Cyclone separator and spore separation device therewith

A technology for cyclone separator and spore separation, which is applied in the direction of the device whose axial direction can be reversed, the cyclone device, the method of using spores, etc. It can solve the problem of spore escape, affecting the purity of spore powder, and difficult to separate, etc. problem, to achieve the effect of simple structure, small occupied area, and complete separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

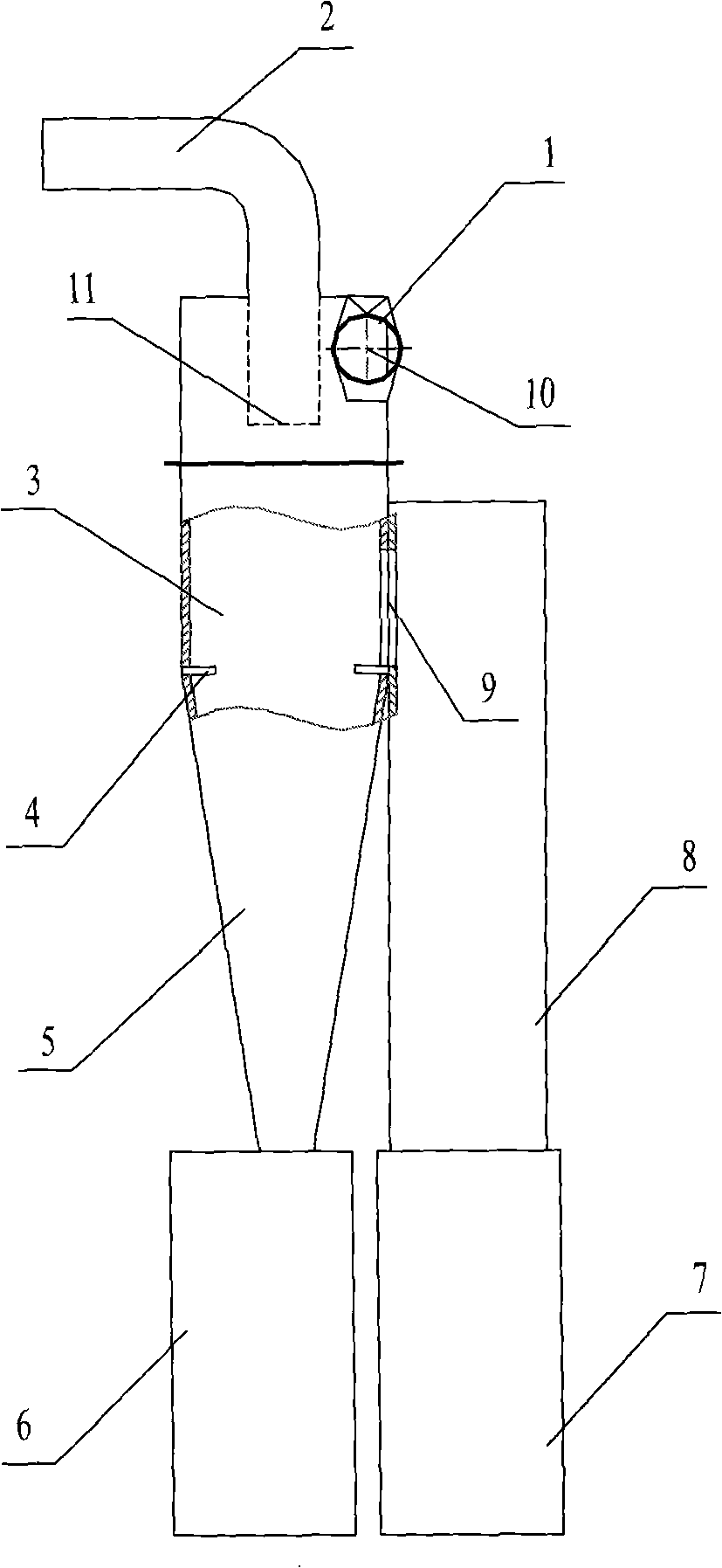

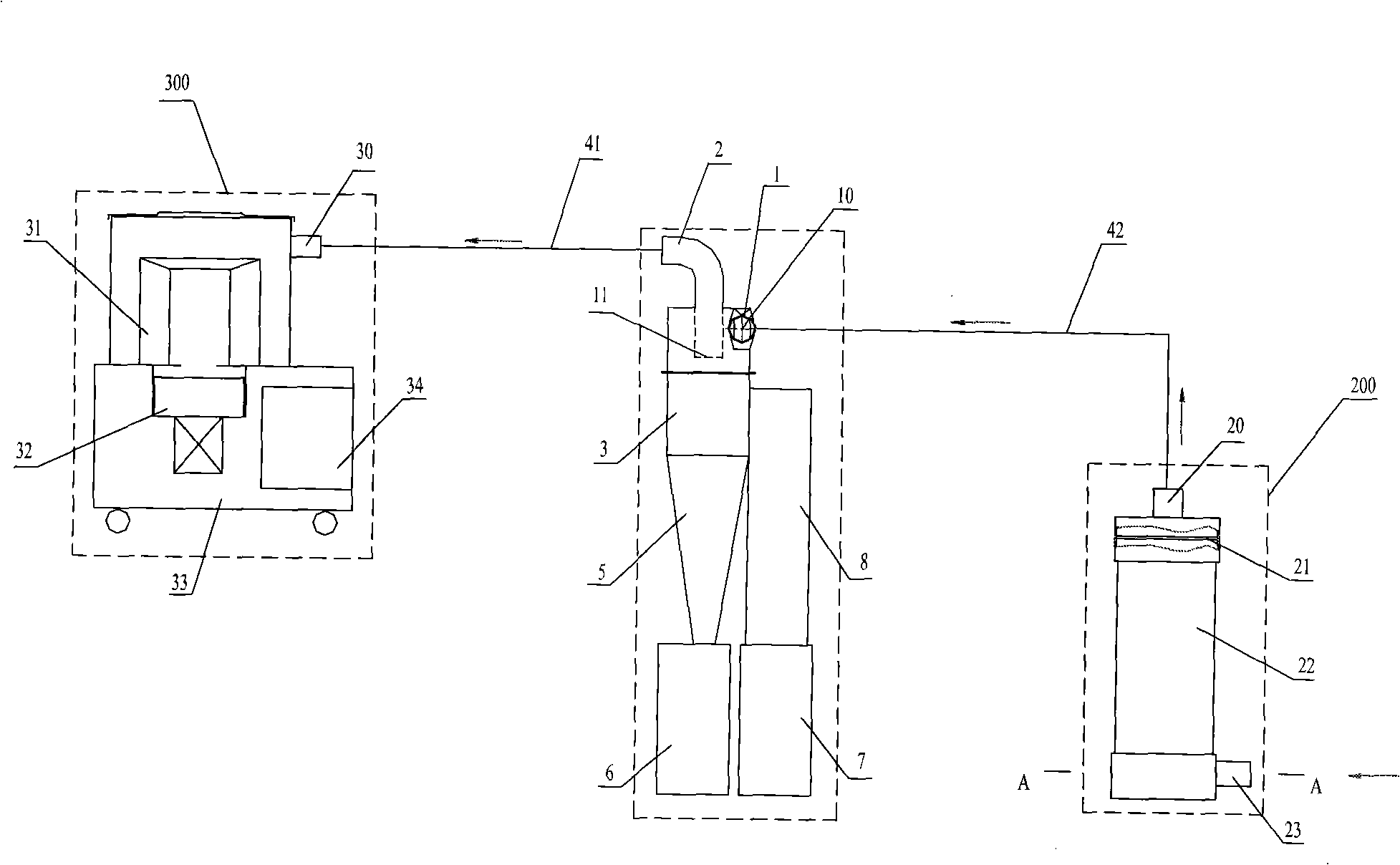

[0025] Embodiment 1. A cyclone separator includes a hollow primary separator and a hollow secondary separator 8 . The main separator includes a connected cylindrical body 3 and a cone 5, the cylindrical body 3 is located directly above the cone 5, that is, the central axis of the cylindrical body 3 overlaps with the central axis of the cone 5; the cone 5 is An inverted cone with a large top and a small bottom, the upper end of the cone 5 is connected with the cylindrical body 3 . The primary separator consisting of the cylindrical body 3 and the cone 5 and the secondary separator 8 are made of stainless steel.

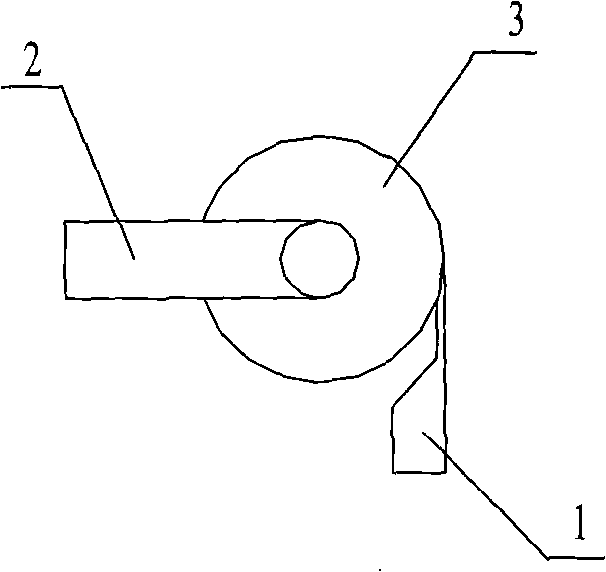

[0026] An air outlet channel 2 made of stainless steel is arranged on the top surface of the cylindrical body 3. The air outlet channel 2 is L-shaped. 11 is located in the inner cavity of the cylindrical body 3 . There is a cutout on the side wall of the cylindrical body 3, which is parallel to the tangent of the side wall of the cylindrical body 3, and the cutout is...

Embodiment 2

[0028] Embodiment 2. A spore separation device, comprising the cyclone separator as described in Embodiment 1, and further comprising a cyclone feeder assembly 200 and a fan assembly 300 .

[0029]The swirl feeder assembly 200 comprises a hollow cylindrical swirl feeder 22, the top surface of the swirl feeder 22 is provided with an outlet 20; Slit is arranged, and this otch is parallel with the tangent of swirl feeder 22 sidewalls, and this otch is close to the bottom surface of swirl feeder 22; The feed port 23 is perpendicular to the side wall of the swirl feeder 22; thereby realizing the tangential connection between the feed port 23 and the swirl feeder 22 side walls, and the feed port 23 and the swirl feeder The inner cavity of the feeder 22 is connected. A screen 21 is provided in the cyclone feeder 22 , and the screen 21 is located between the discharge port 20 and the feed port 23 ; that is, the screen 21 is located above the feed port 23 and below the discharge port ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com