Recovering and treating process for waste printed circuit board and special clamp

A printed circuit board, recycling technology, applied in the direction of electronic waste recycling, recycling technology, manufacturing tools, etc., can solve the problems of increased energy consumption, increased cost of liquid nitrogen, complicated procedures, etc., to reduce pollution, improve purity, The effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

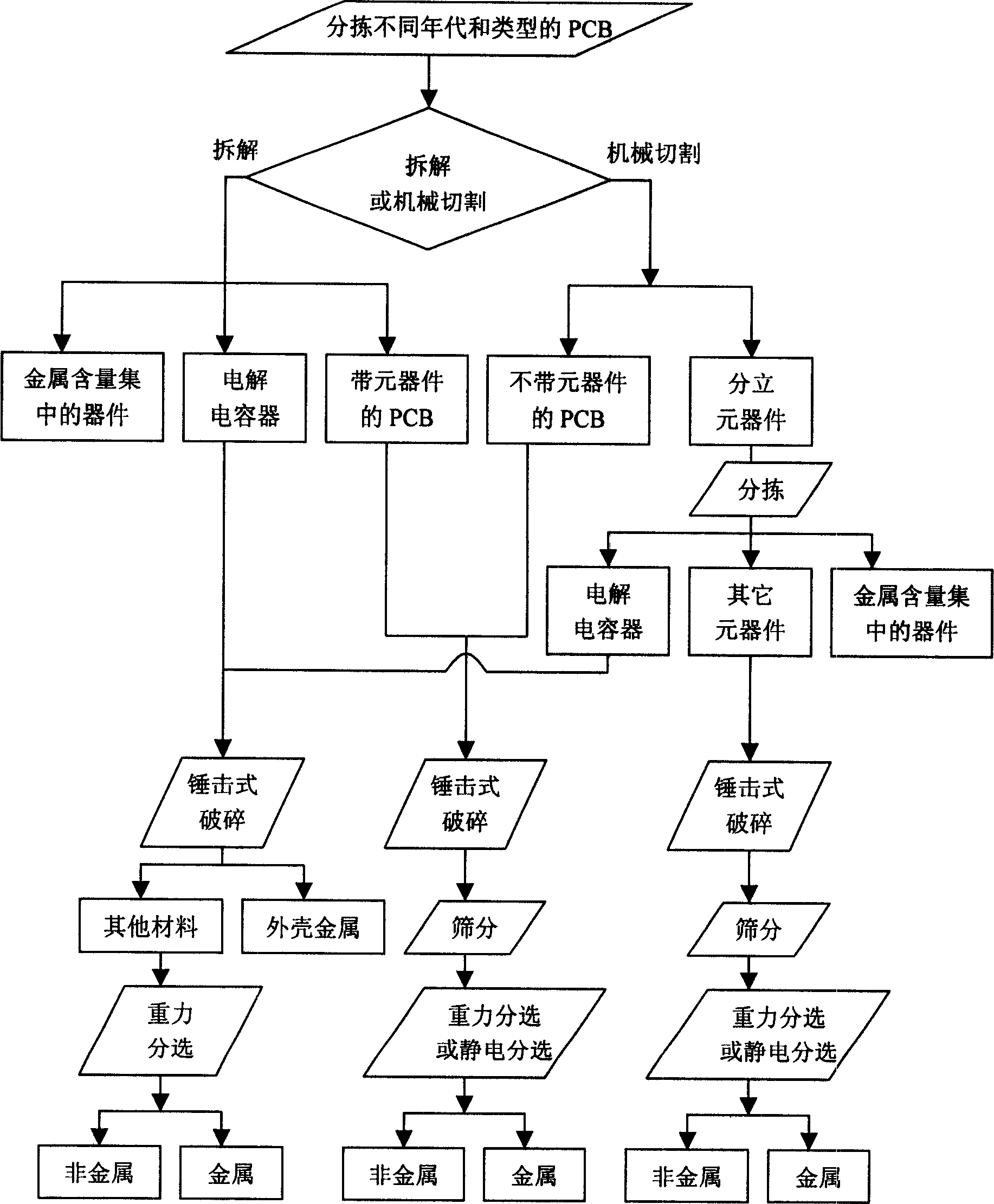

Method used

Image

Examples

example 1

[0040] Example 1: Remove the electrolytic capacitor and aluminum heat sink on the discarded computer motherboard, and then put the remaining PCB into a hammer crusher, using a wire mesh with a diameter of 3mm. After crushing, the separation of metal and non-metal reaches 95%. Above; use standard sieves such as 5 mesh, 10 mesh, 20 mesh, 26 mesh and 30 mesh to sieve the pulverized particles, and the particles of various meshes are separated by hydrocyclone method to separate metal and non-metallic materials, and the particles are centrifugally rotated The rotation speed is 50rpm, and after standing for 30s, the suspended material is released and filtered. The non-metallic material is on the top of the filter, and the water can be recycled; the material that sinks at the bottom of the suspension container contains more than 90% metal; the separation effect is shown image 3 .

[0041] The selected electrolytic capacitors are crushed by a hammer crusher, and a wire mesh with a dia...

example 2

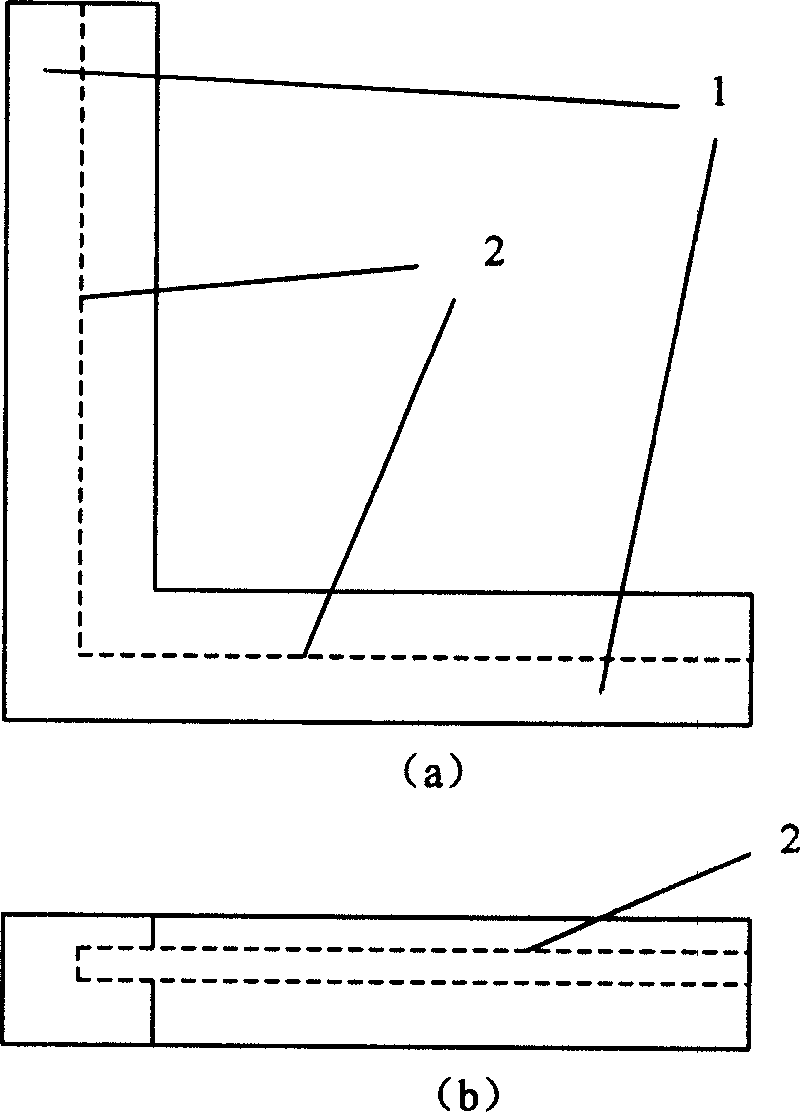

[0042] Example 2: the discarded welder power supply plate is fixed on the fixture made by the present invention, and the components are cut off from the substrate by using a shearing machine, thereby realizing 100% separation of the components and the substrate; from the separated components Manually pick out the electrolytic capacitors and coil windings. The length of the two arms of the fixture is 200mm, the thickness of the arm is 15mm, and the width of the arm is 15mm; the unilateral through groove is 3mm deep and 1.5mm wide, and the groove is 1.5mm away from one side of the two arms. Two 45 steel rods are used to mill the groove and then screw mechanically connected.

[0043] Cut the circuit board directly into small pieces of 100mm×100mm with a shearing machine, put the small pieces into a hammer crusher, use a wire mesh with a diameter of 3mm, and after crushing, the separation of metal and non-metal reaches more than 99%; Half of the particles were sieved with standar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com