Multi-level supersonic speed cyclone separator

A cyclone separator and supersonic technology, applied in cyclone devices, devices whose axial direction of cyclone remains unchanged, etc., can solve the problems of low gas-liquid separation efficiency and separation purity, and improve separation efficiency and separation purity. , the effect of reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

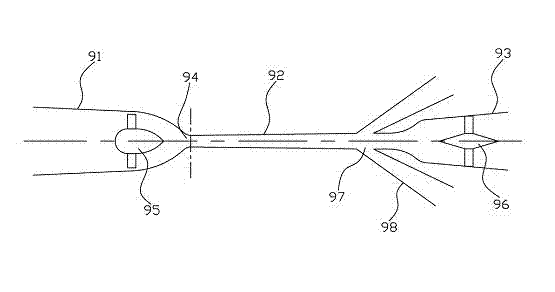

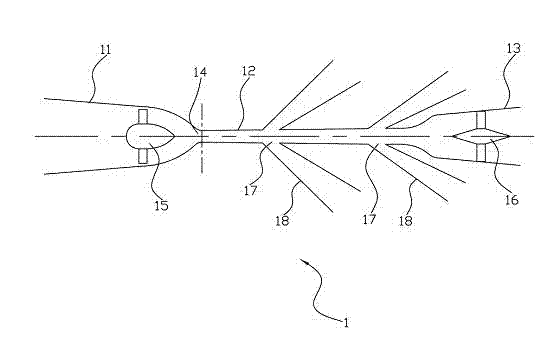

Embodiment 1

[0021] Such as figure 2 As shown, the multi-stage supersonic cyclone separator 1 provided by the first embodiment of the present invention includes a contraction tube 11, a supersonic condenser tube 12, and a diffuser tube 13 that are coaxially connected from left to right. The cross section of the contraction tube 11 It gradually decreases from left to right and shrinks to the middle into a narrow throat 14. The supersonic condenser tube 12 extends from the narrow throat 14 from left to right and the cross section gradually becomes larger. The cross section of the diffuser tube 13 gradually changes from left to right Large, the shrink tube 11 is provided with a rotating mechanism 15, the diffuser tube 13 is provided with a guide vane 16, and the supersonic condenser tube 12 is provided with at least two separation outlets 17 from left to right (that is, on the supersonic condenser tube 12). A plurality of separation outlets 17 before and after are provided, and the separation ...

Embodiment 2

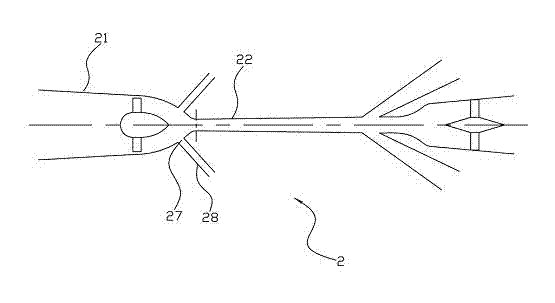

[0030] Such as image 3 As shown, the multi-stage supersonic cyclone separator 2 provided in the second embodiment of the present invention is approximately the same as the multi-stage supersonic cyclone separator 1 provided in the first embodiment. The difference is: The shrink tube 21 of the supersonic cyclone separator is also provided with at least one separation outlet 27, and the separation outlet 27 is also connected to a separation pipe 28. By providing at least one separation outlet 27 in the shrink tube 21, the liquid and solid impurities in the high-pressure gas that has not reached the speed of sound in the receiving tube 21 will be discharged from the separation outlet 27 on the shrink tube 21, and these liquid and solid impurities do not need to follow. The high-speed air flow is discharged from the separation outlet 27 on the supersonic condenser tube 22, which further reduces the energy loss of the high-speed air flow, thereby promoting the realization of higher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com