material of each frame member is 0.55mm. In the illustrated embodiment, each frame member comprises an elongated "C" section channel member. Other sections, such as "Z" and "I" shapes, are also applicable. Preferably, each frame member includes a pair of spaced apart parallel flanges 41,42. These flanges are not only used to help secure the FRC panels, as described below, they will also reinforce the wall, floor or ceiling.

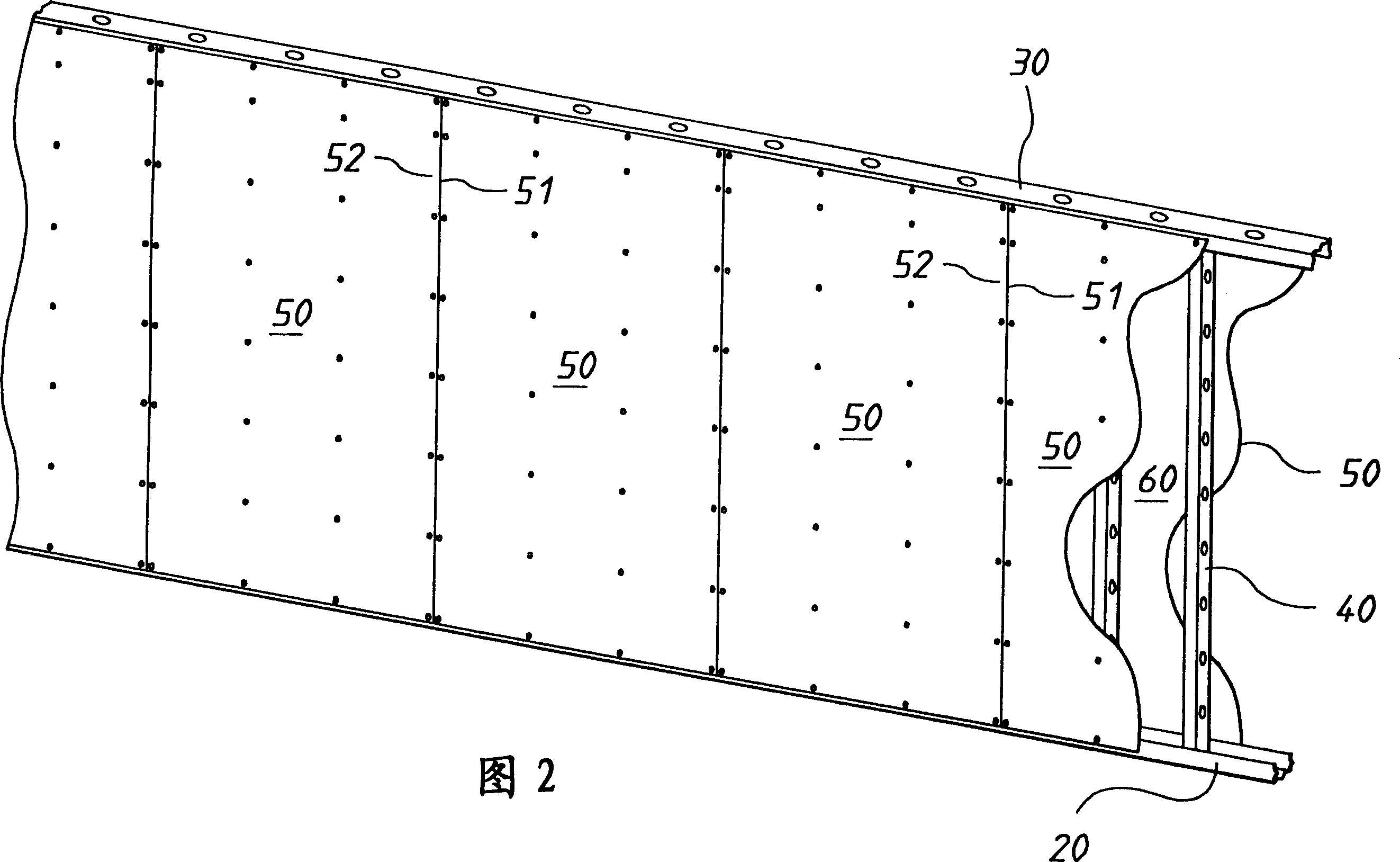

[0035] As shown in Figure 2, the next step in the method of the present invention is to fix a number of fiber cement s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com