Continuous recycling method of NMP (N-methyl pyrrolidone) solvent for polyphenylene sulfide production device

A production device, polyphenylene sulfide technology, applied in the field of continuous recovery of N-methylpyrrolidone solvent, can solve the problems of increasing equipment maintenance time, increasing NMP solvent loss, easy blockage of tower kettle and pipeline, etc., to achieve The effect of saving steam consumption and cooling consumption, reducing adhesion effect, and reducing the use of steam and cooling consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the devices and embodiments of the accompanying drawings, but does not impose any limitation on the present invention.

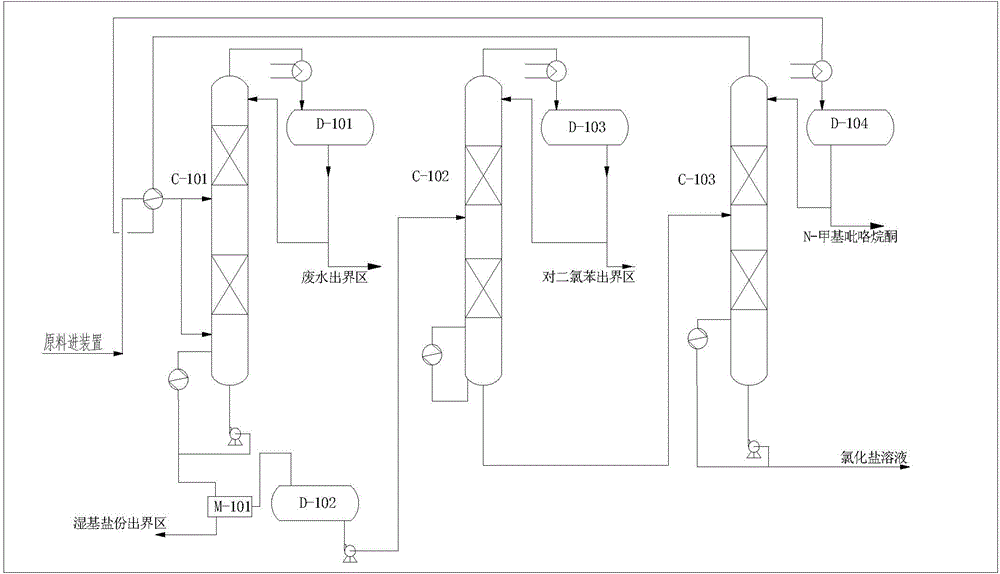

[0013] The solvent recovery process of the polyphenylene sulfide production plant is composed of three rectification tower systems. After the raw material is preheated, it enters the rectification tower C-101, and removes water at the top of the tower. With the removal of water, the liquid in the bottom of the tower gradually becomes thicker. Disturbance of the salt in the liquid prevents crystallization from clogging the tower kettle and pipes, the other part enters the centrifuge for separation, the wet base salt is sent out of the boundary, and the liquid component enters the rectification tower C-102. The rectification tower C-102 distills the component p-dichlorobenzene at the top of the tower and sends it outside the boundary area, and the bottom component is extracted and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com