Sorting method and equipment for reprocessed plastic

A technology for recycled plastics and sorting, applied in the field of waste recycling, can solve the problems of difficult to achieve high-purity raw material grade standards, difficult to achieve automatic flow operations, uneven processing conditions, etc., to achieve low cost, easy to implement, The effect of less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

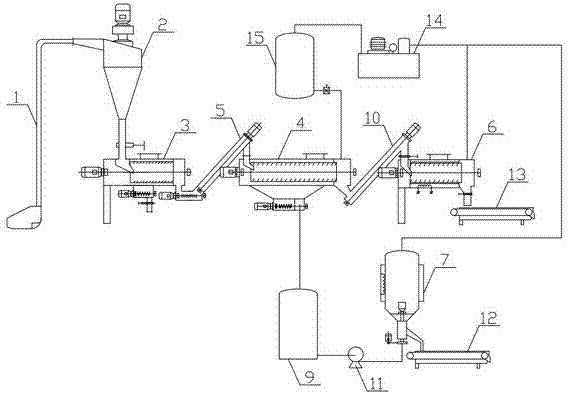

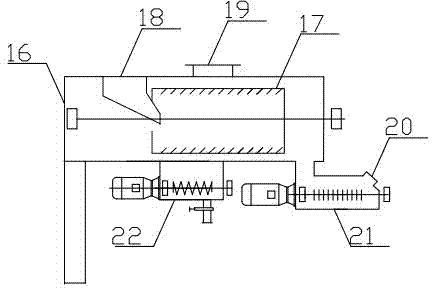

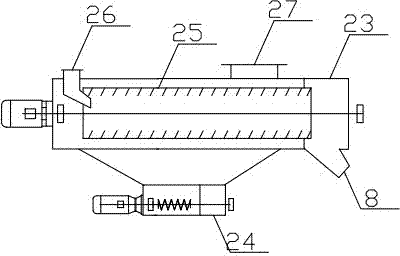

Image

Examples

Embodiment 1

[0042] A sorting method for recycled plastics, comprising the steps of:

[0043] (1) Crush the materials to be separated containing plastics A and B, remove impurities in the materials, and set aside;

[0044] (2) Add a solvent to the material to fully swell A; the solvent swells A but not B;

[0045] (3) Beating the swollen material, crushing the swollen A into a slurry, and obtaining a slurry of A and a mixture of B;

[0046] (4) Sorting the mixture of the slurry of A and B, drying the sorted plastic B to obtain plastic B; spray drying the slurry of A, and then centrifugally granulating to obtain plastic A.

Embodiment 2

[0048] The plastic A is PVC, the plastic B is PET, and the solvent is tetrahydrofuran.

[0049] Follow the steps below to sort:

[0050] (1) Crush the material to be separated containing plastic PVC and PET, the diameter of the crushed material is less than 1cm, remove the impurities in the material, and set aside;

[0051] (2) Add tetrahydrofuran to the material to fully swell PVC;

[0052] (3) Beating the swollen material, crushing the swollen PVC into pulp to obtain a mixture of PVC slurry and PET;

[0053] (4) Sorting the mixture of PVC slurry and PET, drying the sorted PET to obtain PET; spray-drying the PVC slurry, and then centrifugally granulating to obtain PVC.

Embodiment 3

[0055] Plastic A is PVC, plastic B is PET, and solvent uses cyclohexanone.

[0056] Follow the steps below to sort:

[0057] (1) Crush the material to be separated containing PVC and PET, the diameter of the crushed material is less than 1cm, remove the impurities in the material, and set aside;

[0058] (2) Add cyclohexanone to the material to fully swell PVC;

[0059] (3) Beating the swollen material, crushing the swollen PVC into pulp to obtain a mixture of PVC slurry and PET;

[0060] (4) Sorting the mixture of PVC slurry and PET, drying the sorted PET to obtain plastic PET; spray-drying the PVC slurry, and then centrifugally granulating to obtain PVC.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com