Benzene board concrete floor block and manufacture method thereof

A technology for concrete and concrete layers, applied in chemical instruments and methods, floor slabs, manufacturing tools, etc., can solve the problems of increasing construction difficulty, reducing load bearing, heat preservation and energy saving, and low strength, so as to achieve good heat preservation and energy saving effects and reduce floor load bearing , The effect of small thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

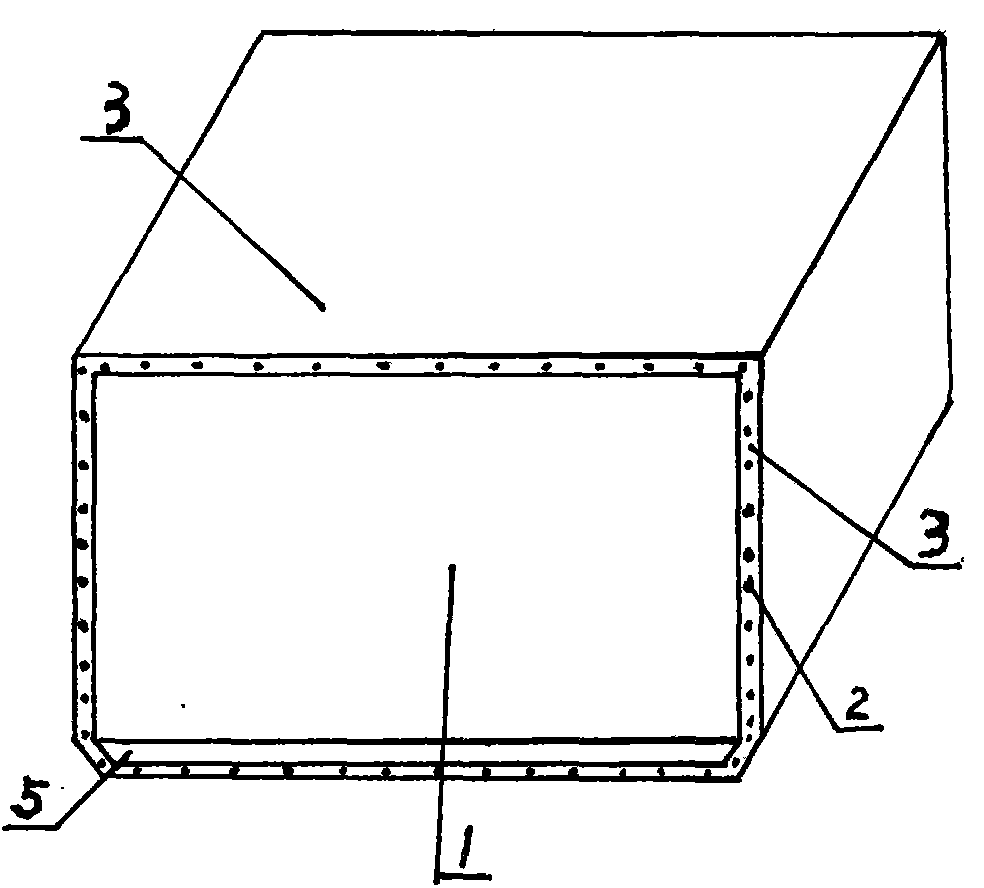

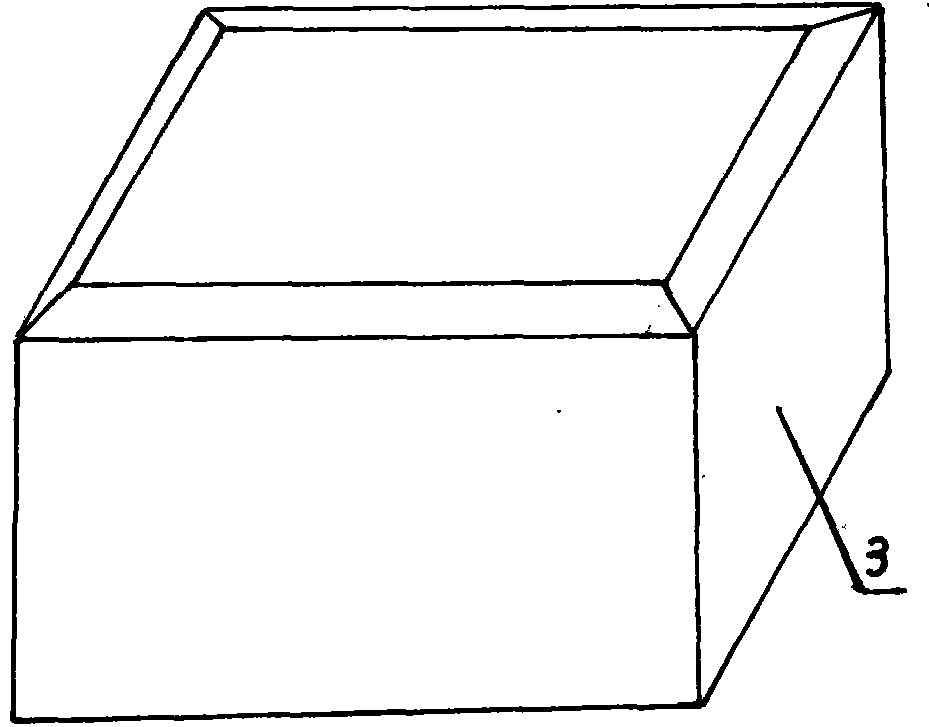

[0012] Example 1, such as figure 1 , figure 2 , image 3 and Figure 4 As shown, for this benzene-slab concrete floor block, each outer surface of the benzene slab 1 is smeared and bonded with a concrete layer 3 with a glass fiber mesh 2 in the middle, and the concrete layers of each adjacent two outer surfaces are seamlessly bonded. knot, forming a monolithic block whose inner core is benzene slab and outer layer is concrete layer.

[0013] The manufacturing method of the above-mentioned benzene board concrete floor block comprises the following steps: the first step is to smear a layer of concrete with an area slightly larger than the area of the top surface of the benzene board 1 on a plank larger than the top surface of the benzene board 1, and then apply the concrete on this layer Lay a layer of glass fiber mesh 2 on the concrete, then smear a layer of concrete on the glass fiber mesh 2, and then paste the top of the benzene board 1 on the concrete layer; Apply a l...

Embodiment 2

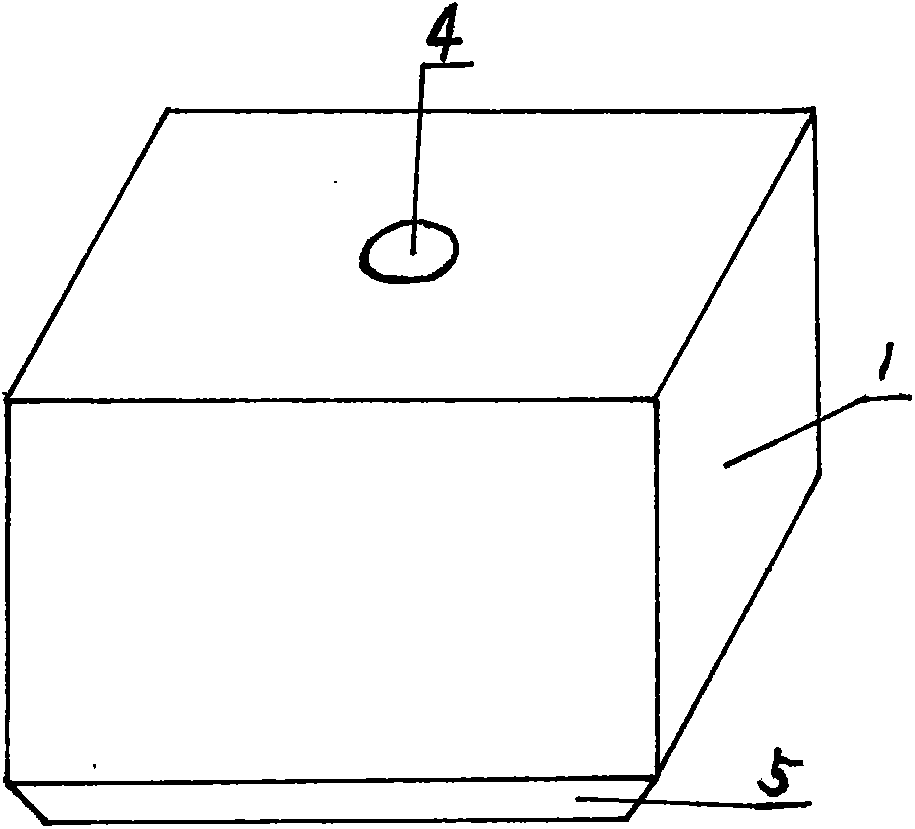

[0014] Embodiment 2, the benzene slab concrete floor block as described in embodiment 1, the center of the benzene slab 1 is provided with a cylindrical hole 4 from the top surface to the bottom surface, and the cylindrical hole 4 is filled with concrete, which becomes a support column after solidification.

Embodiment 3

[0015] Embodiment 3, the benzene board concrete floor block as described in embodiment 1 or 2, benzene board 1 is a straight prism, the bottom surface edge of the right prism is cut into a prism body 5, and each surface of the prism body 5 is smeared with adhesive Concrete layer with fiberglass mesh sandwiched in the middle. Its purpose is to make the concrete infiltrate into the space under the prism body 5, so as to facilitate the condensation of the bottom of the benzene slab concrete floor block with the floor slab better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com