Patents

Literature

210results about How to "High separation purity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

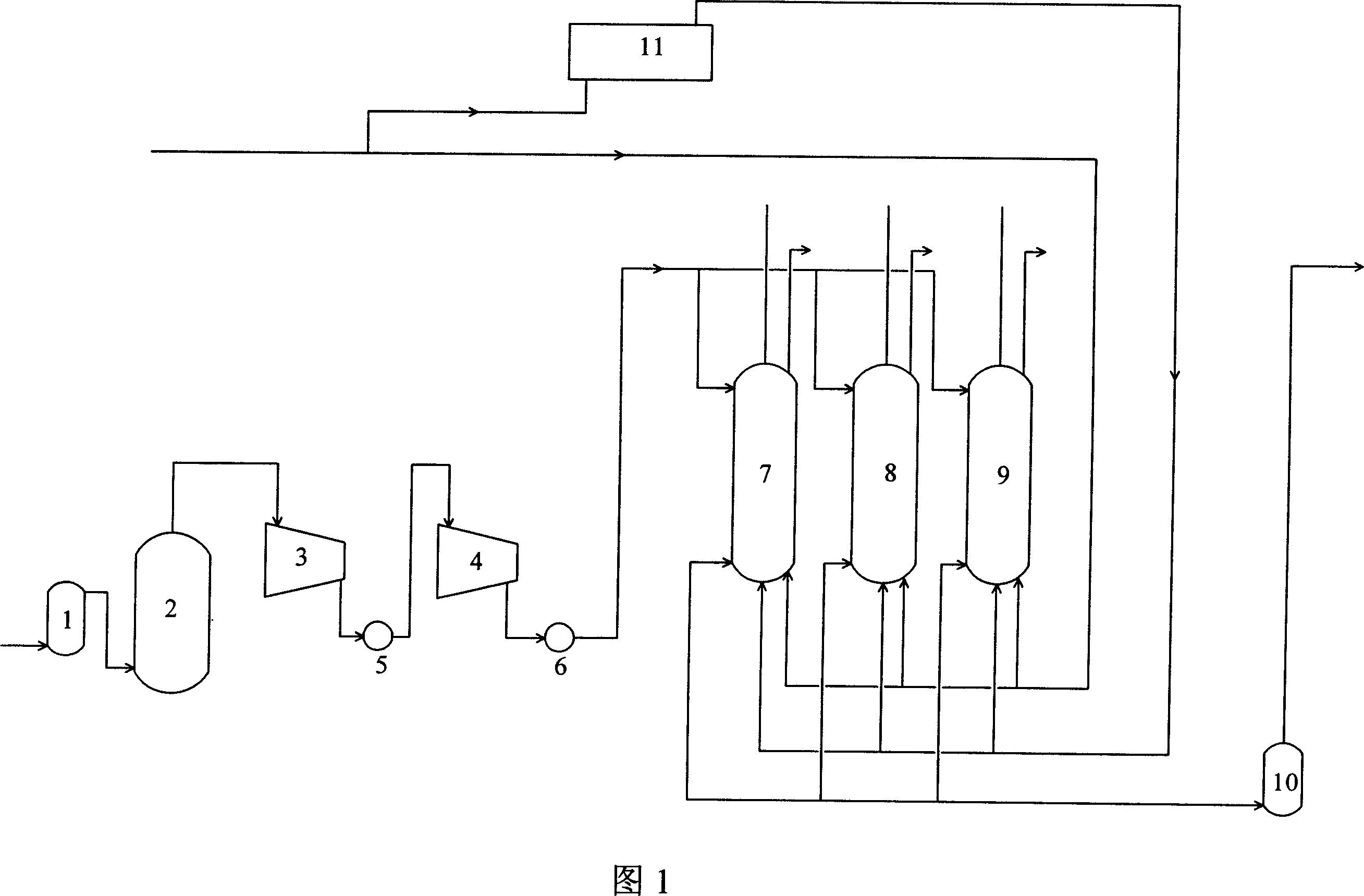

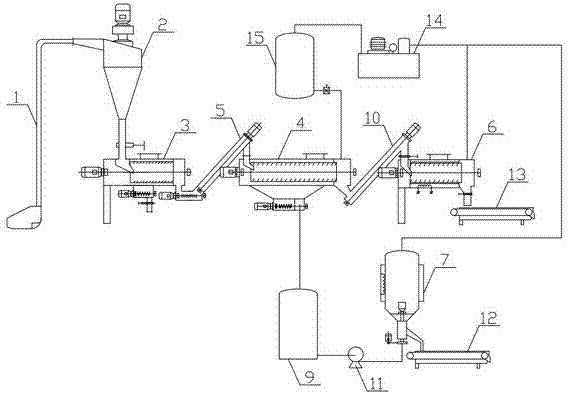

Process and equipment for liquefying air-containing coal-bed gas

InactiveCN1952569AEfficient use ofAvoid pollutionSolidificationLiquefactionSeparation technologyPhysical chemistry

The invention discloses a liquefaction technology for coal-bed gas with air, comprising compressing and purifying technology, refrigeration technology and liquefaction and separation technology. Double-grade rectifying method in low temperature is applied in the liquefaction and separation technology. Liquefaction and separation are carried out in low temperature and it is provided with high separation purity and good safety. The purity of liquefied natural gas can achieve more than 99% and the content of firedamp drained in air is only 1% or so. The resource is recycled efficiently. The invention also provides liquefaction equipment for the coal-bed gas with air.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

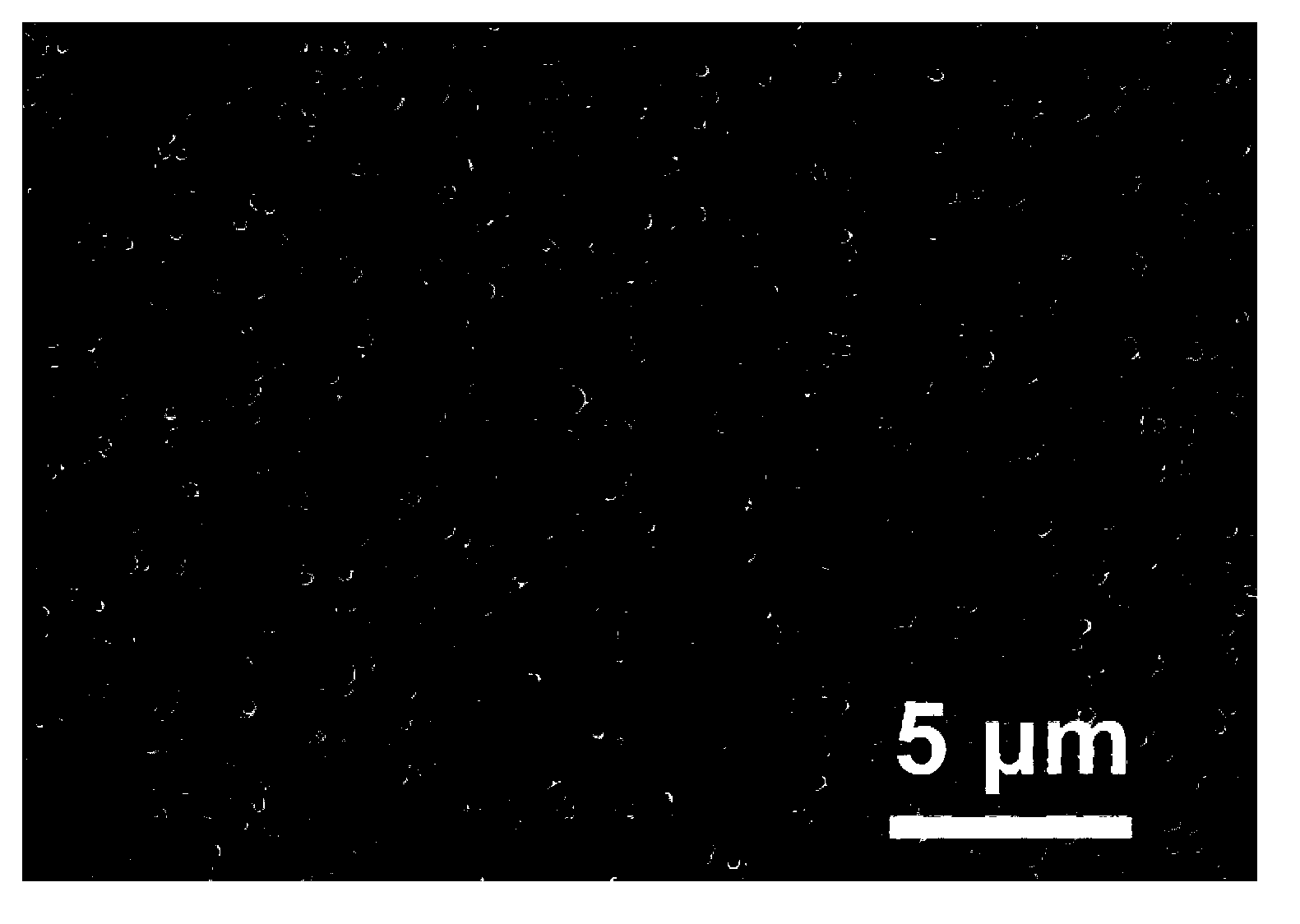

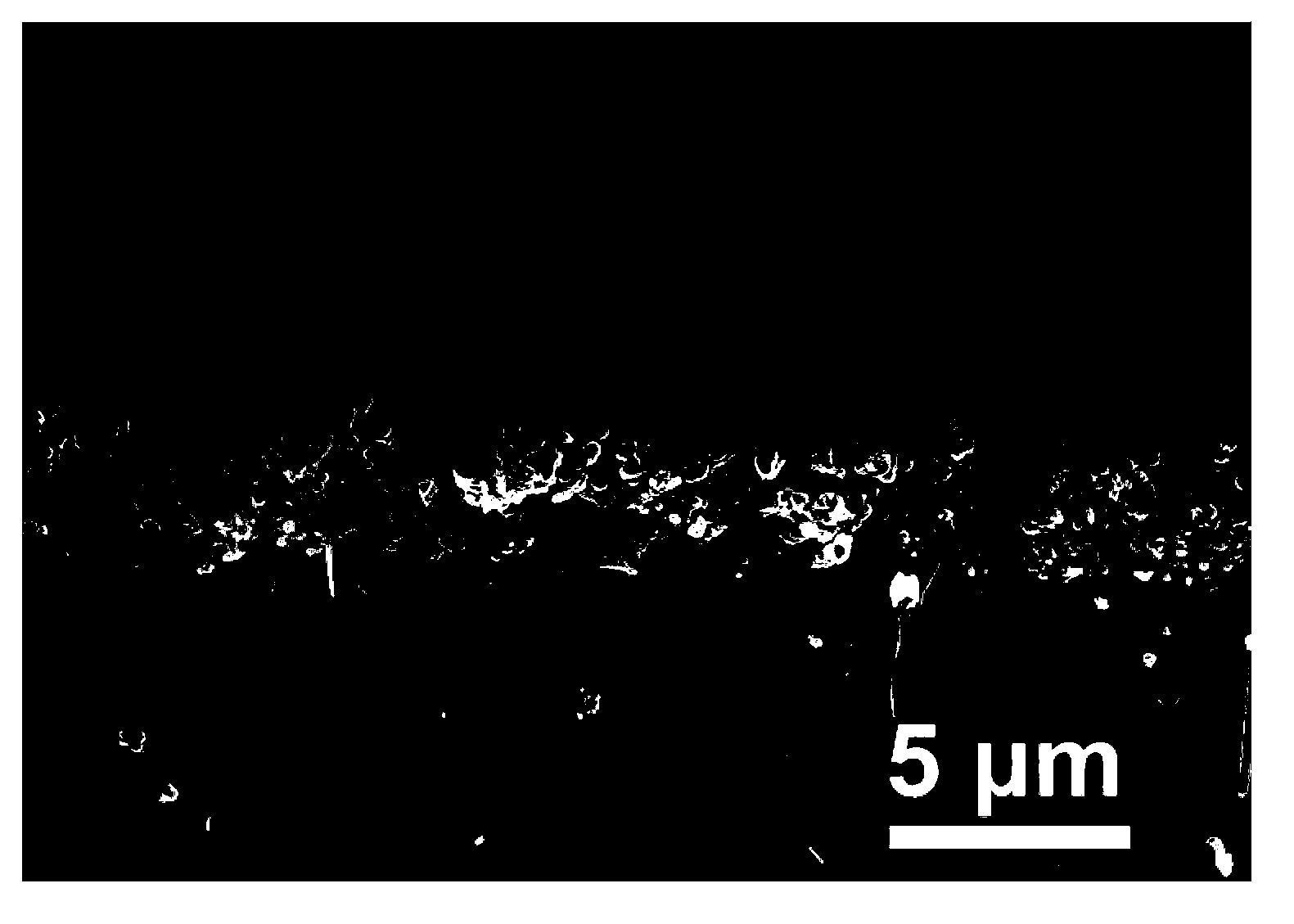

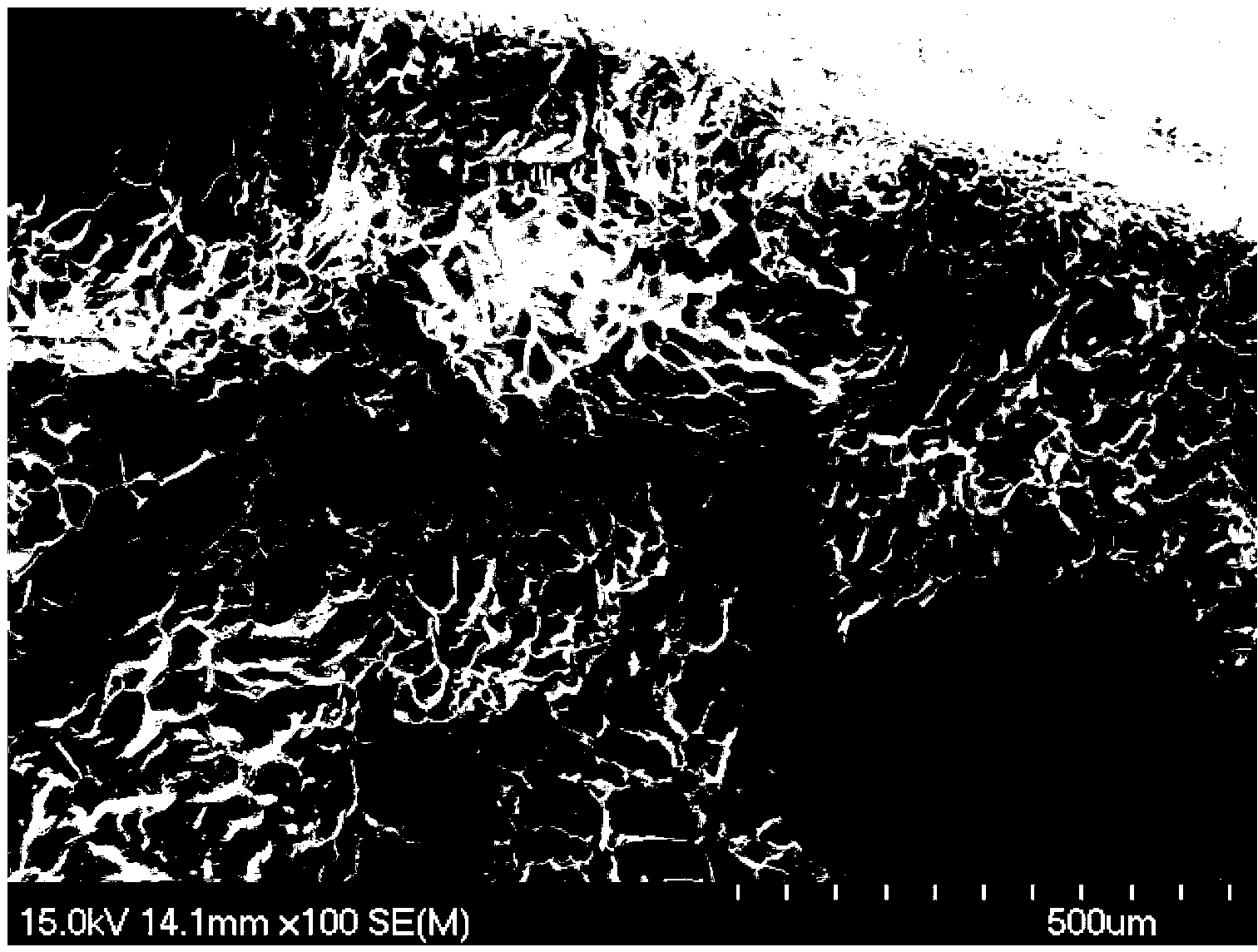

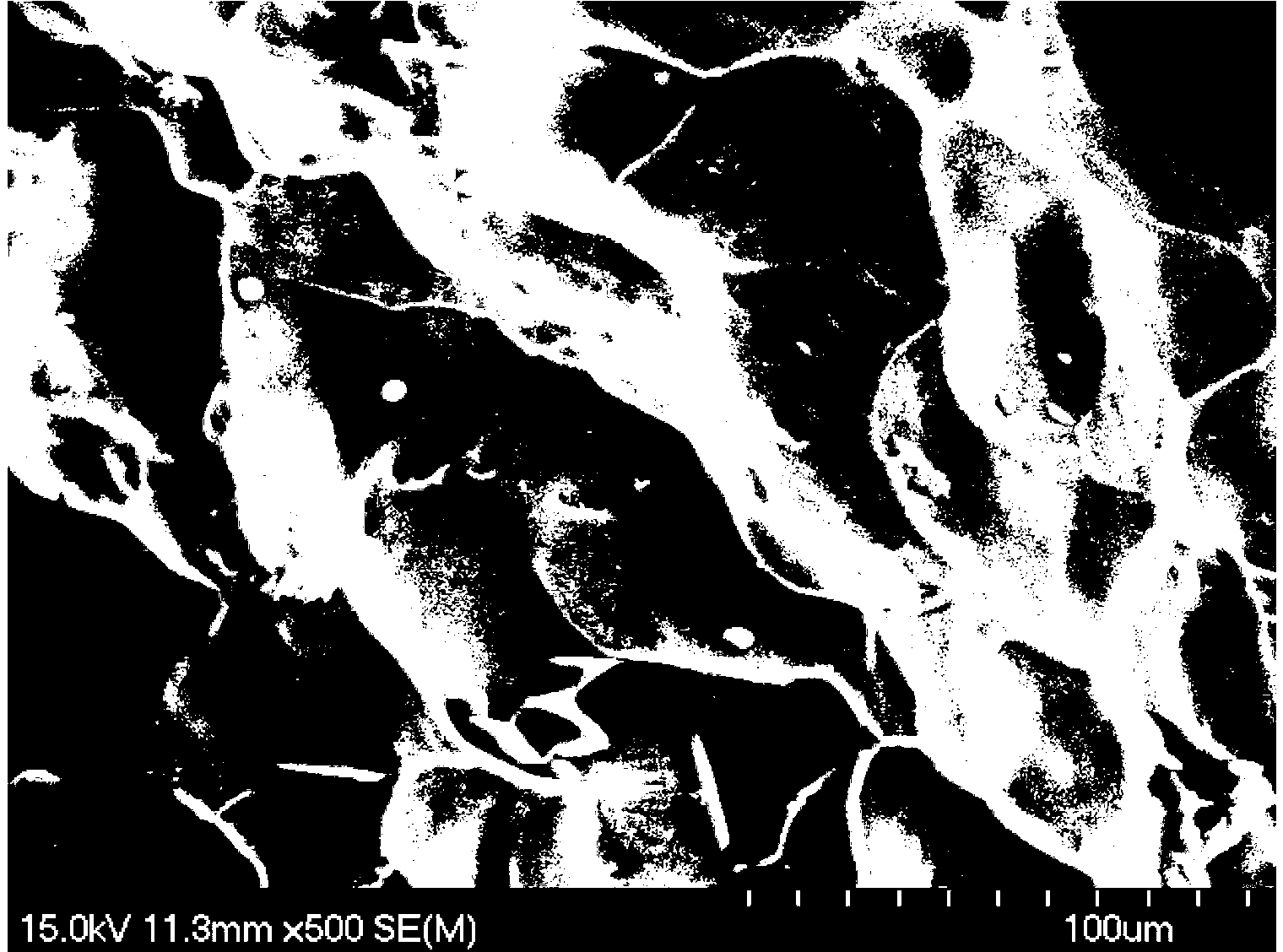

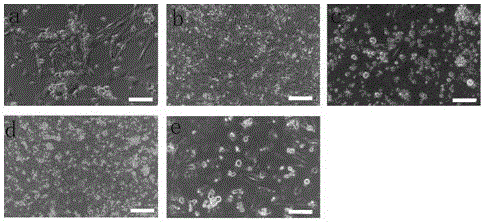

Biochip for enriching and detecting circulating tumor cells and preparation method thereof

InactiveCN103725589AEfficient enrichmentConducive to correct detectionBioreactor/fermenter combinationsBiological substance pretreatmentsSilica particleMicrometer

The invention relates to a biochip for enriching and detecting circulating tumor cells and preparation method thereof. The invention comprises the following steps: placing a clean substrate on flame, obtaining a cigarette ash layer composed of nano cigarette ash particles on surface of the substrate by deposition, using the nano cigarette ash particle as template, and deposing a layer of silica housing layer on external surface of nano cigarette ash particles by chemical vapor deposition method; removing nano cigarette ash particles in the silica housing layer by high temperature calcining, and obtaining a silicon dioxide layer composed of nano silica particles with micrometer thickness; finally, modifying an anti-EpCam antibody which can specifically identify tumor cells on the surface of the silicon dioxide layer, thereby obtaining a biochip for enriching and detecting circulating tumor cells. The biochip can enrich circulating tumor cells with high efficiency and high sensitivity, and the product has high transparency under water and can be used for detecting real time captured circulating tumor cells.

Owner:INST OF CHEM CHINESE ACAD OF SCI

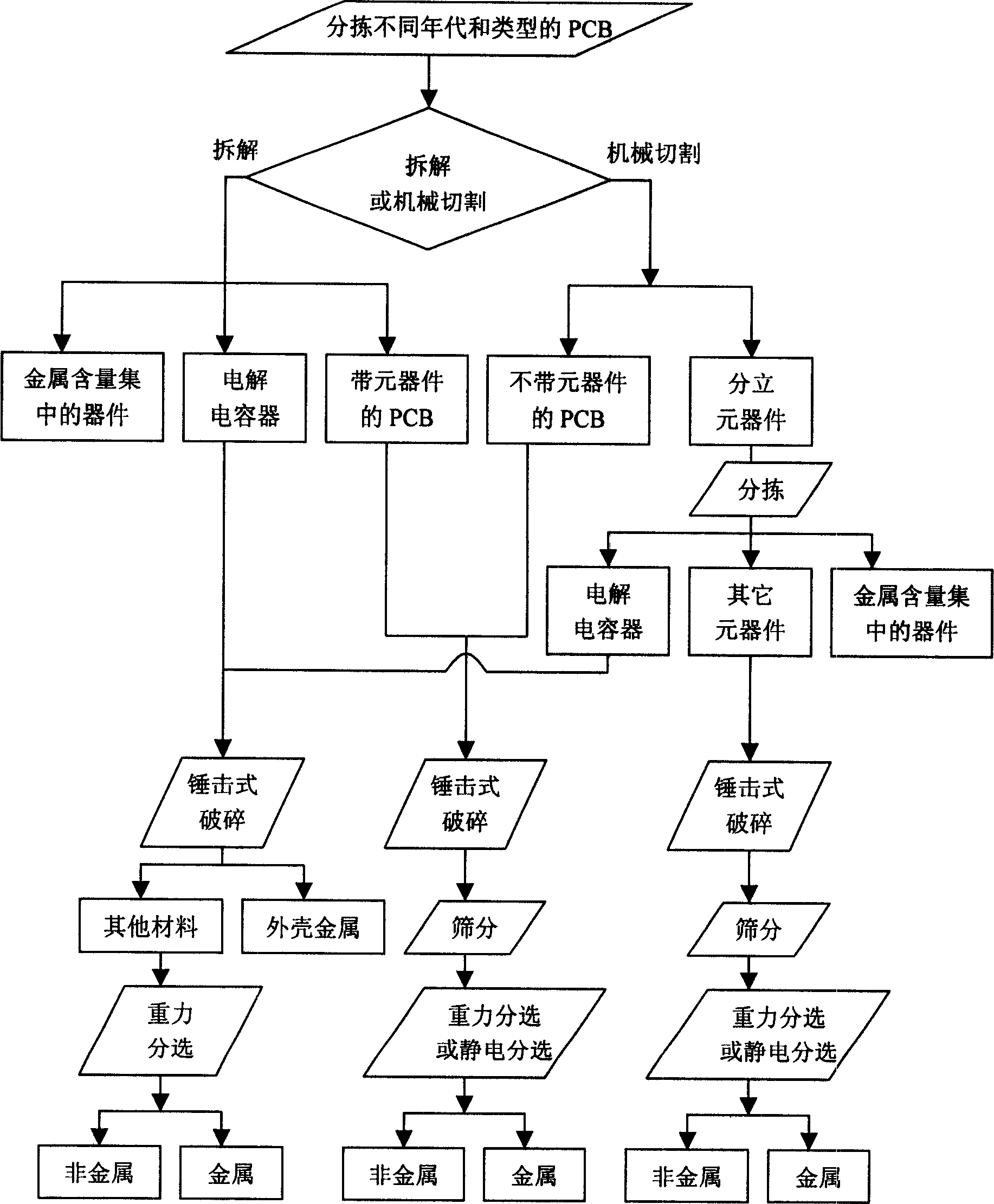

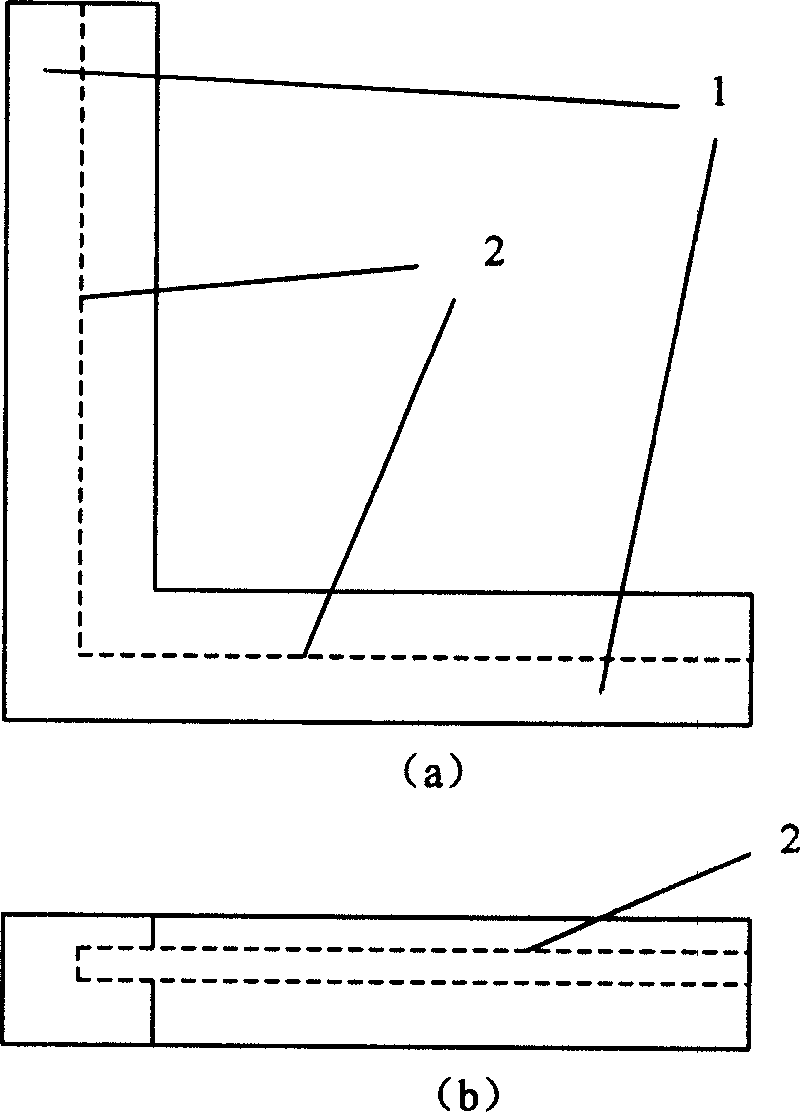

Recovering and treating process for waste printed circuit board and special clamp

InactiveCN1586746AConducive to secondary development and utilizationEasy to purifySolid waste disposalPositioning apparatusElectrolysisResource recovery

The present invention belongs to the field of electric appliance resource recovering and reusing technology. The technological process of recovering and treating waste printed circuit board includes the following steps: sorting printed circuit boards; separating electrolytic capacitor and other elements and devices mechanically from the printed circuit board; crushing printed circuit board, sieving and separating metal and non-metal gravitationally or electrostatically; crushing electrolytic capacitor, separating the shell metal, separating metal and non-metal of electrolytic capacitor gravitationally, crushing other elements and devices, separating metal and non-metal of other elements and devices gravitationally. The special clamp for separating electrolytic capacitor and other elements and devices mechanically from the printed circuit board is an L-shaped one with continuous single-end notches in two arms.

Owner:BEIJING UNIV OF TECH

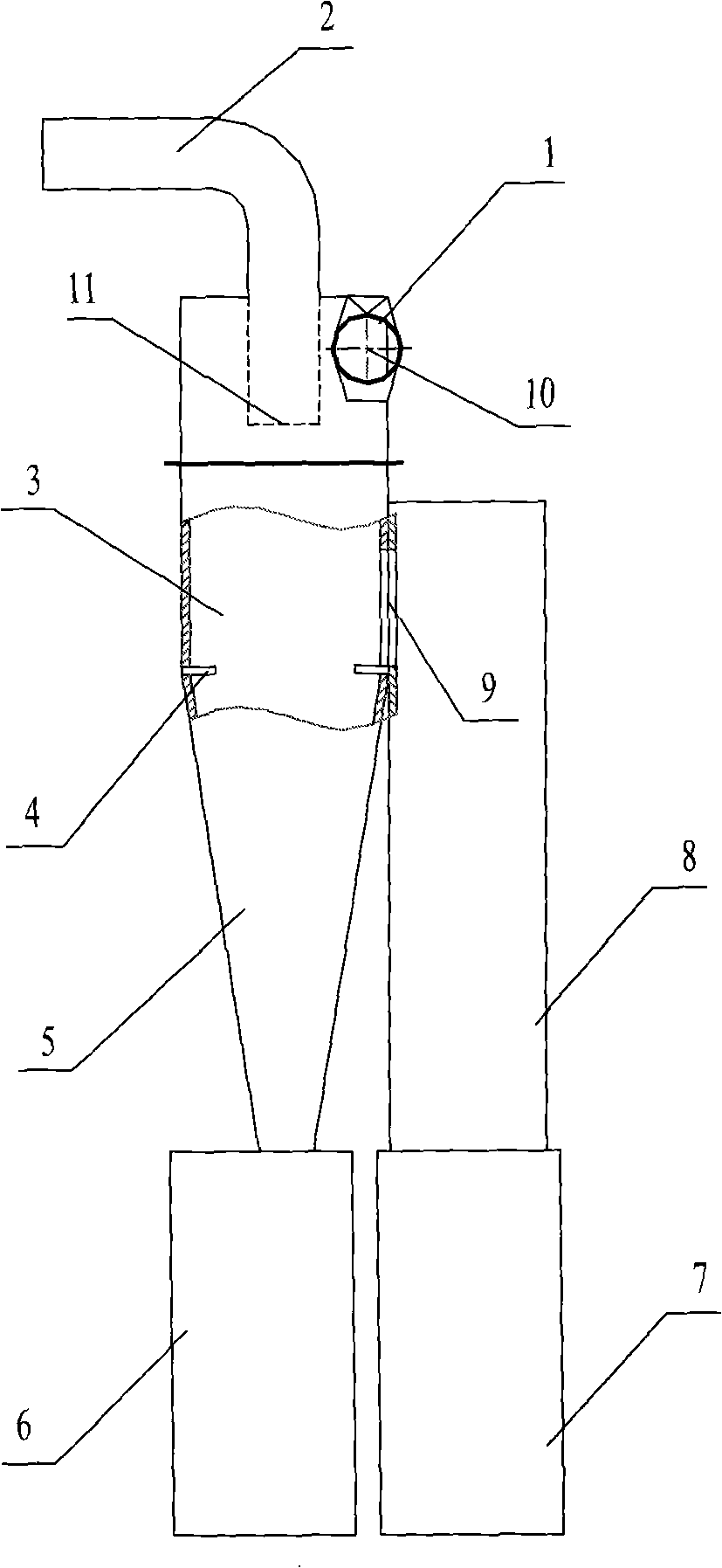

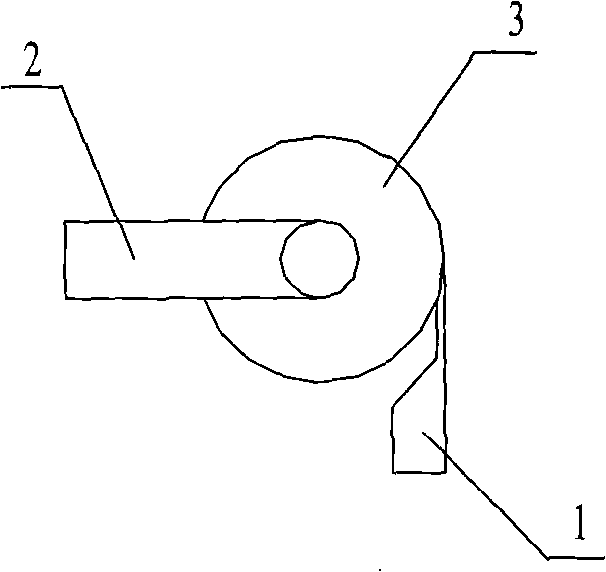

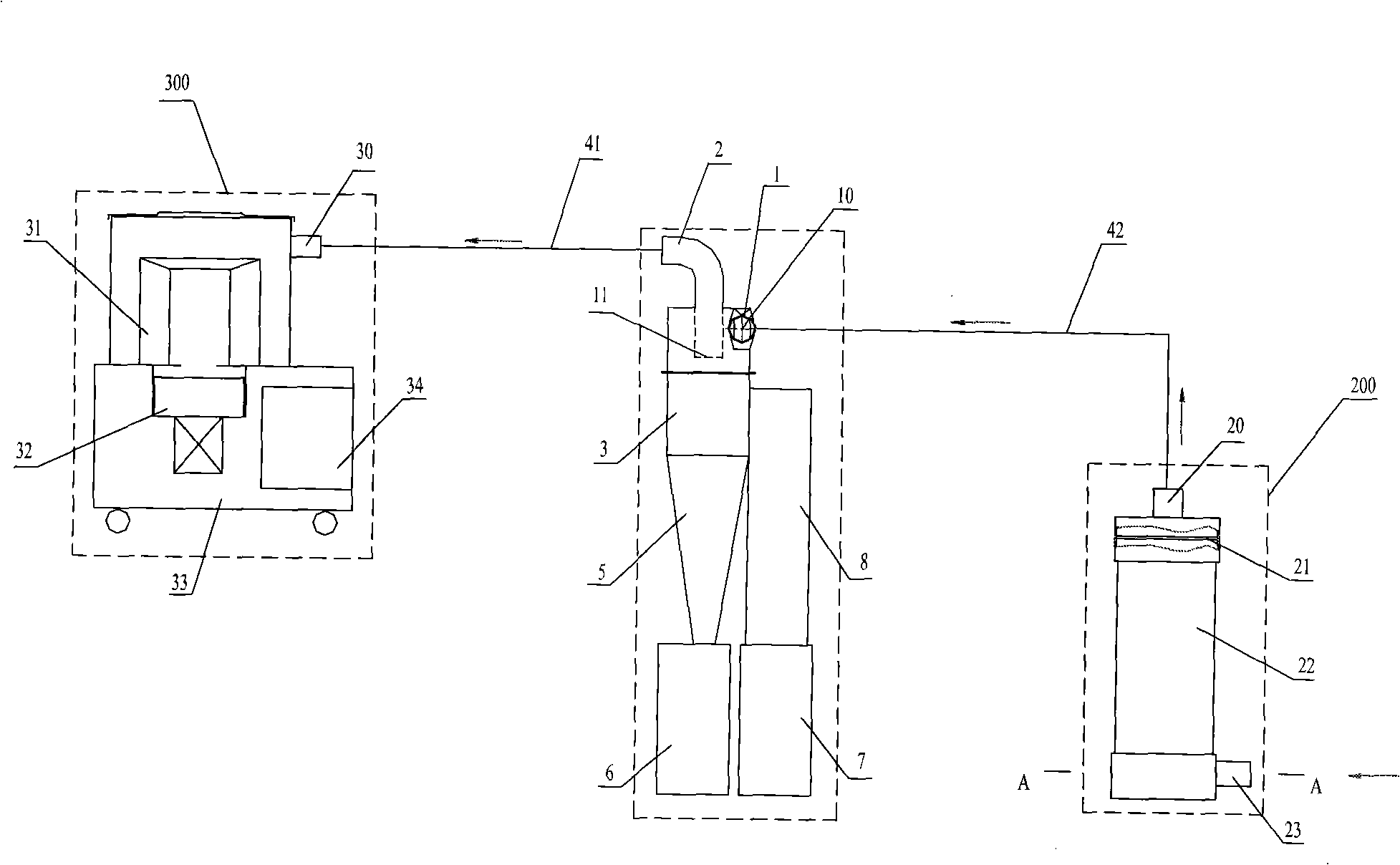

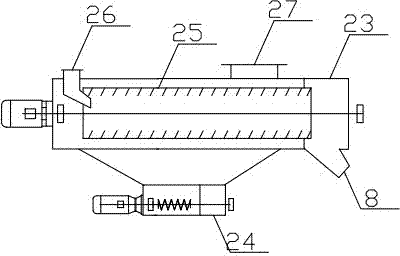

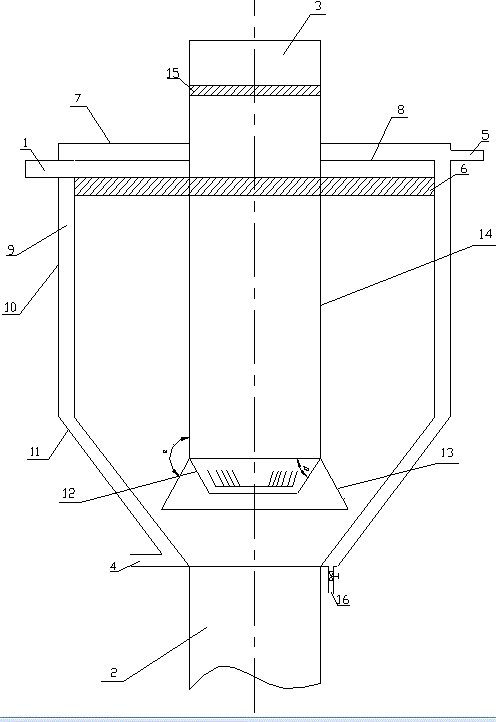

Cyclone separator and spore separation device therewith

InactiveCN101524672ASafe and Low Consumption SystemComplete separationBioreactor/fermenter combinationsBiological substance pretreatmentsAir volumePhencyclone

The invention discloses a cyclone separator, comprising a primary separator and a secondary separator (8) which are communicated by a channel (9), the bottom of the primary separator is connected with a primary collection tube (6), the bottom of the secondary separator is connected with a secondary collection tube (7); the top surface of the primary separator is provided with an air outlet channel (2), the side wall of the primary separator is tangentially provided with an air inlet channel (1), the air outlet channel (2) and the air inlet channel (1) are both communicated with the inner cavity of the primary separator; an air volume regulator (10) is arranged inside the air inlet channel (1), and the channel (9) is positioned below the air inlet channel (1). The invention also discloses a spore separation device with the cyclone separator, wherein a blower component (300) is connected with the air outlet channel (2) in a sealing way, and a swirling flow feeder component (200) is connected with the air inlet channel (1) in a sealing way. The spore separation device of the invention can efficiently separate solid fermentation fungal spore.

Owner:ZHEJIANG UNIV

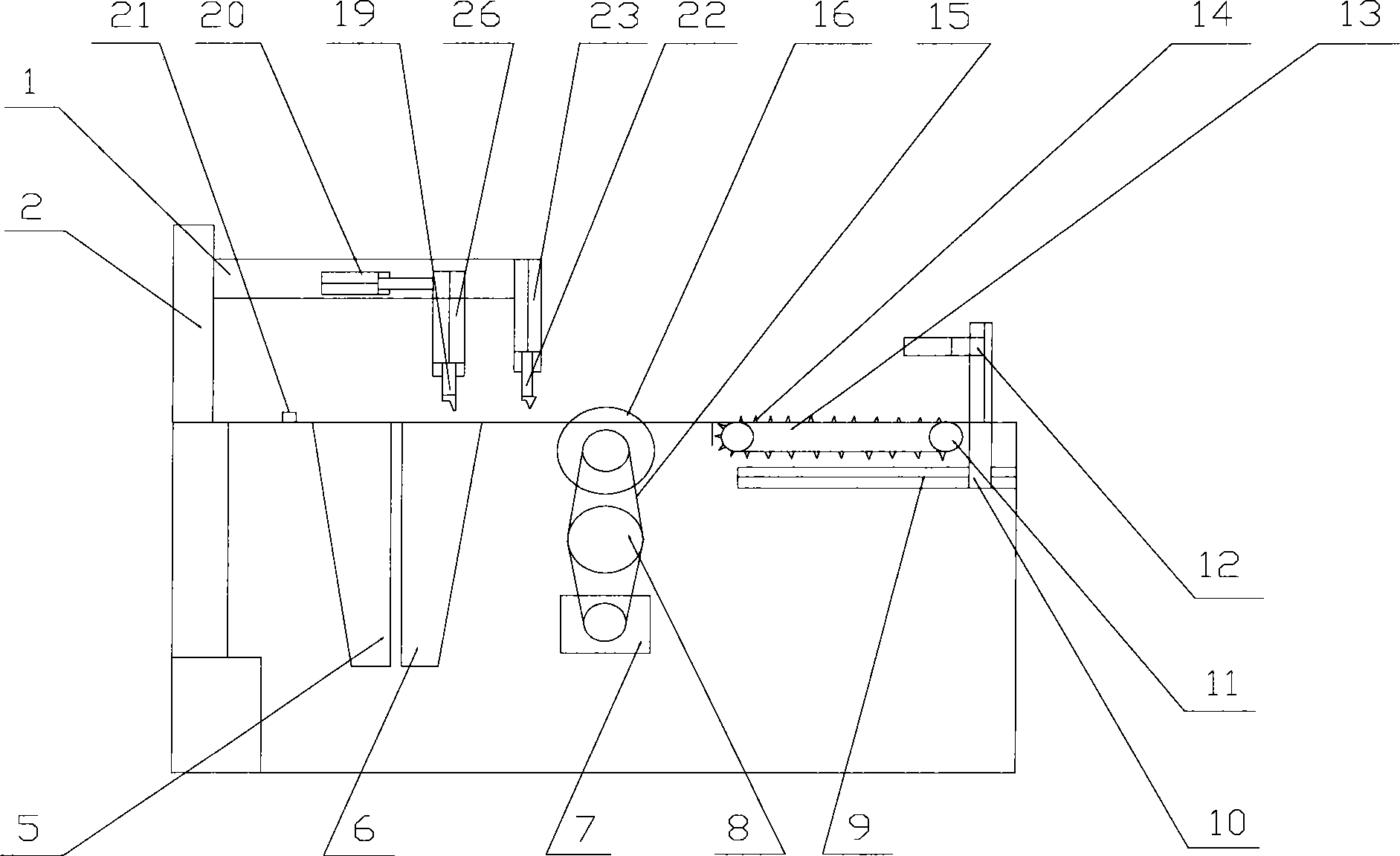

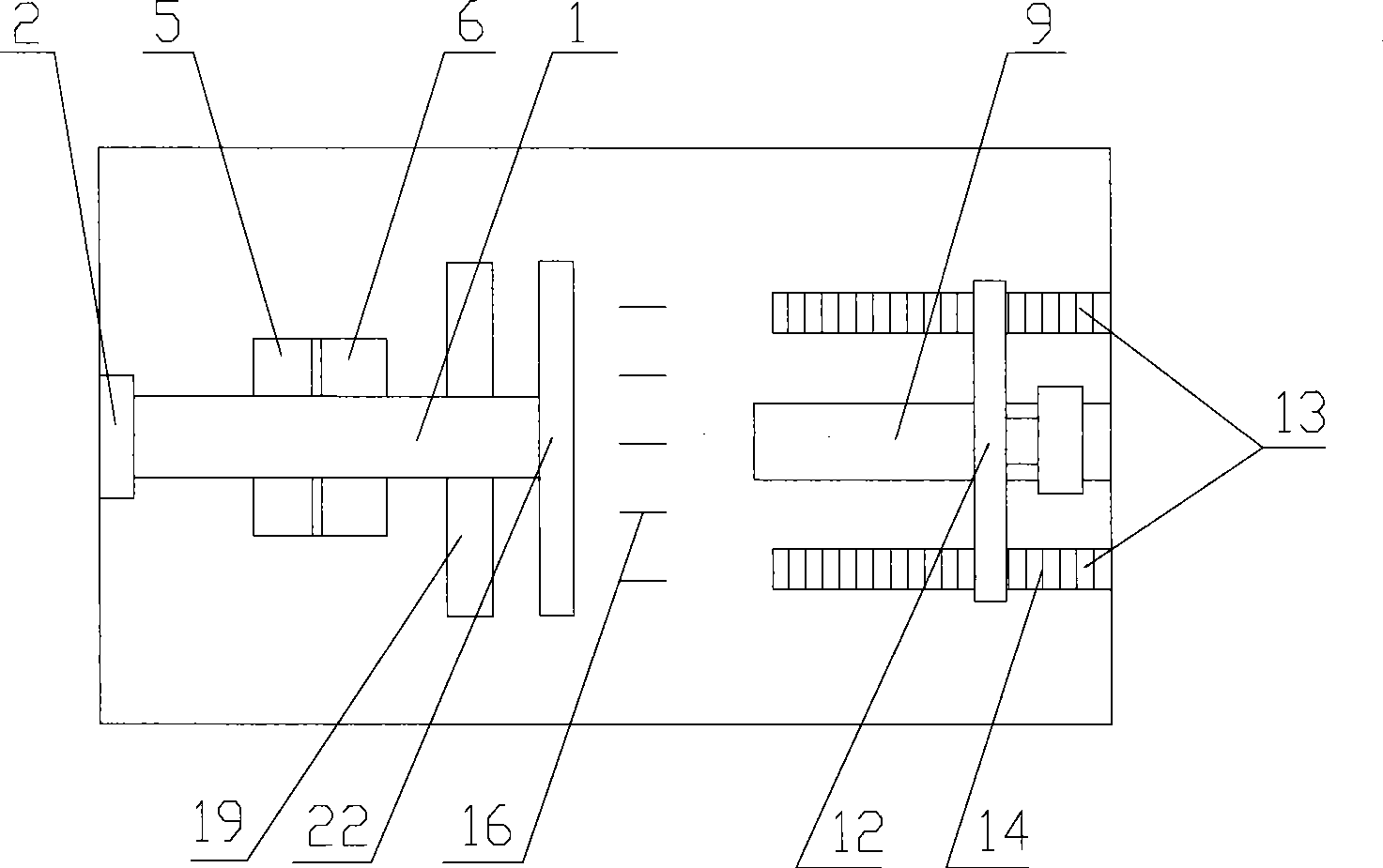

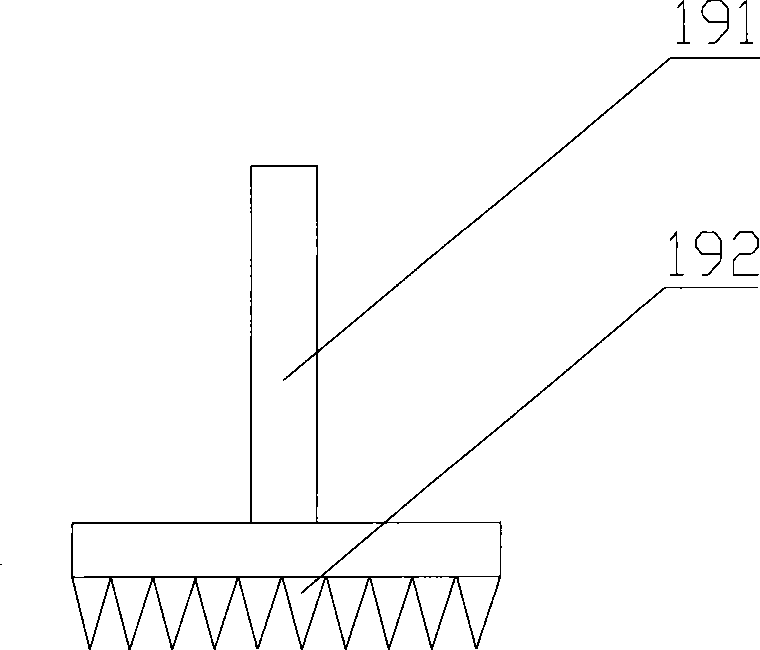

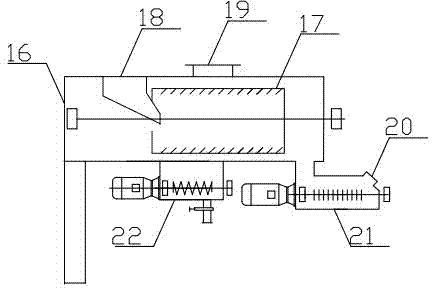

Heat-exchanger copper aluminum separation device

ActiveCN101450348AHigh separation purityMetal-working feeding devicesSolid waste disposalEngineeringCantilever

The invention discloses a copper-aluminum separation device for a heat exchanger, which is used for separating copper-aluminum materials in the heat exchanger of an air-conditioner. The copper-aluminum separation device comprises a rectangular work table, a cutting tool row and a harrowing and cutting system which are arranged in the middle of the work table, and a workpiece clamping device and a workpiece transmitter which are arranged on one end of the work table, wherein the harrowing and cutting system comprises a cantilever beam and a strut, a cutting tool and a harrow which are perpendicularly arranged on one end of the work table; the cantilever beam is arranged on one end of the strut and parallel to the work plane of the work table; the cutting tool is fixed in an end head position of the cantilever beam; and the harrow is provided with a harrow head which takes the shape of a harrow and perpendicularly arranged on the cantilever beam. The workpiece clamping device clamps workpieces; a transmission control device drives the clamped workpieces to move towards the direction of the cutting tool row; and the harrow harrows an aluminum sheet, and the cutting tool cuts off a copper tube, so that copper materials and aluminum materials of the heat exchanger of the air-conditioner are separated and good separation effect can be obtained.

Owner:HAIER GRP CORP +1

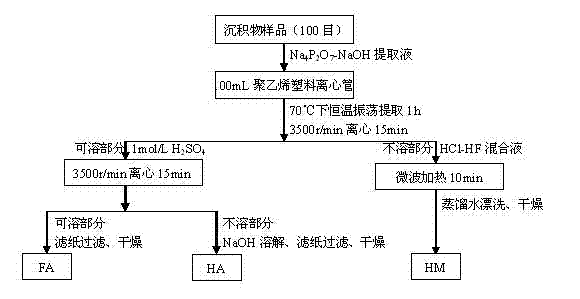

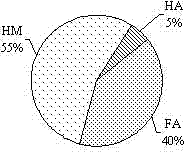

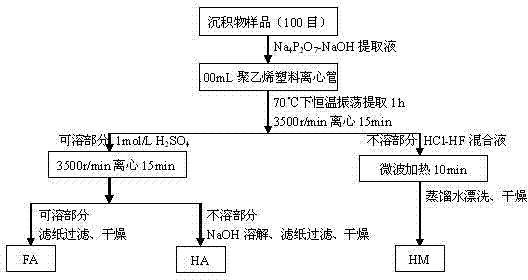

Separation and purification method of humus in wetland sediment

InactiveCN102295781AReduce extraction timeImprove extraction efficiencyOrganic chemistrySoil scienceFiltration

The invention relates to a method for separating and purifying humus in wetland sediments. The specific steps of the method are as follows: after the wetland sediment is pretreated, it is passed through a 100-mesh sieve; an alkali extract solution with a pH value of 13 is prepared and shaken at a constant temperature at 70° C. for 1 hour to extract humus in the wetland sediment; centrifugal separation and filtration are obtained. The supernatant is the alkali extractable liquid HE, and the obtained filter residue is the crude humic substance humin HM; adjust the pH value of the extractable liquid HE obtained in the alkali step b to 1.0-1.5, and centrifuge; filter the obtained supernatant with medium-speed quantitative filter paper That is, the fulvic acid FA solution is obtained; the obtained precipitate is dissolved with 0.1mol / L NaOH and filtered with a medium-speed quantitative filter paper to obtain the humic acid HA solution; a mixture of 1mol / LHCl and 10% HF by volume is added to the filter residue obtained in step b solution, filter residue and mixed solution weight volume ratio is 1:5, microwave heating with 30W power for 10min, remove the supernatant, rinse the residue with distilled water to obtain humin HM; the above fulvic acid FA solution, humic acid HA The solution and Humin HM were dried. The method for separating and purifying humus in wetland sediments of the invention is simple, fast, effective, easy to operate, low in cost and good in effect.

Owner:SHANGHAI UNIV

Process of extracting lycopdine A from plant

InactiveCN1861580AImprove solubilityImprove the extraction effectOrganic chemistryActivated carbonChloroform

A process for extracting huperzine A from clubmoss herb, cryptomeria, or masson fir includes such steps as breaking, immersing in acid solution, concentrating, decoloring by activated carbon, regulating pH value, extracting by chloroform, vacuum recovering, volatilizing, eluting out, vacuum recovering, crystallizing and drying.

Owner:HENAN TALOPH PHARMACEUTICAL STOCK CO LTD

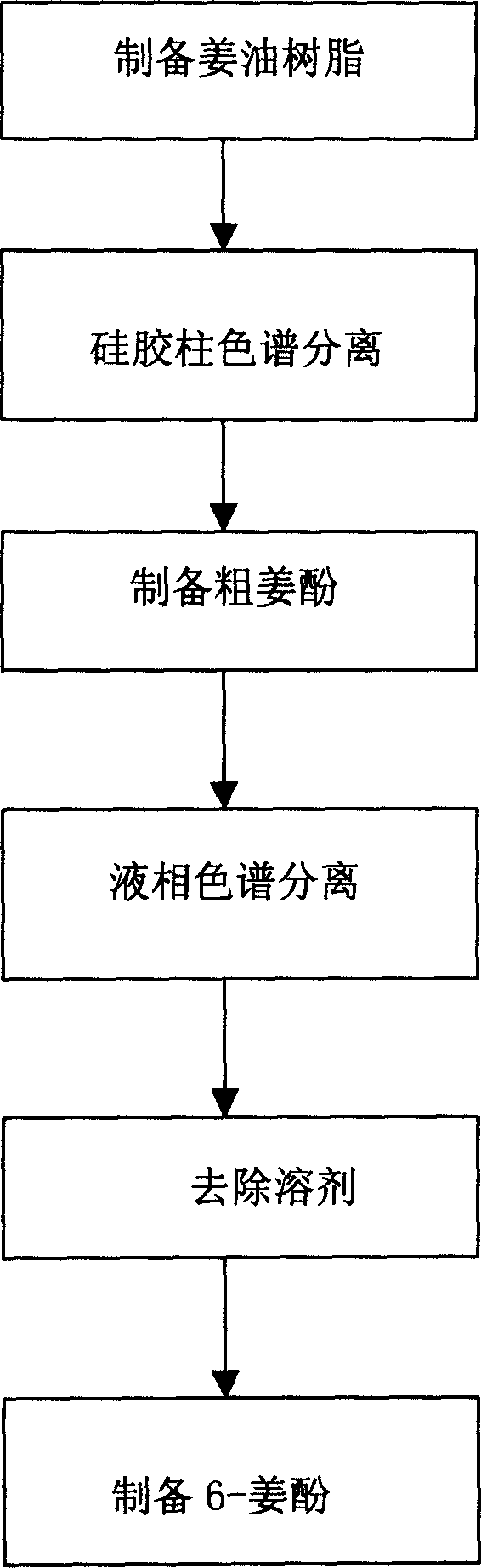

Method for separating 6-gingerol from ginger

ActiveCN1616391AHigh purityImprove separation efficiencyCarbonyl compound separation/purificationChromatographic separationOleoresin

The technological process of separating 6-gingerol from ginger includes the steps of: preparing ginger oleoresin, chromatographic separation with silica gel column, preparing coarse gingerol, liquid phase chromatographic separation, eliminating solvent, preparing pure 6-gingerol product, etc. The present invention has high 6-gingerol purity, simple operation, simple technological process and high separation efficiency.

Owner:北矿检测技术股份有限公司

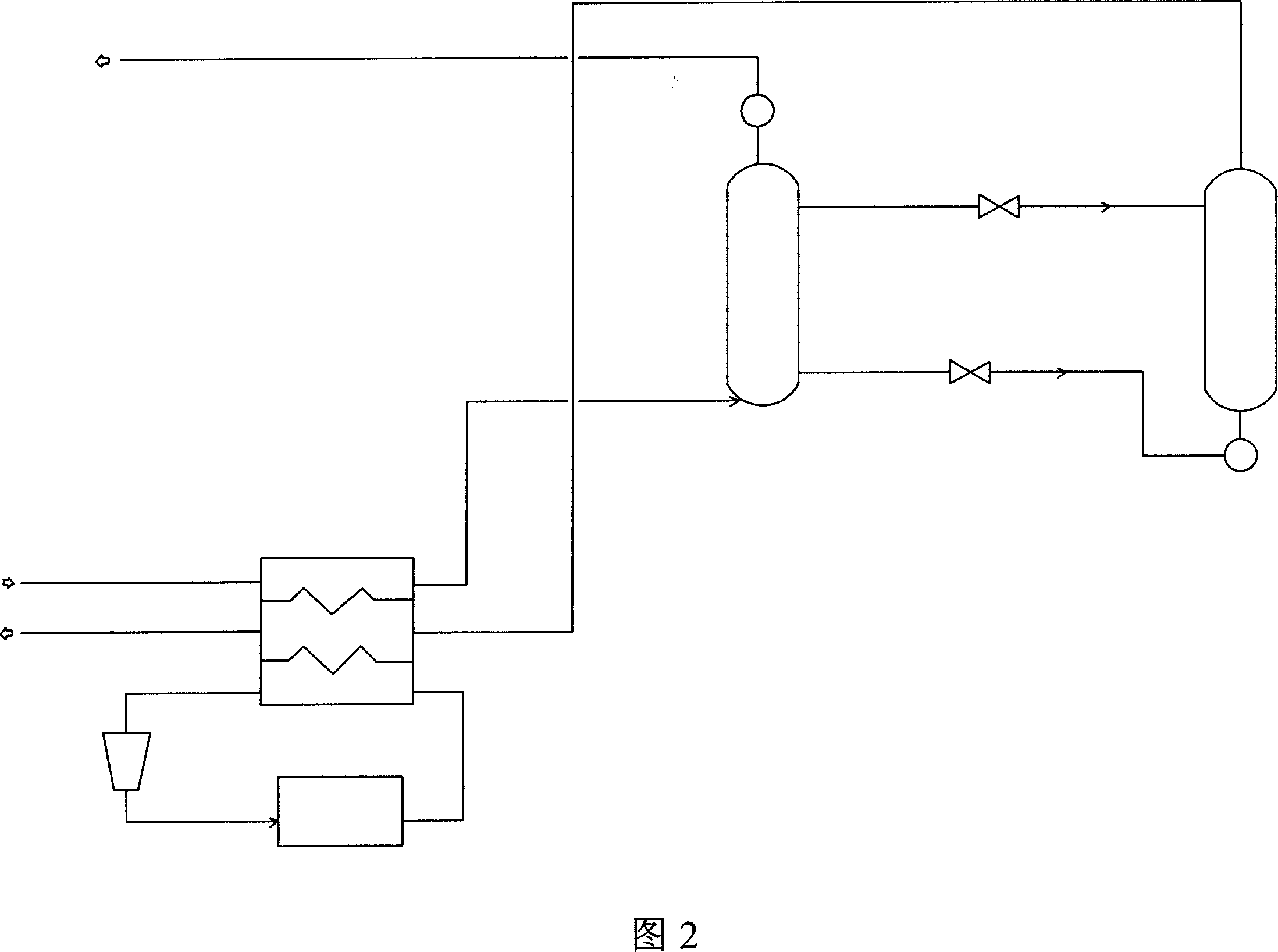

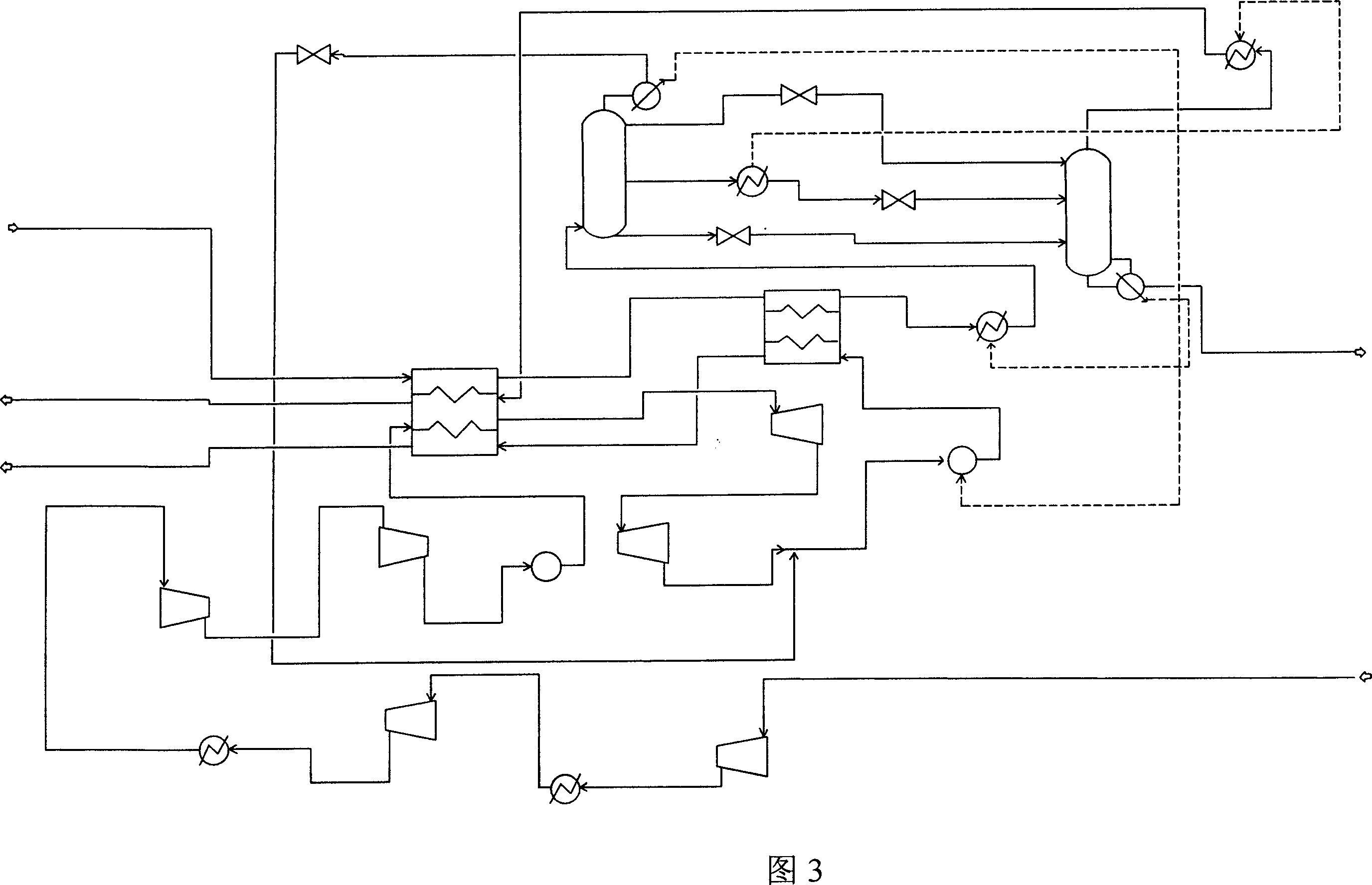

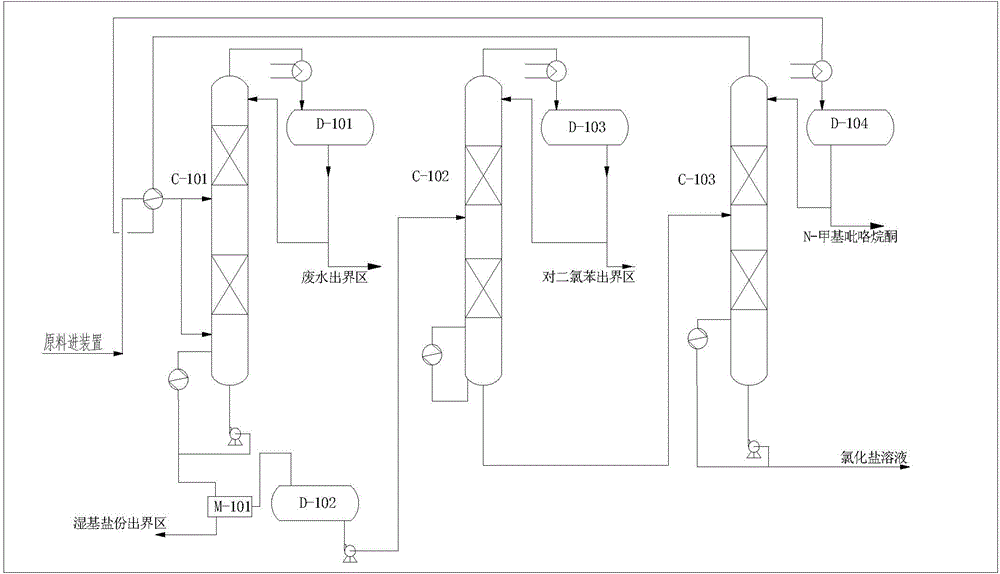

Continuous recycling method of NMP (N-methyl pyrrolidone) solvent for polyphenylene sulfide production device

ActiveCN104447480AAvoid lostReduce lossesOrganic chemistryChemical industryHigh concentrationRecovery method

The invention discloses a novel continuous recycling method of an NMP (N-methyl pyrrolidone) solvent for a polyphenylene sulfide production device. The polyphenylene sulfide production device comprises three vacuum rectifying towers, a heat exchanger, a centrifuge machine, a storage tank, a pump and relevant pipelines. In an existing polyphenylene sulfide solvent recycling process, pipelines are easily blocked by salt crystals in a dehydration process, so that the halt maintenance needs to be frequently carried out, the rate of equipment utilization is low, and the solvent loss is high. According to the novel continuous recycling method of the NMP (N-methyl pyrrolidone) solvent for the polyphenylene sulfide production device, a novel technological process device is developed; by virtue of forced circulation of high-concentration salt fraction at the tower bottoms, solid salt formed after water and the solvent are removed can be adequately stirred and circulated, and the blockage, caused by the salt crystals, of valves of the pipelines is avoided, so that the heating efficiency of the column bottoms is increased, the yield of NMP is improved, the quality of an recycled NMP product can reach 99.5% or above, recycling requirements of a system are met, and meanwhile, the long-period, stable and efficient operation of the device are guaranteed.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

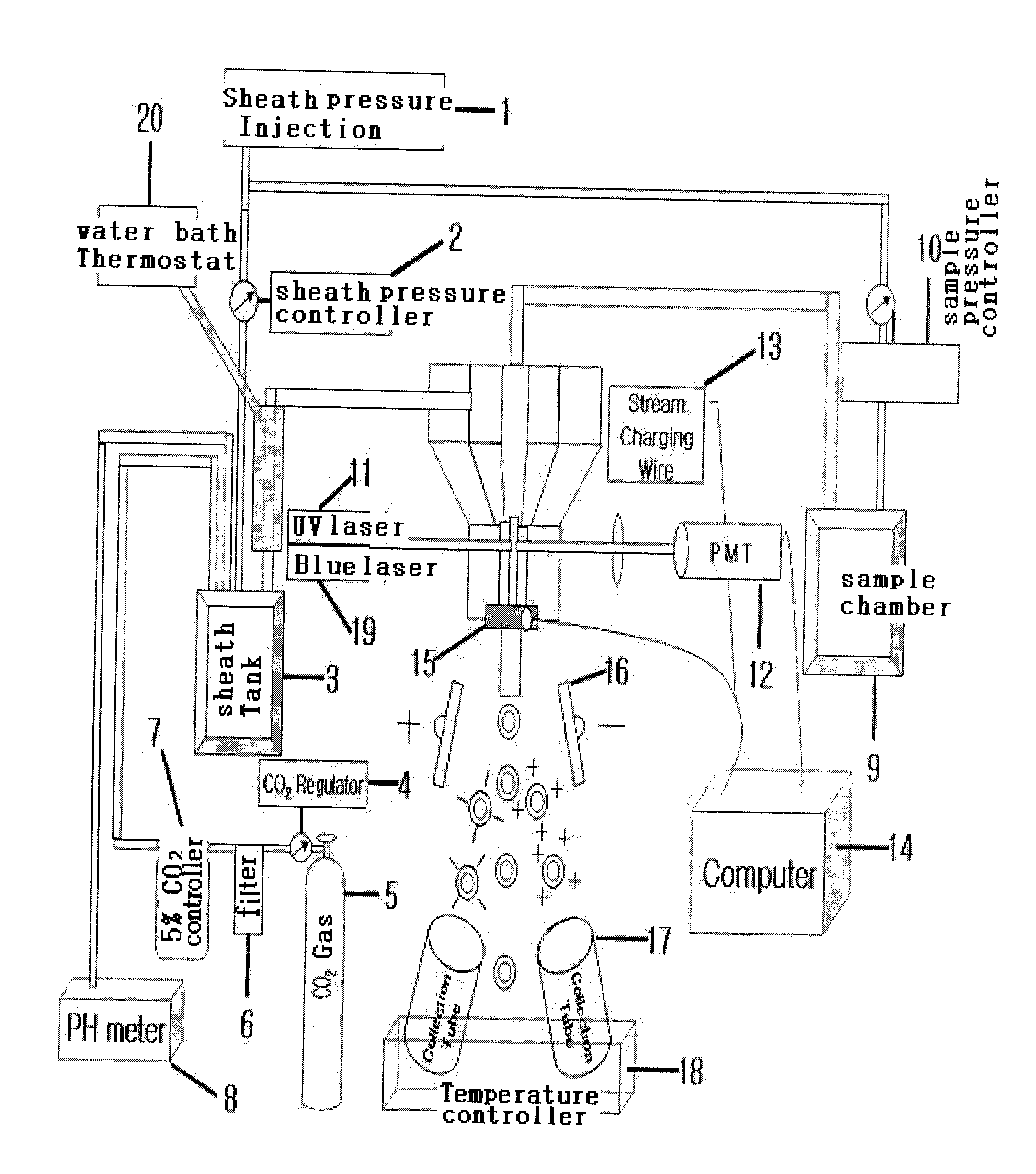

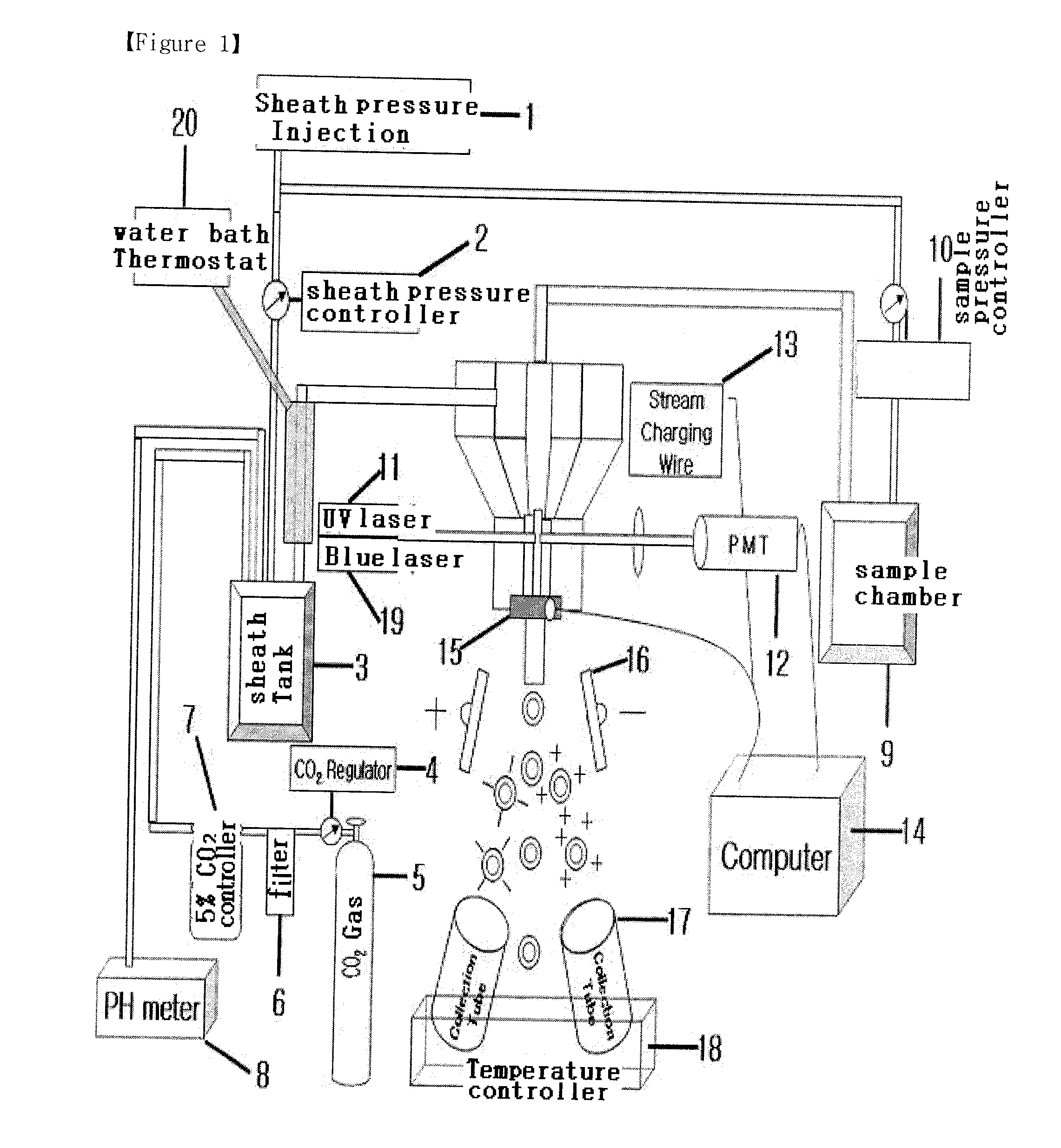

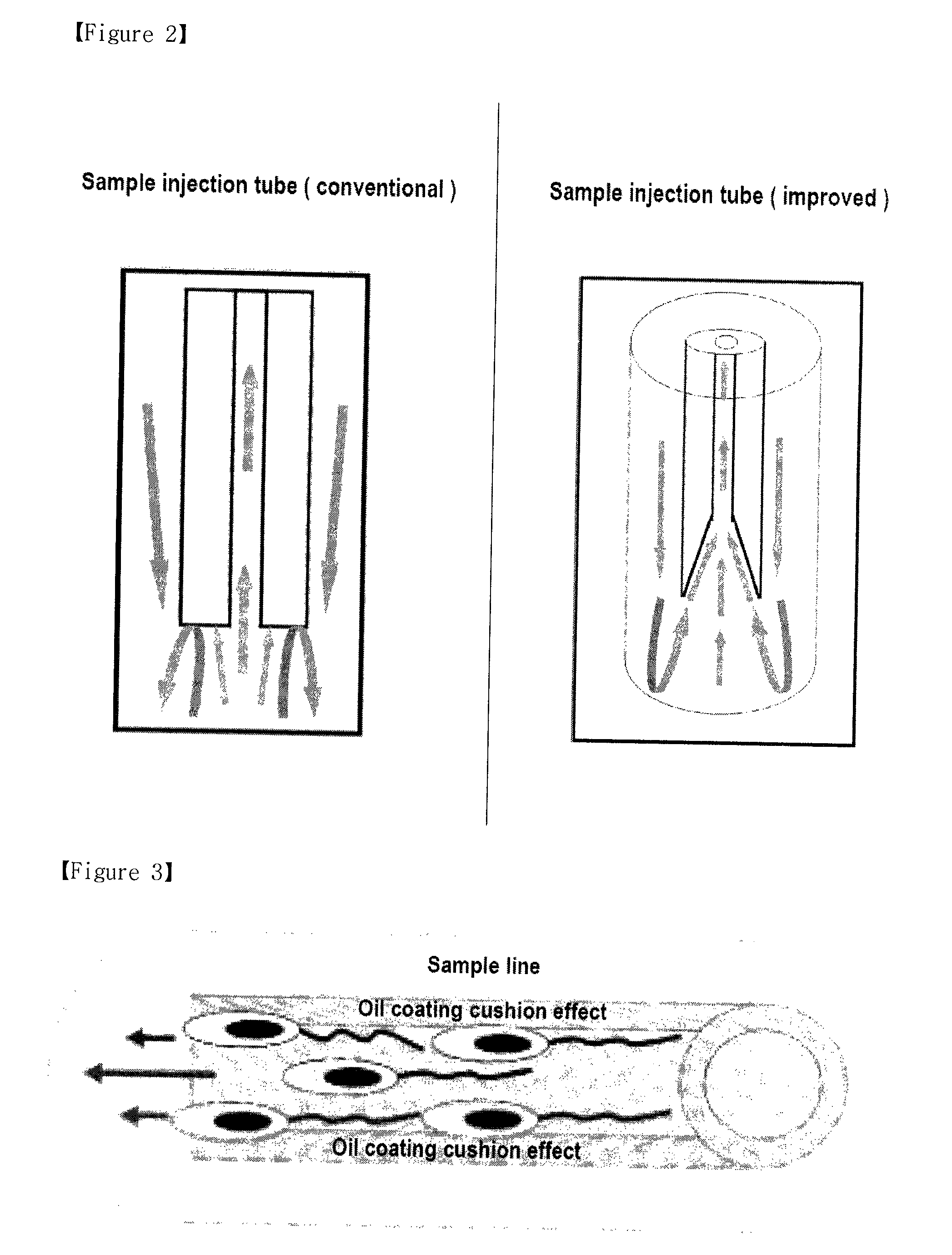

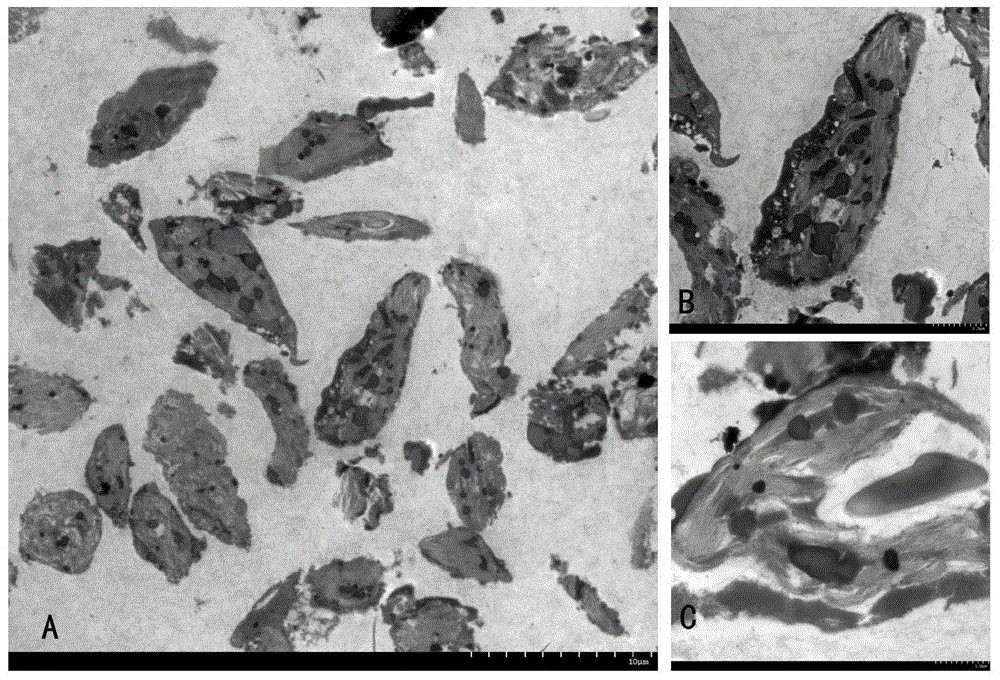

Parameter for x- and y- chromosome bearing sperm sorting with high degree of purity

InactiveUS20100167336A1High separation purityRestrains sperm motilityMicrobiological testing/measurementGerm cellsX chromosomeMotility

Current invention is about the sex-specific separation of sperm in high purity. For more details, this invention is about the methods for improving the separation efficiency of sperm by removing factors deteriorating separation efficiency by utilizing several parameters and adjusting few conditions for the purpose of separating sperm into X-chromosome bearing and Y-chromosome bearing groups in high purity. Current invention, for the purpose of separating X-chromosome bearing and Y-chromosome bearing sperm based on physiological characteristics, utilize the difference of sperm's nucleus width as a parameter to recognize the difference in DNA content between X and Y chromosome. Current invention is about the sex-specific separation of sperm in high purity. This invention, unlike any known conventional methods, requires neither special conditions nor special treatments, can be conducted in a more realistic environment and, as a results, sex-specific sorting of sperm can be conducted without losing viability or motility. Therefore, the limitation conferred on sorting efficiency by the motility can be overcome by our invention.

Owner:NOAH BIOTECH +1

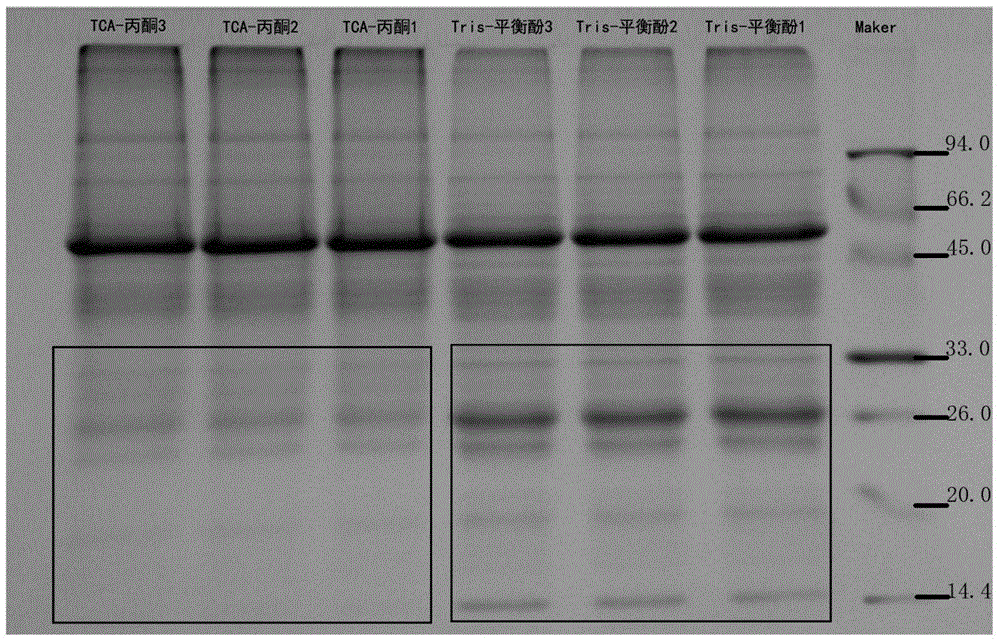

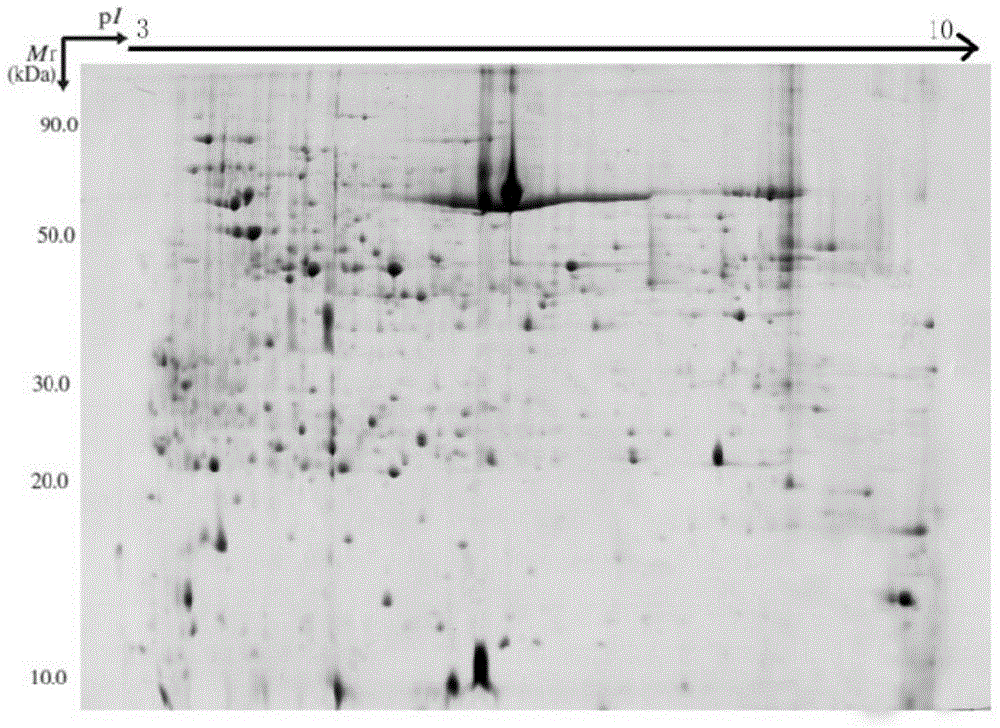

Extraction method of ginkgo leaf chloroplast protein

InactiveCN104592346AHigh purityLess interfering substancesPeptide preparation methodsSolubilityProtein spot

The invention belongs to the field of biological chemistry and specifically relates to extraction method of chloroplast protein of xylophyta ginkgo leaf. The method comprises the following steps of: firstly, preparing coarse chloroplast particles from the ginkgo leaves, performing gradient centrifugation through Percoll, so as to obtain complete chloroplast by a specific centrifugal force; then, dissolving protein by using a protein extraction buffer solution, adding the same volume of Tris-balanced phenol for extraction, and precipitating protein by using a ammonium acetate methanol solution. The extraction method is capable of effectively increase extraction efficiency and purity of chloroplast protein. The ginkgo leaf chloroplast protein obtained by the method can be used for proteomics analysis of ginkgo leaf and other xylophyta materials rich in interfering substances, so that solubility and purity of protein are improved; a 2-DE map of the protein has a clear background and many protein spots are distinguishable.

Owner:NANJING FORESTRY UNIV +2

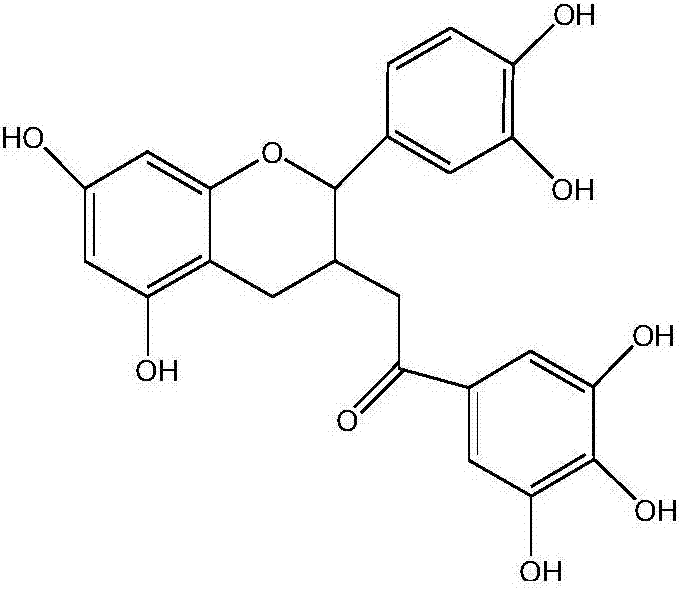

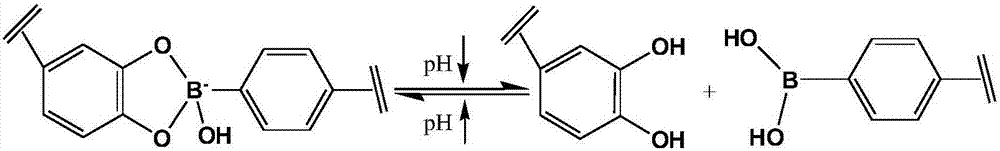

Method used for preparing tea polyphenol adsorption material via cellulose modification

ActiveCN107321322ARealize Adsorption SeparationFast adsorption rateIon-exchange process apparatusOther chemical processesPhenylboronic acidDesorption

The invention provides a method used for preparing a tea polyphenol adsorption material via cellulose modification, and belongs to the technical field of high molecular modification. According to the method, natural cellulose is taken as an initial raw material, free radicals induced graft copolymerization is adopted so as to realize grafting of vinylphenylboronic acid onto cellulose molecular chains, and cellulose is modified and provided with adsorption and desorption performance on tea polyphenol based on mechanisms that a boric acid ester can be produced via reaction of phenyl boric acid with the o-dihydroxybenzene structure in tea polyphenol, and dissociation of the boric acid ester is induced at acid conditions. The adsorption capacity of the tea polyphenol adsorption material is mainly composed of chemisorption capacity, selectivity is high, and separation purity is high.

Owner:QILU UNIV OF TECH

Sorting method and equipment for reprocessed plastic

The invention discloses a sorting method and equipment for reprocessed plastic. The method comprises the following steps of: (1) smashing a material containing plastic A and B to be separated, and removing impurities out of the material for later use; (2) adding a solvent into the material so as to completely swell the plastic A, wherein the plastic B is not swelled; (3) pulping the swelled material, and pulping the swelled plastic A to obtain a mixture of slurry of A and B; (4) sorting the mixture of the slurry of A and B, and drying the sorted plastic B to obtain plastic B; and separating the slurry of A to obtain plastic A. The method and the equipment can be used for thoroughly solving the technical problem in sorting of reprocessed plastic and have the characteristics of high separation purity, simple method and structure, and low cost.

Owner:常州金坛鑫岗橡塑有限公司

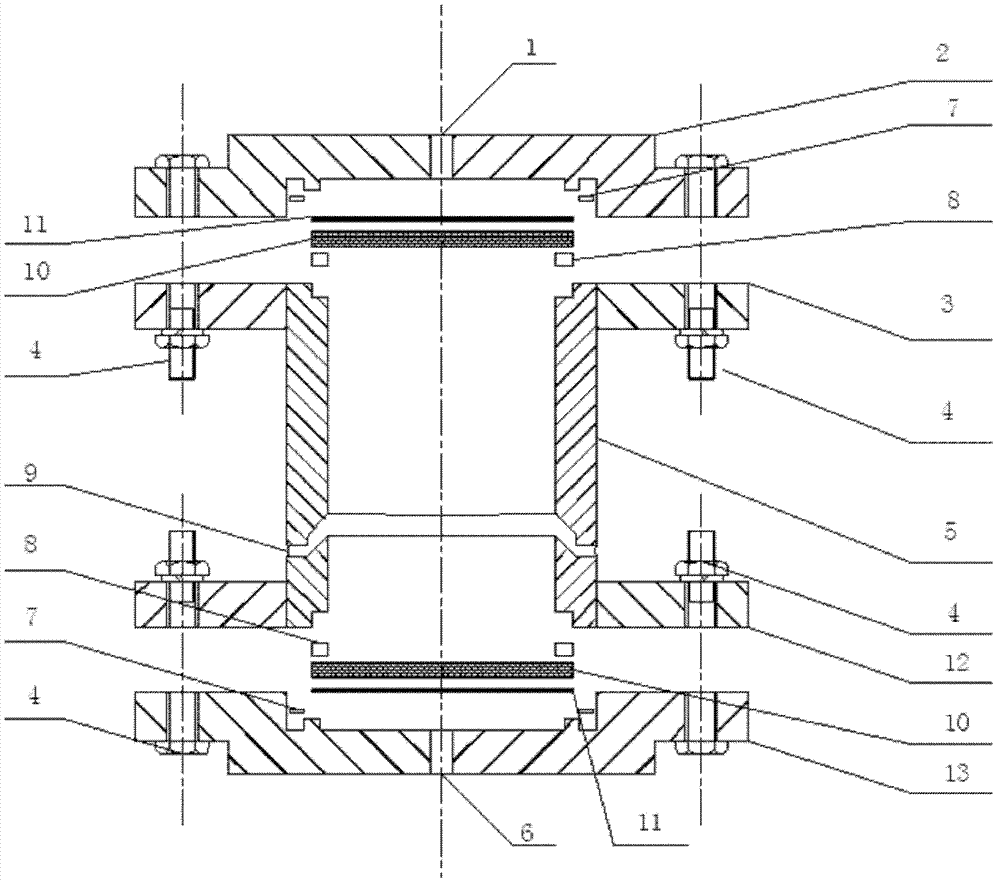

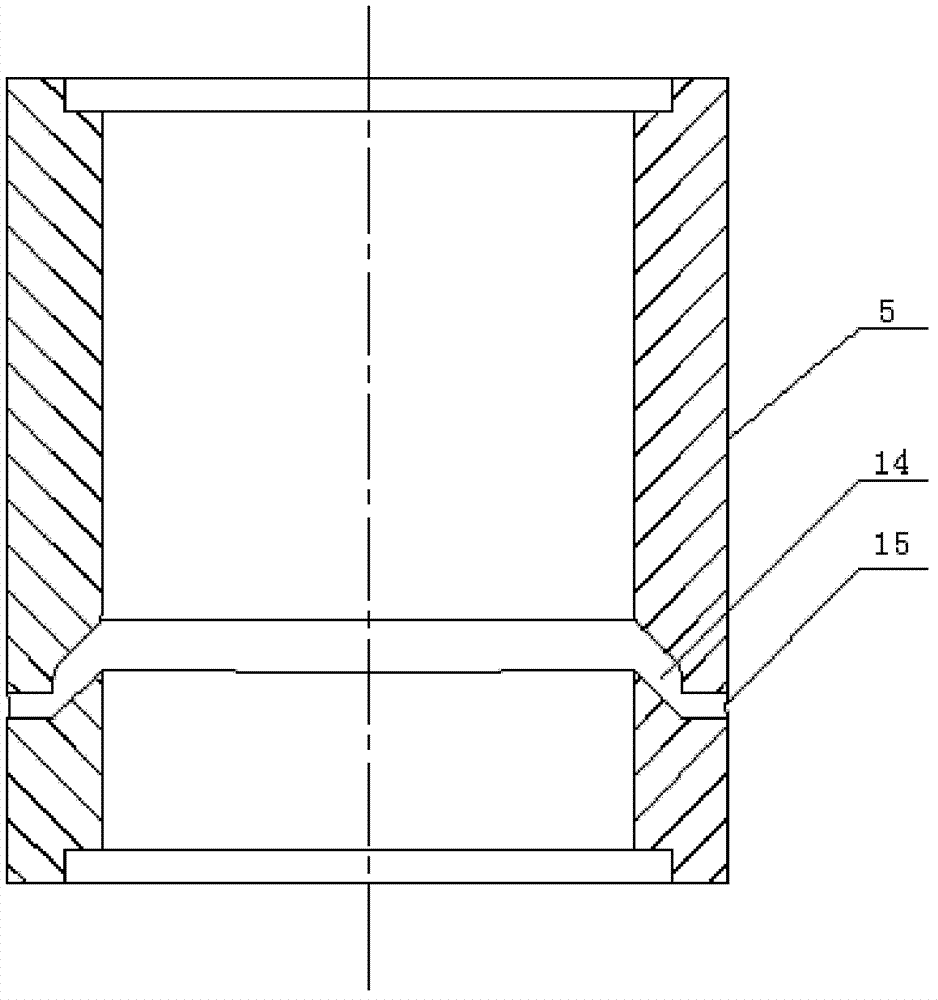

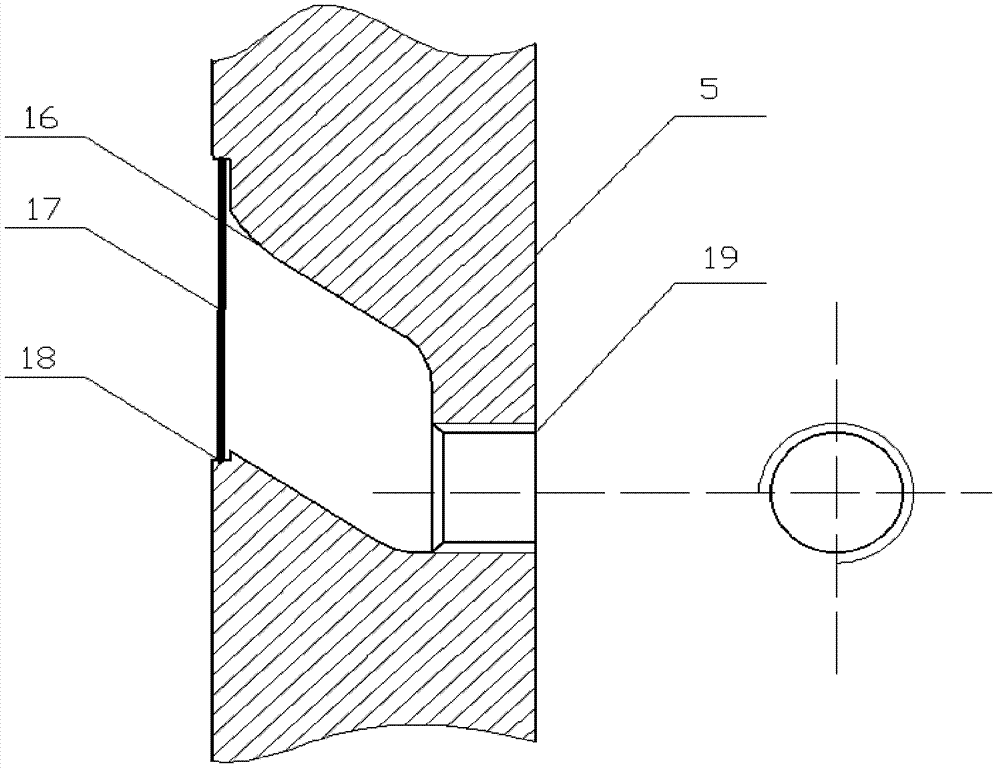

Drainage-type preparation chromatographic column

InactiveCN103083943AObvious beneficial effectHigh separation puritySolid sorbent liquid separationNumerical controlChromatographic separation

The invention discloses a drainage-type preparation chromatographic column. The drainage-type preparation chromatographic column realizes accurate chromatographic separation in a complex environment with two different mediums comprising a viscous fluid and a pipe inner-wall filler. The drainage-type preparation chromatographic column comprises a chromatographic column body, an upper top cover flange, a column body upper flange, a drainage hole, a feeding inlet, a discharge outlet, an outlet pipe, a column body lower flange and a bottom outlet flange. The drainage hole is arranged on the chromatographic column body. A distribution plate and a uniform distribution device are arranged between the upper top cover flange and the column body upper flange. A distribution plate and a uniform distribution device are arranged between the column body lower flange and the bottom outlet flange. The drainage-type preparation chromatographic column can solve the problem of incomplete separation of a boundary layer fluid, can lead out the impure fluid, can improve chromatographic column separation purity, is optimized from the point of fluid machinery, reduces a cost, reduces manpower and material resources, shortens a design period and can be processed easily on a tool.

Owner:UNIV OF SCI & TECH LIAONING

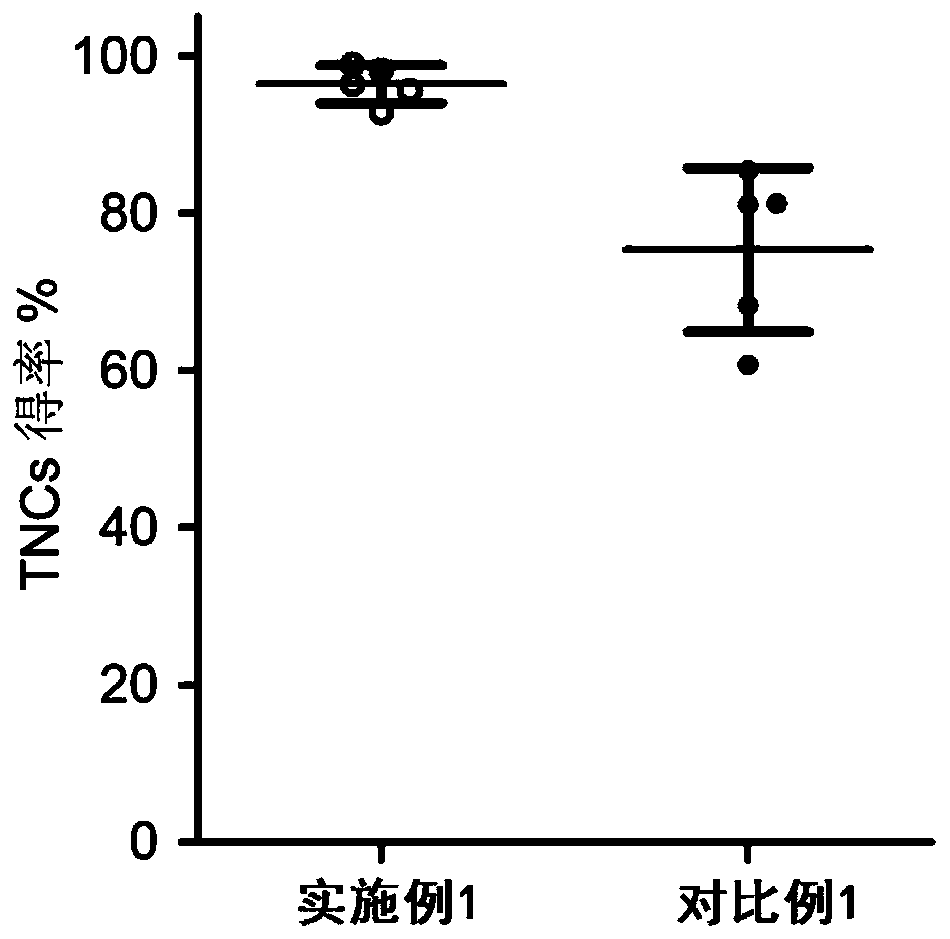

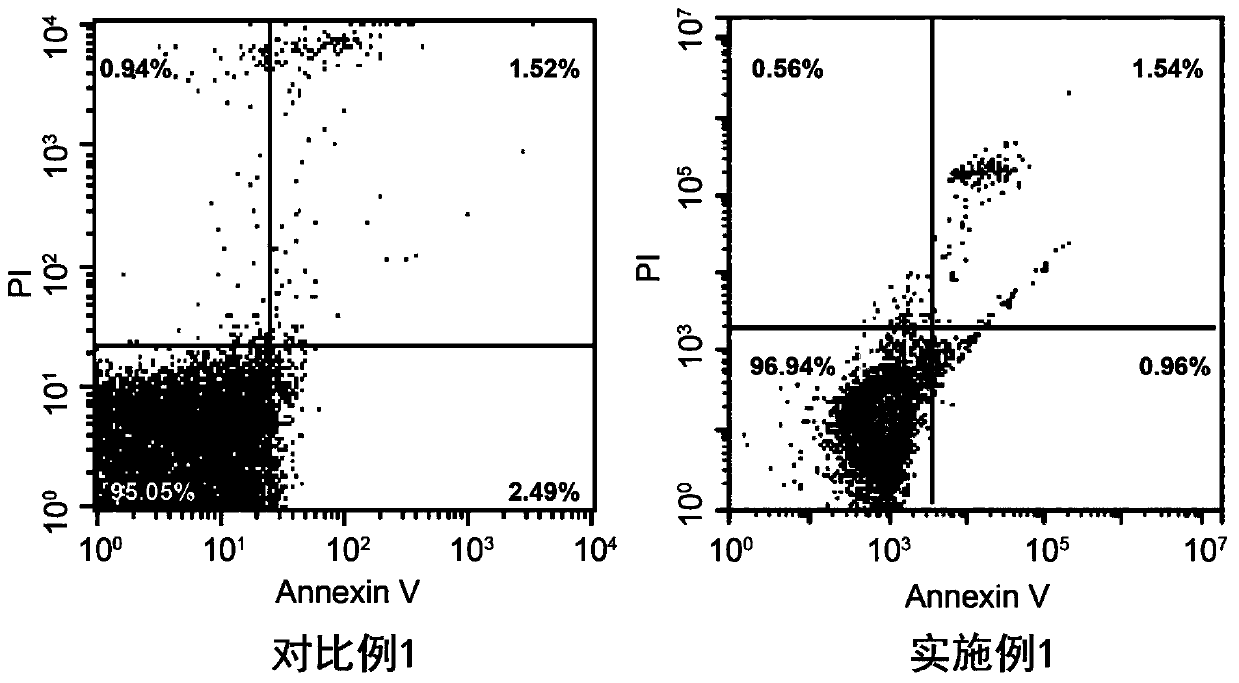

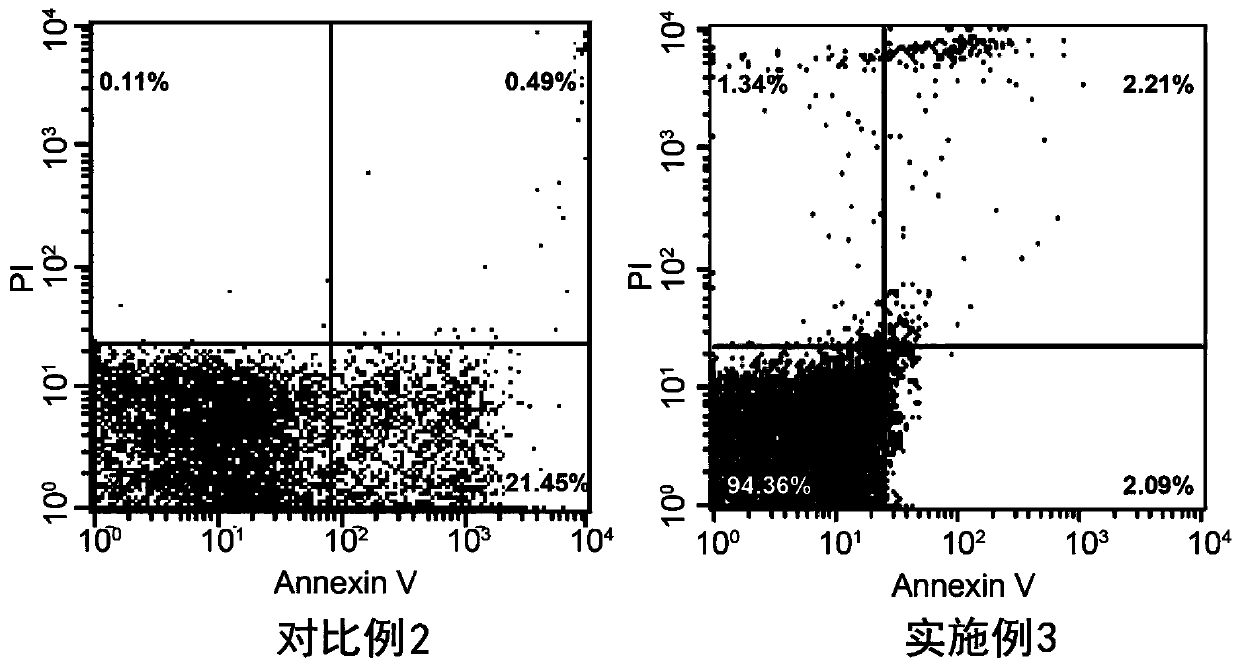

Method for separating total nucleated cells from mononuclear cells from umbilical cord blood

ActiveCN110343663AReduce Toxic DamageReduce osmotic damageCell dissociation methodsBlood/immune system cellsFicollCell separation

The invention provides a method for separating total nucleated cells from mononuclear cells from umbilical cord blood. The method comprises the steps that firstly, TNCs is separated, wherein a PBS buffer solution containing 5% dextran and 2% human serum albumin is added into the umbilical cord blood, centrifugation is conducted to discard supernate, and TNCs precipitate I is obtained; after precipitating and washing, TNCs precipitate is obtained; the TNCs precipitate is subjected to density gradient centrifugation by using a Ficoll lymphocyte separation liquid, a mononuclear cell albuginea layer is collected, and mononuclear cell precipitate is obtained after centrifugation. The method is efficient, convenient to use, capable of saving time and high in repeatability, rich umbilical cord blood resources in an umbilical blood bank can be utilized, and the separation efficiency of derived stem cells and immune cells in the cryopreserved umbilical cord blood is improved.

Owner:SHANDONG QILU STEM CELL ENG

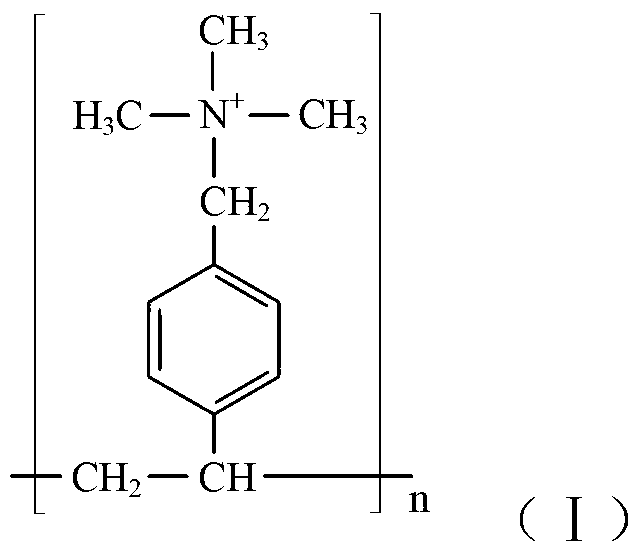

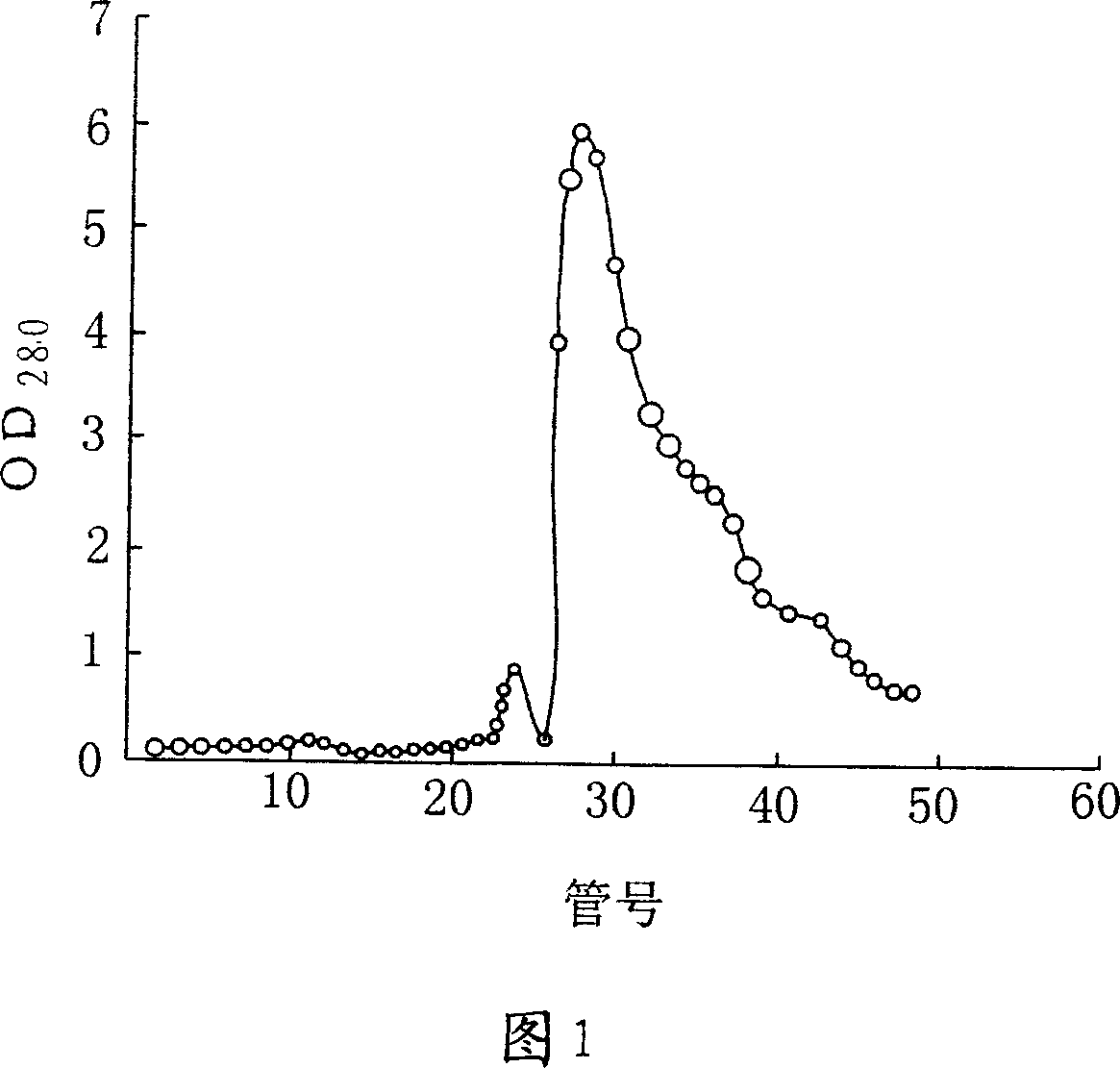

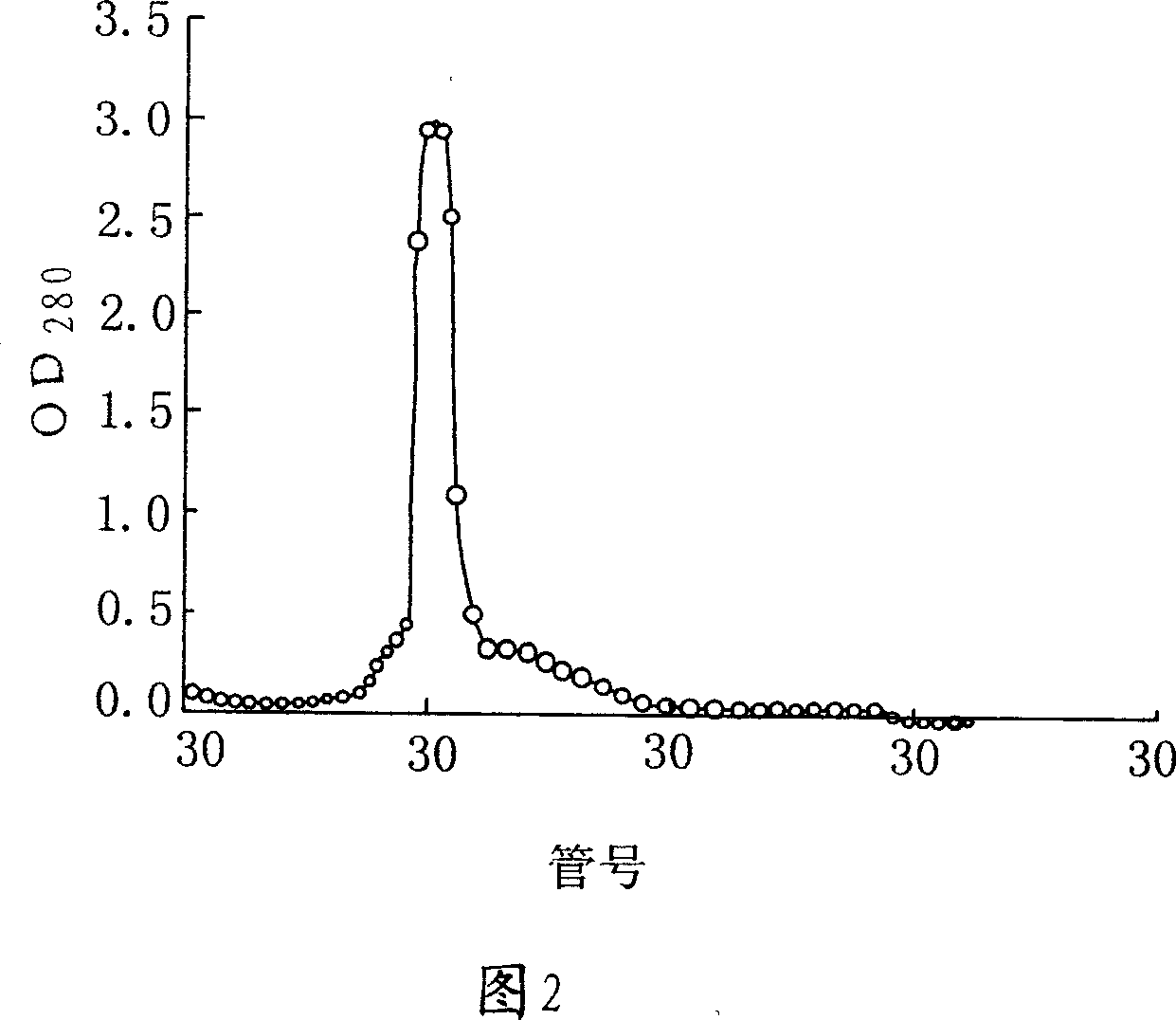

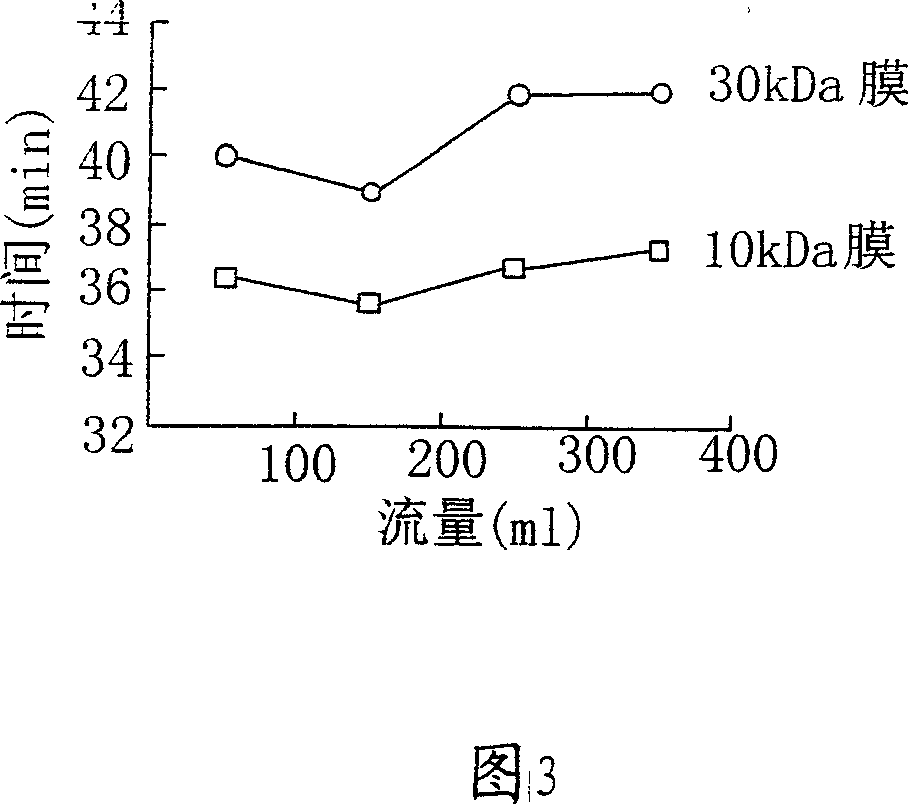

Composite continuous bed cryogel and preparation thereof, and application in separating IgG and albumin

ActiveCN103230784AImprove securityGood biocompatibilityOther chemical processesSerum immunoglobulinsPorosityIon exchange

The invention discloses a composite continuous bed cryogel and a preparation method thereof, and application in quickly separating human serum IgG and albumin. The pore size of the composite continuous bed cryogel is 0.1-300 mu m, and the porosity is 80-95%; and the composite continuous bed cryogel has a hydrophobic benzyl-anion exchange tertiary amino functional group disclosed as Formula (I). The composite continuous bed cryogel polymer chain simultaneously contains amino ion-exchange group and benzyl group with certain hydrophobic functions, so the cryogel can form multi-point adsorption with different competitivenesses with the IgG macromolecule and albumin; and thus, after the composite continuous bed cryogel is sequentially decomposed after being eluted by saliferous eluates with different concentrations. The composite continuous bed cryogel has the advantages of high separation purity and favorable separating properties. The chromatography method has the advantages of fewer steps and quick separation process, is simple to operate, and can implement quick separation, thereby having wide application prospects in the aspect of serum protein separation; and the eluates are buffer solution can be easily prepared. In Formula (I), n is a positive integer.

Owner:ZHEJIANG UNIV OF TECH

Method for extracting rubidium and caesium from coal mine water

ActiveCN107130111AHigh selectivitySimplified separation procedureProcess efficiency improvementDesorptionRubidium

The invention relates to a method for extracting rubidium and caesium from coal mine water. The method includes the steps of 1), evaporating the coal mine water and adjusting the pH value of the same to be 8-11.5; 2), allowing the treated coal mine water to pass a first ion exchange column loaded with a mixture composed of zirconium phosphate, titanium phosphate and a binder to obtain a filtrate; 3), allowing the filtrate passing the first ion exchange column to pass a second ion exchange column loaded with calcium alginate-ammonium molybdopho-sphate; 4), taking raw materials in the first ion exchange column, performing desorption on caesium ions by performing ion exchange with an ammonium chloride solution, and performing evaporation and concentration to obtain a caesium solution; 5), taking out the calcium alginate-ammonium molybdopho-sphate from the second ion exchange column, performing desorption on rubidium ions by adopting water solutions of nitric acid and hydrobromic acid, and carrying out evaporation and concentration to obtain a rubidium solution. The rubidium and the caesium are selectively adsorbed through different substances, the extraction process of the rubidium and the caesium in the coal mine water is simplified, the method is good in safety and short in production cycle, and labor cost is reduced.

Owner:HEBEI UNIV OF ENG

Extraction process of camel colostrum immune globulin IgA, IgG.

InactiveCN101045750AHigh recovery rate of activitySuitable for separation and purificationMilk immunoglobulinsNatural sourceUltrafiltration

This invention relates to extraction process of camel colostrum immunoglobulin IgA and IgG, belongs to biochemistic product field. The camel colostrum is the most prolific natural source of immunoglobulin, and is one of the biotic resources that has most concentrated immune factor. This invention supplies a craft of using gradient elution to extract IgA and using ultrafiltration and metal chelate chromatography to extract IgG. By test has show that in product IgA basicly has no other impurity, purity of IgG can reach 97 percent and above.

Owner:甘肃省华龙农业开发有限公司

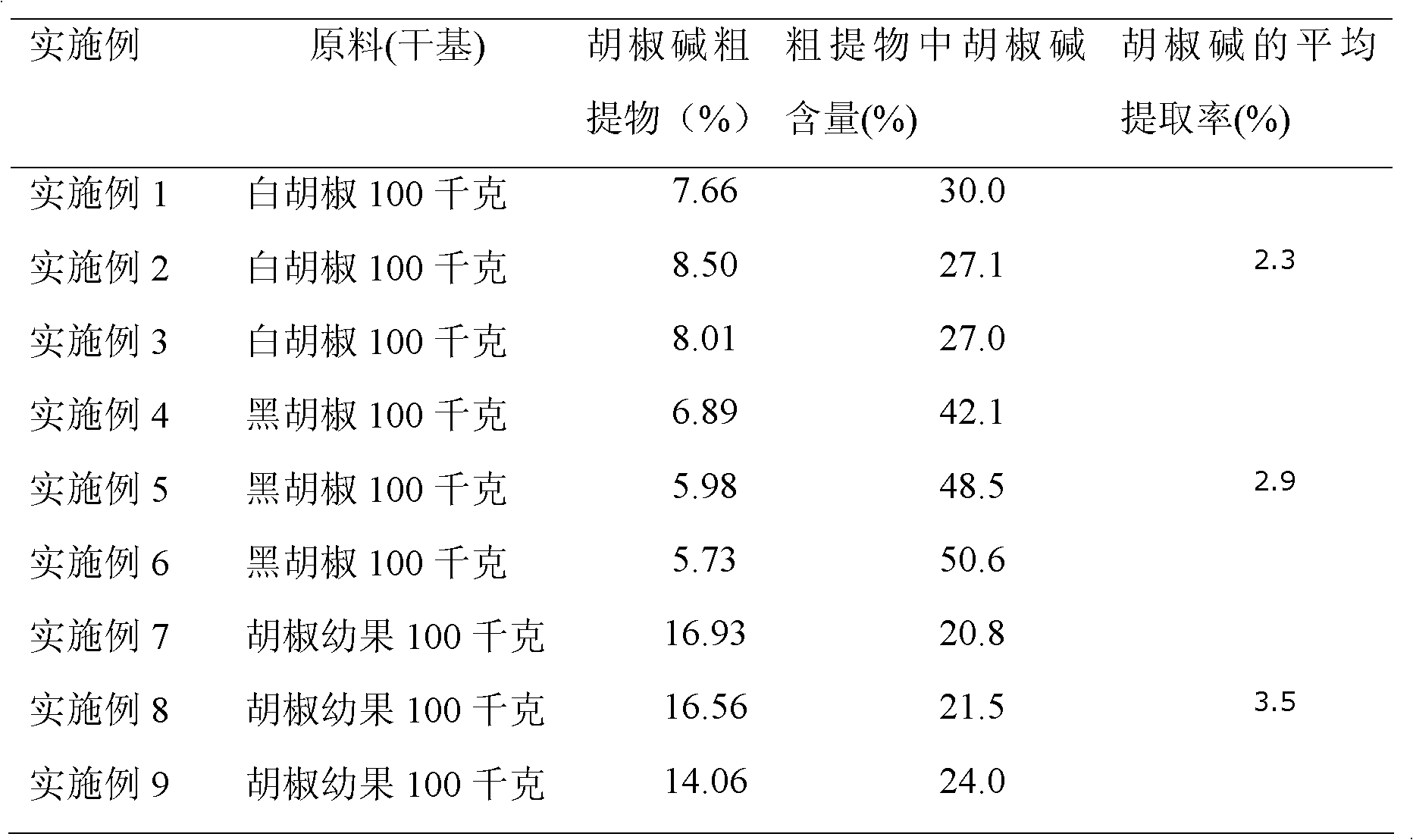

Method for producing piperine

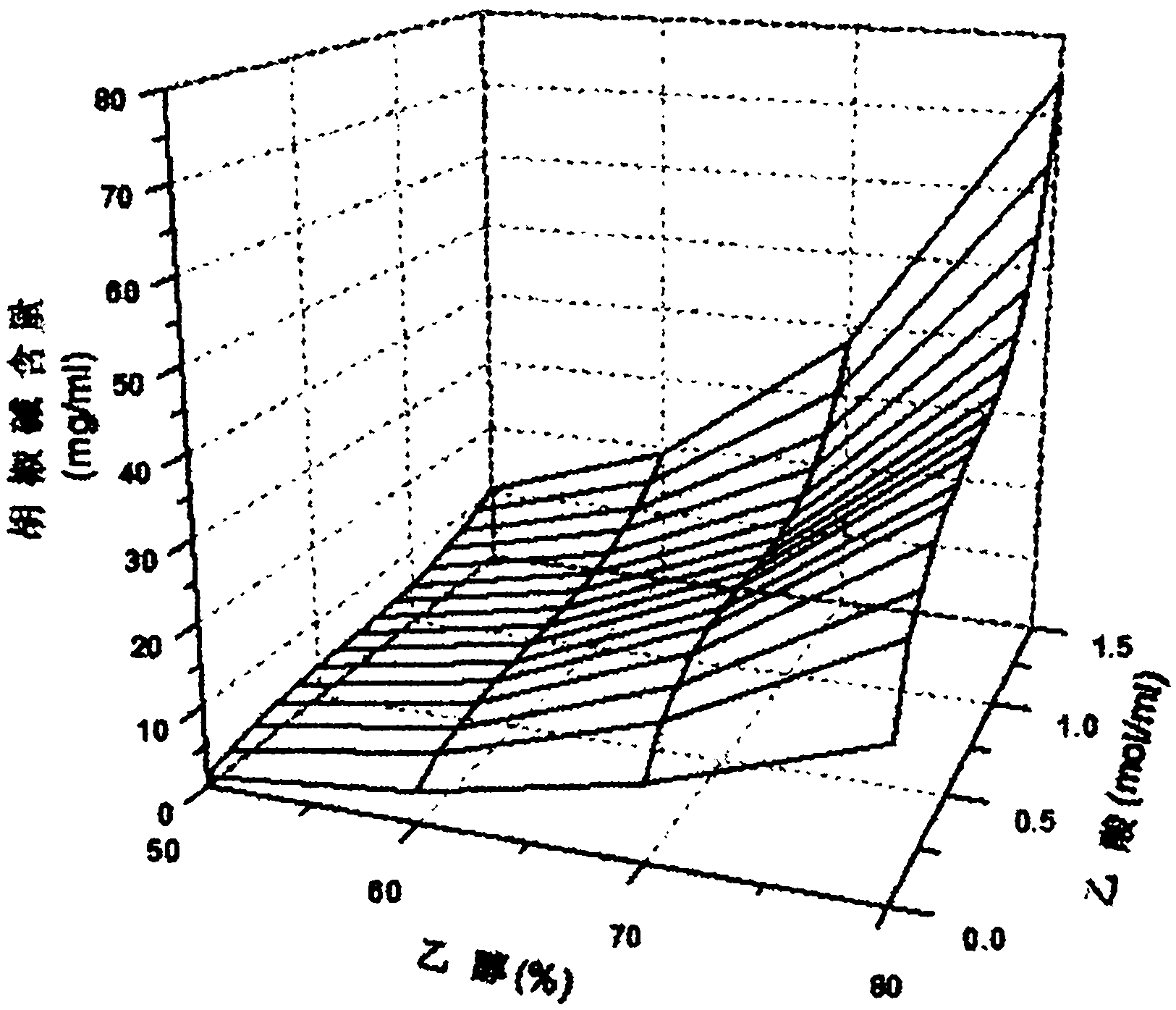

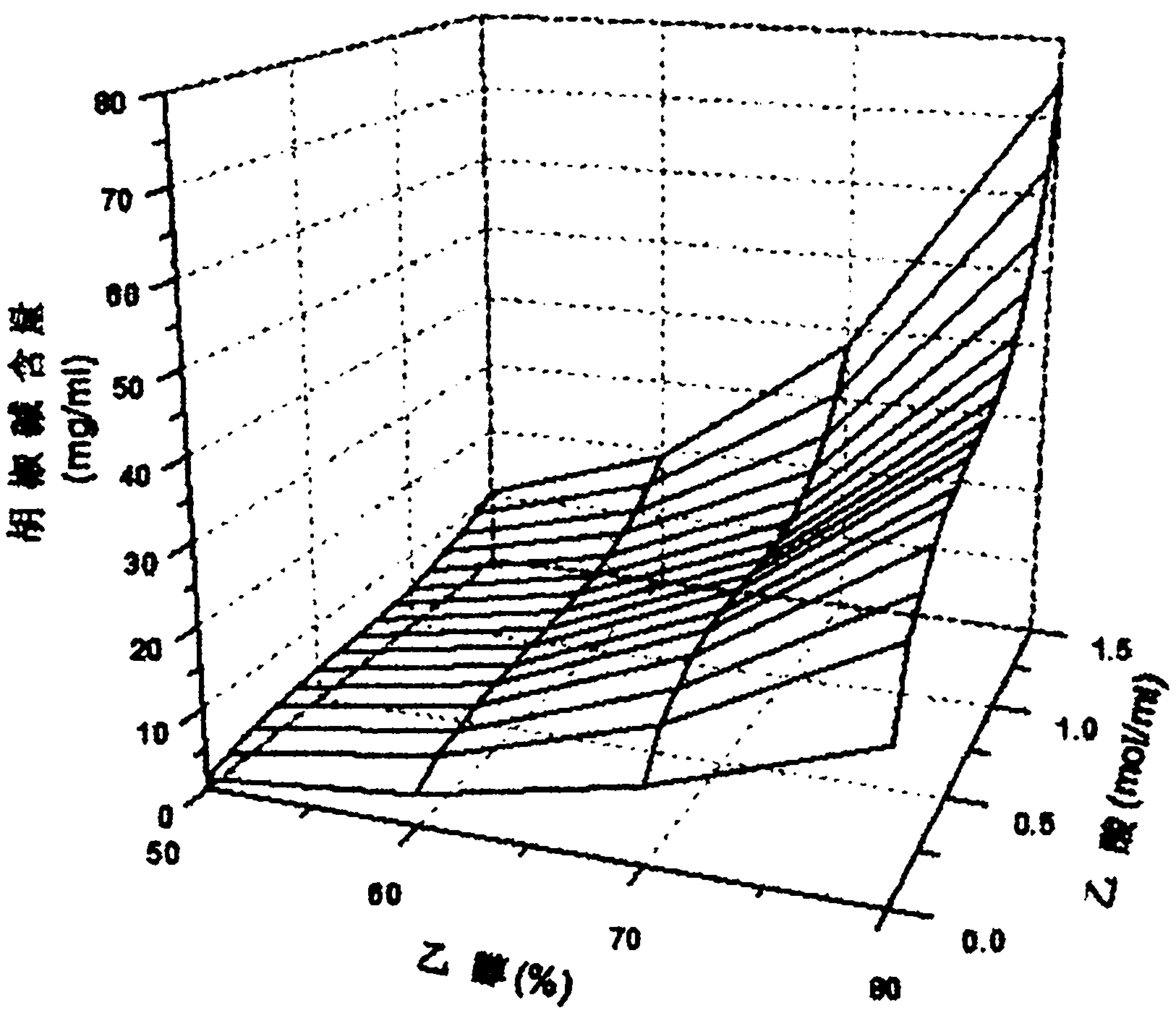

InactiveCN101985440AImprove solubilityImprove extraction efficiencyOrganic chemistryOrganic solventSolvent

The invention discloses a method for producing piperine, which comprises the following steps of: uniformly mixing an acid solvent and a piperine-containing raw material, allowing leach liquor to flow through an adsorption resin chromatographic column, stopping adding the leach liquor until the piperine is adsorbed to flow out, and eluting the adsorbed piperine by using an eluting solvent; concentrating the piperine eluent in vacuum and recovering an organic solvent to obtain piperine concentrate; dissolving the piperine concentrate, and adding seed crystals for crystallization; and recrystallizing to obtain piperine crystals with the purity of over 98 percent. According to the alkaloid properties of the piperine, the acid organic solvent is used, the dissolubility of the piperine is greatly improved, and the extraction efficiency is improved; the chromatography is used, so the separation efficiency and purity of the piperine are improved, the whole production process is low in energy consumption, and the prepared piperine has high yield and purity; besides, the immature pepper fruits which are always wasted and discarded conventionally are used for extracting the piperine, and sources of raw materials for producing the piperine are increased.

Owner:JINAN UNIVERSITY

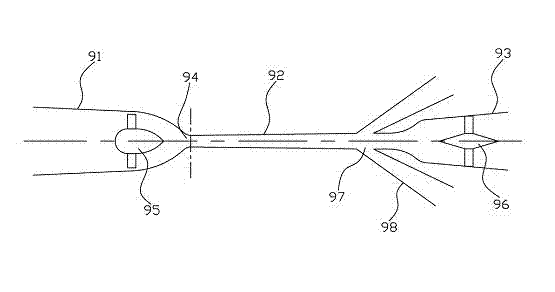

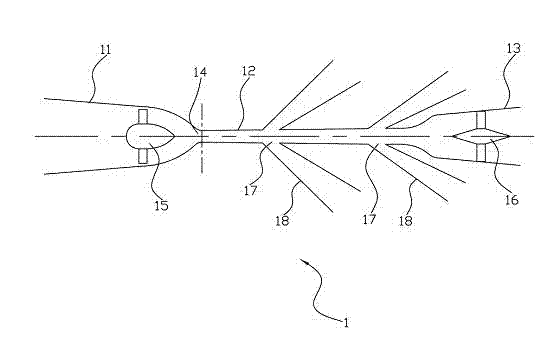

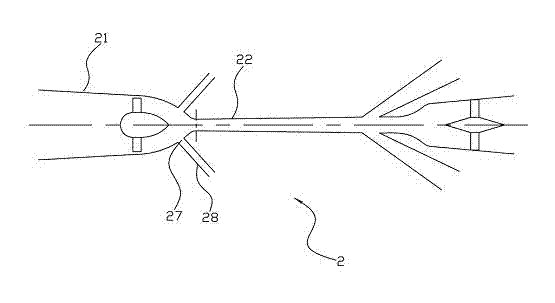

Multi-level supersonic speed cyclone separator

InactiveCN102641790AReduce energy lossImprove separation efficiencySingle direction vortexCycloneBoiling point

The invention discloses a multi-level supersonic speed cyclone separator. The multi-level supersonic speed cyclone separator comprises a retracting pipe, a supersonic speed condensation pipe and a pressure diffusing pipe which are coaxially communicated from left to right sequentially, wherein the cross section of the retracting pipe is gradually reduced from left to right and is shrunk into a narrow throat from the middle; the supersonic speed condensation pipe is extended from left to right from the narrow throat; the cross section of the supersonic speed condensation pipe is gradually increased from left to right; the cross section of the pressure diffusing pipe is gradually increased from left to right; a rotating mechanism is arranged in the retracting pipe; a flow guide sheet is arranged in the pressure diffusing pipe; and at least two separating outlets are sequentially formed in the supersonic speed condensation pipe from left to right and are respectively connected with separating pipes. The at least two separating outlets are sequentially formed in the supersonic speed condensation pipe from left to right, the separating outlet in the front half section of the supersonic speed condensation pipe is used for separating out a fluid with relatively high boiling point, and the separating outlet in the rear half section of the supersonic speed condensation pipe is used for separating out the fluid with relatively low boiling point, so that the energy loss of high-speed air flow is reduced, and the separation efficiency and the separation purity of gas and liquid are improved.

Owner:SHENZHEN LK SCI&TECH

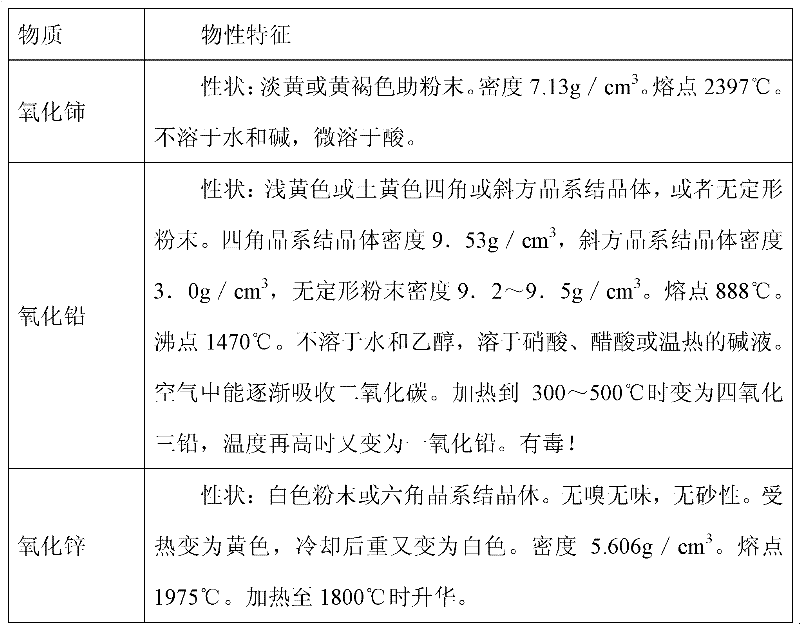

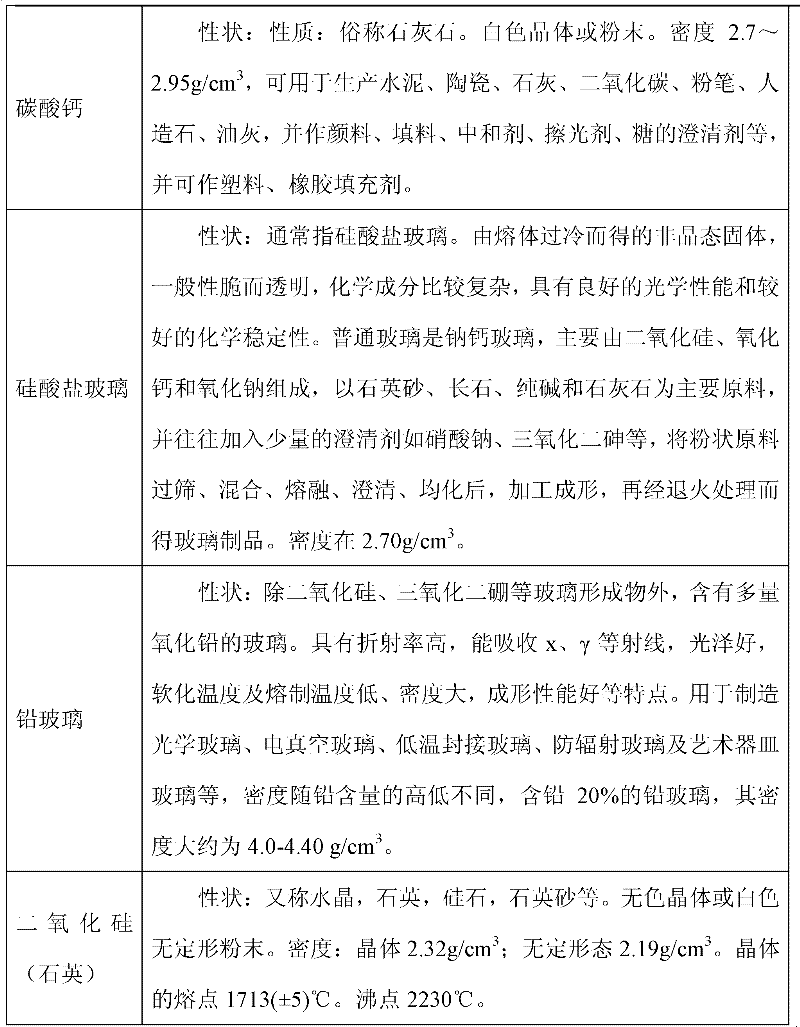

Method for separating each component in waste residue in crystal industry

InactiveCN102357398AHigh separation purityCreate pollutionPolishing compositionsWet separationInorganic compositionRare earth

The invention discloses a method for separating each component in waste residue in the crystal industry, and relates to a method for separating rare earth polishing powder, lead-containing crystal glass and other light components. The method is characterized in that the components are separated by a sorting technology in the mineral separation industrial according to the characteristic that the density of each component is larger in difference. The method comprises the following technical processes of milling crystal waste residue by milling equipment, so that the grain diameter of the waste residue reaches a certain size; mixing the milled waste residue; and repeatedly reelecting and sorting by reselection equipment. Higher-purity components within different density ranges are obtained after separation, so that the heavy component is the high-content rare earth polishing powder component, the intermediate component is the lead-containing crystal glass component, the light component is the inorganic composition which mainly contains the crystal glass, and the separated high-content component can be subsequently and cyclically utilized at a high added value. The method belongs to a physical separation method which is an environment-friendly, high-efficiency and low-cost processing method.

Owner:JINHUA GUANHUA CRYSTAL +1

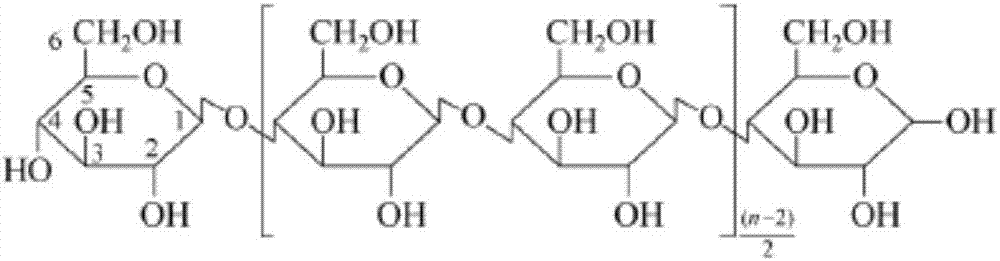

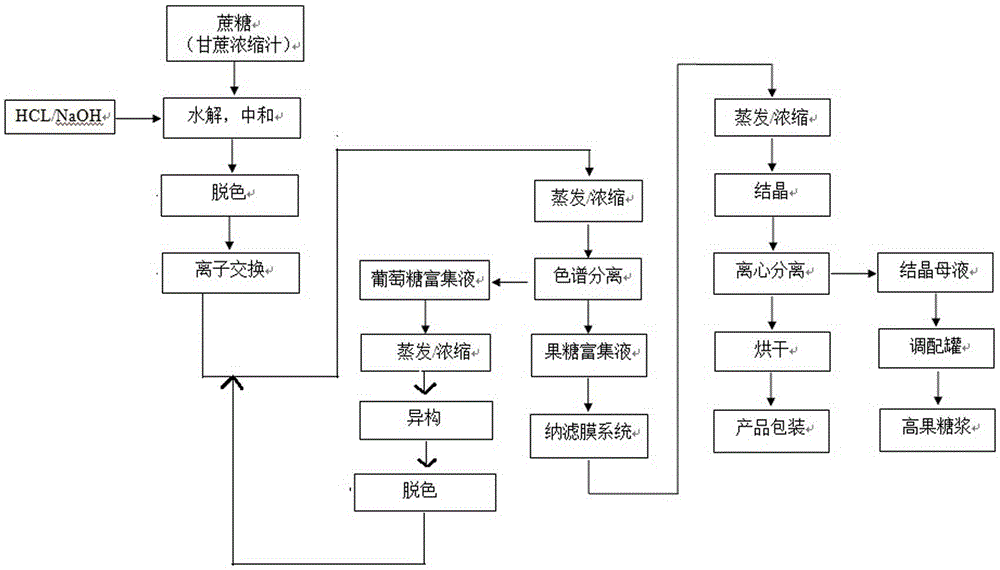

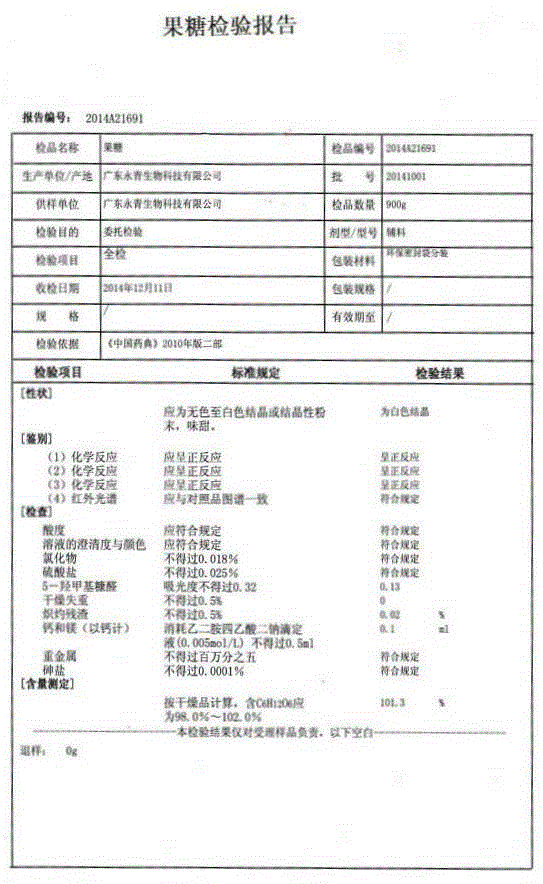

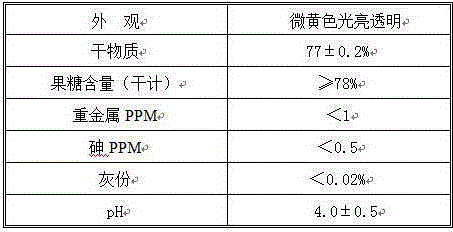

Method for preparing medicinal waterless crystallized fructose by taking sugarcane as raw material

PendingCN105331751AIncrease fructose contentIncreased spawn chanceFructose productionInvert sugar productionBiotechnologyHigh-fructose corn syrup

A method for preparing medicinal waterless crystallized fructose by taking sugarcane as raw material is disclosed. The technological process of the method comprises the following steps: performing cane juice squeezing concentration, preparing high fructose corn syrup, refining high fructose corn syrup, separating refined high fructose corn syrup, crystallizing fructose and recovering a glucose solution. In the method, the equipment and technological parameters of all procedures are comprehensively optimizes and reasonable matched, the method is suitable for industrialized production demand, equipment investment and production cost are substantially reduced, the once yield of the industrialized produced crystallized fructose product is up to 50%, the technology content of fructose production is improved, and the situation that fructose market severely depends on imported high-quality medicinal fructose and technology equipment thereof is solved.

Owner:姜蓉生

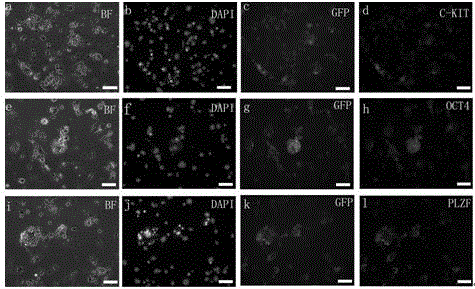

Method for efficiently separating mouse spermatogonial stem cells

InactiveCN105969723AHigh separation purityIncrease the number ofGerm cellsEnzyme digestionMale infertility

The invention discloses a method for efficiently separating mouse spermatogonial stem cells. The method includes the following steps that firstly, mouse testis are collected, and a testicular cell suspension is prepared through a two-step enzyme digestion method; secondly, the testicular cell suspension is inoculated in a porous plate according to a certain density, and a spermatogonial stem cell culture solution is added for in-vitro culture; thirdly, the culture solution is removed, testis cells of different times are cultured through tryptic digestion, and spermatogonial stem cells are sorted from the testis cells through the magnetic activated cell sorting; fourthly, the sorted spermatogonial stem cells are inoculated to an STO trophoblast, and a spermatogonial stem cell culture solution is added for primary culture and subculture of the spermatogonial stem cells. A mouse spermatogonial stem cell system is built through the method including the steps of separation, culture, re-separation and re-culture. The method can achieve the aim of efficiently enriching the spermatogonial stem cells in vitro, and is economical and easy to implement, so that a direction is provided for protection of rare animal varieties and treatment of male infertility.

Owner:INNER MONGOLIA UNIVERSITY

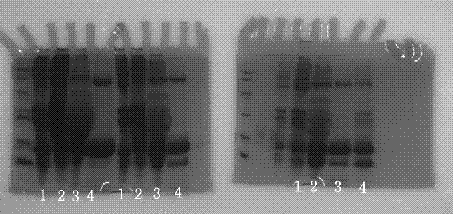

Method for separating beta-lactoglobulin from desalted whey powder

InactiveCN103923202AEasy to operateSimple processPeptide preparation methodsAnimals/human peptidesUltrafiltrationSalting out

The invention discloses a method for separating beta-lactoglobulin from desalted whey powder. According to the method, desalted whey powder is used as a treatment object which is subjected to ammonium sulfate salting out, primary ultrafiltration desalting, primary ion-exchange column chromatography, secondary ultrafiltration desalting, secondary ion-exchange column chromatography, gel chromatography and final separation so as to obtain beta-lactoglobulin with relatively high purity. Compared with the prior art, the method has the advantages that firstly, the operation is convenient, the process is simplified, related requirements are lowly required, and the operation can be carried out in a small laboratory; secondly, operators are lowly required, and the popularization and the application are convenient; thirdly, beta-lactoglobulin is relatively high in separation purity, the strip is clear and the separation is thorough; fourthly, the application range is wide, and different varieties of protein can be separated.

Owner:CHINA JILIANG UNIV

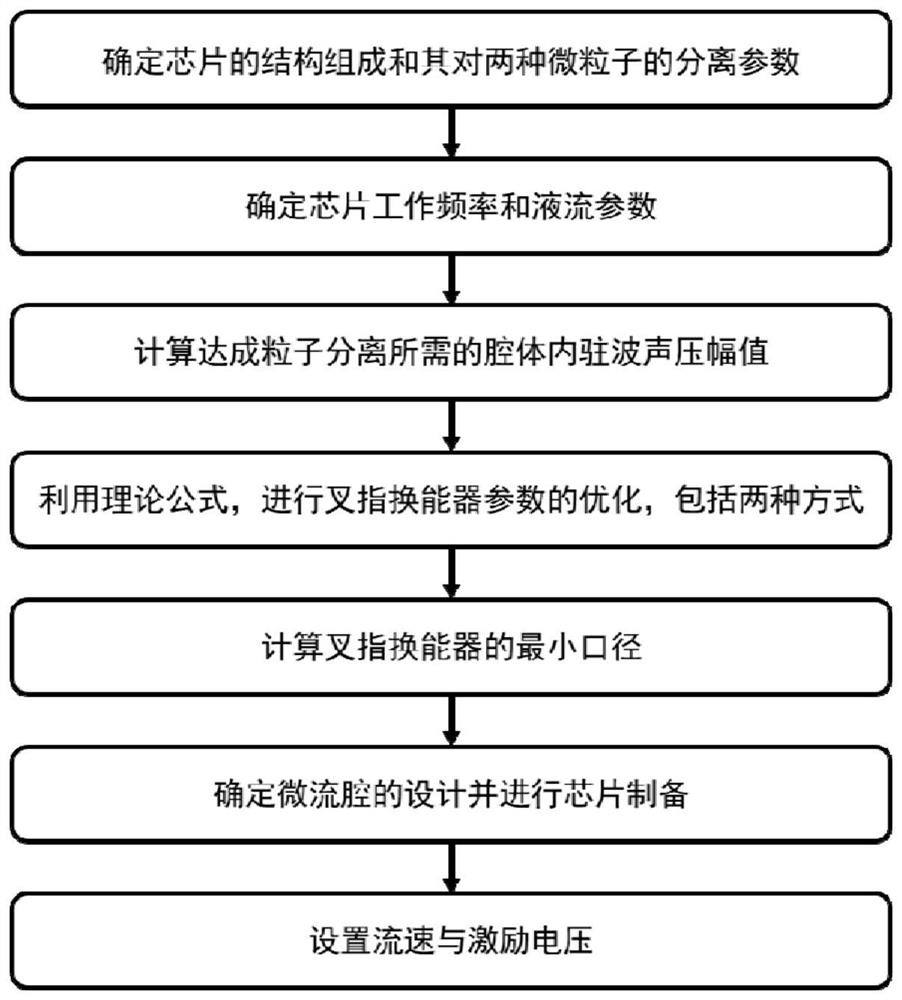

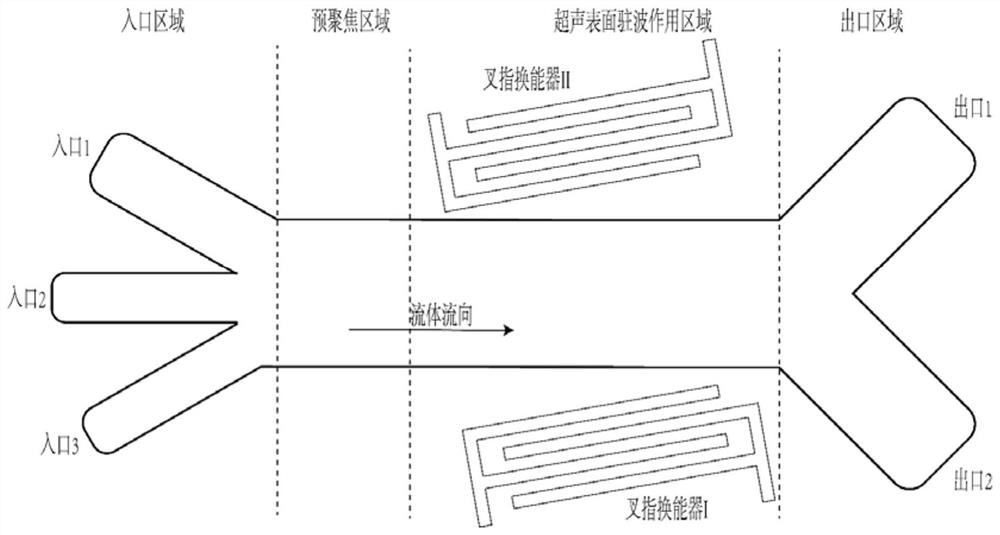

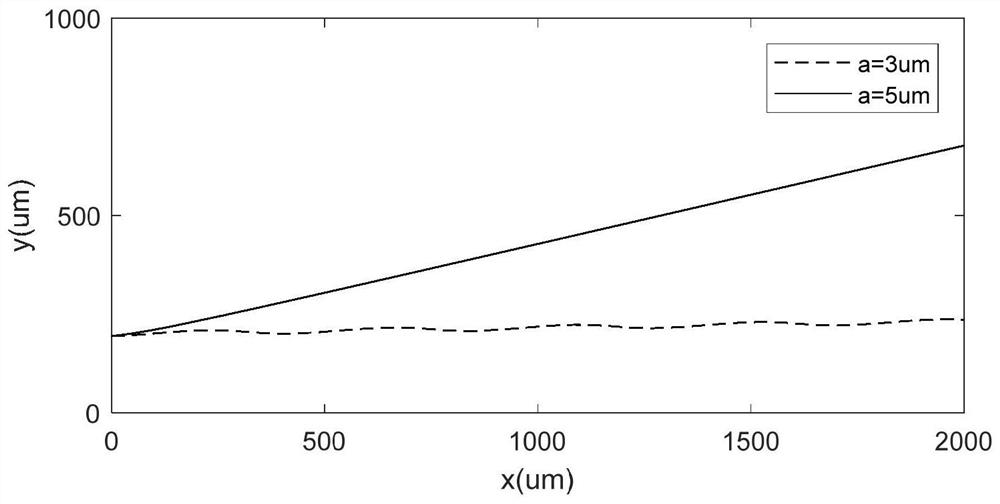

Design method of ultrasonic surface standing wave micro-fluidic chip for micro-particle separation

ActiveCN111659479AImprove separation efficiencyHigh separation purityLaboratory glasswaresFluid controllersEngineeringMechanical engineering

The invention discloses a design method of an ultrasonic surface standing wave micro-fluidic chip for micro-particle separation, belongs to the technical field of micro-fluidic analysis, and aims at the problems in the prior art that when a microfluidic chip is used for separating micro-particles, parameter design of the ultrasonic surface standing wave action area is judged only according to experience, particle separation efficiency is low and a large amount of time and cost are wasted. The invention provides a design method of a micro-fluidic chip for micro-particle separation. The method is based on the theory of stress and movement of micro-particles in an ultrasonic surface standing wave micro-fluidic chip. The method comprises the following steps: separating parameters of micro-particles and structure composition of a chip, determining the working frequency and the liquid flow parameters of the chip, further determining the design parameters of the interdigital transducer and the micro-fluidic cavity, finally determining the cavity design and the working parameters of the chip are determined, and based on the particle separation technology of the ultrasonic surface standingwave micro-fluidic chip, the device preparation difficulty is reduced, and the particle separation efficiency is improved.

Owner:NANJING UNIV

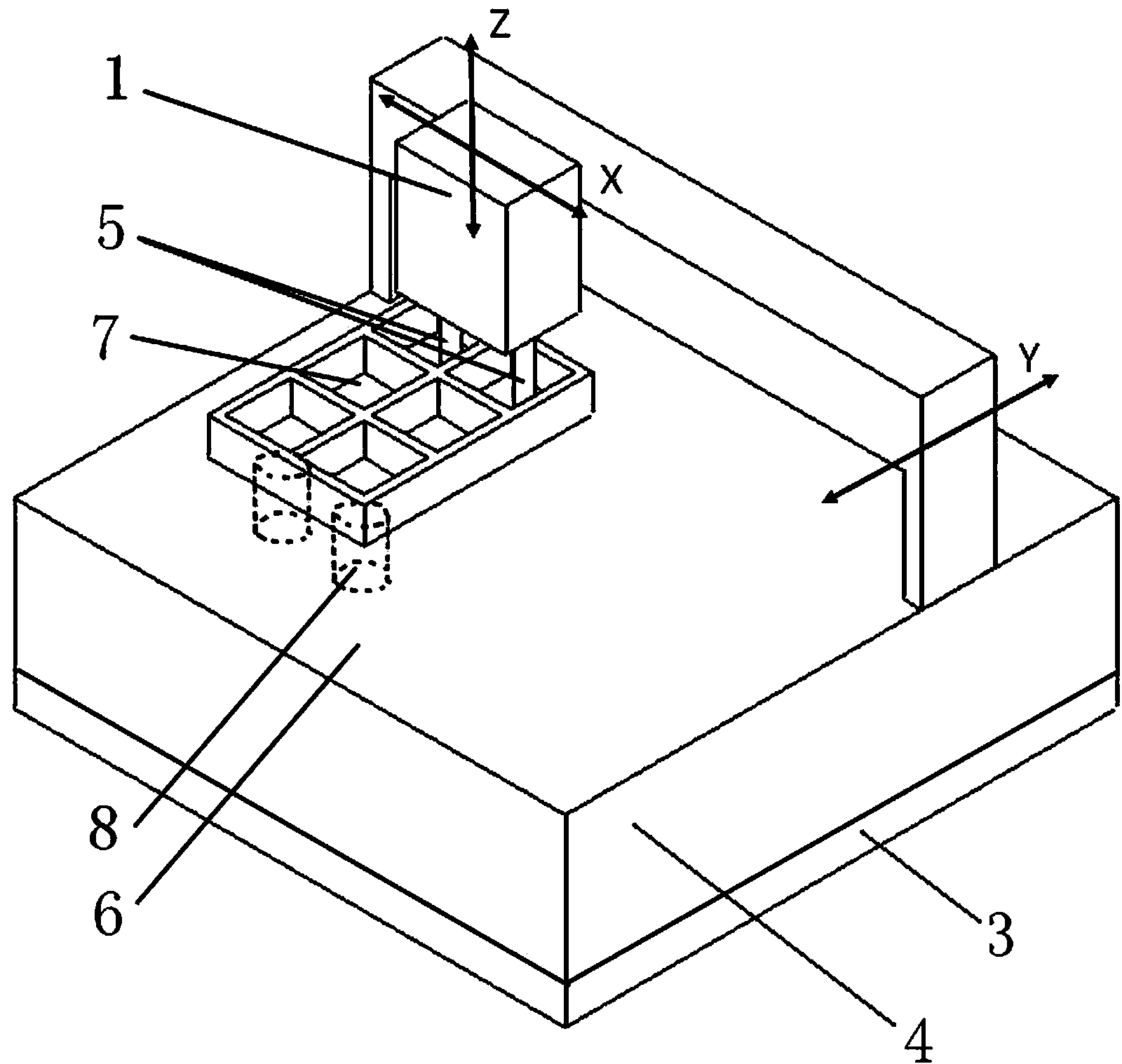

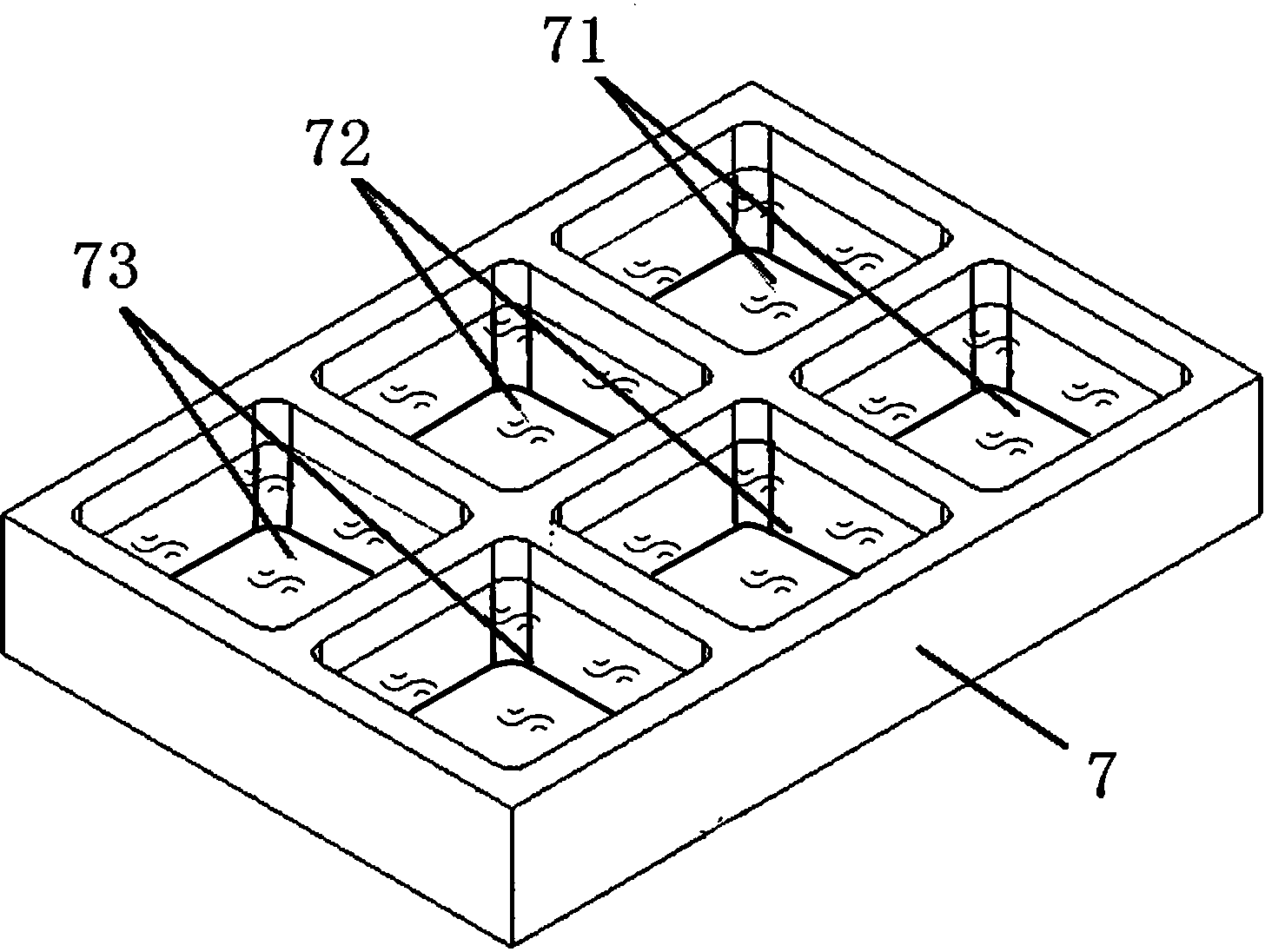

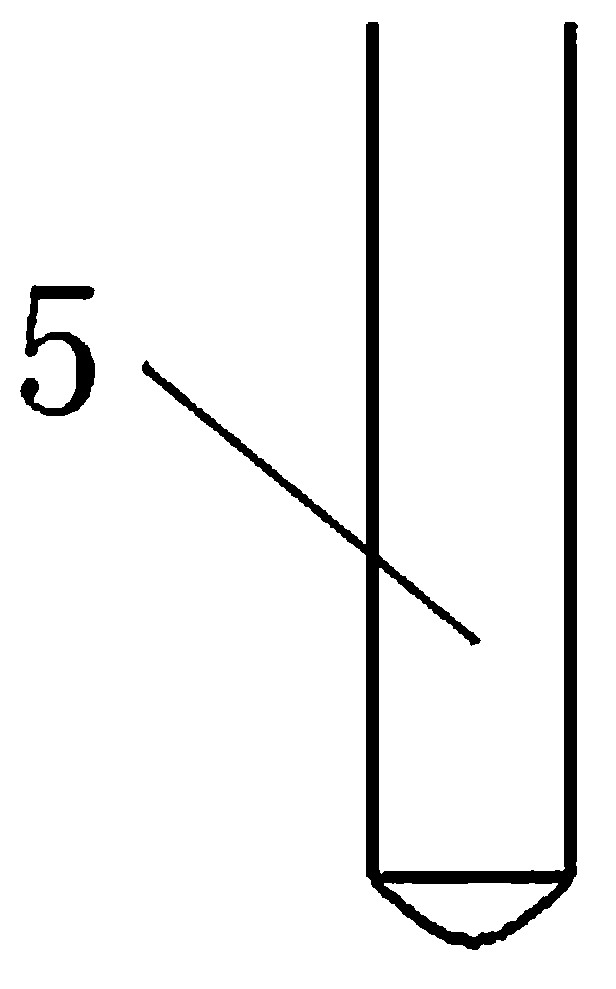

Magnetic probe search type cell sorting device

ActiveCN103642684AHigh sensitivity heightImprove reliabilityBioreactor/fermenter combinationsBiological substance pretreatmentsBiochemical engineeringManipulator

The invention relates to a magnetic probe search type cell sorting device. The sorting device is composed of a gantry type XYZ three-axis mechanical arm device, a mechanical arm digital controller, an engine base, a machine body, a magnetic probe, a probe fixture, a test board, a test box and a release magnet body, wherein the magnetic probe is connected to the probe fixture, the probe fixture is arranged on the gantry type XYZ three-axis mechanical arm device, the mechanical arm digital controller is connected with the gantry type XYZ three-axis mechanical arm device, the gantry type XYZ three-axis mechanical arm device is arranged above the test box, the test box is arranged on the table top of the test board, the test board is arranged on the machine body, the machine body is arranged above the engine base, and the release magnet body is arranged in the machine body and is located below the test box; sample liquid is filled in the test box, the magnetic probe is arranged on the probe fixture, the probe fixture can move in the gantry type XYZ three-axis mechanical arm device, the magnetic probe sucks and captures a target cell in the test box, and the release magnet body sucks the target cell to recycle and collect the target cell on the magnetic probe.

Owner:YUNNAN HUIBO TECH

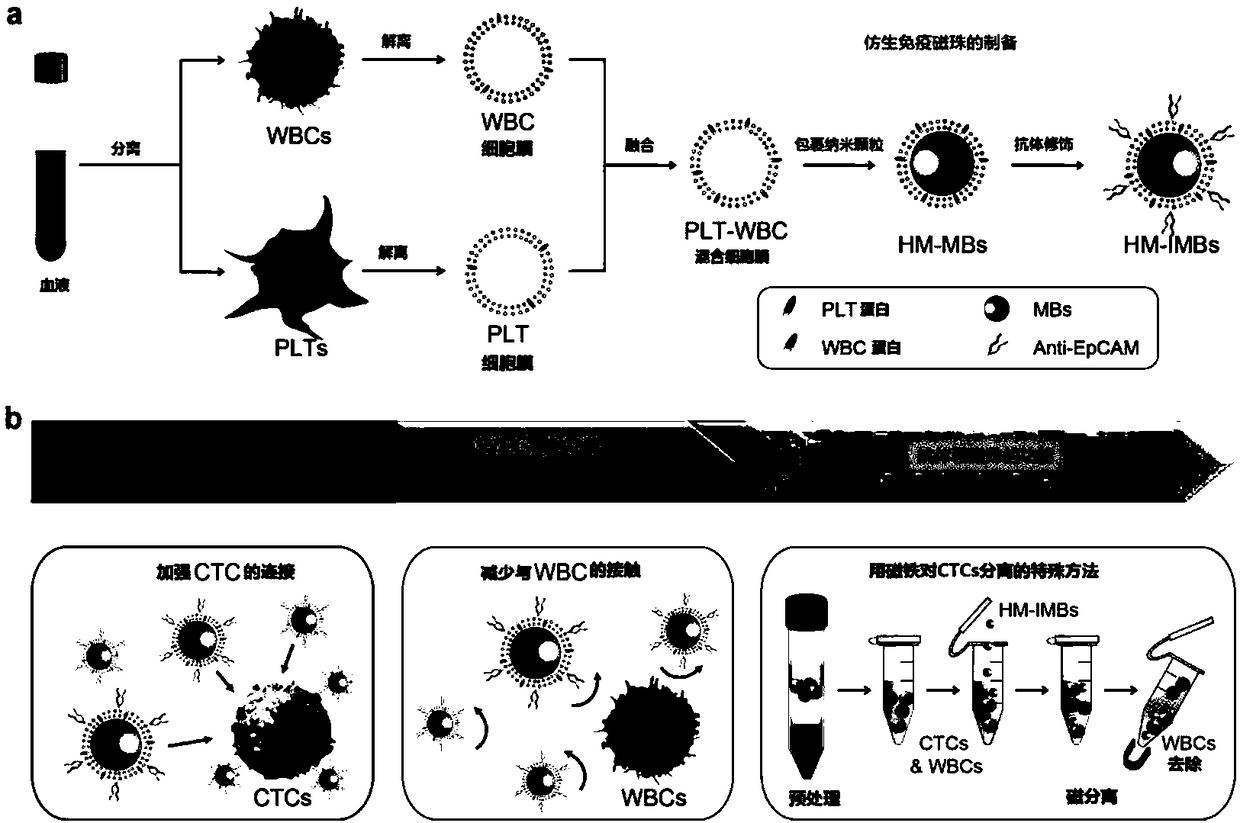

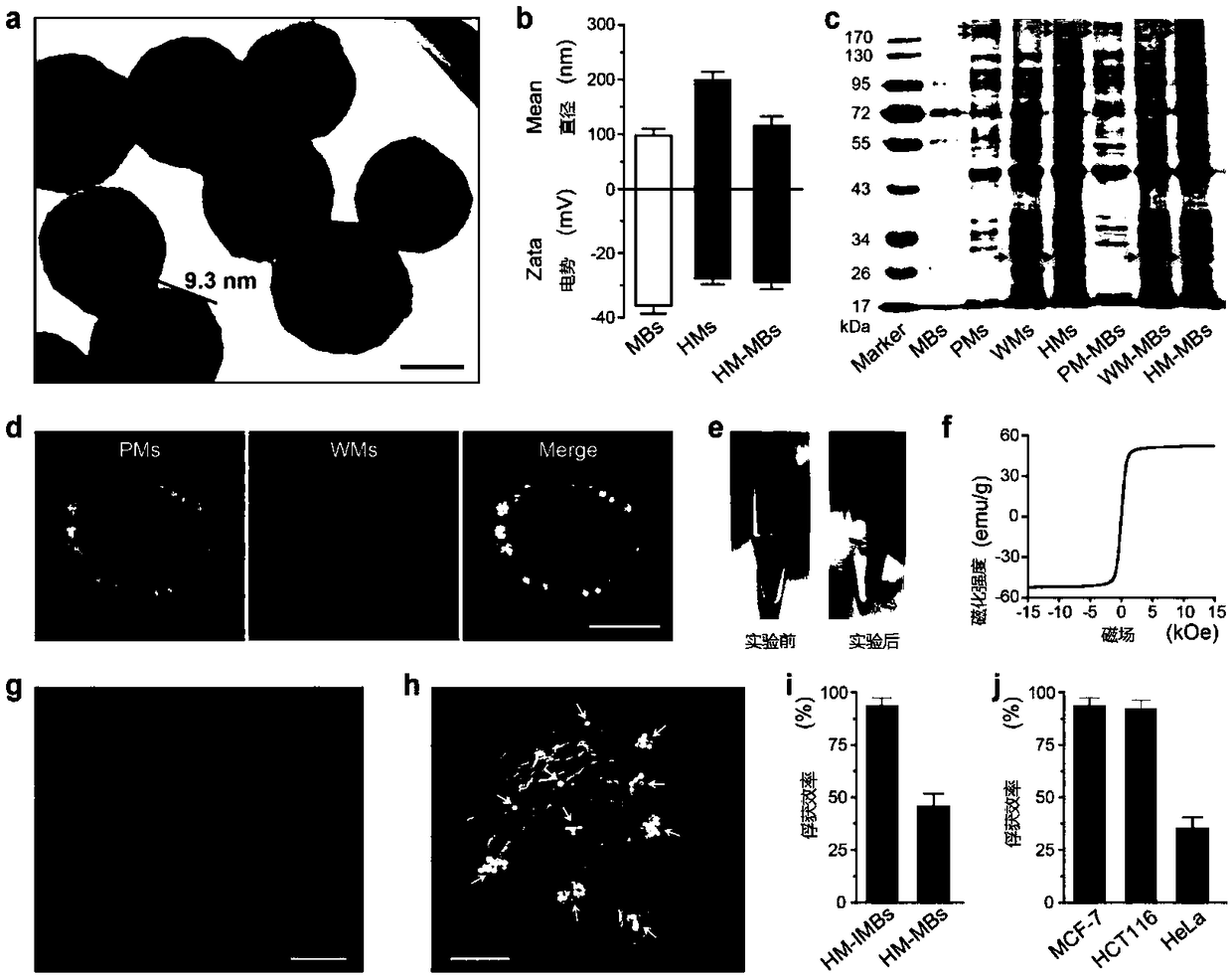

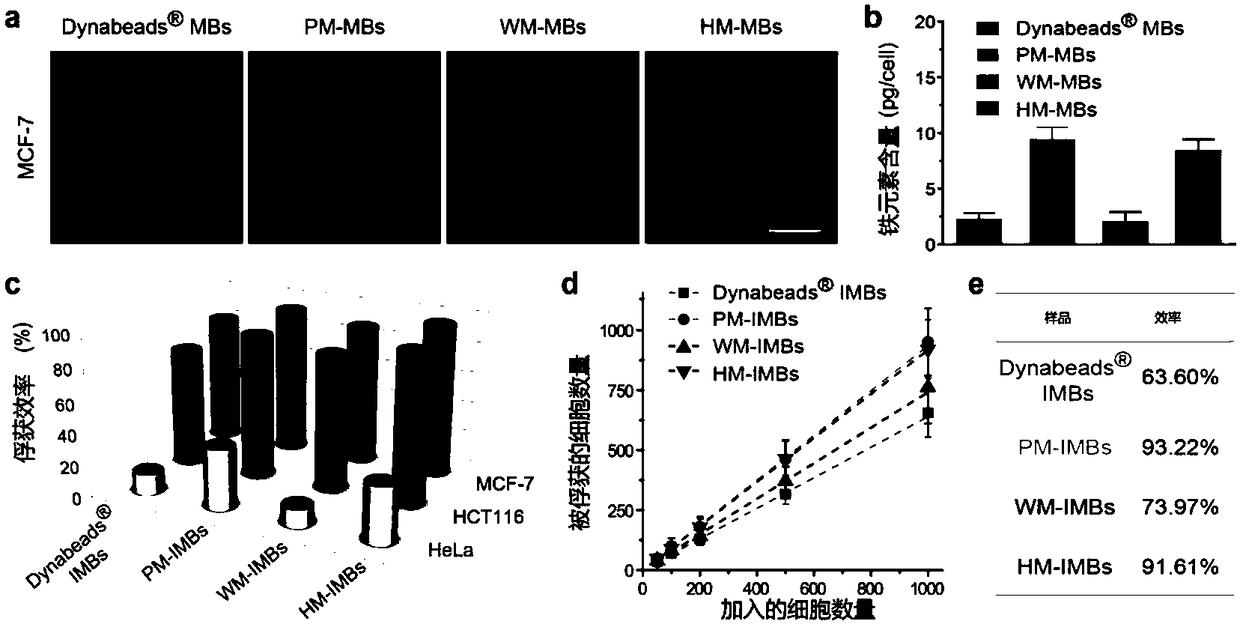

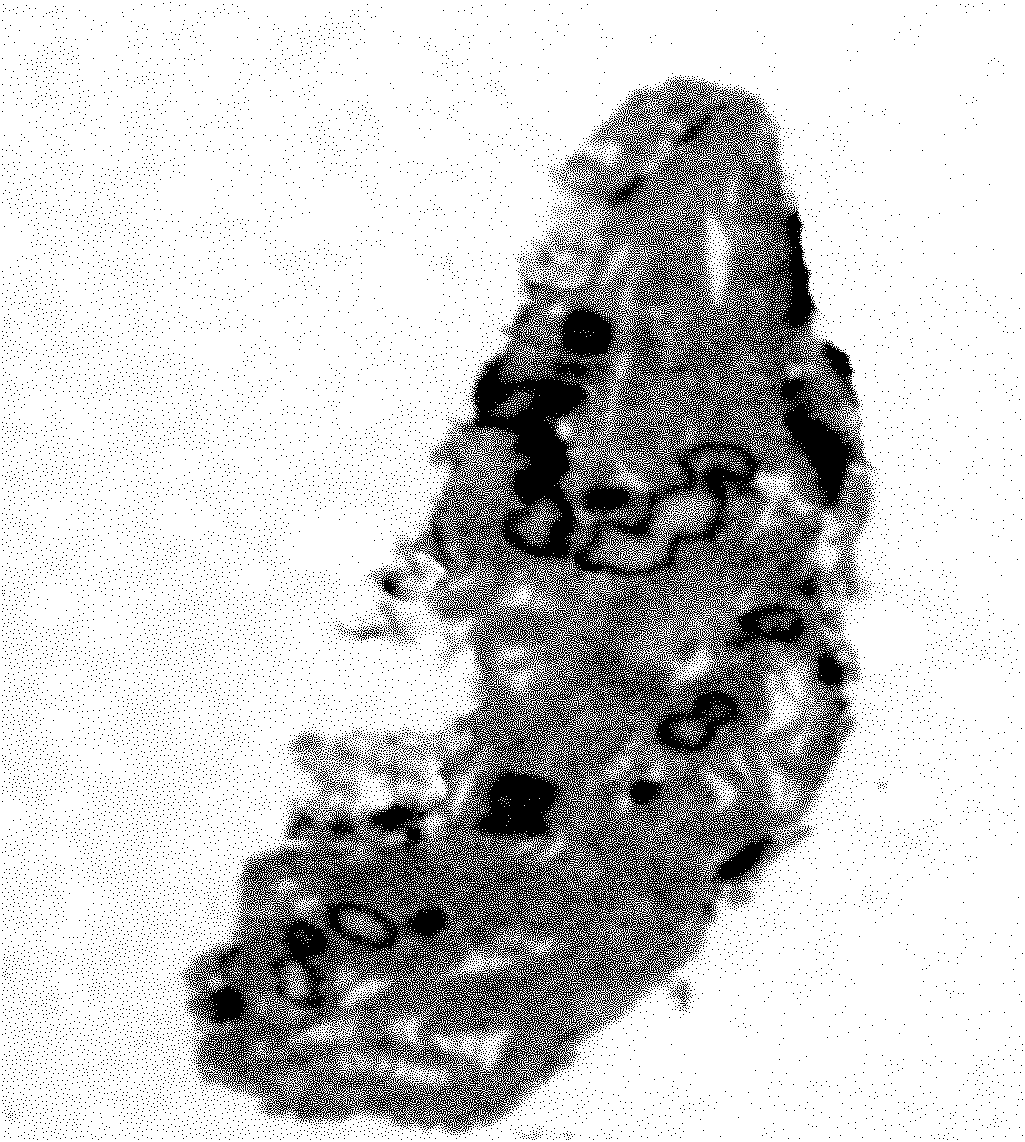

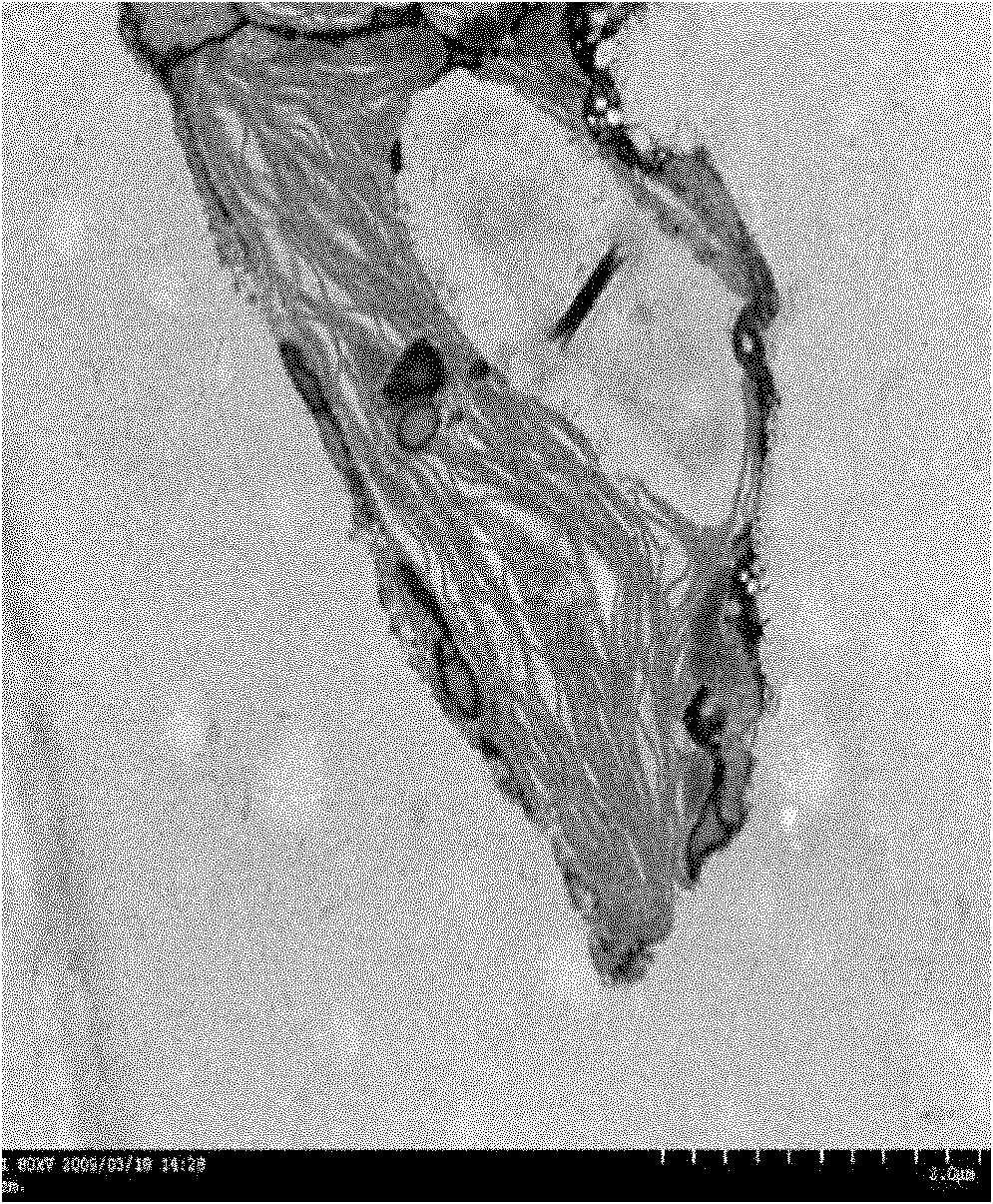

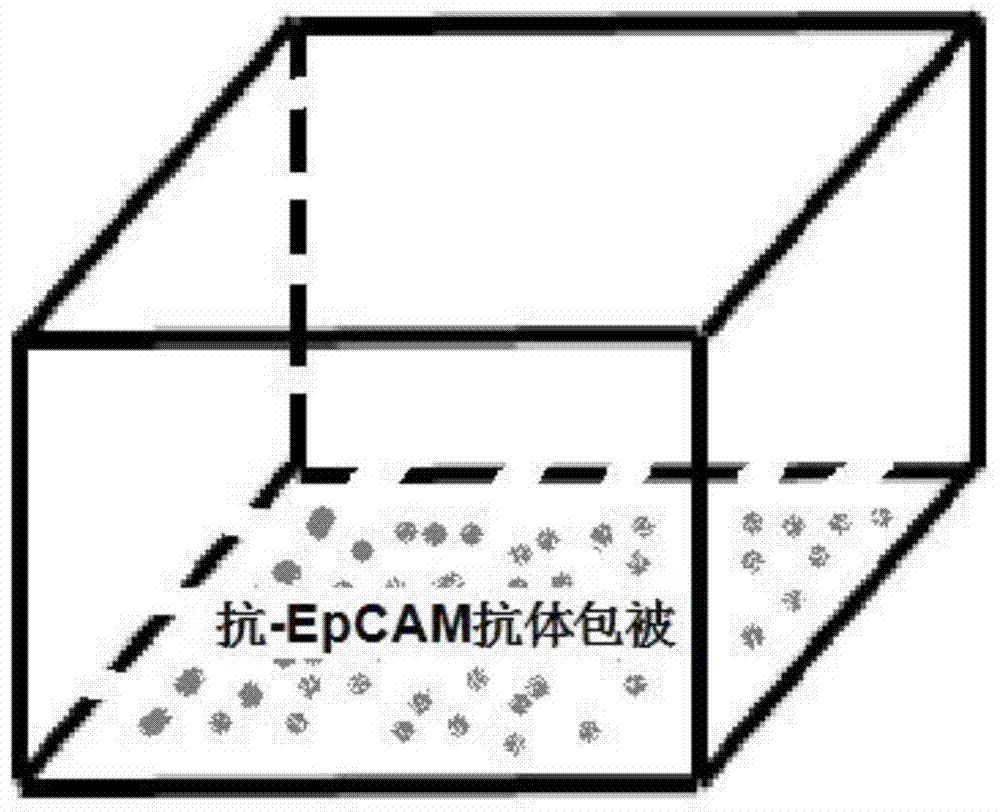

Platelet-leukocyte hybrid membrane-coated immunomagnetic beads and preparation method and application thereof

ActiveCN109100504AImprove separation efficiencyHigh separation purityMaterial analysisCancers diagnosisWhite blood cell

The invention discloses a platelet-leukocyte hybrid membrane-coated immunomagnetic beads and a preparation method and an application thereof. Magnetic beads were coated by using a hybrid membrane of platelet (PLT)-white blood cells (WBC), and then the surface thereof is modified with circulating tumor cells (CTCs)-specific antibodies to obtain PLT-WBC hybrid membrane-coated immunomagnetic beads (HM-IMBs). HM-IMBs inherit the enhanced CTC-binding ability from PLT and the ability to reduce homologous WBC interactions from WBC, therefore, the efficiency and the purity of the cell separation is effectively increased. According to the use of the HM-IMBs, 16 CTCs in clinical blood samples collected from patients with colorectal cancer, breast cancer, or gastric cancer were successfully identified, and the purity of isolated CTCs was greater than 85%. Therefore, this liquid biopsy tool will open up new areas of technology for cancer diagnosis and treatment.

Owner:江阴市珞珈飞流数字科技有限公司

Method for extracting intact chloroplast from ginkgo leaves

InactiveCN102021150AUniform gradientReduce stayEnzymesFermentationWoody plantGradient centrifugation

The invention relates to a technology for extracting intact chloroplast from high-yield officinal woody plant ginkgo rich in secondary metabolites, belonging to the biochemistry field. The method of the invention comprises the following steps of: preparing coarse chloroplast granules from ginkgo leaves in a special growth period, and then carrying out gradient centrifugation to Percoll to acquire chloroplast through special centrifugal force. The invention can effectively improve the purity and the integrity of the extracted chloroplast, the ginkgo chloroplast obtained by adopting the method reaches the integrity rate of above 80 percent, and the extracted chloroplast does not contain other impurities. The chloroplast granules are suitable for fundamental researches on cell biology, biochemistry, molecular biology, and the like.

Owner:NANJING NORMAL UNIVERSITY

Separation device for high temperature products of coal pyrolysis

InactiveCN106362879AFast and efficient passIncrease temperatureReversed direction vortexGas dust removalGas solidEngineering

The invention provides a separation device for high temperature products of coal pyrolysis. An gas-solid feeding opening is formed in one side of the upper end of a straight cylinder part and communicates with a cylinder inner cavity in the tangential direction of the cylinder wall; a heating media outlet is formed in the other side of the upper end of the straight cylinder part; a central pipe is arranged in the axial direction of the straight cylinder part and extends upward to the top end of the straight cylinder part to serve as a gas outlet; a filter screen is arranged in the gas outlet; the central pipe extends downward to the lower portion of a conical cylinder part; a circular-truncated-cone-shaped metal filter element and a conical gas collector are arranged at the bottom end of the central pipe; and a solid material outlet and a hot media inlet are formed in the lower portion of the conical cylinder part. According to the separation device for the high products of coal pyrolysis, intorting upflow is separated by the conical gas collector and the filter element quickly and effectively, and the separation effect is good; heating media are led into a cylinder interlayer to keep the temperature of gas-solid materials, tar precipitation is prevented, and material losses are reduced; and the separation efficiency and purity are further improved through the metal filter element and the filter screen arranged in the central pipe.

Owner:TAIYUAN UNIV OF TECH

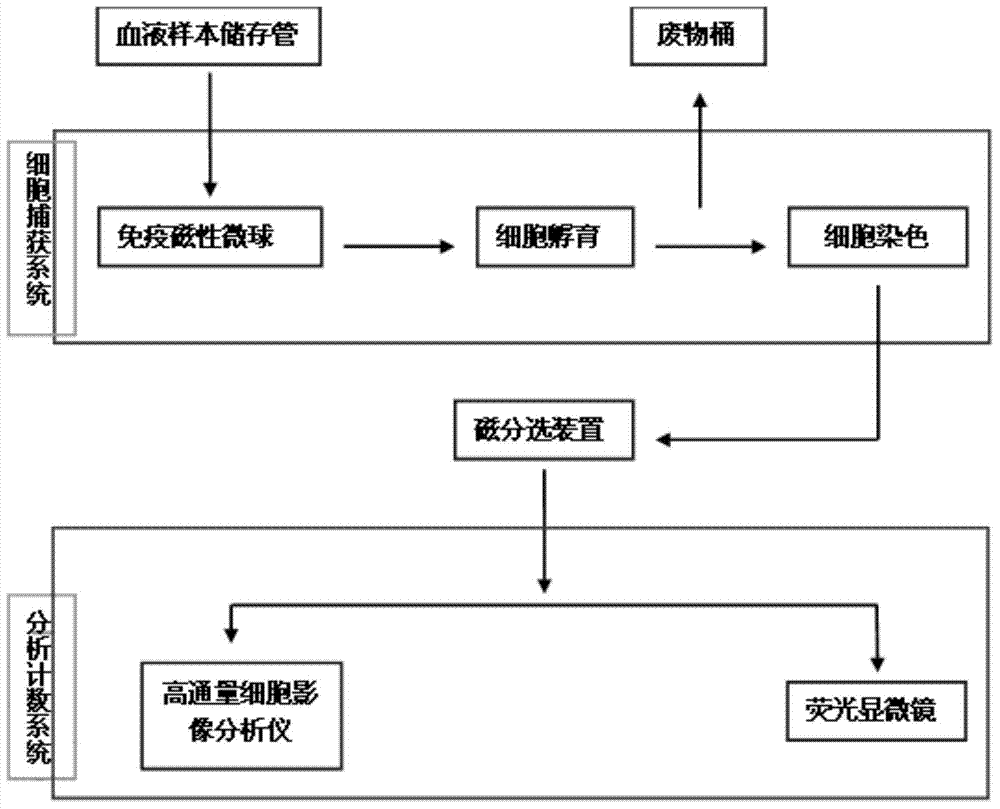

Breast cancer circulating tumor cells detection system and kit

ActiveCN103940997ARealize analysisImprove reliabilityDisease diagnosisMicrosphereEarly breast cancer

The invention relates to a breast cancer circulating tumor cells detection system and a kit, the detection system comprises a breast cancer circulating tumor cells capture system, a magnetic sorting apparatus and an analysis counting system; the breast cancer circulating tumor cells capture system comprises a functional enrichment box, an immunization magnetic microballoon, a cell incubation apparatus and a fluorescence coloring agent; the automatic magnetic sorting apparatus is used for enriching the tumor cells and performing fluorescence dyeing; the analysis counting system includes a fluorescence microscope and a high flux cell image analyzer; and the kit comprises the immunization magnetic microballoon and the fluorescence coloring agent. According to the invention, a magnetic cell sorting technology and an immunocytochemistry technology are combined for detecting peripheral blood circulation tumor cells, analysis and counting are carried out on the tumor cells by the analysis counting system, and the analysis on the molecule and gene aspects of the circulating tumor cells can be realized with high efficiency.

Owner:上海柏慧康生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com