Process and equipment for continuously producing glufosinate-ammonium

A technology of glufosinate-ammonium and equipment, which is applied in the field of continuous production of glufosinate-ammonium technology and equipment, can solve the problems of inapplicability to large-scale industrial production, unstable product quality, long production cycle, etc., and avoid post-treatment process , low production cost and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

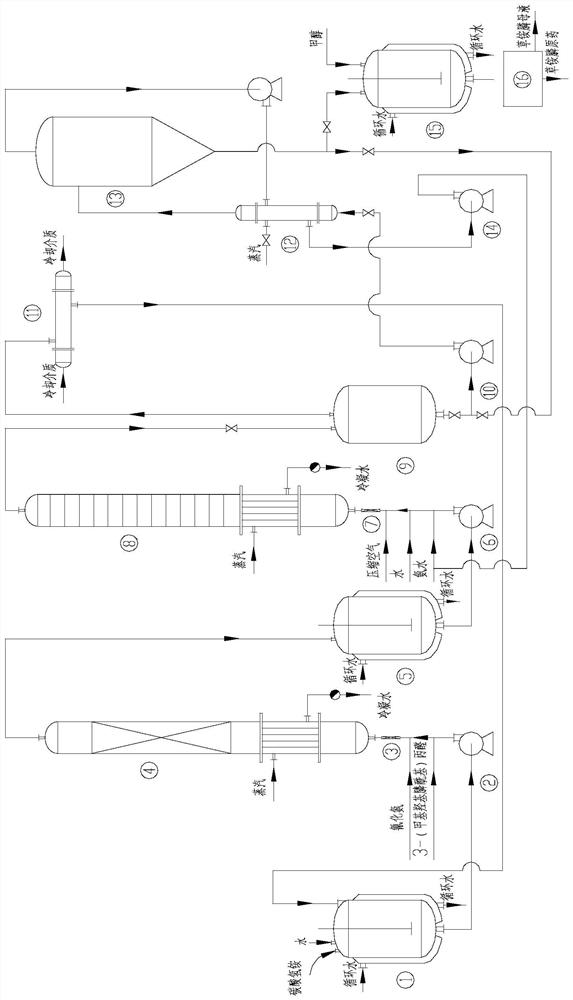

Method used

Image

Examples

Embodiment

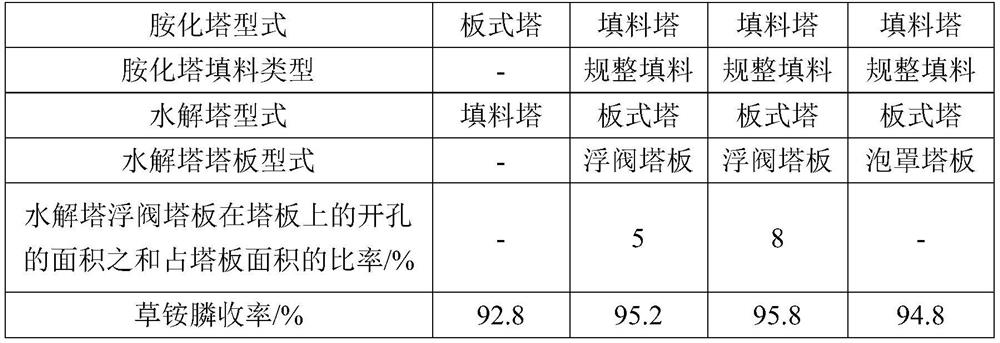

[0039] Table 1 is the same reaction conditions, the embodiment of different equipment types and parameters, wherein in the amination reaction of step A, the mol ratio of 3-(methylhydroxyphosphono) propanal, ammonium bicarbonate and ammonium cyanide is 1 : 1.2: 1.0, the solubility of ammonium cyanide aqueous solution is 21%, and the total amount of water is 50 times of the molar weight of substrate 3-(methylhydroxyphosphono) propionaldehyde; total phosphorus and ammonium in the hydrolyzate in the described step B The molar ratio of ions is 1:7, and the total water content is 150 times of the total phosphorus molar mass in the solution; the temperature of the tower bottom of the amination tower is 80°C, the pressure inside the tower is 0.20MPa, and the average residence time of the reaction liquid in the tower is 4h; the temperature in the bottom of the hydrolysis tower is 160°C; the pressure inside the tower is 2.0MPa, and the average residence time of the reaction liquid in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com