Separation device for high temperature products of coal pyrolysis

A separation device and coal pyrolysis technology, which is applied in the direction of the swirl axis can be reversed device, swirl device, gas dust removal, etc., can solve the problems of reduced tar yield, low density, small centrifugal force, etc., to achieve reduction Material loss, improving separation efficiency and purity, and preventing tar precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

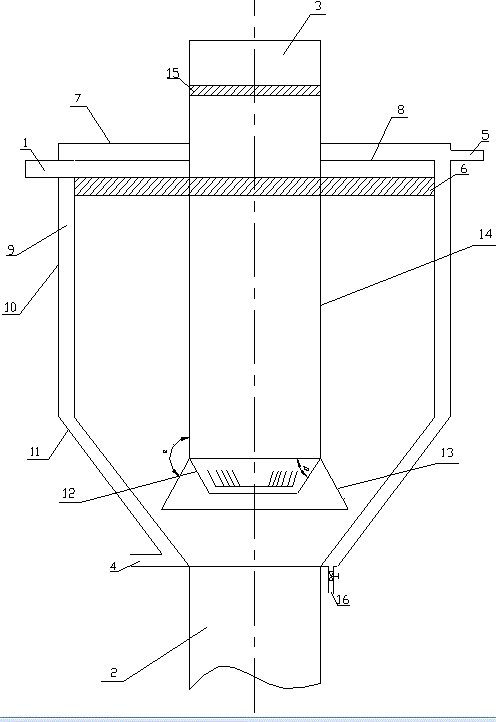

[0017] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0018] as attached figure 1 As shown, the separation device for coal pyrolysis high-temperature products provided above to implement the present invention includes a cylinder body composed of a straight cylinder part 10 and a cone cylinder part 11 . A heating medium channel is formed between the inner surface of the inner wall 7 of the cylinder and the outer surface of the outer wall 8 of the cylinder. A gas-solid feed port 1 and a heating medium outlet 5 are arranged on the upper part of the cylinder body. The gas-solid feed port 1 is cut along the wall of the cylinder. Set in the opposite direction, communicating with the inner cavity of the cylinder. A guide vane 6 is arranged below the gas-solid feed inlet, and a solid material outlet 2 and a heating medium inlet 4 are arranged at the lower part of the cylinder. A central tube is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com