Method for separating 6-gingerol from ginger

A gingerol and ginger technology, applied in the separation/purification of carbonyl compounds, organic chemistry, etc., can solve the problems of less research on the separation and extraction of active ingredients in ginger, no preparation of 6-gingerol monomer, etc., and achieve easy operation , high purity and high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

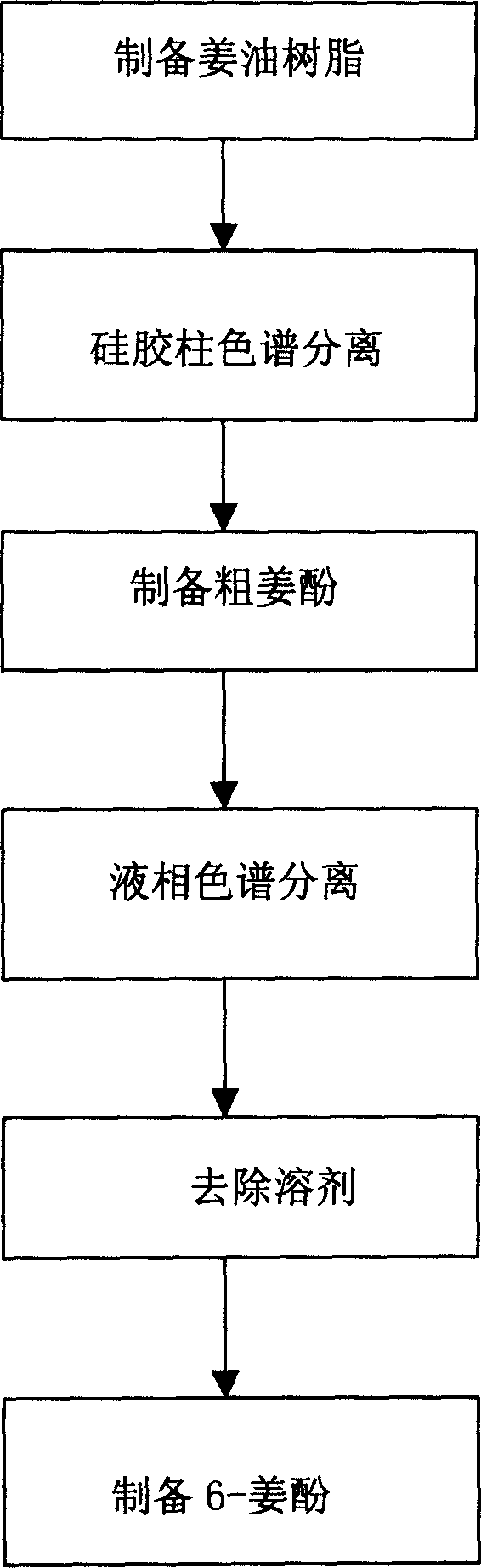

Image

Examples

Embodiment 1

[0027] (1) prepare ginger oleoresin

[0028] Fresh ginger is dried at low temperature and crushed to 100 mesh, soaked in acetone to obtain ginger oleoresin;

[0029] (2) Coarse separation by silica gel column chromatography

[0030] Column chromatography specification: 15mm×300mm; stationary phase: silica gel for chromatography, 160-200 mesh. Taking ginger oleoresin as a sample, the amount of stationary phase: 13.0 g, and the sample size: 0.3 g. At a flow rate of 0.8mL / min, sequentially use the mobile phase 1 (n-hexane: ether) = 2: 3, 2 (n-hexane:ether)=1:4, methanol 35mL each to wash the chromatographic column. Collect 2 (n-hexane: ether)=1:4 fraction section;

[0031] (3) prepare crude gingerol

[0032] The above-mentioned fraction containing 6-gingerol was placed on a rotary evaporator to evaporate the solvent to obtain crude gingerol;

[0033] (4) liquid chromatography separation

[0034] The crude gingerol was dissolved in ether to prepare a sample solution...

Embodiment 2

[0041] (1) prepare ginger oleoresin

[0042] Fresh ginger is dried at low temperature and crushed to 100 mesh, soaked in acetone to obtain ginger oleoresin;

[0043] (2) Coarse separation by silica gel column chromatography

[0044] Column chromatography specification: 20mm×400mm, stationary phase: silica gel for chromatography, 160-200 mesh. Taking ginger oleoresin as a sample, the amount of stationary phase: 35.0 g, and the sample size: 0.8 g. At a flow rate of 1.5mL / min, sequentially use the mobile phase 1 (n-hexane: ether) = 2: 3, 2 (N-Hexane: Ether) = 1:4, 110mL methanol each to wash the chromatographic column, collect 2 (n-hexane: ether)=1:4 fraction section;

[0045] (3) prepare crude gingerol

[0046] The above-mentioned fraction containing 6-gingerol was placed on a rotary evaporator to evaporate the solvent to obtain crude gingerol;

[0047] (4) liquid chromatography separation

[0048] Dissolve crude gingerol in ether to prepare a sample solution with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com