Separation and purification method of humus in wetland sediment

A purification method and sediment technology, applied in organic chemistry and other directions, can solve the problems of low extraction rate, high concentration of extractant, and time-consuming extraction and separation process for several hours, so as to improve the extraction efficiency and separation purity, and shorten the extraction time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

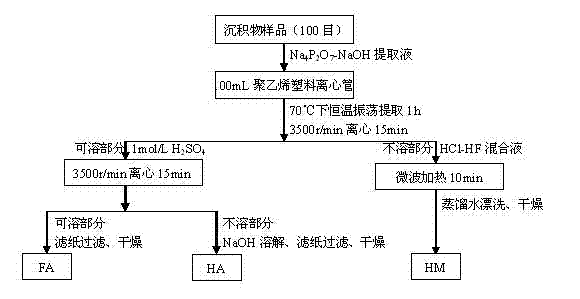

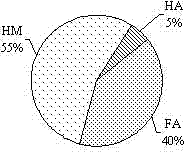

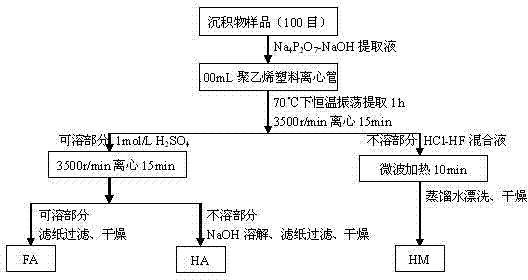

Method used

Image

Examples

Embodiment Construction

[0022] 1. Materials

[0023] 1. Wetland sediment sampling,

[0024] (1) Sediment sampling location: Huangpu River-Yangtze River estuary coastal wetland (N31°23’5.4’’ E121°30’28.3’’) sediment;

[0025] (2) Sediment collection and processing: Select the wetland sediment sampling area, set sampling points at intervals of 10m vertically and parallel to the river water direction, collect samples of 0-10cm and 10-20cm of the surface layer of the sediment respectively, and collect samples at the intersection of the vertical and parallel directions The section sediment samples were collected at an interval of 10 cm in the vertical direction downward; the collected sediment samples were removed from residual roots and debris, air-dried, and passed through a 100-mesh sieve for later use.

[0026] (3) Basic physical and chemical properties of the sediment: pH 7.93, organic matter 7.08g / kg, clay content 26.14%, Kjeldahl nitrogen content 635.71 mg / kg, phosphorus content 913.97 mg / kg, pota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com