Food grade starch master batch composition, food grade starch master batch and preparation method of master batch

A food-grade, composite technology, applied in the chemical field, can solve the problems of restricting the application of starch-based plastics and the toxicity of compatibilizers, and achieve the effects of increasing the amount and ratio of addition, excellent plastic performance, and cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

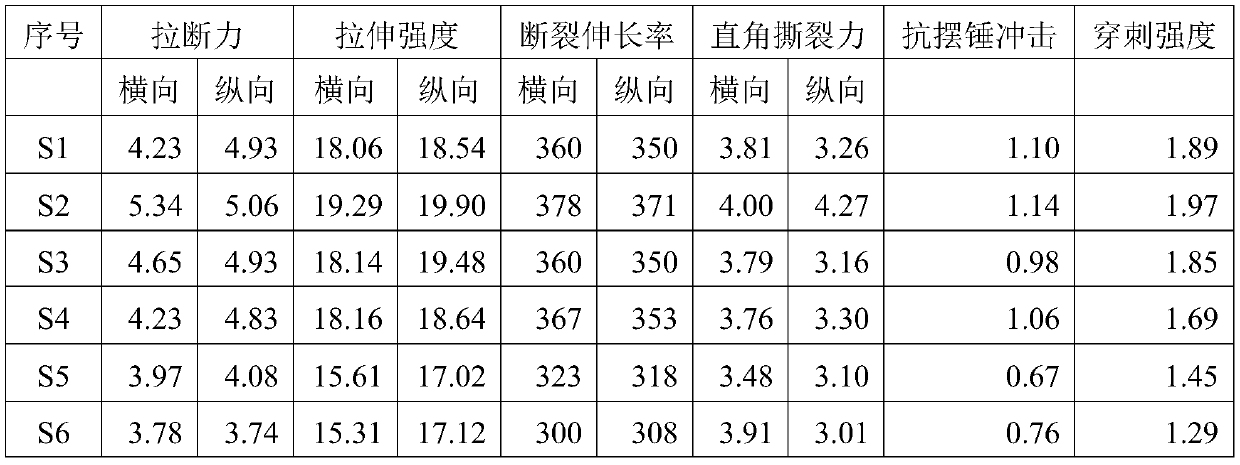

Examples

preparation example Construction

[0038] In the second aspect, the present invention provides a preparation method of food-grade starch masterbatch, the method comprising:

[0039] The food-grade starch masterbatch composition of the present invention is prepared by granulation. In the specific embodiment of the present invention, prepare according to the following steps:

[0040] (1) Preparation of raw materials

[0041] The plasticized starch obtained in the above-mentioned manner, the matrix, the lubricant and the auxiliary agent are added to the high-speed mixer successively, and the rotating speed is adjusted to 300 rpm and stirred for 5 minutes before discharging, and discharging for subsequent use;

[0042] (2) Preparation of masterbatch

[0043] The uniformly mixed material in step (1) is added to the hopper in the twin-screw extruder, and the food-grade starch masterbatch can be obtained by extruding and granulating. Use a parallel twin-screw pelletizing unit to extrude and pelletize, and set the t...

preparation example 1

[0051] 80 parts by weight of corn starch and 20 parts by weight of glycerin.

preparation example 2

[0053] 80 parts by weight of potato starch, 18 parts by weight of glycerin, and 2 parts by weight of glycerol monostearate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com