Patents

Literature

78 results about "Allyl thiocyanate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Allyl isothiocyanate (AITC) is the organosulfur compound with the formula CH2CHCH2NCS. This colorless oil is responsible for the pungent taste of mustard, radish, horseradish, and wasabi.

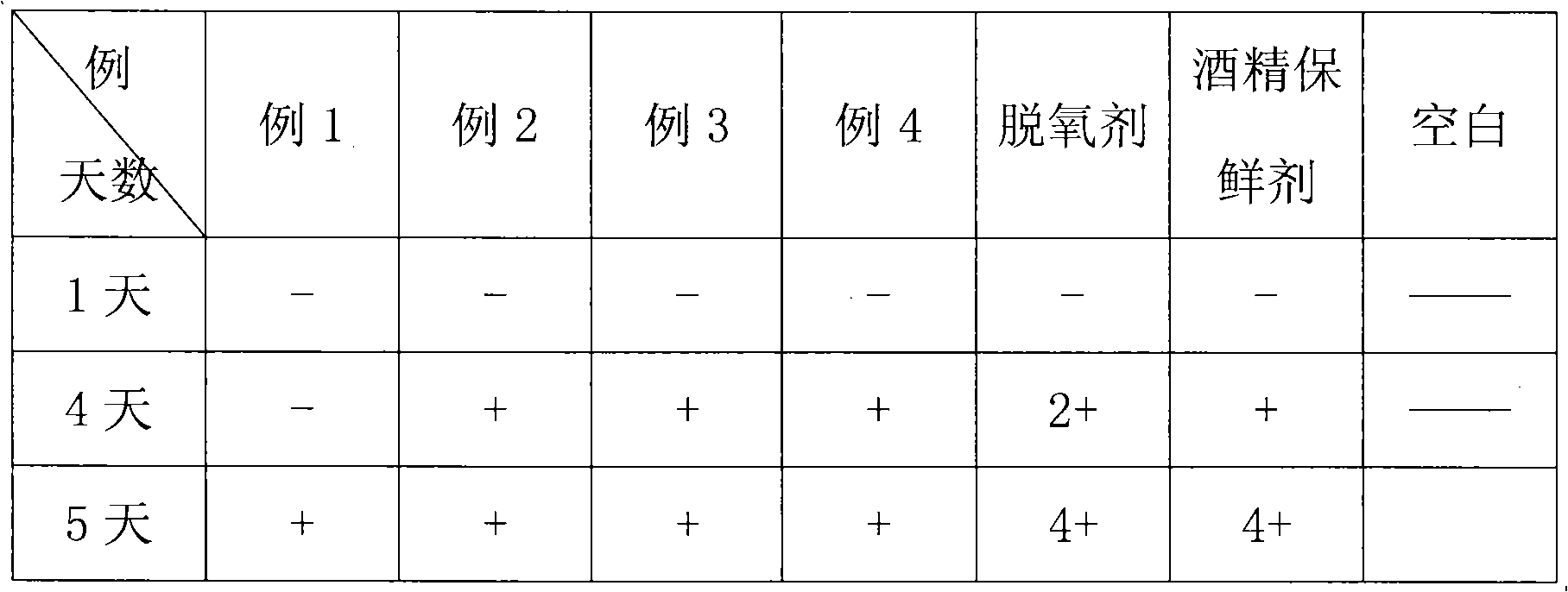

Bacterium-restraining deoxidization dual-purpose food antistaling agent and preparation thereof

The invention relates to an antibacterial deoxidizing double-effect food preservative, which is formed by combining a deoxidizer component with a bacteriostat component, wherein the deoxidizer component accounts for 60-90 percent, and the bacteriostat component accounts for 10-40 percent. The bacteriostat component comprises an adsorption carrier and an antibacterial solution. The adsorption carrier comprises salep, silicon dioxide, vermiculite, diatomaceous earth, zeolite, bentonite, fiber, etc. The antibacterial solution comprises one of or the composite mixture of edible alcohol and propylene glycol. Antibacterial synergist comprises allyl isothiocyanate, allicin, cinnamic aldehyde, cinnamic acid, carvacrol, eugenol, thymol, citral, etc. The antistaling agent integrates double protection functions of absorbing oxygen, sterilizing and inhibiting bacteria, which is remarkable in preservation effect and wide in application range.

Owner:GUANGDONG GUANGYI TECH IND

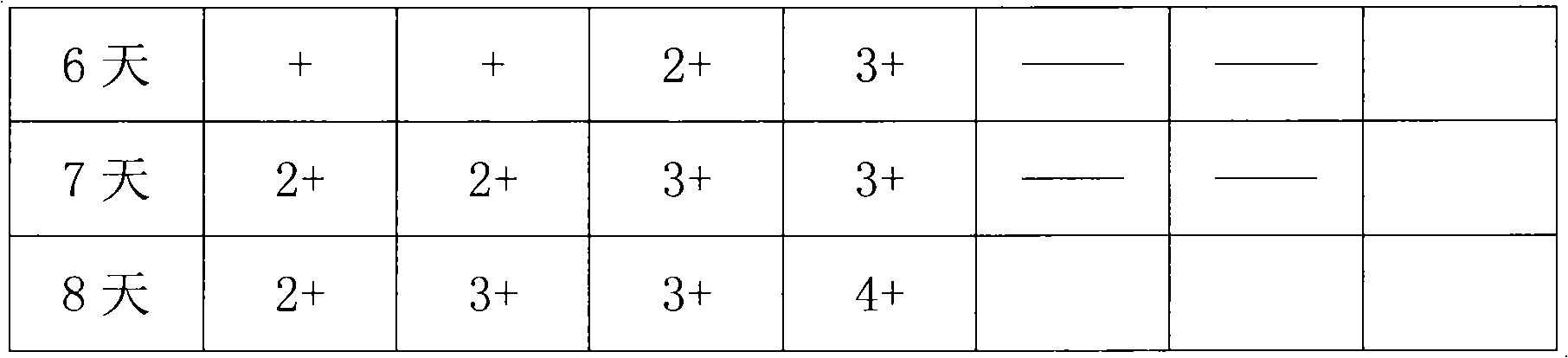

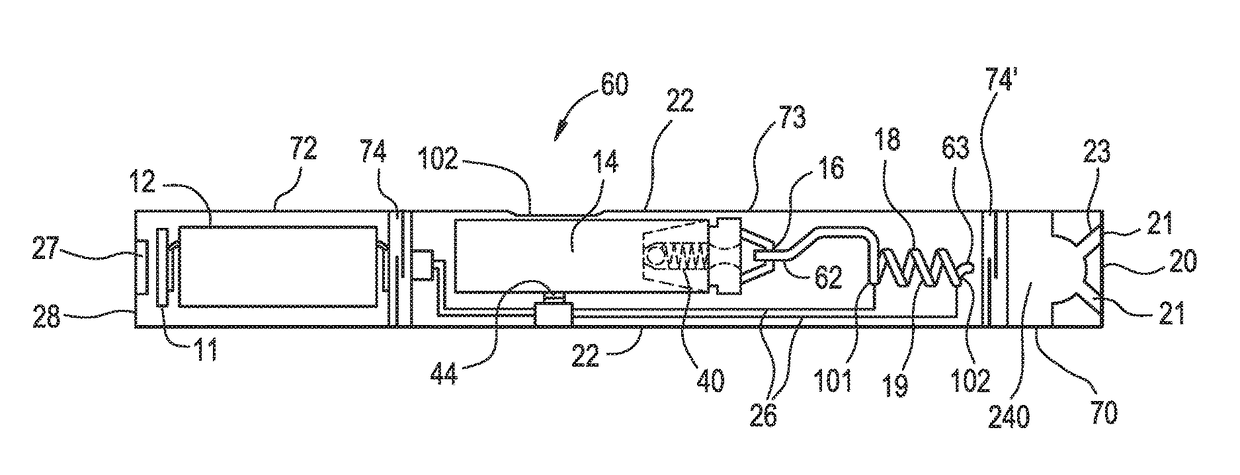

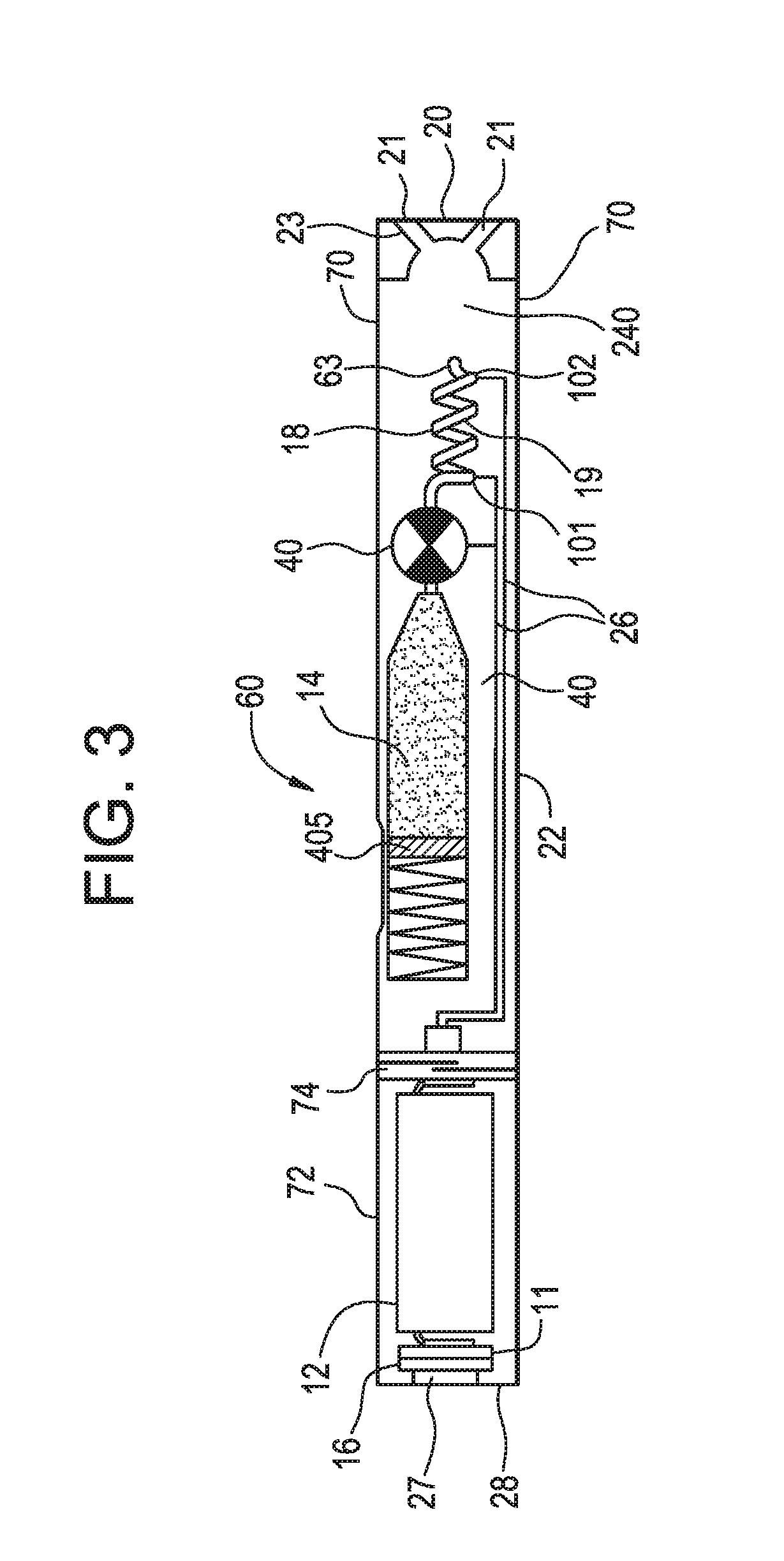

Strength enhancers and method of achieving strength enhancement in an electronic vapor device

InactiveUS20170172204A1Increasing harshnessDesirable balanceTobacco treatmentTobacco devicesGrapefruit oilCayenne pepper

A pre-vaporization formulation pre-vaporization formulation for an e-vaping device, the pre-vaporization formulation including a vapor former including a combination of propylene glycol and glycerol, and an additive including at least one of capsicum, allyl isothiocyanate, piperine, isoeugenol, carvacrol, thymol, menthol, monomenthyl succinate, N-(2-hydroxyethyl)-2,3-dimethyl-2-isopropyl butanamide, horseradish oil, garlic extract, onion oil, black pepper, cayenne pepper, ginger oil, thyme oil, cinnamon bark oil, turmeric, fenugreek, cardamom, rosemary extract, grapefruit oil and andrographis extract.

Owner:AKRIA CLIENT SERVICES LLC

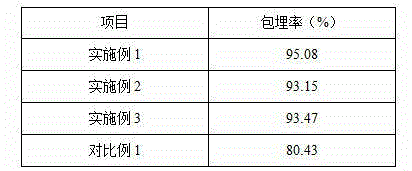

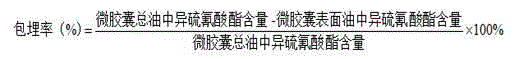

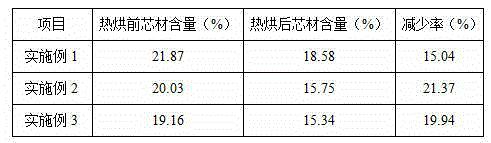

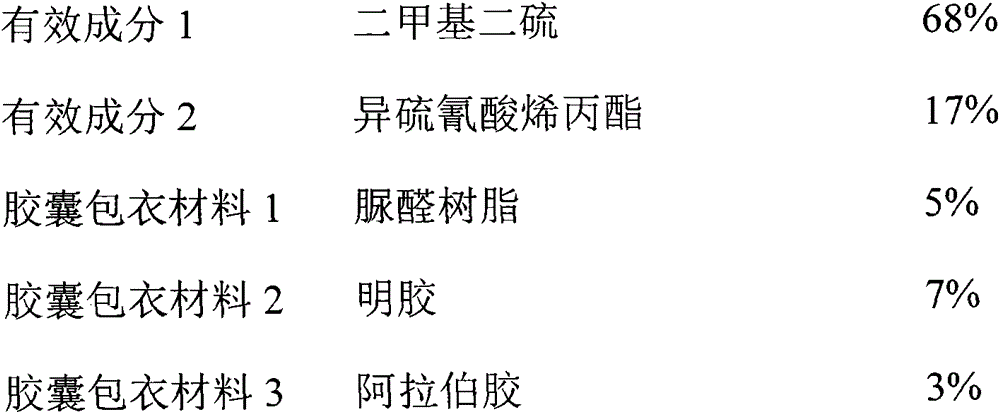

Microcapsule mustard essence and preparation method thereof

InactiveCN104921047APackage completelyReasonable ratioFood ingredient as thickening agentFood ingredient as encapsulating agentPolymer scienceAllyl thiocyanate

The present invention discloses a microcapsule mustard essence which consists of wall materials and core materials; the wall materials are prepared by using the following components in parts by weight: starch sodium octenylsuccinate 5.0-25 parts, soybean protein isolate 1.0-5.0 parts, sodium caseinate 0.1-3.0 parts, maltodextrin 20-60 parts and thickening agents 0.2-6.5 parts; and the core materials comprise the following raw materials in parts by weight: natural mustard oil 1.0-20 parts and / or allyl isothiocyanate 1.0-20 parts, and fragrance enhancing and coordinating agents 0.4-1.5 parts. The microcapsule mustard essences have high embedding rate and good heat resistance, can improve the stability of the mustard oil, overcome the shortcomings of highly volatility and strong irritation of liquid essences used in the past, and not easily being preserved in products, and better exert the fragrance of the mustard oil; and at the same time, the wall materials of the microcapsule mustard essences are widely accessible, have low production cost, and can be widely promoted and applied.

Owner:ZENGCHENG HANDYWARE SEASONING

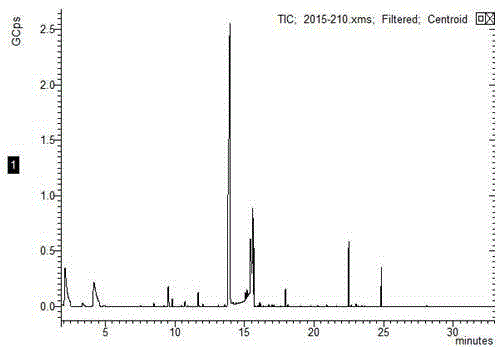

Composition for soil fumigation

The invention relates to a composition for soil fumigation, the effective components of which are allyl isothiocyanate (A) and dimethyl disulfide (B) in a mass ratio of 1:1-1:100. The composition provided by the invention is used for soil fumigation of melons and vegetables, medicinal materials, strawberries, tobacco, fruit trees, and nurseries.

Owner:SHENZHEN NOPOSION AGROCHEM

Compositions and process for nematode control

InactiveUS6720352B1Lower overall dosage of pesticideHighly effectiveBiocideDead animal preservationGrowth plantChemical composition

Chemical compositions having superior nematicidal properties are formulated. The compositions contain one or more selected aldehydes as the major component and one or more aliphatic or cyclic isothiocyanates as a minor component. Preferred mixtures contain furfural and one or both of methyl isothiocyanate and allyl isothiocyanate. Plant-parasitic nematodes are controlled by contacting the nematodes with the nematicidal compositions, by, for example, applying the compositions to soil or other plant growth media containing the nematodes.

Owner:ILLOVO SUGAR LTD

Tea leaf cigarette

InactiveCN1513389AWill not affect healthIncrease excitementCigar manufactureBARLEY BRANAllyl thiocyanate

A tea cigarette features that its threds are made of tea leaves, roasted barley bran, ginger oil, cinnamon bark oil, origanum herb oil, coffeine, allyl isothiocyanate, etc. Its advantages are no damage to human health and good enjoyment to smoke it.

Owner:颜廷良

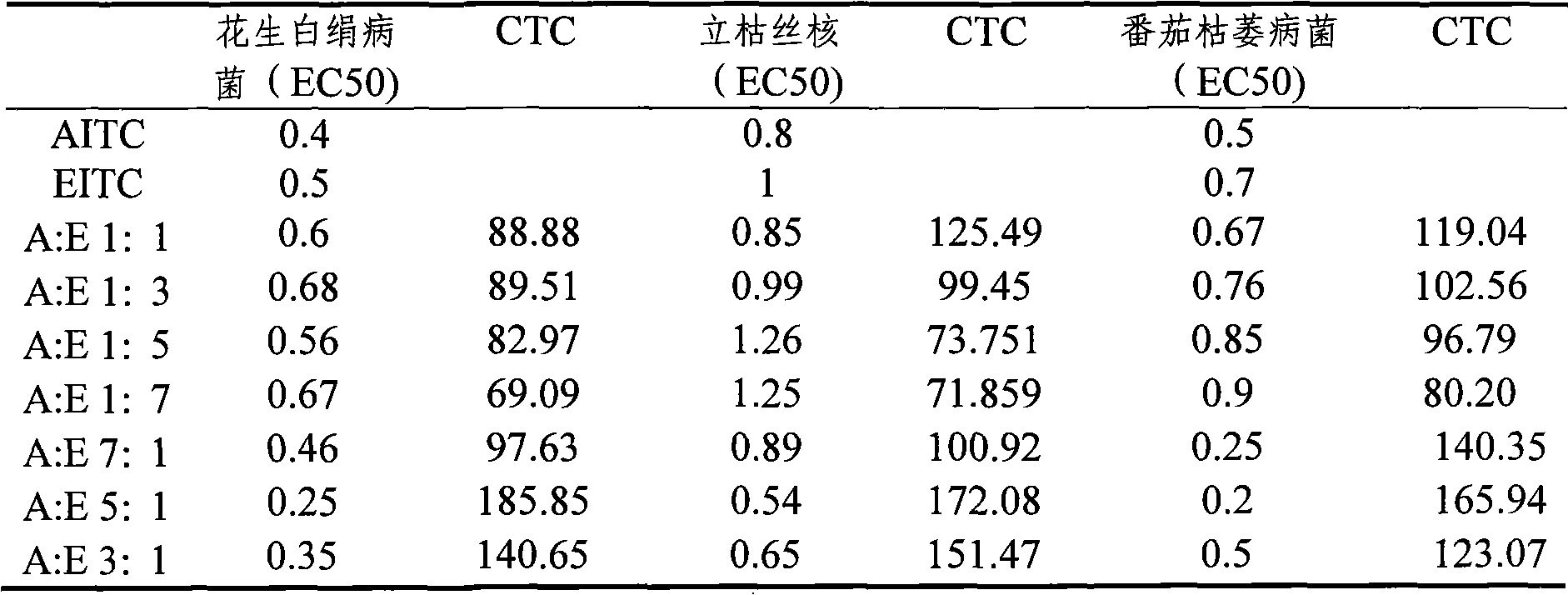

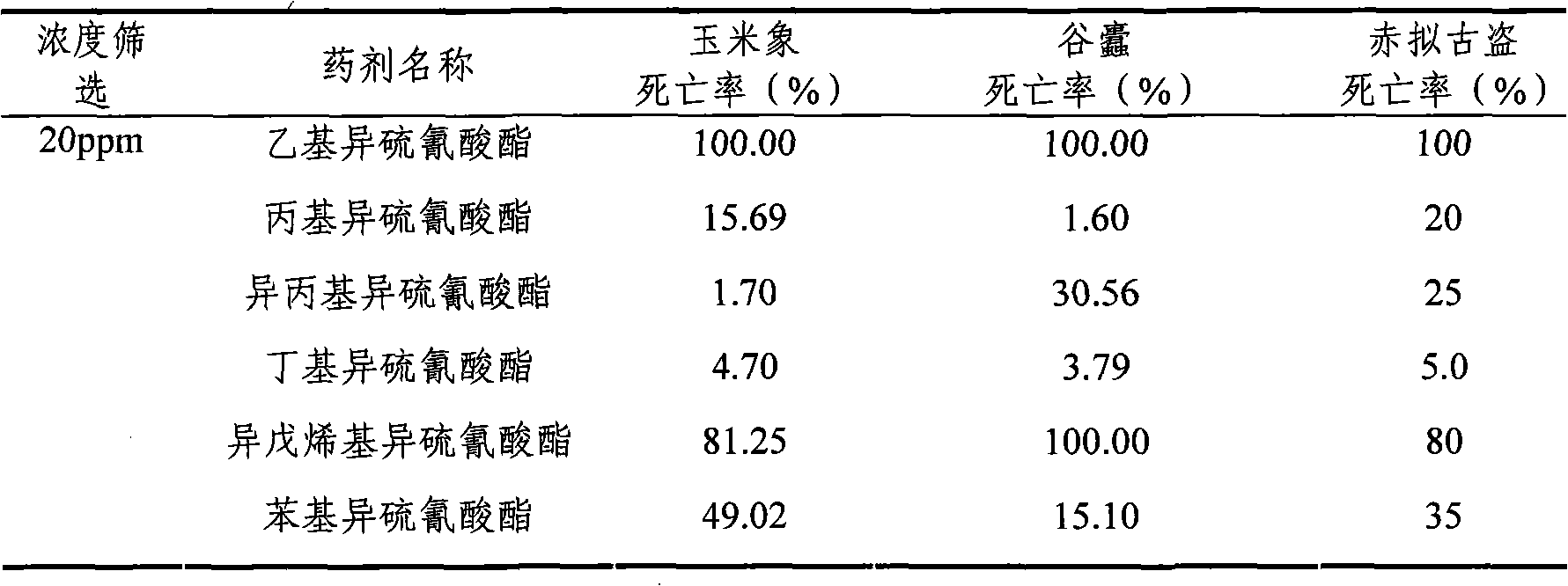

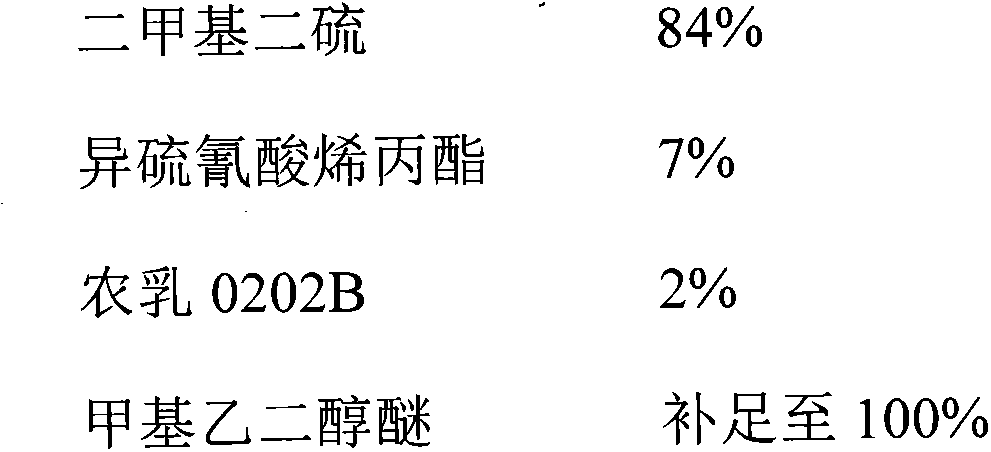

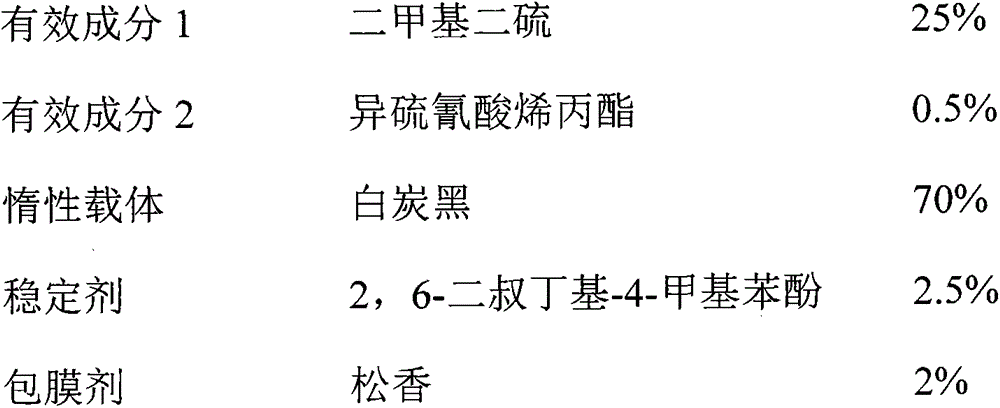

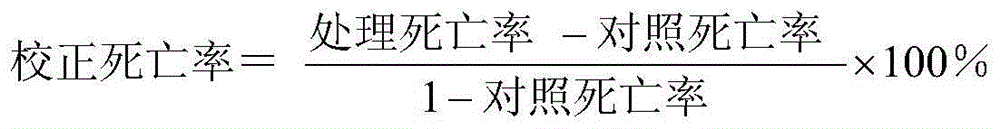

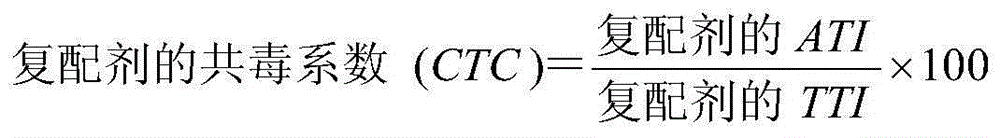

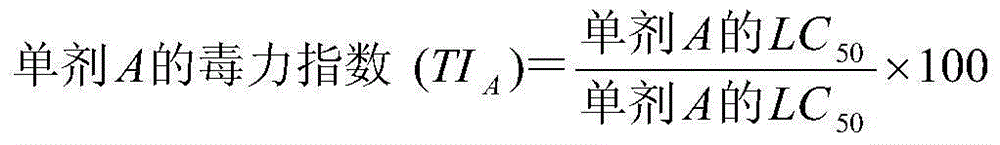

Compound agent of ethyl isothiocyanate and allyl isothiocyanate and application thereof

ActiveCN101558760ASignificant synergyHigh antibacterial and insecticidal activityBiocideSeed preservation using chemicalsAllyl thiocyanateNematode

The invention provides a compound agent, which is prepared by performing binary compounding on plant-source compounds of ethyl isothiocyanate and allyl isothiocyanate according to the weight ratio of 1:7-7:1. The compound agent can be prepared into a dissoluble liquid, an aqueous emulsion, an oil solution or a tablet, and is applied to preparing a pesticide fumigant for controlling insect pests and harmful mould fungi in storehouses and soil. The compound agent has the advantages of obvious synergy, high bacteriostatic and insecticidal activity, less relative usage, and obvious fumigation effect on pests of food, tobacco and soil nematodes and the like, and can be used for substituting bromomethane which is forbidden fumigant.

Owner:北京中德恒星科技有限公司

Farm chemical composition and application thereof

InactiveCN103814932ALower doseReduce the labor required for pesticide applicationBiocideFungicidesAllyl thiocyanatePesticide residue

The invention provides a farm chemical composition and application thereof. The farm chemical composition comprises the active components of dimethyl disulfide and allyl isothiocyanate. The farm chemical composition is used for disinfecting soil of crop fields for vegetables, strawberry, flower, melons, Chinese herbal medicines and the like and soil of a nursery, an orchard, a tea garden and a forest before sowing, and can effectively prevent and control root knot nematodes, soil-borne pathogenic fungi, soil-borne pathogenic bacteria and common farmland weeds during agricultural crop planting, especially the root knot nematodes, fusaria and abutilon theophrasti. The farm chemical composition has the benefits as follows: (1) the farm chemical composition has an unexpected synergistic effect within a certain proportion range, so that nematode-killing, bactericidal and weeding effects of the farm chemical composition are obviously better than those of a single component, the using dosage of farm chemicals, the farm chemical delivering labor and the farm chemical delivering cost are reduced, and the adverse effect on the environment and farm chemical residues are reduced; (2) the farm chemical composition has a wide prevention and control spectrum, and can be widely used for preventing and controlling soil-borne pathogenic nematodes, soil-borne pathogenic bacteria and weeds during agricultural crop planting.

Owner:INST OF PLANT PROTECTION CHINESE ACAD OF AGRI SCI

Soil fumigant, herbicide, larvacide, ovacide and fungicide

A treatment for eliminating unwanted organisms in agriculture, the treatment comprising a first component comprising allyl isothiocyanate emulsified in water, and a second component comprising a solution of phosphorus and water.

Owner:RIORDAN FREDRICKA

Gentle type yellow mustard sauce easy to smear and preparation method thereof

The invention discloses a gentle type yellow mustard sauce easy to smear and a preparation method thereof, and belongs to the fruit and vegetable food processing technical field. The product is prepared through activation, preliminary crushing, superfine grinding, heating dissolving, stirring, fermentation, compounding, ultrasonic emulsification and sterilization. Yellow mustard seeds are subjected to low-temperature crushing, so that myrosase activity is protected, enzyme inactivation is avoided from being caused by high temperature, allyl isothiocyanate is fully generated from glucosinolate in the mustard seeds, and thus the production of other bitter substances is reduced. With addition of a right amount of soybean protein, the stability of allyl isothiocyanate hydrolyzed from the mustard powder is improved, and main flavor substance isothiocyanates are not easy to volatilize. With addition of sorbitol, the water activity of the yellow mustard sauce is reduced, hydrolysis of allyl isothiocyanate is inhibited, and the flavor of the yellow mustard sauce is extended. Beta-cyclodextrin is added for embedding allyl isothiocyanate, so that the product is mellower in taste, tastes gentle and does not produce stimulation of nose choking, and the acceptable degree of the product is increased. Intermittent ultrasonic emulsification homogenization makes the yellow mustard sauce be more homogenous and have better smearing property, and flexible sterilization is adopted at a later period so as to better retain the flavor of the product.

Owner:JIANGNAN UNIV +1

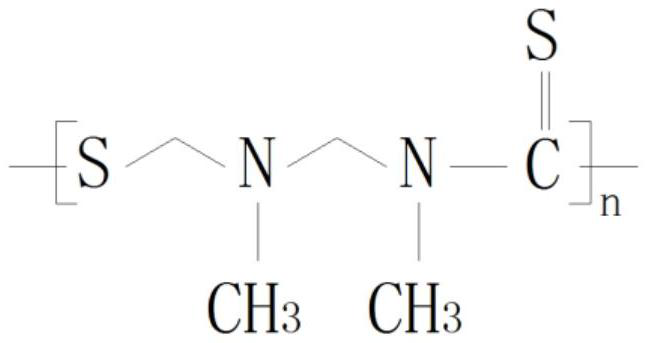

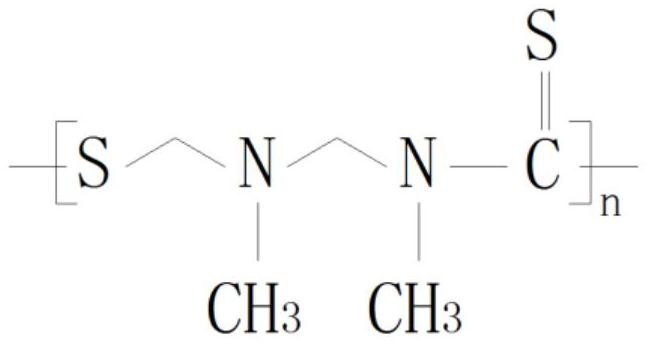

Molecularly imprinted polymer and preparation method and application thereof

ActiveCN102977334AGood slow releaseImprove freshnessPaper coatingCoatingsPolymer scienceFunctional monomer

The invention relates to a molecularly imprinted polymer which is an allyl isothiocyanate slow-release polymer synthesized by using allyl isothiocyanate as template molecule and beta-cyclodextrin as functional monomer. The obtained polymer is a new molecularly imprinted polymer having good slow-release properties, so as to provide a feasible preparation approach to the synthesis of allyl isothiocyanate molecularly imprinted polymers. Meanwhile, the prepared allyl isothiocyanate molecularly imprinted polymer is applied to the preservation field, and preservative paper made of the allyl isothiocyanate molecularly imprinted polymer has good preservative properties, which provides a feasible basis for the application of allyl isothiocyanate molecularly imprinted polymers in the preservation field.

Owner:GUIZHOU UNIV

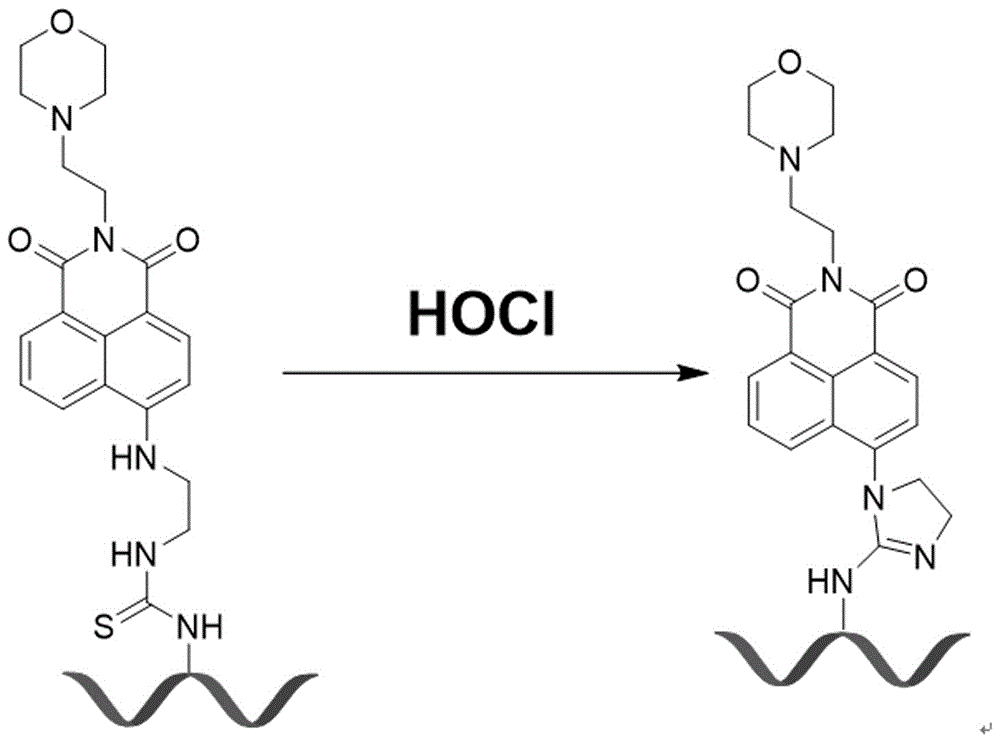

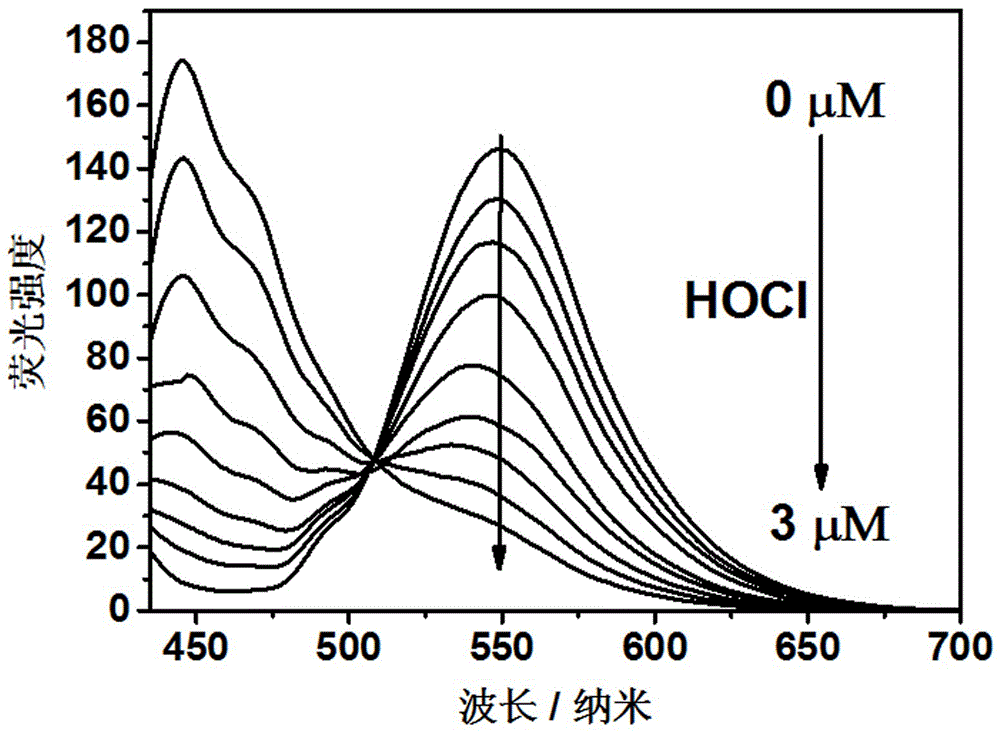

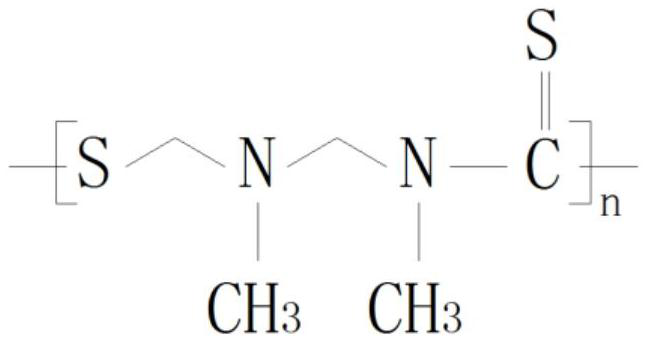

Polymer fluorescence sensor with hypochlorous acid ratio detection function and application of polymer fluorescence sensor

ActiveCN106478892AHigh selectivityRapid Specific IdentificationFluorescence/phosphorescenceCytotoxicityPolyethylene glycol

The invention discloses a polymer fluorescence sensor with a hypochlorous acid ratio detection function and application of the polymer fluorescence sensor. The polymer fluorescence sensor is a novel ratio fluorescence sensor prepared from polyethylene glycol monoethyl ether chain transfer agents (PEG-TTC), styrene (St), 4-bromine-1, 8-naphthoyl dianhydride and allyl isothiocyanate. Quick ratio detection can be carried out on the hypochlorous acid by the polymer fluorescence sensor in pure aqueous solution in a high-selectivity and high-sensitivity manner. Compared with existing fluorescence detection technologies, the polymer fluorescence sensor and the application have the advantages that the polymer fluorescence sensor is quick in response to hypochlorous acid high-selectivity ratio, low in cytotoxicity and input cost, excellent in water dispersibility and suitable to be applied to amplified synthesis and actual production and has a huge application prospect in the technical fields such as analytical chemistry, life science and environmental science, synthetic routes are simple, and the like.

Owner:HUNAN UNIV OF SCI & TECH

Synthesis and refining method of thiamethoxam intermediate 2-chloroallyl isothiocyanate

InactiveCN105175298AEasy to operateReduce generationOrganic chemistrySodium thiocyanateAllyl thiocyanate

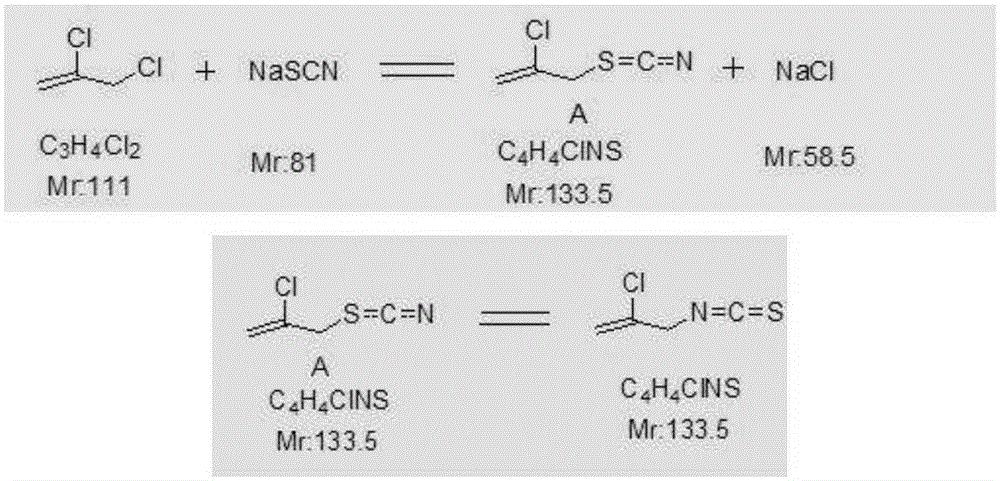

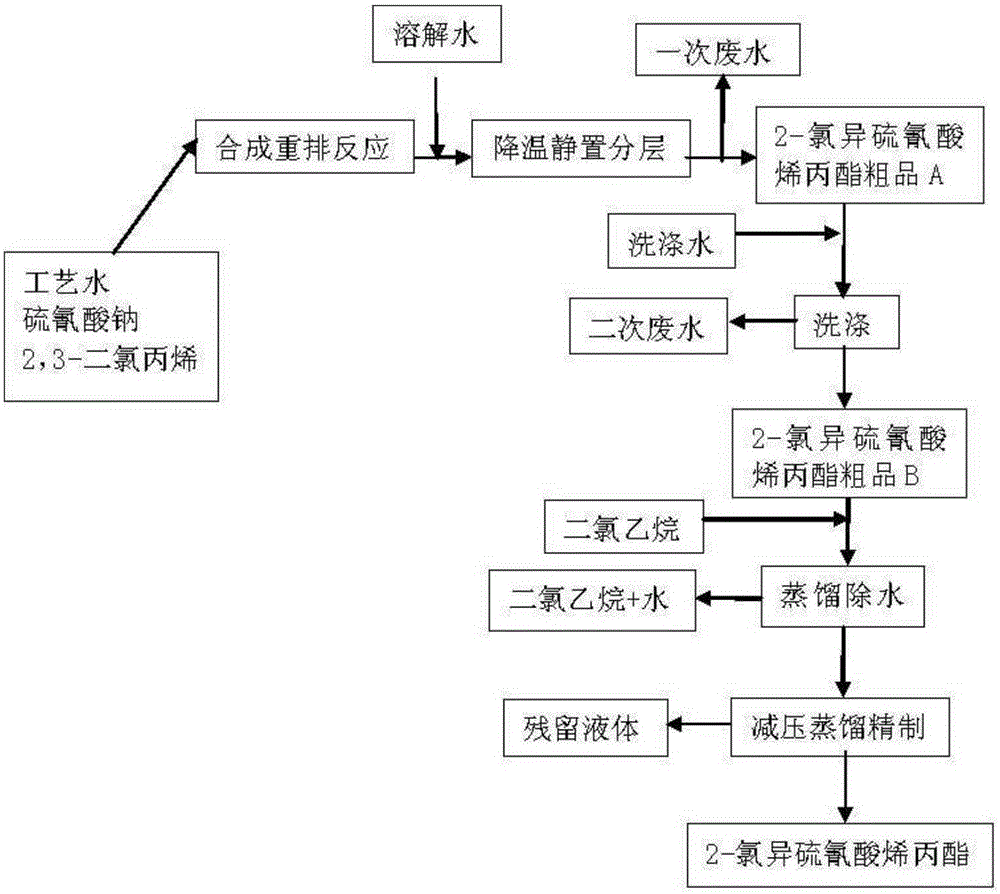

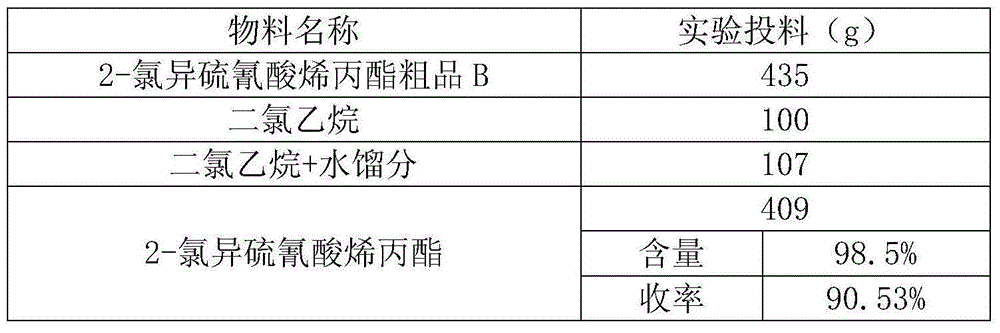

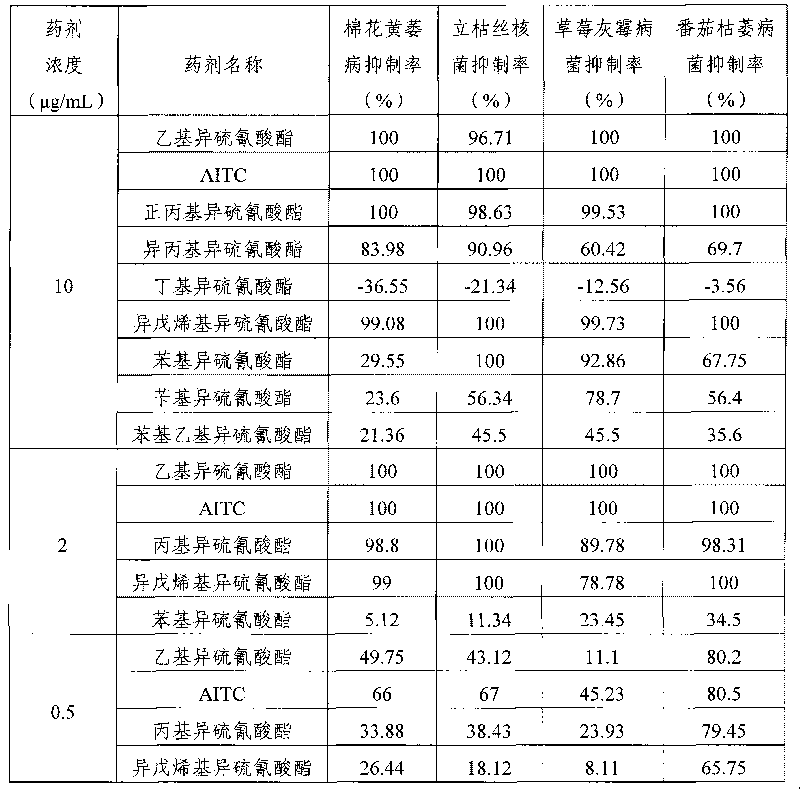

The invention discloses a preparation method of 2-chloroallyl isothiocyanate. The method includes: taking 2, 3-dichloropropene and sodium thiocyanate as reaction raw materials, in the presence of a solvent, replacing chloride ions with thiocyanate radicals to generate allyl thiocyanate, and then carrying out rearrangement reaction on allyl thiocyanate to generate 2-chloroallyl isothiocyanate; at the end of the reaction, conducting cooling, standing and layering on the material to obtain a 2-chloroallyl isothiocyanate crude product; and subjecting the 2-chloroallyl isothiocyanate crude product to dewatering treatment and refining, thus obtaining the2-chloroallyl isothiocyanate product. The method provided by the invention enables smooth and thorough nucleophilic substitution and rearrangement, and can achieve high yield.

Owner:SHANDONG ACADEMY OF PESTICIDE SCI +1

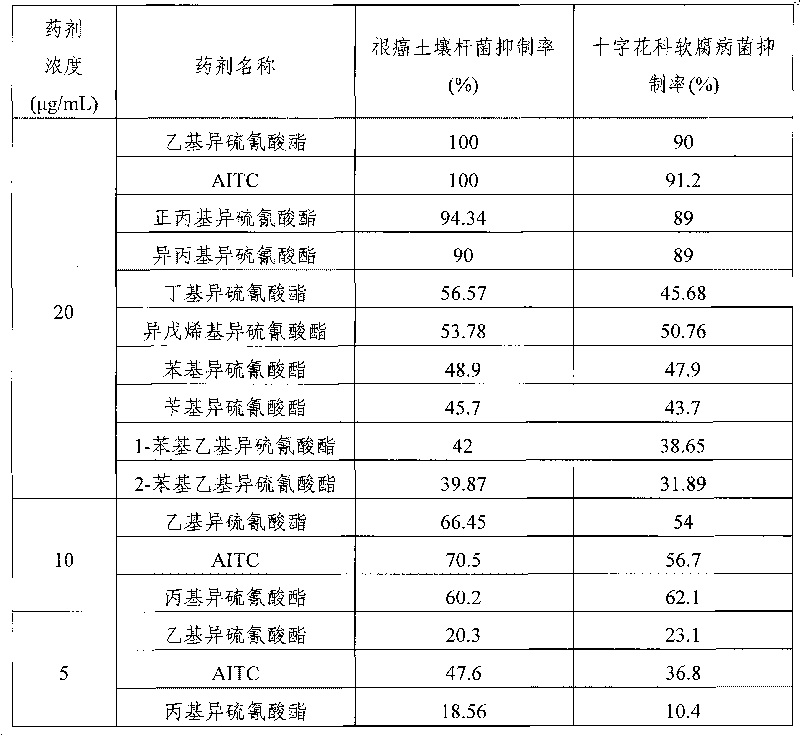

Composition of aromatic isothiocyanate and allyl isothiocyanate and application thereof

ActiveCN101731258AProlong the action timeSignificant synergyBiocideFungicidesAllyl thiocyanateActive ingredient

The invention provides a composition of aromatic isothiocyanate and allyl isothiocyanate, and the weight ratio of the two is 1:9-9:1. The invention further provides an application of the composition in preparation of pesticide fumigants for controlling soil-borne pathogens and soil nematodes. The composition has the advantages that the composition of the aromatic isothiocyanate and the allyl isothiocyanate takes the allyl isothiocyanate as a main active ingredient and takes the aromatic isothiocyanate as a synergistic ingredient, and can prolong the action time of a medicament, improve the control effect, realize the significant synergy, simultaneously reduce the dosage of the medicament, reduce the environmental pollution, be more environmentally friendly and be safe to people and animals.

Owner:武汉乐立基生物科技有限责任公司

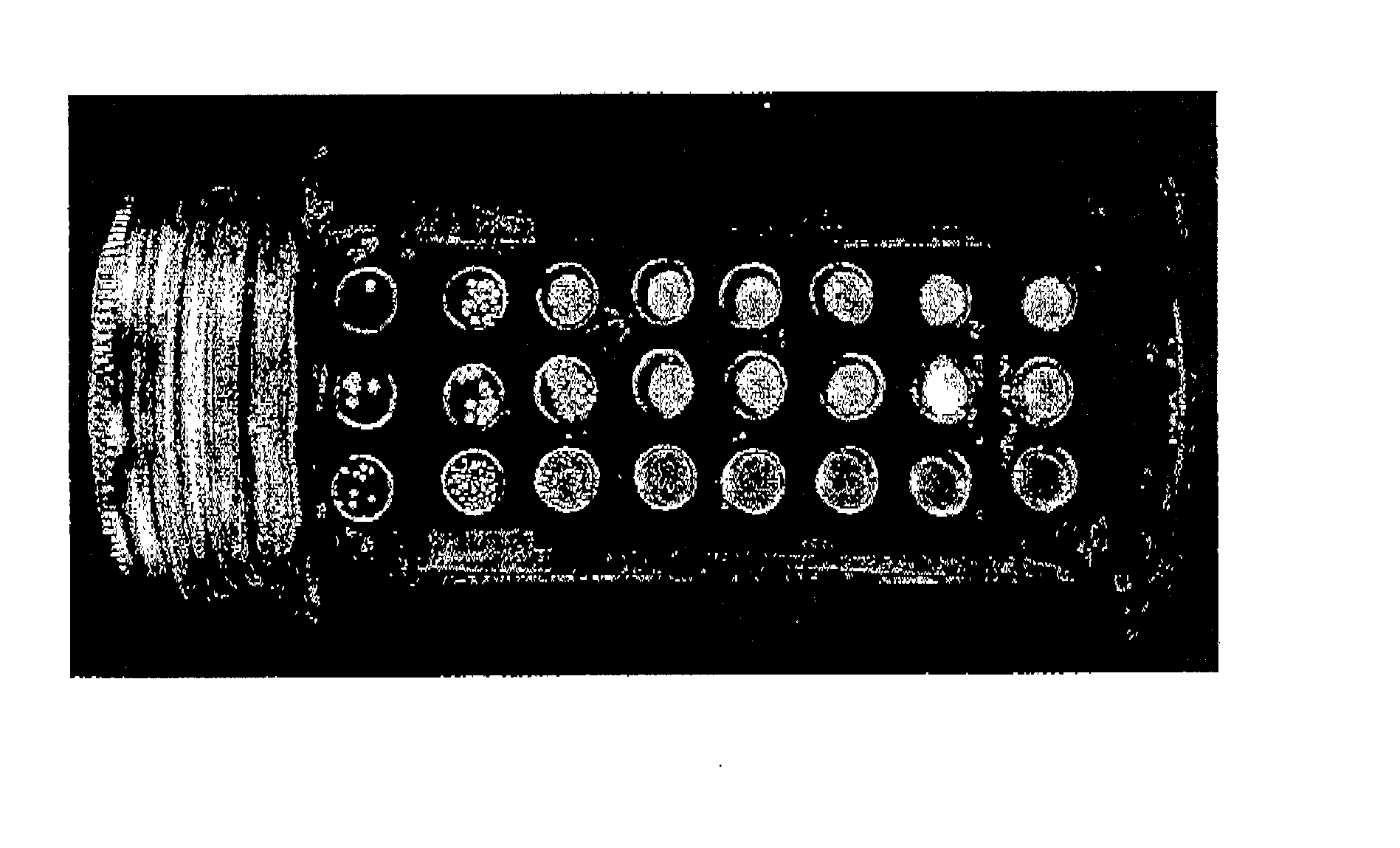

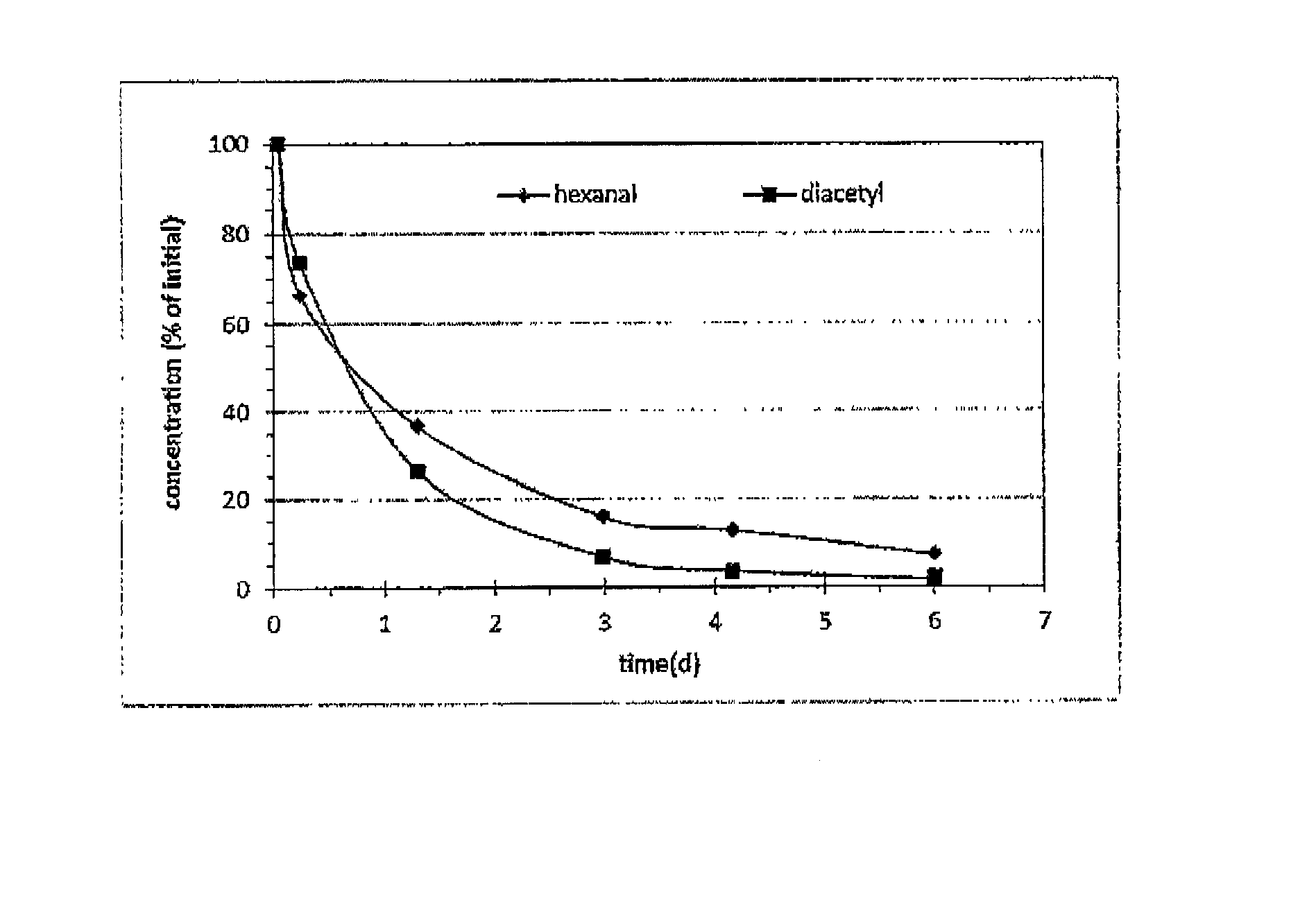

Antimicrobial mixtures of an essential oil derived bactericide and an essential oil derived fungicide which extend the shelf-life of perishable agricultural commodities

The disclosure provides an antimicrobial mixture of at least two volatile compounds derived from essential oils, at least one of which is a bactericide selected from cinnamaldehyde, diacetyl, and acetic acid with another being a fungicide selected from allyl isothiocyanate, hexanal, thymol, and 2-nonane. The antimicrobial mixture inhibits both bacterial and fungal pathogens that negatively impact the shelf-life of perishable agricultural commodities, and at concentrations sufficiently low to avoid phytotoxic effects to agricultural commodities held in closed shipping and storage systems.

Owner:VERSÉA HLDG INC

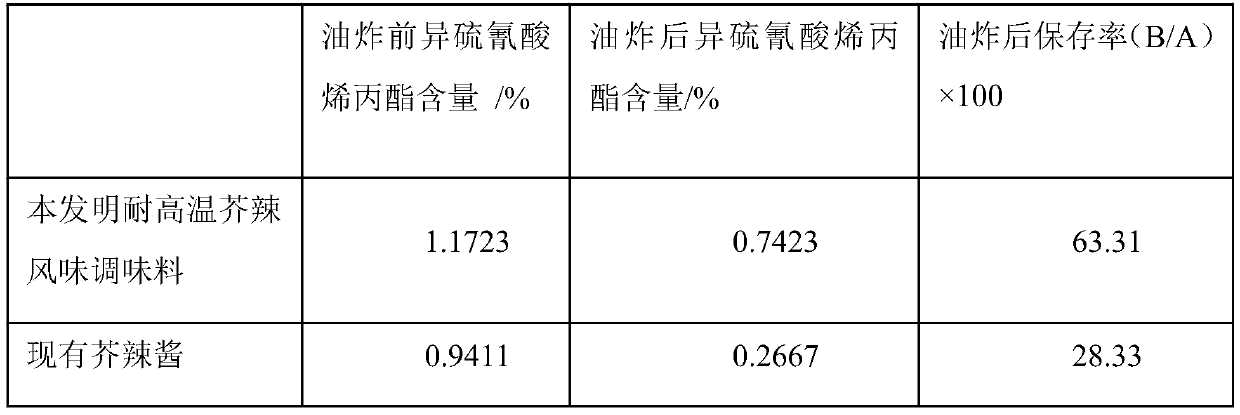

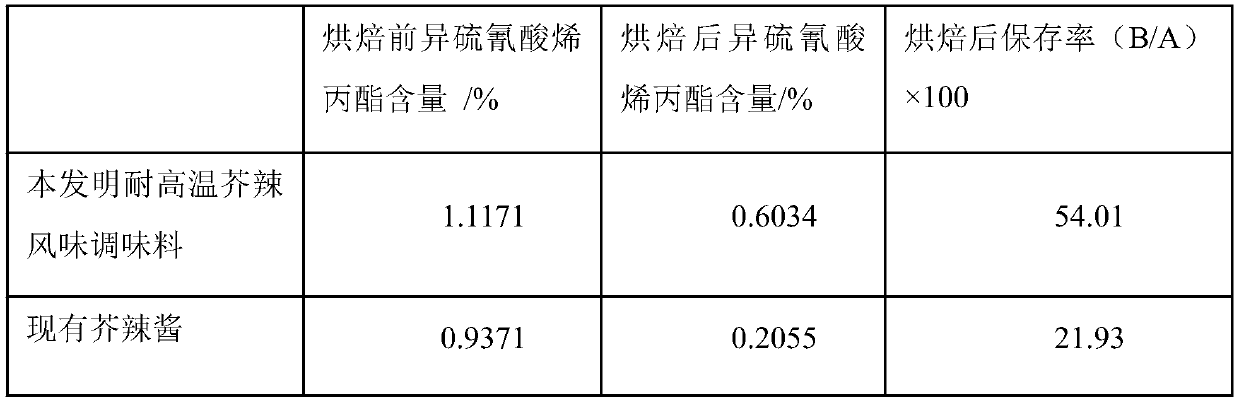

High-temperature-resistant mustard-flavored seasoning and preparation method and application thereof

The invention discloses a high-temperature-resistant mustard-flavored seasoning and a preparation method and application thereof, and belongs to the technical field of seasoning processing. Accordingto the formula, the high-temperature-resistant mustard-flavored seasoning is prepared from the following components in parts by weight: 15-20 parts of horseradish powder, 5-10 parts of mustard powder,5-10 parts of white vinegar, 2-4 parts of salt, 3-9 parts of xylitol, 50-70 parts of water, 6-8 parts of sunflower oil, 0.1-0.3 part of ginger powder, 0.4-0.8 part of xanthan gum, 0.1-0.4 part of white pepper, 4-6 parts of starch sodium octenylsuccinate, 0.2-0.5 part of nano silica sol, 5-6 parts of beta-cyclodextrin, 0.1-0.2 part of ascorbic acid and 0.2-0.4 part of glyceryl monostearate. The high-temperature-resistant mustard-flavored seasoning is prepared by taking horseradish as a raw material through the steps of freeze drying, ball-milling superfine pulverization, heating dissolving, stirring, soaking, burdening and radio frequency sterilization. The high-temperature-resistant mustard-flavored seasoning can be applied to coated high-temperature fried food or coated high-temperaturebaked food, the problem that allyl isothiocyanate substances do not resist heat and are volatile in the heating process of the mustard-flavored seasoning is solved, and the mustard flavor preservationrate of mustard sauce under the high-temperature condition exceeds 95%.

Owner:GUANGDONG JIAHAO FOOD +1

Root knot nematode disease control medicine for crops

InactiveCN104814067AGood insecticidal effectLow costBiocideNematocidesAllyl thiocyanateMeloidogyne incognita

The invention discloses a root knot nematode disease control medicine for crops. Raw materials of the medicine provided by the invention comprise, by weight, 20-40 parts of allyl isothiocyanate, 1-2 parts of a biological nematicide, 1-3 parts of chlorothalonil, 0.005-0.007 part of nimbin A, 0.05-0.2 part of nimbin B, 0.3-0.5 part of nimbin C and 20-30 parts of herb residue. The medicine provided by the invention has an excellent insecticidal effect on root-knot nematode and is low-cost. A method for preparing the medicine is simple. The medicine is friendly to the environment and crops and is pollution-free.

Owner:WEIFANG SHENGQUAN BIOTECH CO LTD

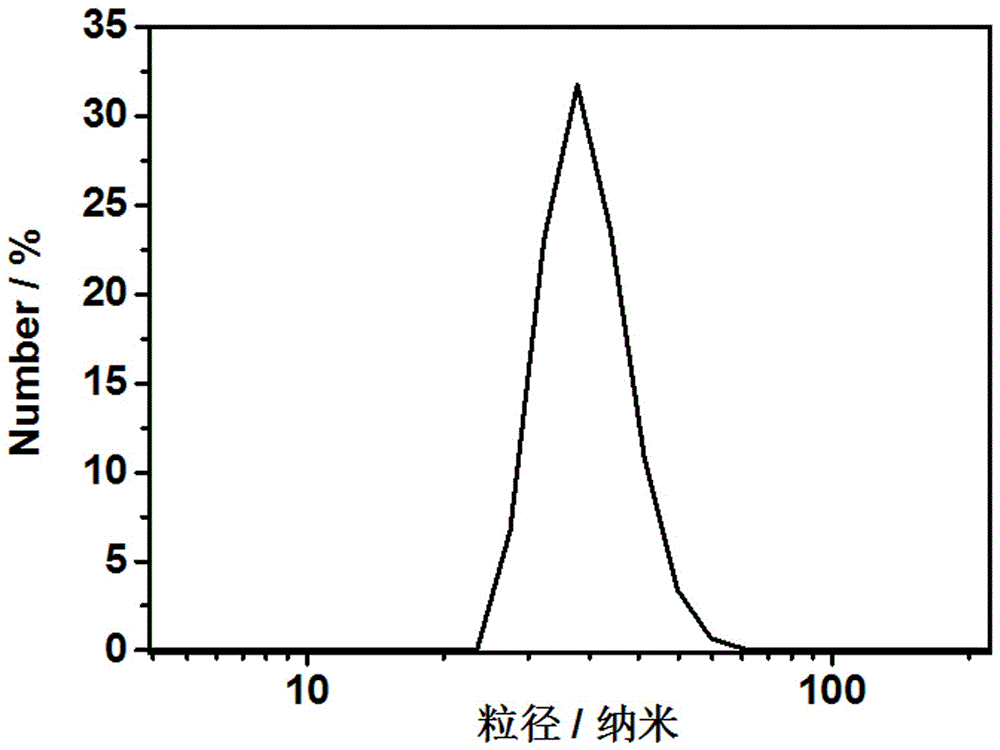

Preparation method of allyl isothiocyanate nanometer lipid carrier

ActiveCN103462934AImprove solubilityClearly targetedPharmaceutical non-active ingredientsEster active ingredientsLipid formationAdjuvant

Owner:上海海虹实业(集团)巢湖今辰药业有限公司

Allyl isothiocyanate and allicin compound and application thereof

InactiveCN104621252ASynergistic effect is obviousImprove insecticidal virulenceEdible seed preservationAllyl thiocyanateAspergillus flavus

The invention discloses an allyl isothiocyanate and allicin compound and an application thereof. The compound is prepared from allyl isothiocyanate (AITc), allicin and an organic solvent, and can be applied in food storage as a fumigation agent for food storage. The allyl isothiocyanate and allicin compound disclosed by the invention has an obvious synergistic effect; the insecticidal toxicity is obviously higher than that of any single dosage; the insecticidal bacteriostatic spectrum is obviously expanded; the control effect on pests, such as tribolium castaneum, oryzae philus surinamensis, sitophilus zeamais, grain moth and cryptolestes ferrugineus, in stored grain reaches over 95%; the bacteriostasis rate on a plurality of stored grain mildews such as aspergillus oryzae, aspergillus flavus, blue mould and aspergillus niger reaches over 95%; and the allyl isothiocyanate and allicin compound has relatively high cost advantages, economic benefits and relatively good control effect.

Owner:WUHAN POLYTECHNIC UNIVERSITY

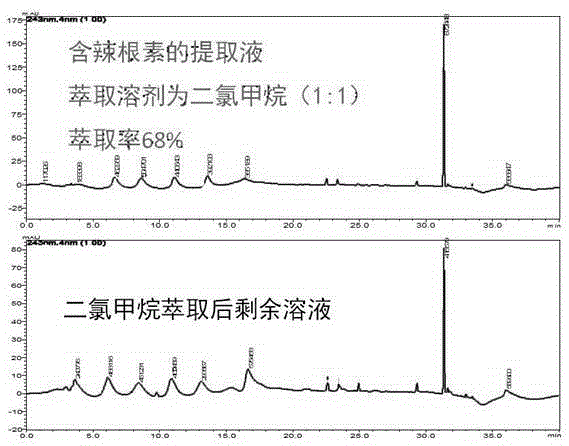

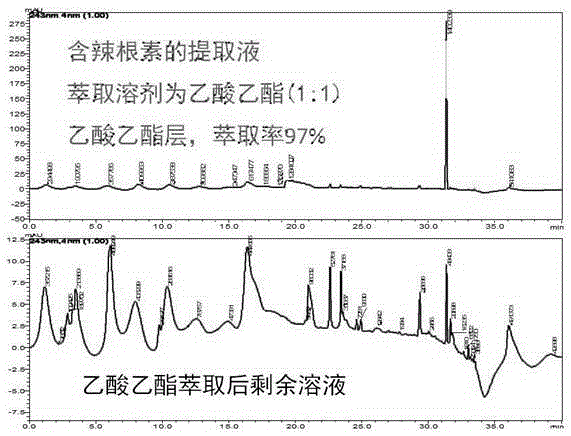

Method for extracting allyl isothiocyanate from horseradish

The invention discloses a method for extracting allyl isothiocyanate from horseradish. The method comprises 1, horseradish pretreatment: drying horseradish in a low temperature environment at a temperature of 35-45 DEG C, and crushing the dried horseradish by a crusher to obtain crude powder, 2, extraction solvent preparation: preparing a solution from ethyl acetate and water according to a ratio of 1: 10-1: 20, and adding sodium chloride into the solution according to a volume ratio of sodium chloride to the solution of 1-2%, and 3, distillation extraction: adding the horseradish crude powder obtained by the step 1 and the solvent obtained by the step 2 into a distillation flask according to a material-liquid ratio of 1: 10-1: 30 and carrying out distillation for 1-2h. The method utilizes ethyl acetate-water-sodium chloride as extraction solvents to realize distillation extraction. The method can be operated simply, has simple processes and a low cost and is suitable for large-scale industrial production.

Owner:山东凯耶生物科技有限公司

Synergistic soil fumigation composition

The invention relates to a synergistic soil fumigation composition, the effective components of which are allyl isothiocyanate (A) and chloropicrin (B) in a mass ratio of 1:1-1:100. The composition provided by the invention is used for soil fumigation of melons and vegetables, medicinal materials, strawberries, tobacco, fruit trees, and nurseries.

Owner:SHENZHEN NOPOSION AGROCHEM

Biological fumigation synergistic composition, safe long-acting biological fumigation agent and application

The invention relates to the technical field of biopesticides, and particularly discloses a biological fumigation synergistic composition, a safe long-acting biological fumigation agent and application, the biological fumigation synergistic composition is prepared from raw materials including allyl isothiocyanate and a synergist, the weight ratio of allyl isothiocyanate to synergist is (1.5-99): 1, the synergist is one or more of eucalyptol, ethylicin and sec-butyl acetate, and the synergist is added into the allyl isothiocyanate so that the pesticide effect of the allyl isothiocyanate is improved, and the biological fumigant has good use effect and safety. Meanwhile, the biological fumigant is prepared into a complexing agent, a soluble concentrate, an oiling agent, an emulsifiable concentrate preparation, a microcapsule suspending agent and the like so that the biological fumigant can be selected according to different occasions and has good stability and persistence.

Owner:BEIJING AGRON BIO PHARM

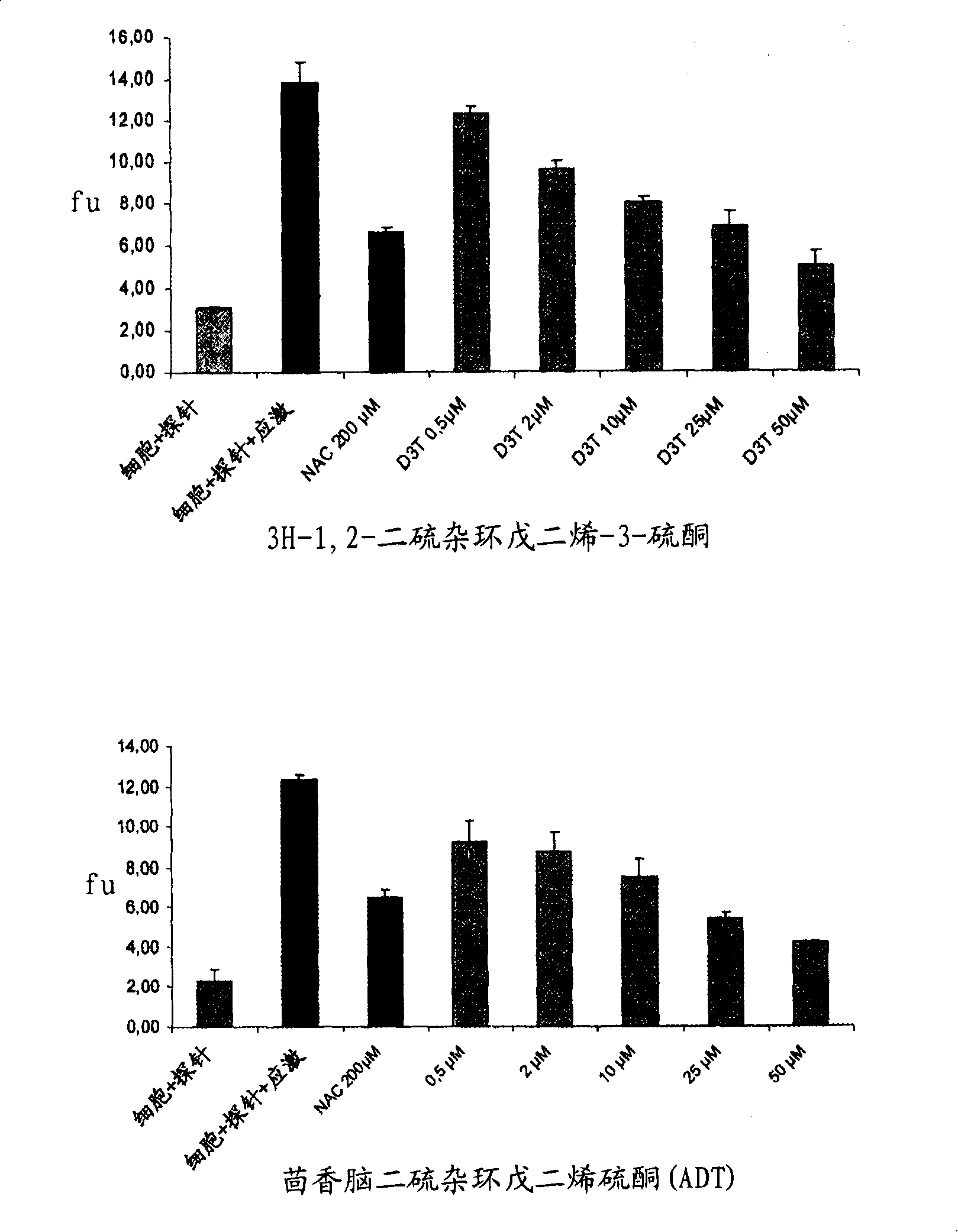

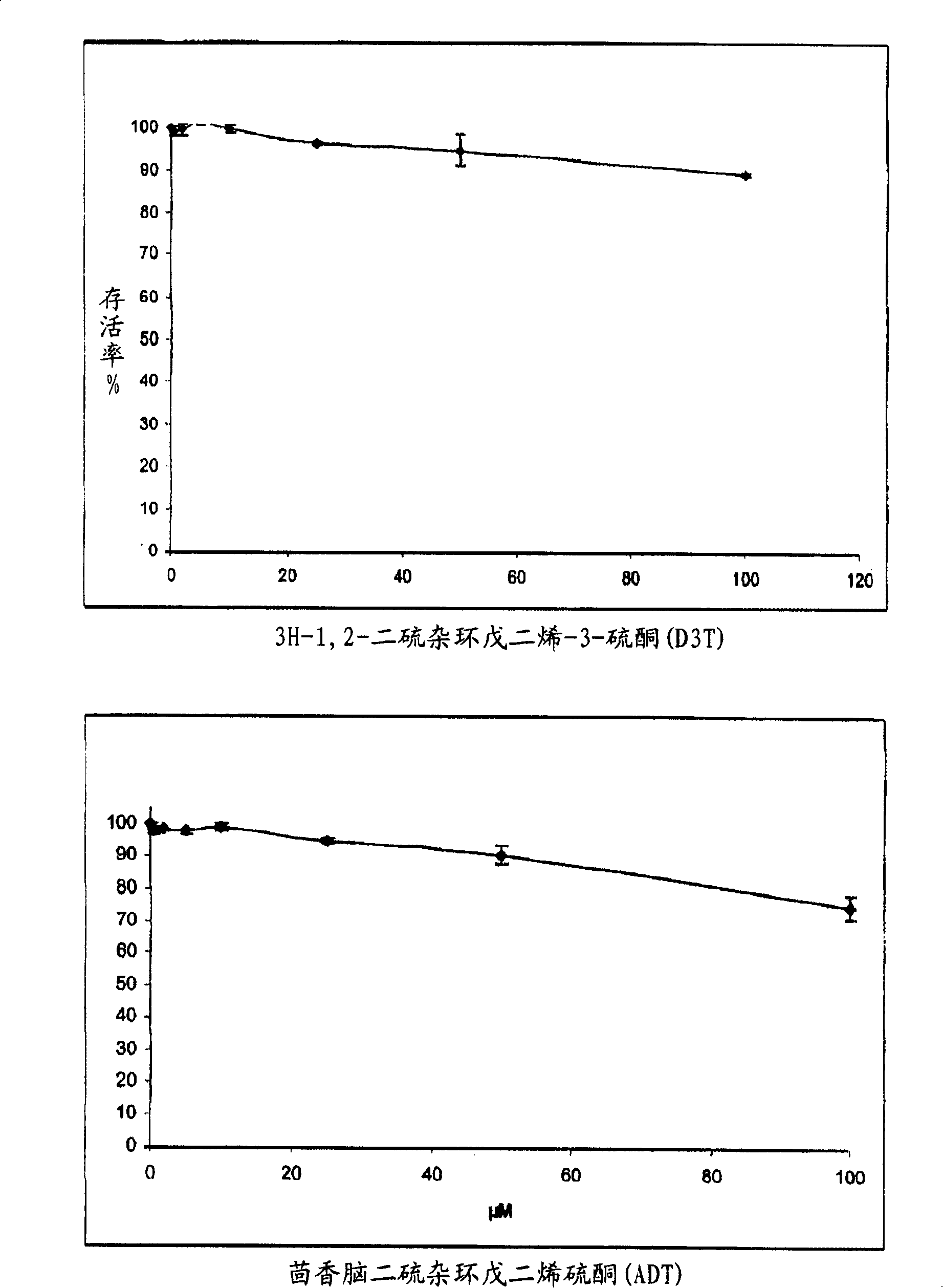

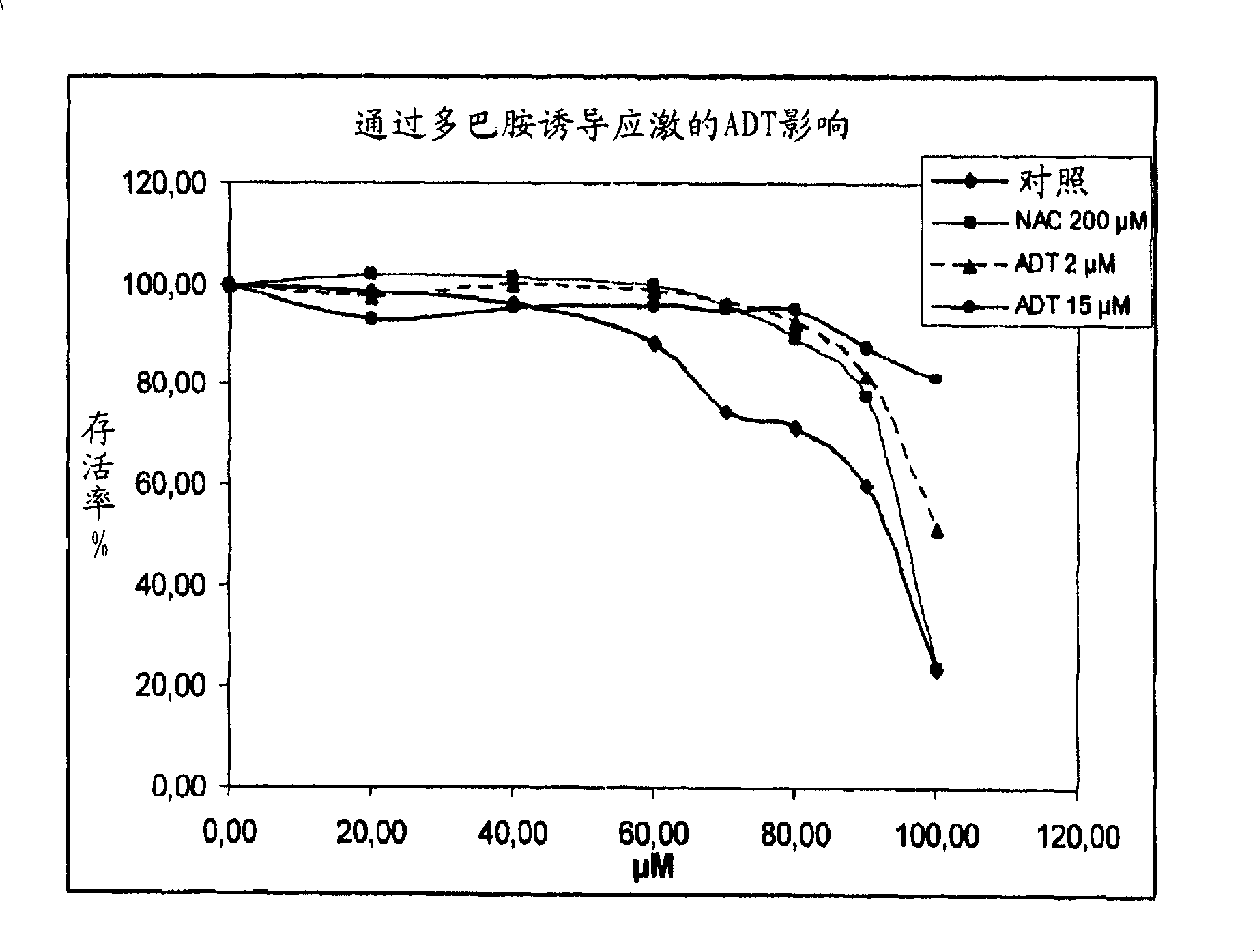

Use of 3h-1,2-dithiole-3-thione, anethole dithiolethione, sulphoraphane, phenethyl isothiocyanate, 6-(methylsulphinyl)hexyl isothiocyanate and allyl isothiocyanate for the treatment of canities

The invention relates to a use of 3h-1,2-dithiole-3-thione, anethole dithiolethione, sulforaphane, phenethyl isothiocyanate, 6-methyl-sulphinyl)hexyl isothiocyanate and allyl isothiocyanate and derivatives thereof for treating whitening of the hair and combination thereof. At least one compound selected from among 3H-1,2-dithiole-3-thione, anethole dithiolethione, sulforaphane, phenethyl isothiocyanate, 6-(methylsulfinyl)hexyl isothiocyanate and allyl isothiocyanate and derivatives and mixtures thereof, and admixtures thereof with other active agents selected from among active agents for combating desquamative conditions of the scalp, plant extracts having propigmenting activity and active agents that slow hair loss and / or promote hair regrowth, are useful for preventing and / or limiting and / or stopping the development of canities.

Owner:LOREAL SA

Attractant for diamondback moth

InactiveCN101347132BGood lure effectStrong attractionBiocidePest attractantsAllyl thiocyanateDiamondback moth

Owner:GUANGDONG INST OF APPLIED BIOLOGICAL RESOURCES

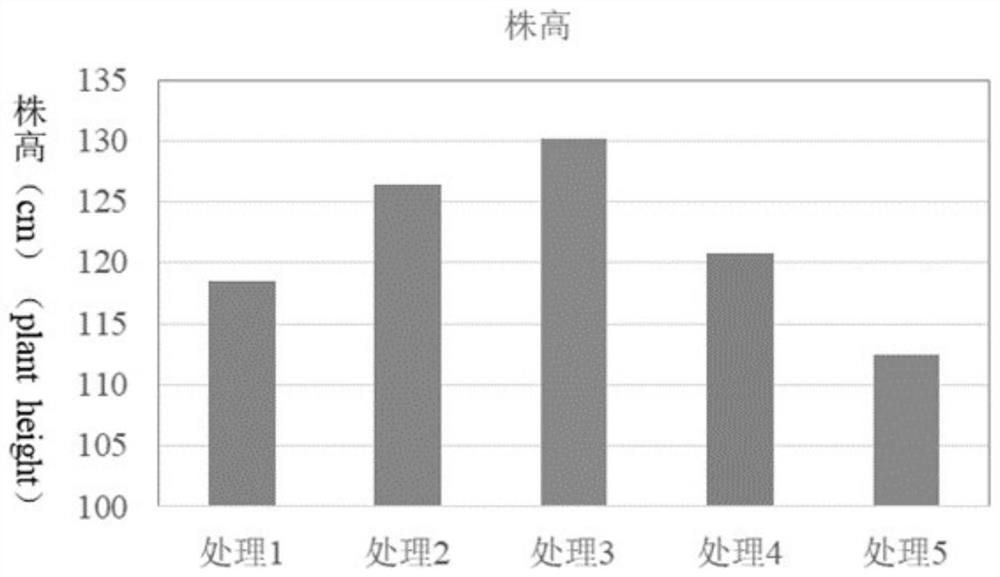

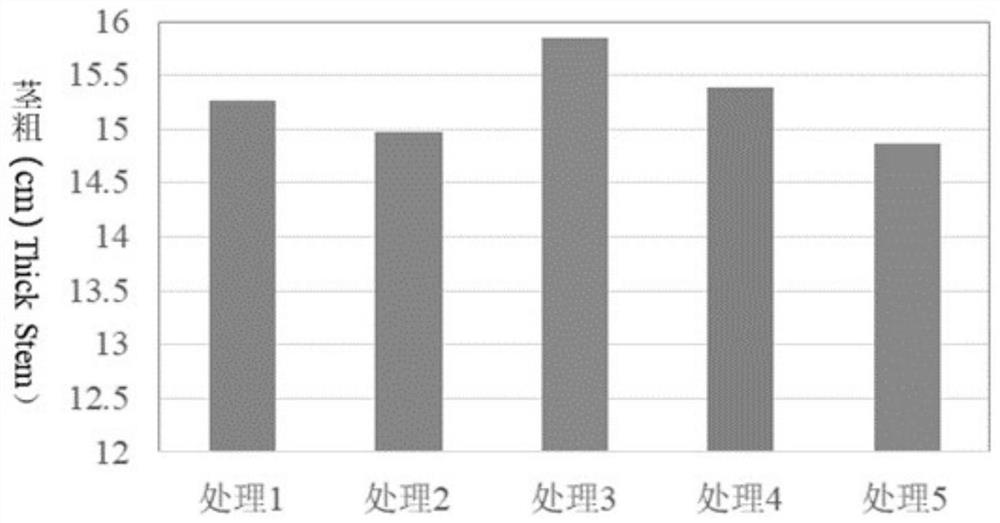

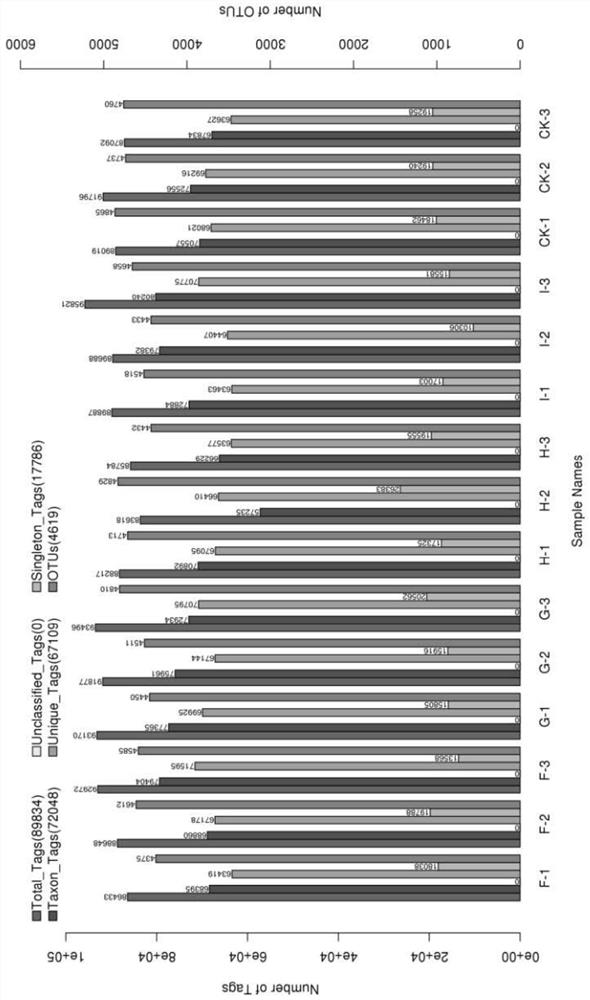

Chili planting method capable of reducing influence of continuous cropping obstacles

PendingCN111758510AReduce the impact of continuous cropping obstaclesPromote growthClimate change adaptationHorticulture methodsBiotechnologyContinuous cropping

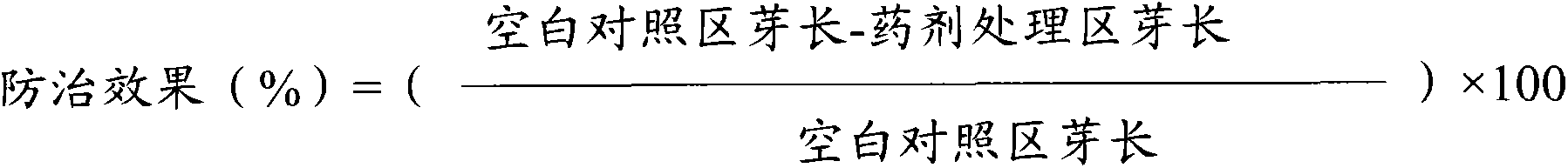

The invention provides a chili planting method capable of reducing the influence of continuous cropping obstacles. The method comprises the following steps: dripping diluted 20% allyl isothiocyanate emulsion in water on the soil to be planted with chilies according to the application amount of 7.0-11.0 L / 667m<2> 3-5 days before chili planting. Test shows, comparing with a control group, the methoddrips diluted the 20% allyl isothiocyanate emulsion in water on the soil to be planted with chilies according to the application amount of 7.0-11.0 L / 667m<2>, and the method is beneficial to growth of chili plants, improvement of photosynthesis in the chili growth process, improvement of soil enzyme activity and improvement of chili planting soil microbial diversity, thereby being beneficial to reduction of chili continuous cropping obstacle influence, prevention and control of chili diseases and insect pests, and improvement of chili yield and quality.

Owner:NINGXIA ACADEMY OF AGRI & FORESTRY SCI

Packaging material for foods

The invention discloses a packaging material for foods. The packaging material for the foods is prepared from, by weight, 10-65 parts of corn, 15-35 parts of soybeans, 20-38 parts of wheat fiber, 10-26 parts of lilies, 18-46 parts of ginger peels, 20-45 parts of casein films, 14-36 parts of a gum solution, 16-66 parts of allyl thiocyanates and 8-40 parts of monoglyceride. In the mode, the packaging material for the foods can keep foods' moisture, has good moisture-proof oxygen-insulation effects, can further control the growth of bacteria in foods and spoilage caused by microorganisms and prolong the refreshing time of the foods, improves the flavors of packaged foods, is degradable and does not cause environmental pollution.

Owner:方益龙

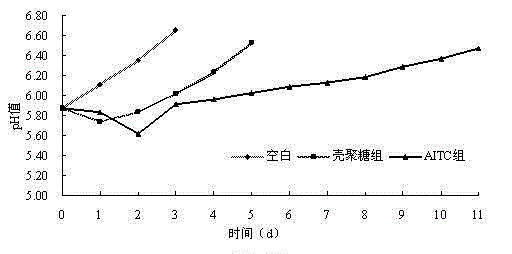

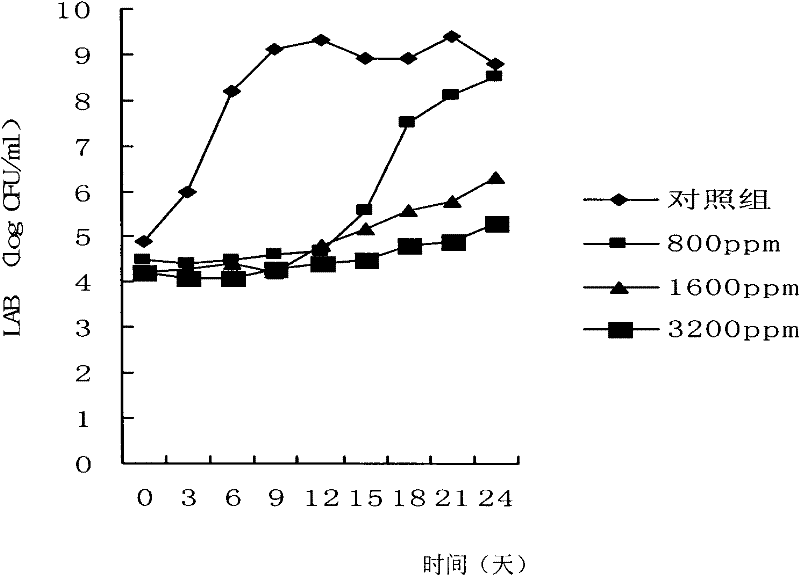

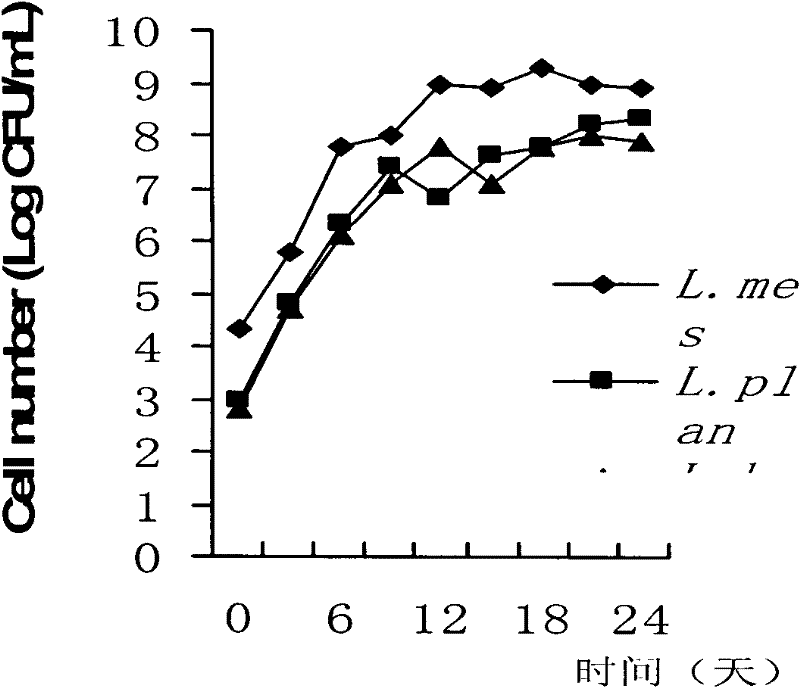

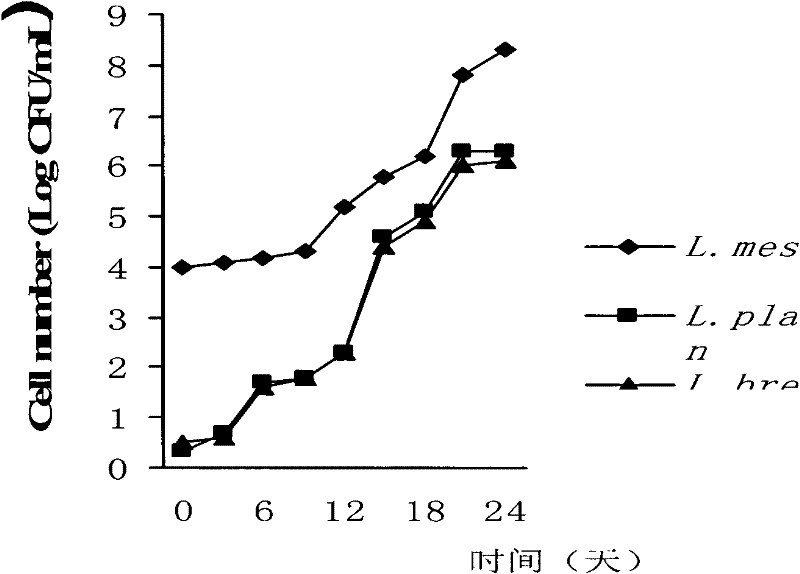

Application of horseradish extract glucose allyl isothiocyanate solution in preparing spicy cabbage food

The invention relates to application of a horseradish extract glucose allyl isothiocyanate solution in preparing spicy cabbage food. The invention is characterized in that the horseradish extract glucose allyl isothiocyanate solution is used as a bacteriostatic agent in preparing the spicy cabbage food; the concentration of the solution is 800-3200ppm; and the dosage is 5-10% (V / W) of the spicy cabbage food. The glucose allyl isothiocyanate solution selected in the invention has a strong sterilization effect. Experiments prove that the solution not only can be used for reducing the bitterness of the traditional fermentation food spicy cabbage, but also can be used for improving the flavor of the spicy cabbage, and simultaneously prolonging the shelf life of the spicy cabbage.

Owner:WEIHAI BAIHE BIOTECH

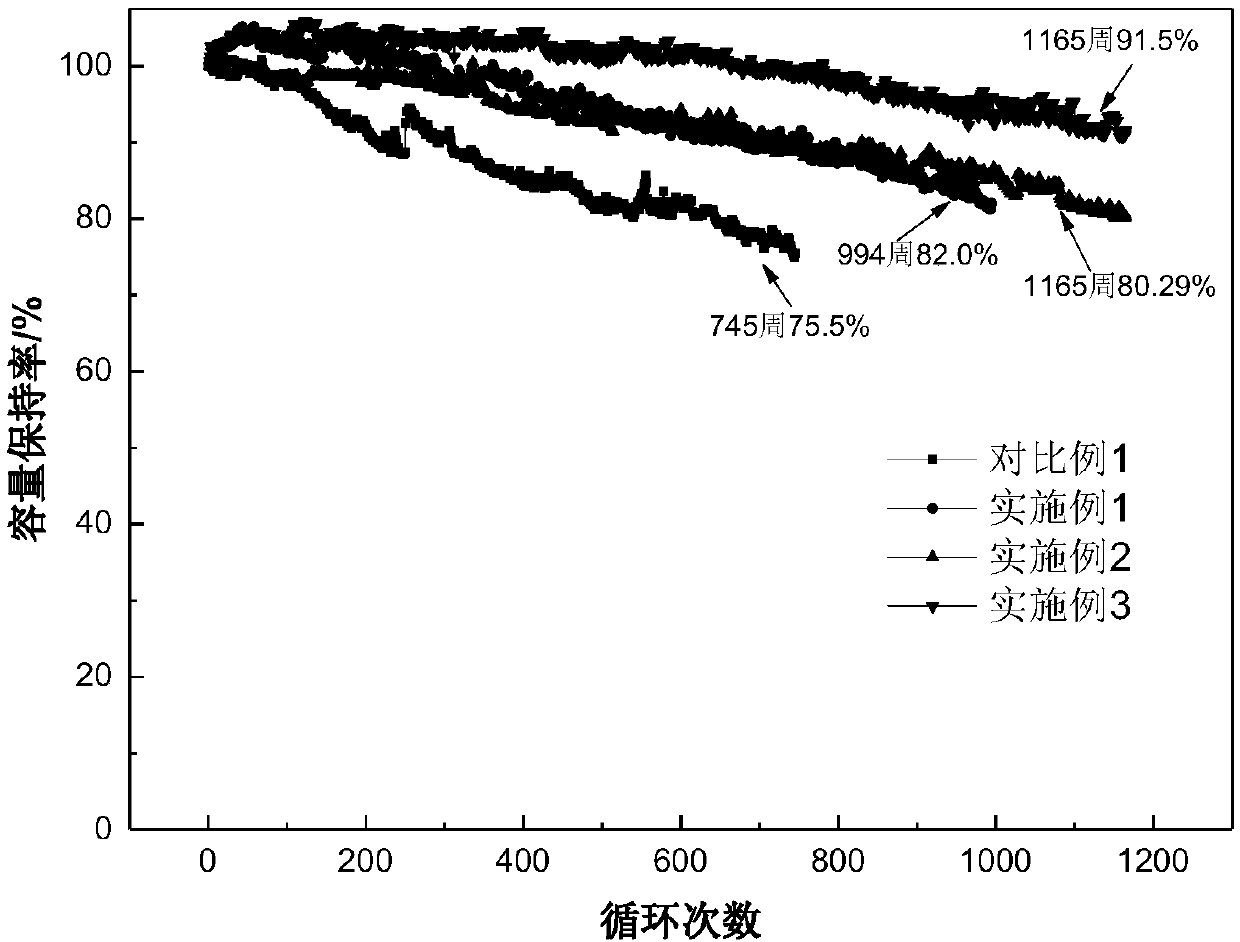

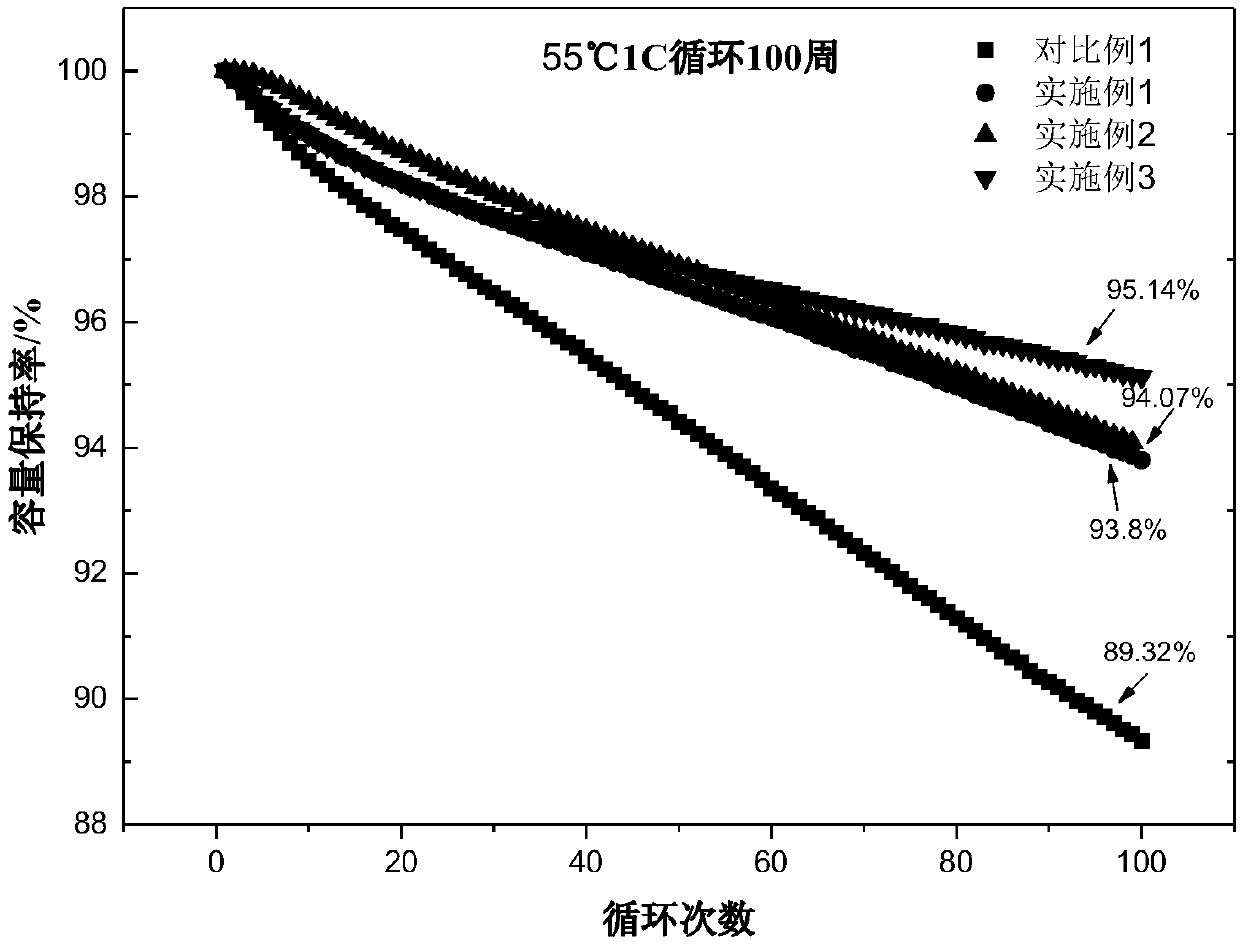

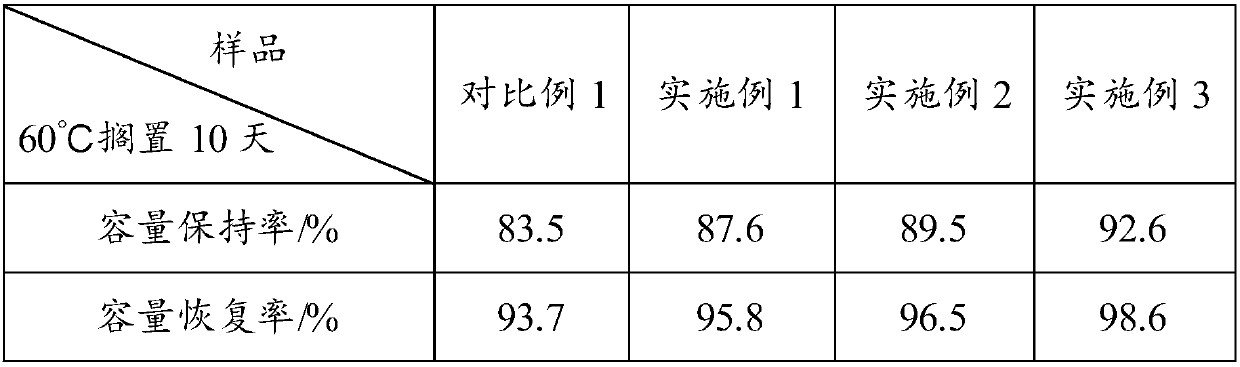

Lithium titanate power battery

InactiveCN107732301APromote circulationHigh capacity retentionSecondary cellsHigh energyAllyl thiocyanate

Owner:SHENZHEN ANDING NEW ENERGY TECH DEV CO LTD

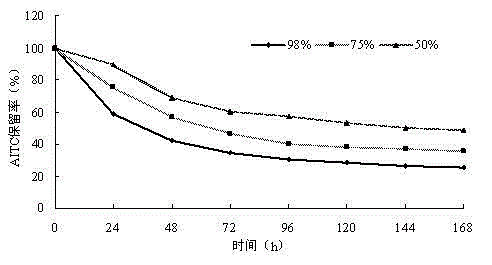

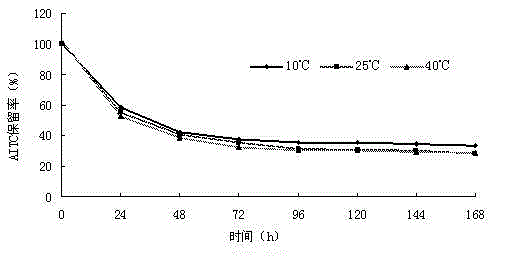

Bactericide composition, controlled release system and applications thereof

ActiveCN110200005AGood control effectLong-term controlBiocideFungicidesControl releaseActive component

The invention provides a bactericide composition, a controlled release system and applications thereof, wherein the active components of the bactericide composition and the controlled release system are allyl isothiocyanate and an aldehyde-based compound. According to the present invention, the bactericide composition and the controlled release system have good prevention and control effects on Phytophthora infestans, and can control Phytophthora infestans in a long-acting manner, reduce the use frequency and reduce the cost; by separately using allyl isothiocyanate or combining allyl isothiocyanate and a certain aldehyde-based compound, Phytophthora infestans can be effectively controlled, and the effective duration can be up to 3 months, such that a certain combination of allyl isothiocyanate and aldehyde can provide the synergistic effects in the prevention and control of Phytophthora infestans.

Owner:NANJING SINO GREEN BIOTECH

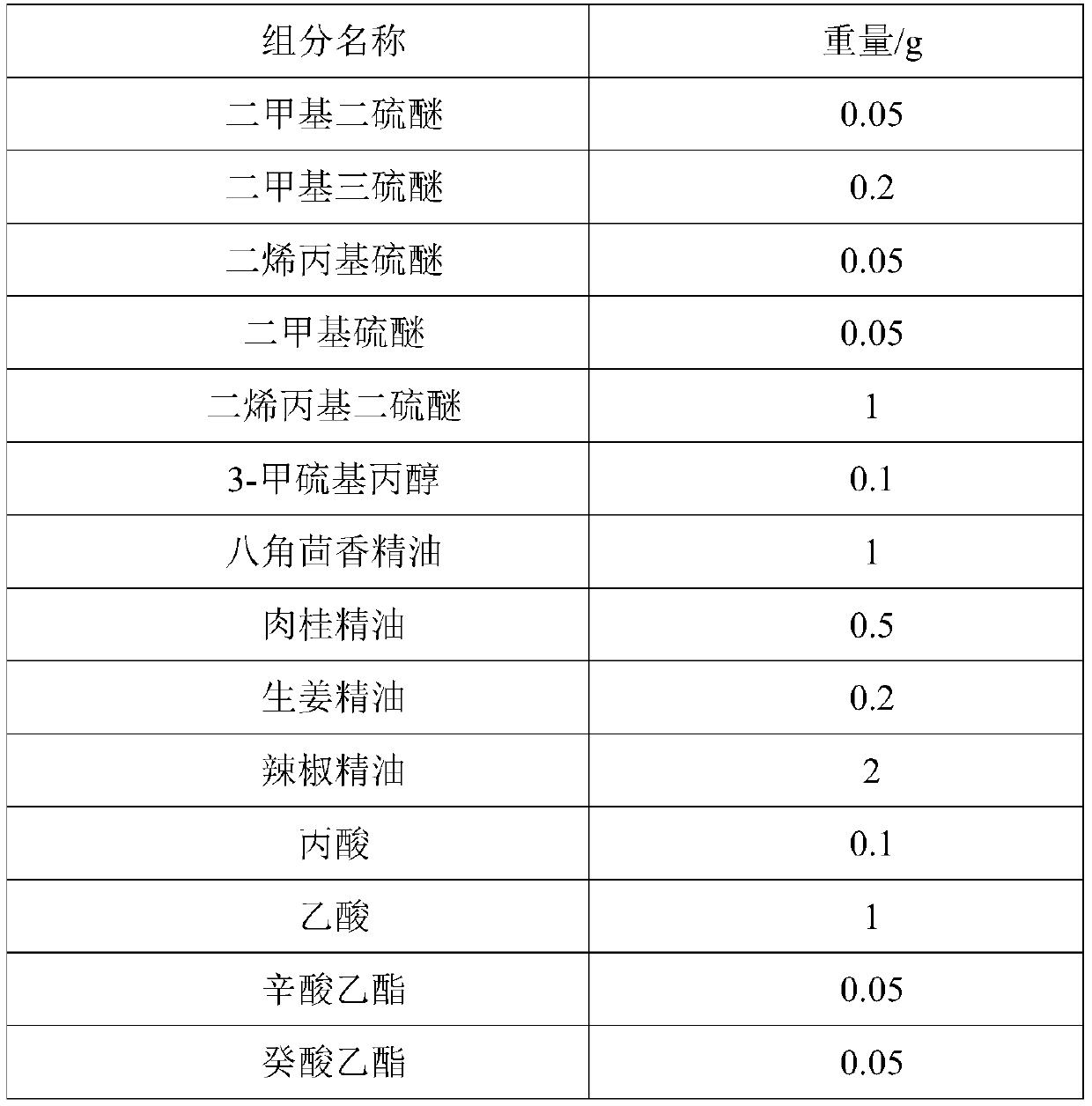

Preparation method of Korean pickled vegetable essence

ActiveCN110140935AFragrance aroma is pure and fullIncrease the fragranceClimate change adaptationAcidic food ingredientsPropanoic acidAllyl thiocyanate

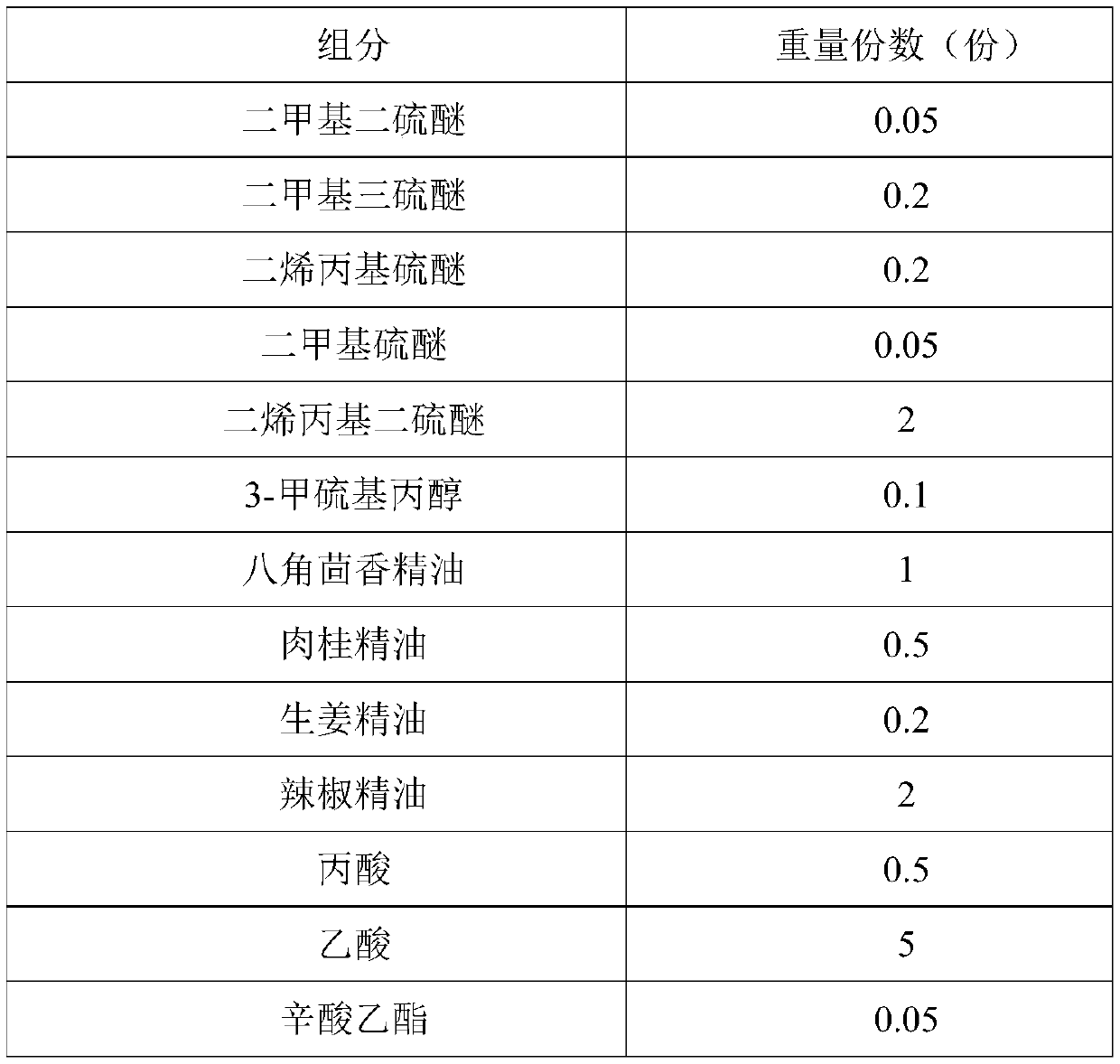

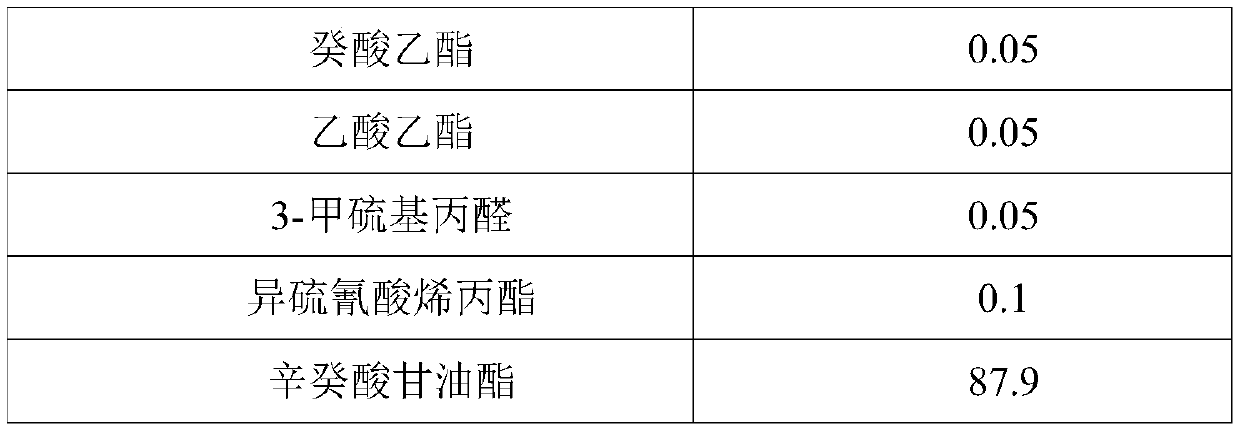

The invention provides a preparation method of Korean pickled vegetable essence. The disclosed Korean pickled vegetable essence comprises the ingredients of Caprylic capric triglycerride,, dimethyl disulfide, dimethyl trisulfide, diallyl sulfide, dimethyl sulfide, diallyl disulfide, 3-methylthiopropanol,, star anise essential oil, cinnamon essential oil, fresh ginger essential oil, chili pepper essential oil, propanoic acid, acetic acid, ethyl caprylate, ethyl caprate, ethyl acetate, 3-methylthiopropyl aldehyde and allyl isothiocyanate. The prepared pickled vegetable essence has the characteristics of being real and natural in fragrance, rich in mouth feel and stable in flavor, the appetence degree of a consumer is increased, and the Korean pickled vegetable essence can be well applied tothe field of foods of leisure puffed foods and the like.

Owner:江西省华宝孔雀食品科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com