Molecularly imprinted polymer and preparation method and application thereof

A technology of molecular imprinting and polymers, applied in textiles and papermaking, fiber raw material treatment, paper coating, etc., can solve the problems of short slow-release time and unfavorable slow-release, and achieve good fresh-keeping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Weigh 5g of β-cyclodextrin and dissolve in 50mL of dimethyl sulfoxide solution, add 0.2mL of allyl isothiocyanate and stir magnetically at 45°C for 6h. Sonicate for 10 minutes to mix well, then remove the air in the liquid, pass through nitrogen protection, and add 3mL 2,4-toluene diisocyanate, and stir at constant temperature for 24 hours at 65°C under nitrogen protection. Cool to room temperature, add stirred acetone to precipitate the molecularly imprinted polymer from the solution, vacuum filter and wash the precipitate repeatedly with acetone and hot water at 50°C, respectively, to elute unreacted cross-linking agent and monomer molecules. Grind finely after vacuum drying and store dryly.

[0038] The yield of the obtained polymer was 53.13%, and the AITC content was 40.45 μl / g.

[0039]

Embodiment 2

[0041] Weigh 5g of β-cyclodextrin and dissolve in 150mL of dimethyl sulfoxide solution, add 0.3mL of allyl isothiocyanate and stir magnetically at 45°C for 6h. Sonicate for 10 minutes to mix well, then remove the air in the liquid, pass through nitrogen protection, and add 4mL of 2,4-toluene diisocyanate, and stir at constant temperature for 24 hours at 65°C under nitrogen protection. Cool to room temperature, add stirred acetone to precipitate the molecularly imprinted polymer from the solution, vacuum filter and wash the precipitate repeatedly with acetone and hot water at 50°C, respectively, to elute unreacted cross-linking agent and monomer molecules. Grind finely after vacuum drying and store dryly.

[0042] The yield of the obtained polymer was 53.97%, and the AITC content was 49.14 μl / g.

[0043]

Embodiment 3

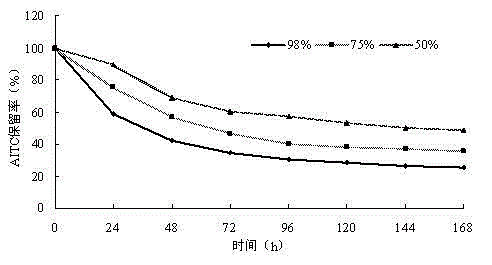

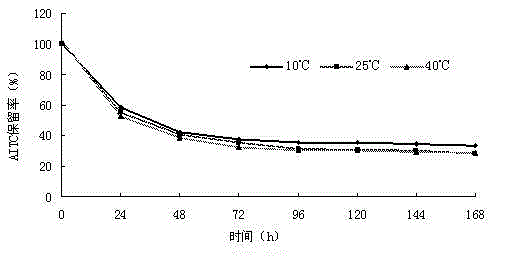

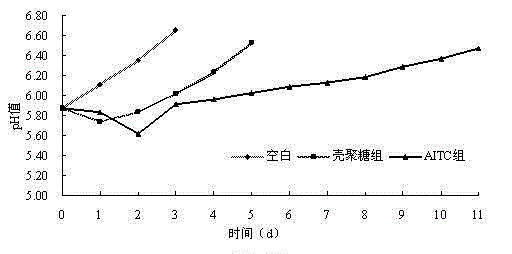

[0045] Sustained-release effect of allyl isothiocyanate molecularly imprinted polymer under different humidity conditions

[0046] Weigh 5g of β-cyclodextrin and dissolve in 100mL of dimethyl sulfoxide solution, add 0.4mL of allyl isothiocyanate and stir magnetically at 45°C for 6h. Sonicate for 10 minutes to mix well, remove the air in the liquid, pass through nitrogen protection, add 5mL 2,4-toluene diisocyanate, and stir at 65°C for 24 hours under nitrogen protection. Cool to room temperature, add stirred acetone to precipitate the molecularly imprinted polymer from the solution, vacuum filter and wash the precipitate repeatedly with acetone and hot water at 50°C, respectively, to elute unreacted cross-linking agent and monomer molecules. Grind finely after vacuum drying and store dryly.

[0047] The yield of the obtained polymer was 65.02%, and the AITC content was 53.66 μl / g.

[0048] Weigh about 2.0 g of the prepared molecularly imprinted polymer, spread it evenly on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com