Production line of pure water demanded by production of purified water, wine and beverages

A pure water and production line technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve reverse osmosis membrane damage, reduced pure water volume, and reverse osmosis membrane working strength Large and other problems, to achieve the effect of increasing water production, reducing workload and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

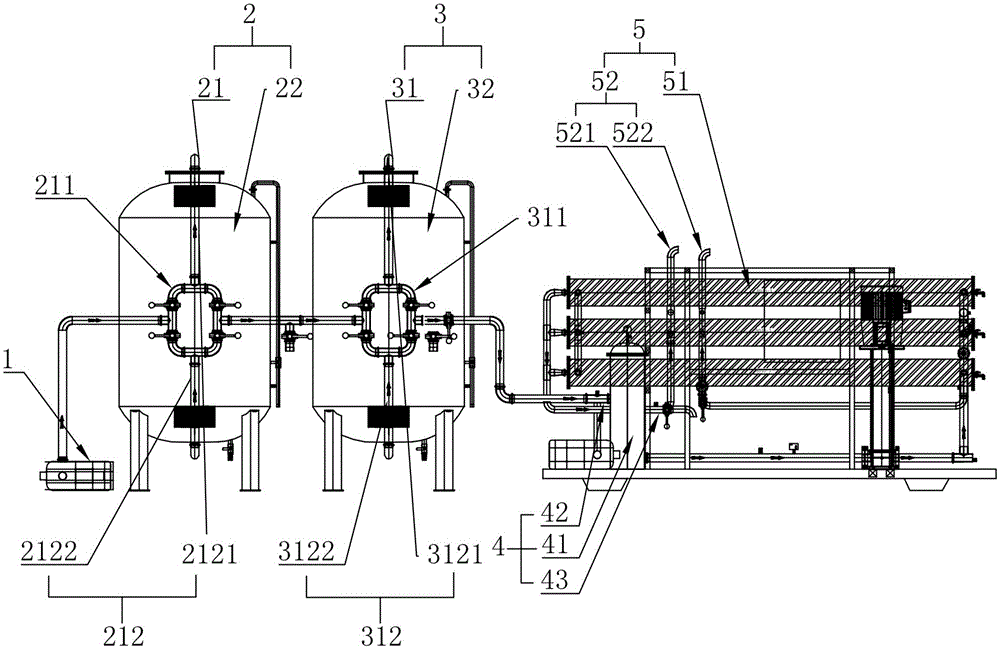

[0012] refer to figure 1 As shown, a production line for pure water, wine and beverage production in this embodiment includes a quartz sand filter 2, an activated carbon filter 3, a precision filter 4, a reverse osmosis device 5 and a source for extracting external water sources The water pump 1, the reverse osmosis device 5 includes a reverse osmosis membrane 51 and a water outlet 52, wherein the source water is sucked from the source water pump 1, and then enters the reverse osmosis through a quartz sand filter 2, an activated carbon filter 3, and a precision filter 4. In the membrane 51, it flows out from the water outlet 52. When drinking water needs to be produced, the external source water is first drawn in by the source water pump 1, and then enters the quartz sand filter 2. After being filtered by the quartz sand filter 2, The silt and other large particles inside the source water will be filtered out, and then the water will enter the activated carbon filter 3, and af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com