A kind of full-fit frame glue for touch screen and preparation method thereof

A full lamination and touch screen technology, applied in adhesives, adhesive additives, polymer adhesive additives, etc., to achieve low shrinkage, avoid equipment tailing, and meet operational requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

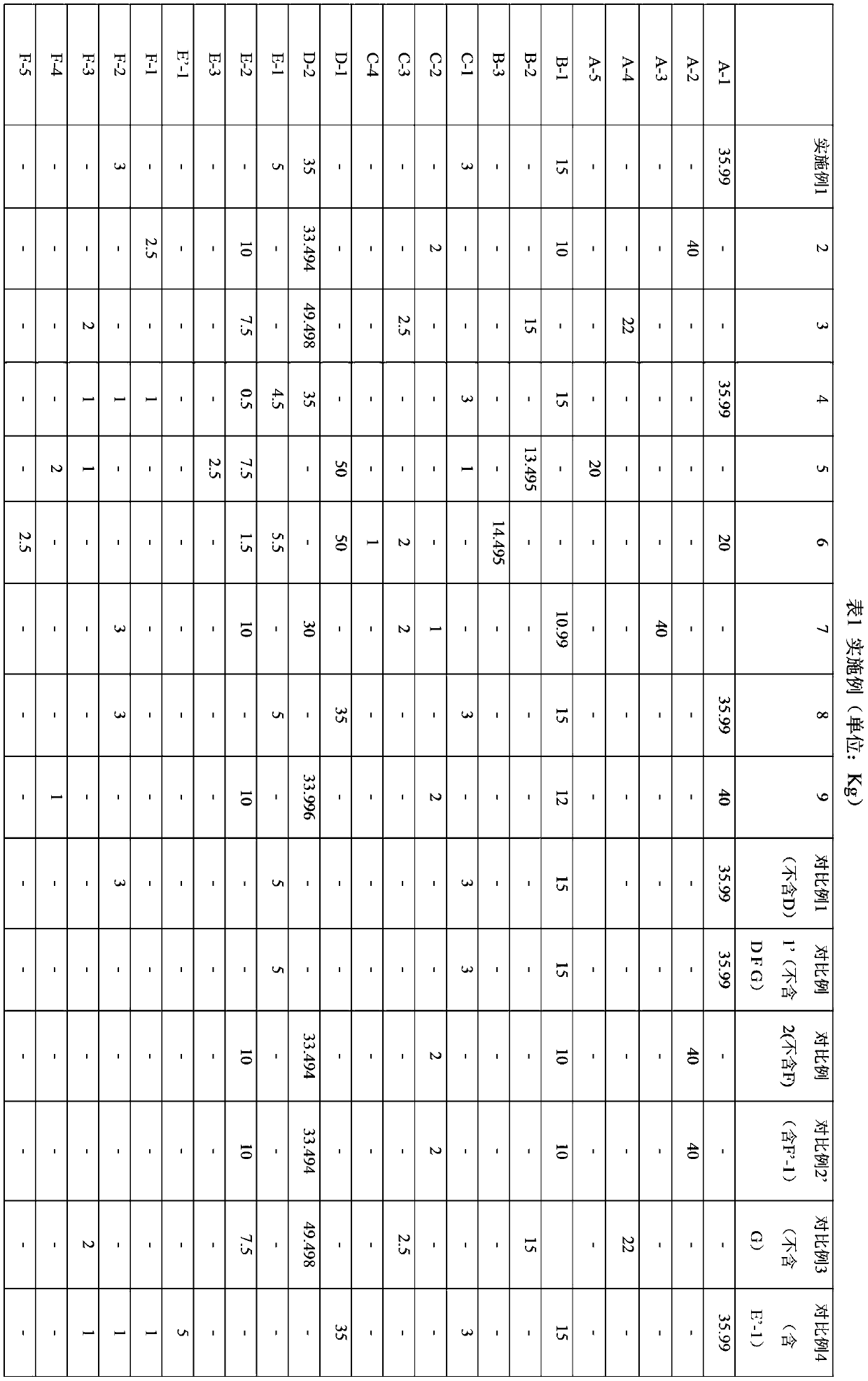

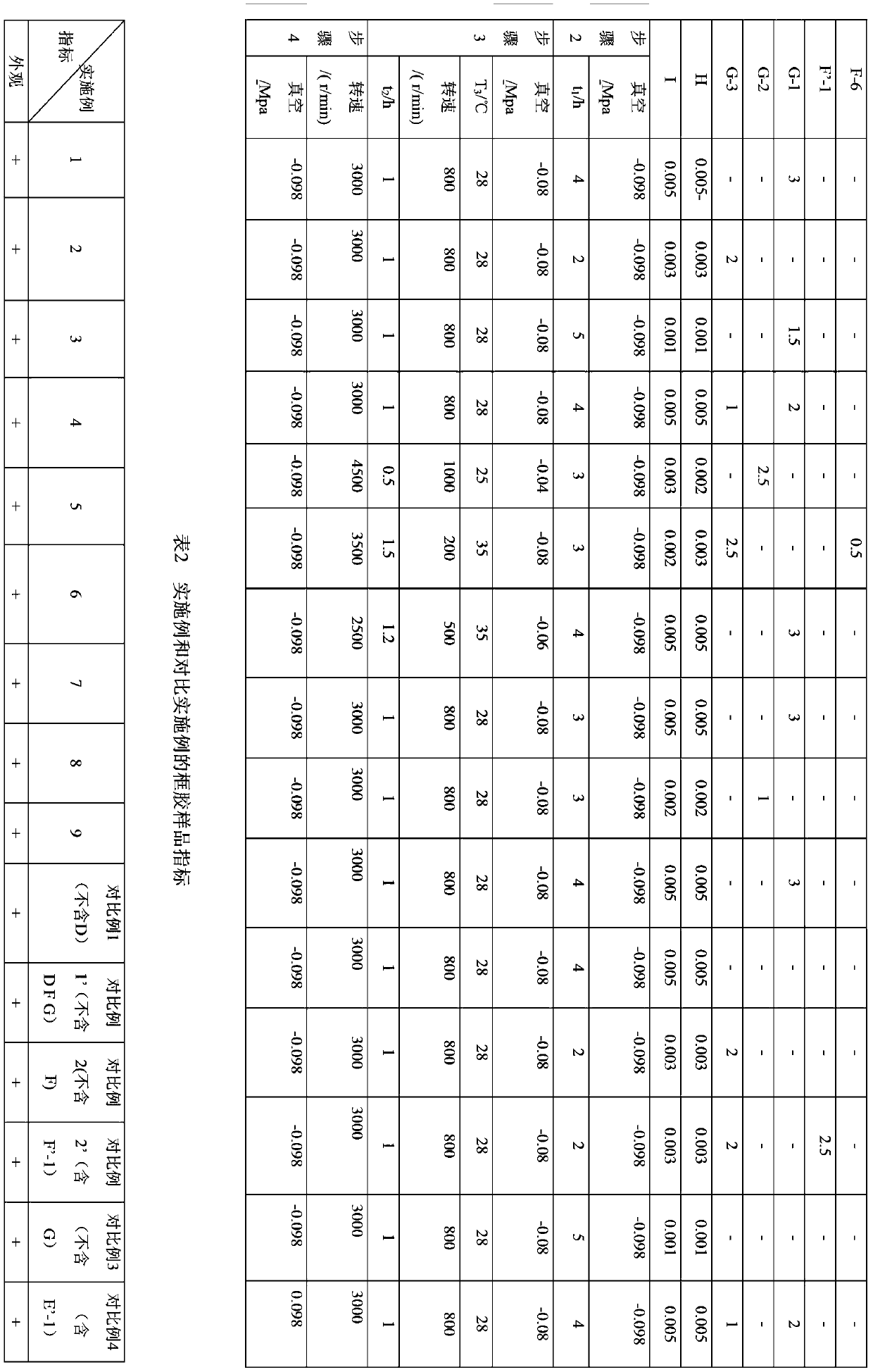

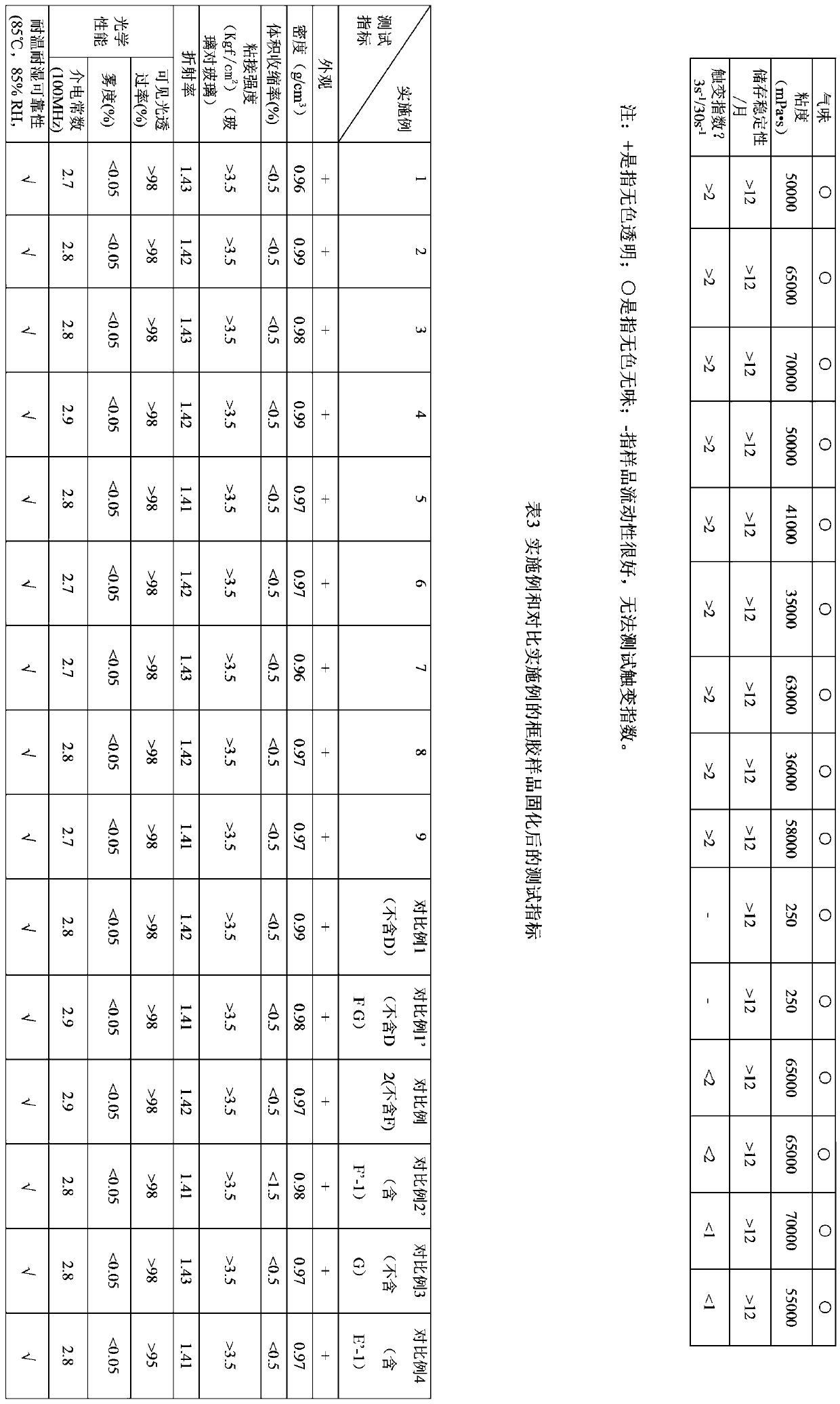

[0025] The present invention and its beneficial effects will be further described in detail below with reference to the examples, but the embodiments of the present invention are not limited thereto.

[0026] A is vinyl silicone oil, A-1 is vinyl-terminated polydimethylsiloxane with a viscosity of 100mPa·s; A-2 is vinyl-terminated polydimethylsiloxane with a viscosity of 800mPa·s; A- 3 is vinyl-terminated polydimethylsiloxane with a viscosity of 1500mPa·s; A-4 is vinyl-terminated polydimethylsiloxane with a viscosity of 2000mPa·s; A-5 is vinyl-terminated polymethylsiloxane Vinyl siloxane with a viscosity of 1000mPa·s.

[0027] B is hydrogen-containing silicone oil. The viscosity of the hydrogen-containing silicone oil on the B-1 side at 25°C is 30mPa·s, and the hydrogen content is 0.5%. The viscosity of the hydrogen-containing silicone oil on the B-2 side is 55mPa·s at 25°C, containing The hydrogen content is 0.35%; the B-3 terminal hydrogen-containing silicone oil has a visc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com