High-temperature-resistant mustard-flavored seasoning and preparation method and application thereof

A flavor seasoning, high temperature resistant technology, applied in the field of seasoning processing, can solve the problem that the spicy flavor weakens the pungent flavor of allyl isothiocyanate, the spicy flavor of mustard is not fully utilized, and the isothiocyanate substances are not fully utilized. Stability and other issues, to achieve the effect of prolonging the wasabi flavor, good wasabi flavor, and avoiding the volatilization of isothiocyanates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

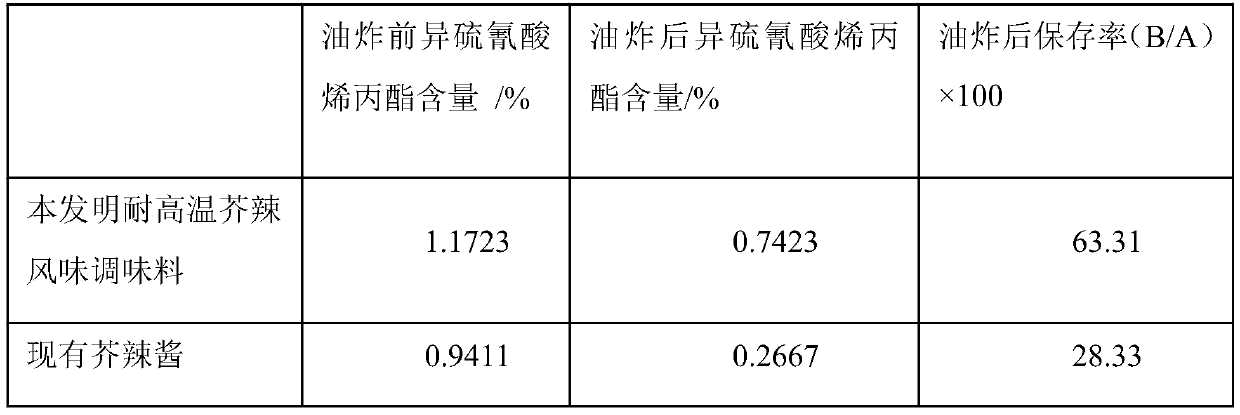

[0032] Example 1 Preparation of high temperature resistant mustard flavor seasoning and its application in fried pea coating

[0033] The formula ratio of high temperature resistant mustard flavor seasoning is as follows: 15 parts of horseradish powder, 5 parts of mustard powder, 5 parts of white vinegar, 2 parts of salt, 5 parts of sodium glutamate, 3 parts of xylitol, 60 parts of water, 6 parts of sunflower oil 0.1 part of ginger powder, 0.5 part of xanthan gum, 0.2 part of white pepper, 4 parts of sodium starch octenyl succinate, 0.5 part of nano-silica sol, 4 parts of β-cyclodextrin, 0.1 part of ascorbic acid, monostearic acid 0.2 part of glyceride.

[0034] The specific preparation steps of the high-temperature-resistant mustard flavor seasoning are as follows:

[0035] 1) Drying: Wash and slice 500g of horseradish, put it into a freeze dryer for drying, the temperature of the cold trap is -42°C, and the degree of vacuum is 80Pa;

[0036] 2) Ball milling: Use an ultra-mic...

Embodiment 2

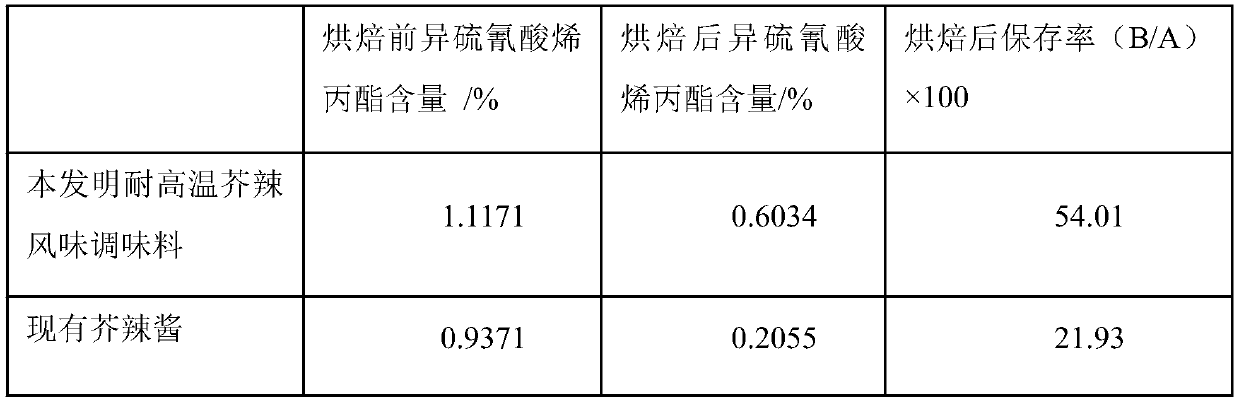

[0047] Example 2 Preparation of high temperature-resistant mustard flavor seasoning and its application in baking peanut coating

[0048] The formula ratio of high temperature resistant mustard flavor seasoning is as follows: 15 parts of horseradish powder, 5 parts of mustard powder, 3 parts of white vinegar, 5 parts of salt, 5 parts of sodium glutamate, 3 parts of xylitol, 55 parts of water, 4 parts of sunflower oil 0.1 part of ginger powder, 1 part of xanthan gum, 0.2 part of white pepper, 5 parts of sodium starch octenyl succinate, 0.4 part of nano-silica sol, 5 parts of β-cyclodextrin, 0.1 part of ascorbic acid, monostearic acid 0.2 part of glyceride.

[0049] The specific preparation steps of the high-temperature-resistant mustard flavor seasoning are as follows:

[0050] 1) Drying: Wash and slice 500g of horseradish, put it into a freeze dryer for drying, the temperature of the cold trap is -42°C, and the degree of vacuum is 80Pa;

[0051] 2) Ball milling: Use an ultra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com