Garbage incinerator with furnace sealing combustion function

A technology of waste incinerator and function, applied in the combustion method, combustion type, incinerator and other directions, can solve the problems of thin incineration material layer, high combustion cost of incinerator, and ceasefire.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

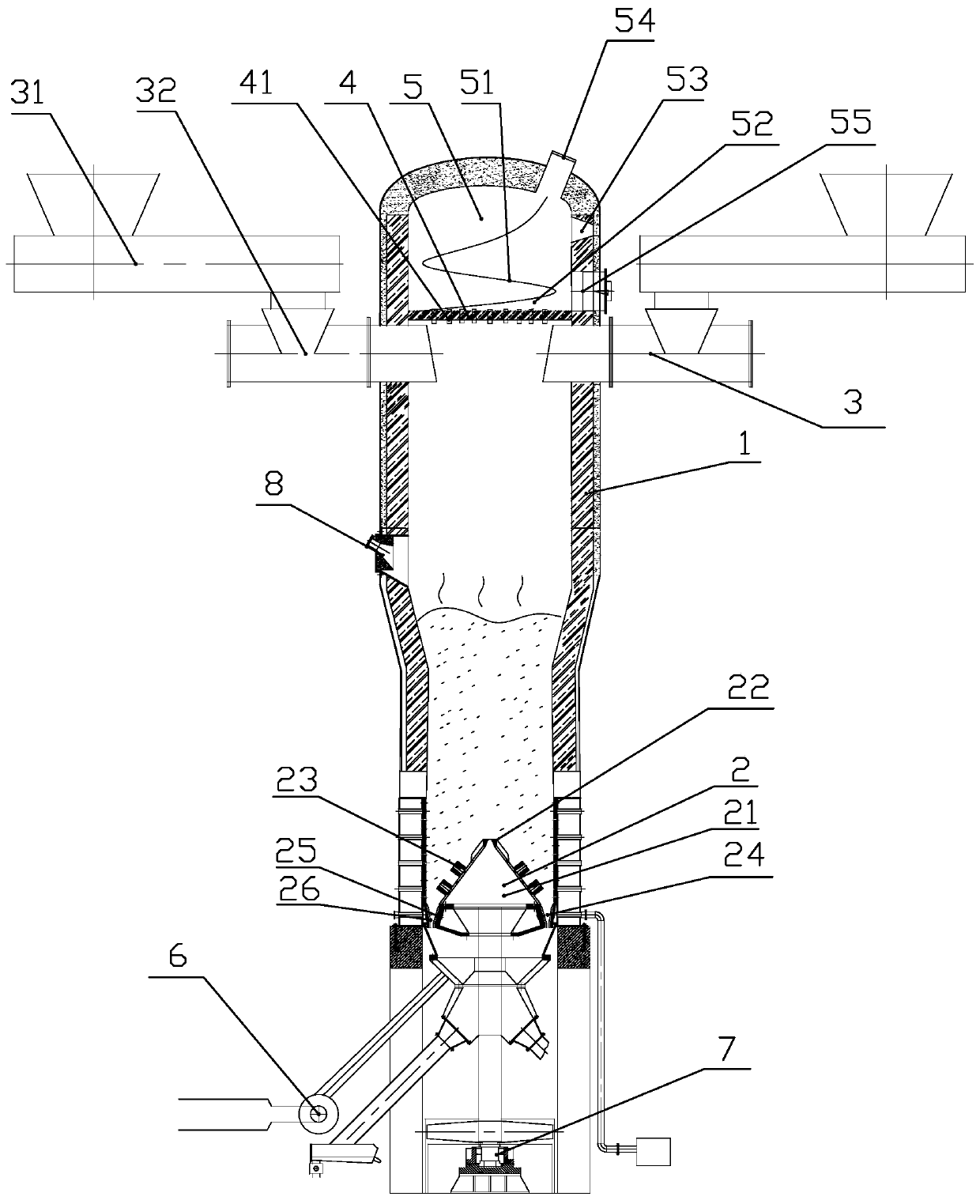

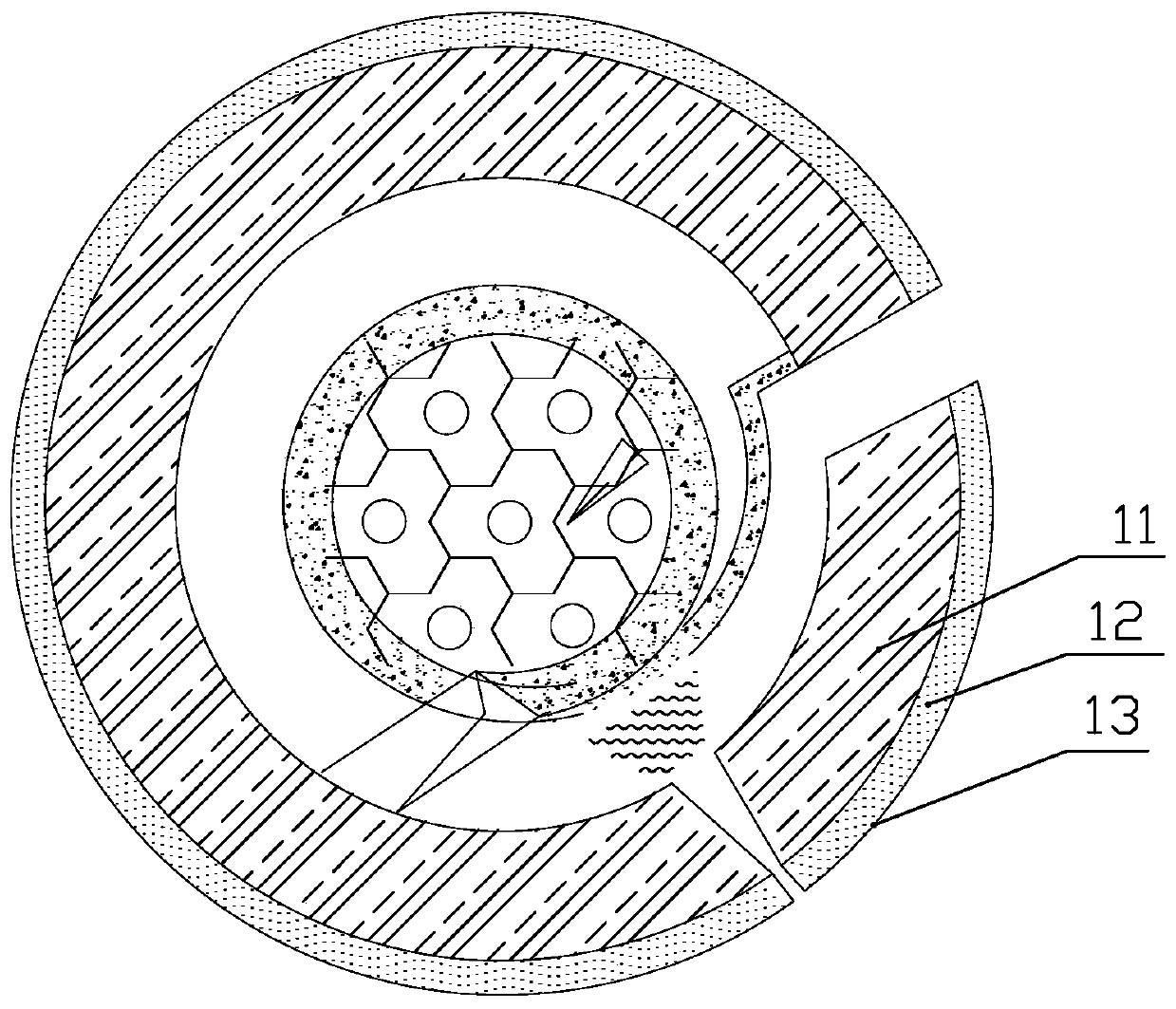

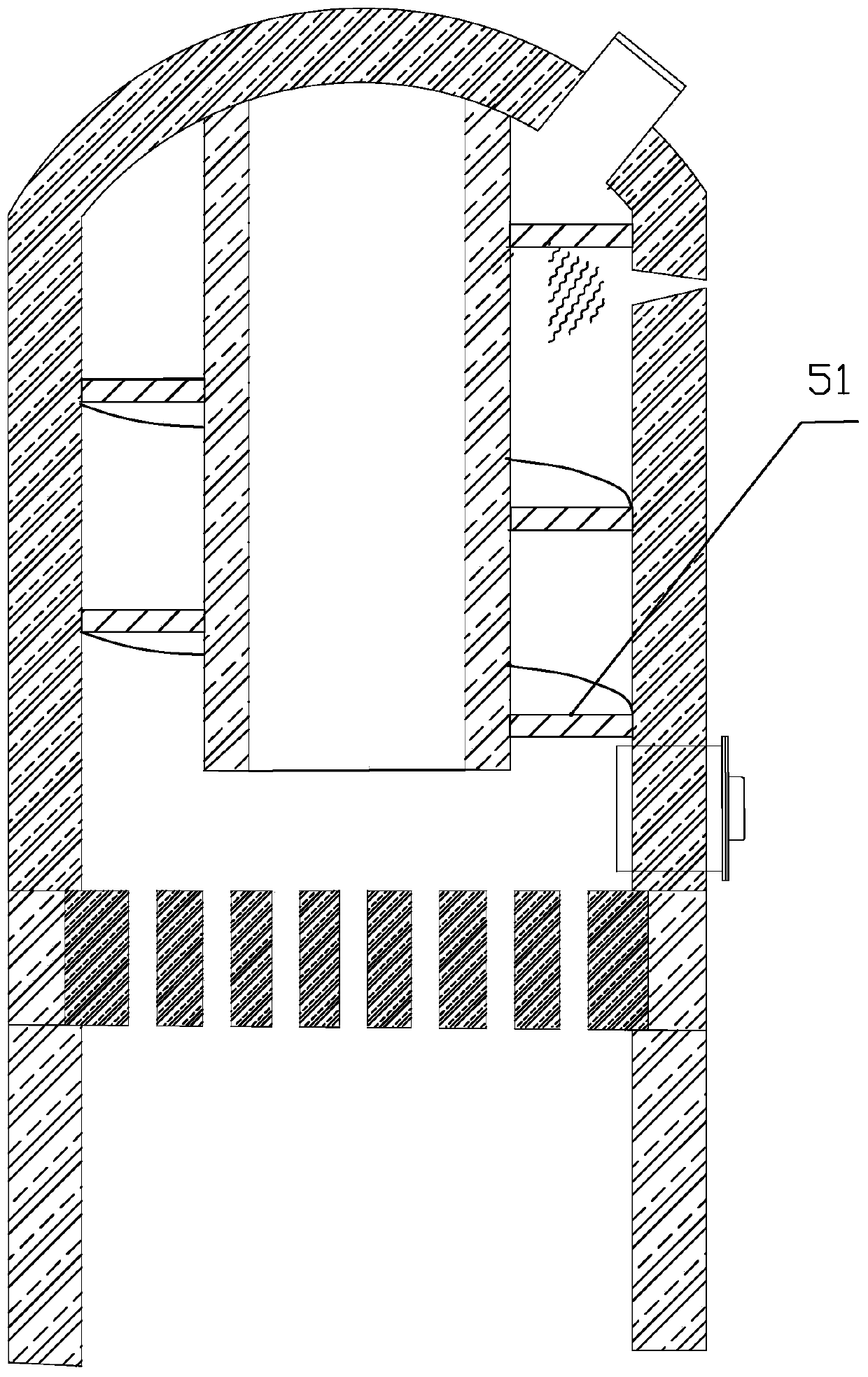

[0019] Specific implementation mode one: combine Figure 1~3 Description of this embodiment, a garbage incinerator with the function of closing the furnace for combustion, which includes a furnace body 1, a fire grate 2 that is rotatably arranged on the inner lower part of the furnace body 1, and a grate that is distributed on the outer upper part of the furnace body 1 and communicates with the furnace body 1. A number of screw feeding devices 3 are characterized in that: it also includes an isolation plate 4 fixed horizontally on the inner upper part of the furnace body 1, and the isolation plate 4 is located above several screw feeding devices 3, and the furnace body 1 is a vertical Type furnace body 1, the space above the isolation plate 4 is the second combustion chamber 5, the second combustion chamber 5 is provided with a spiral passage 51 along the vertical direction, and the isolation plate 4 is vertically provided with several vents 41, the spiral The bottom of passag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com