Lean ceramic powder size for direct-forming 3D ceramic printing as well as preparation method and application of lean ceramic powder size

A ceramic powder and 3D printing technology, which is applied in the field of 3D printing, can solve the problems of barren ceramic powder without plasticity, achieve simple and reliable control methods, high printing accuracy, and solve the effects of printing speed and printing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

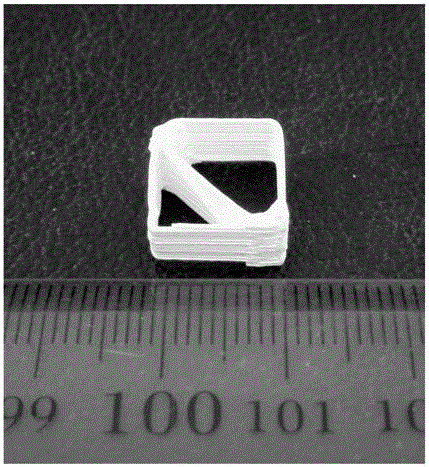

Image

Examples

Embodiment 1

[0034] 1. In this embodiment, a method for preparing a sterile ceramic powder slurry for direct molding 3D ceramic printing, the steps are as follows:

[0035] (1) Dissolve 1.1g D-305 in 20.6g deionized water and mix evenly to obtain a dispersant solution;

[0036] (2) 65.0gAl 2 o 3 The powder (d50=0.5μm) is gradually added to the dispersant solution under high-speed stirring (4000rpm) and mixed evenly to obtain suspension A;

[0037] (3) Add 0.2g guar gum powder and 0.2g sodium carboxymethylcellulose powder (viscosity 300-800mPa·s) to suspension A under high-speed stirring to form suspension B;

[0038] (4) Add 2.4g of polyvinyl alcohol and 0.5g of leveling agent MB-26 into the suspension B, and continue to stir for 60 minutes to obtain a sterile ceramic powder slurry for direct molding 3D ceramic printing with a solid content of 72.2%.

[0039] 2. In this embodiment, an application of sterile ceramic powder slurry for direct molding 3D ceramic printing is used for direct ...

Embodiment 2

[0046] 1. In this embodiment, a method for preparing a sterile ceramic powder slurry for direct molding 3D ceramic printing, the steps are as follows:

[0047] (1) Dissolve 1.1g D-305 in 17.0g deionized water and mix evenly to obtain a dispersant solution;

[0048] (2) 73.1g ZrO 2 The powder (d50=0.8μm) is gradually added to the dispersant solution under high-speed stirring (4000rpm) and mixed evenly to obtain suspension A;

[0049] (3) 0.3g of guar gum powder and 0.2g of sodium carboxymethylcellulose powder (viscosity 300-800mPa·s) were also added to suspension A under high-speed stirring to form suspension B;

[0050] (4) Add 4.2g of polyvinyl alcohol and 0.8g of leveling agent MB-26 into the suspension B, and continue to stir for 60 minutes to obtain a sterile ceramic powder slurry for direct molding 3D ceramic printing with a solid content of 75.6%.

[0051] 2. In this embodiment, an application of sterile ceramic powder slurry for direct molding 3D ceramic printing is u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com