Dust collector filtering bag component and cloth bag dust collector

A dust collector and filter bag technology, applied in the field of filter bag components, can solve the problems of high cost, increase in floor space, increase the volume of the dust collector, etc., and achieve the effect of reducing the volume, improving the filtering effect, and being easy to install.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below through specific examples.

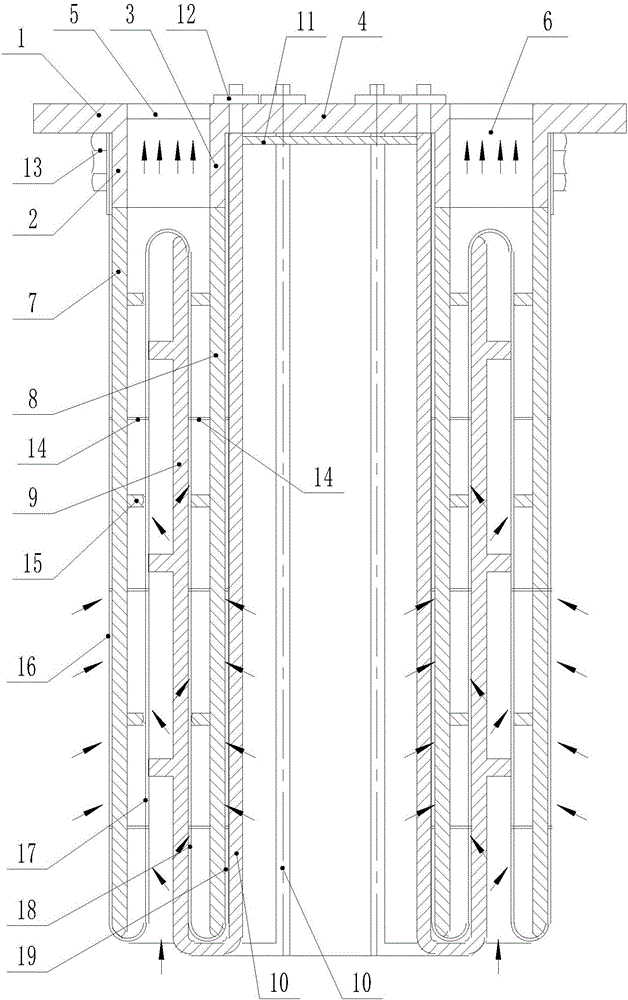

[0026] The internal and external mentioned in this embodiment are figure 2 The installation method is determined, the outside is outside, and the inside of the filter bag is inside.

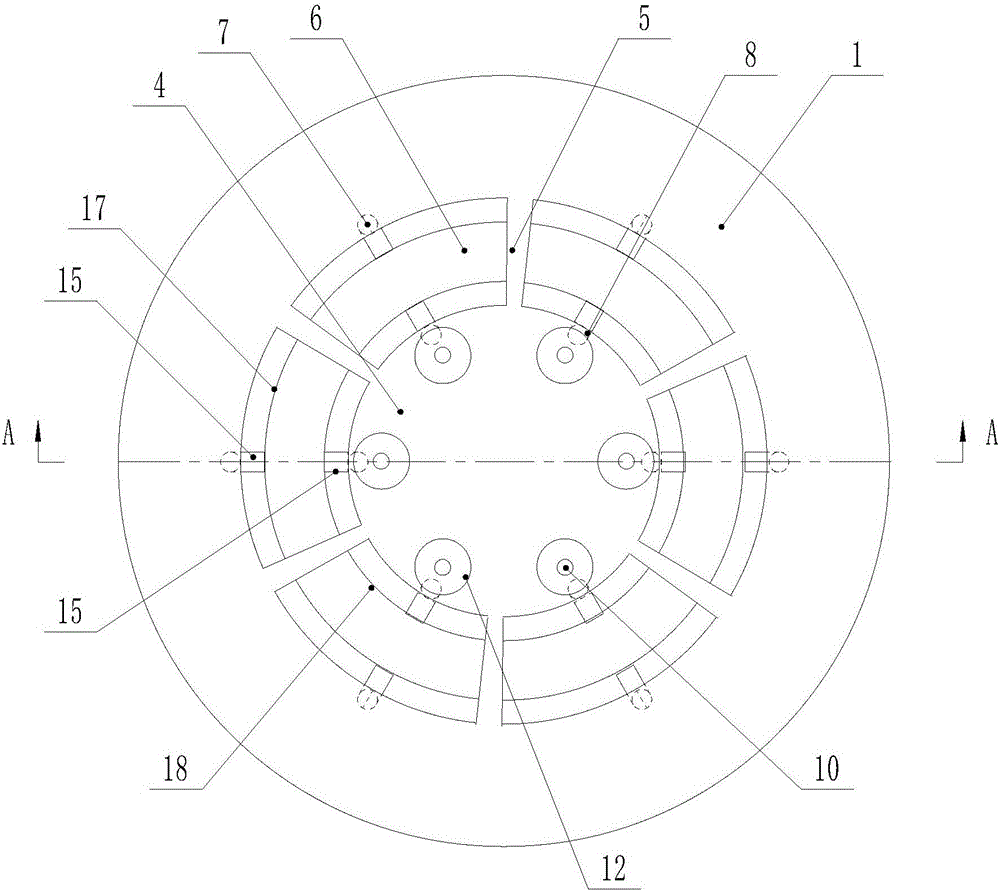

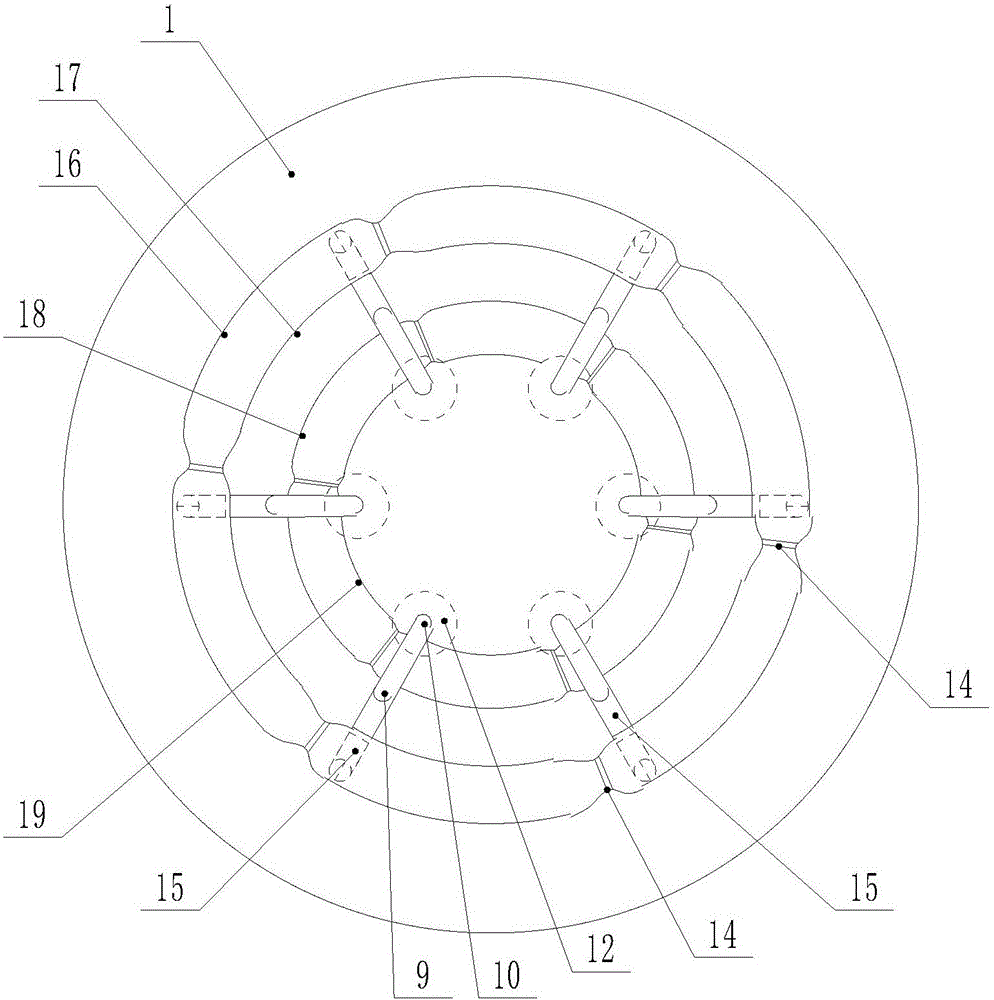

[0027] Such as Figures 1 to 4 As shown, a dust collector filter bag assembly includes a filter bag and a cage frame supporting the filter bag. The filter bag includes an outer filter bag body 16, an inner filter bag body 19, and a filter bag body connecting the outer filter bag body 16 and the inner filter bag body. 19, the connecting bag body, the outer filter bag body 16 is a cylindrical shape with an upper end opening, and the outer edge of the upper end of the outer filter bag body 16 is provided with an elastic pocket 13, and the elastic pocket 13 can be made of an elastic belt , For example, it can be a polytetrafluoroethylene elastic band, and it can also be made of a polyester elastic b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com