Lithium titanate power battery

A power battery, lithium titanate technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of high de-intercalation potential, low energy density, easy gas production of batteries, etc., to achieve good charge-discharge performance and capacity retention. The effect of high rate and excellent cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

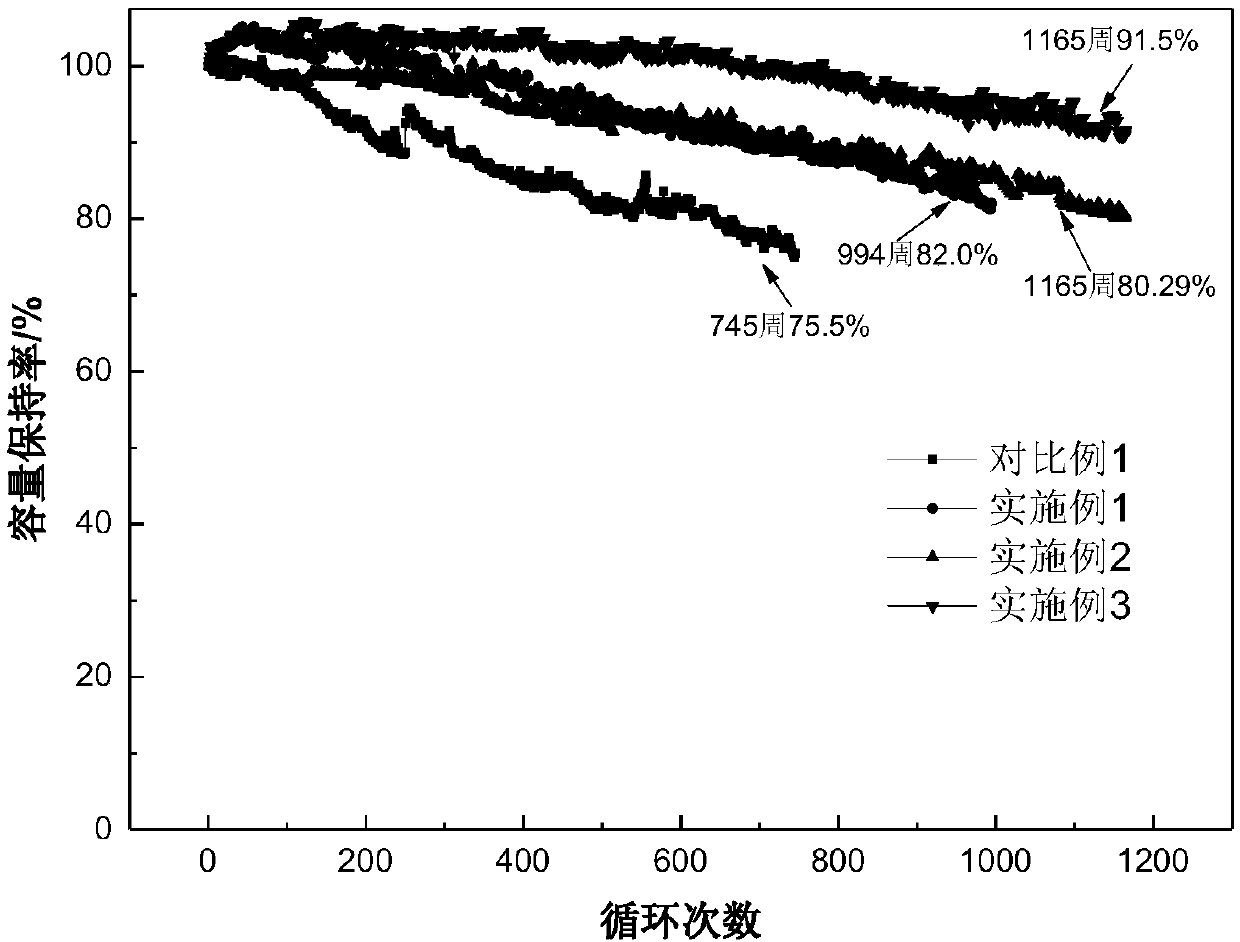

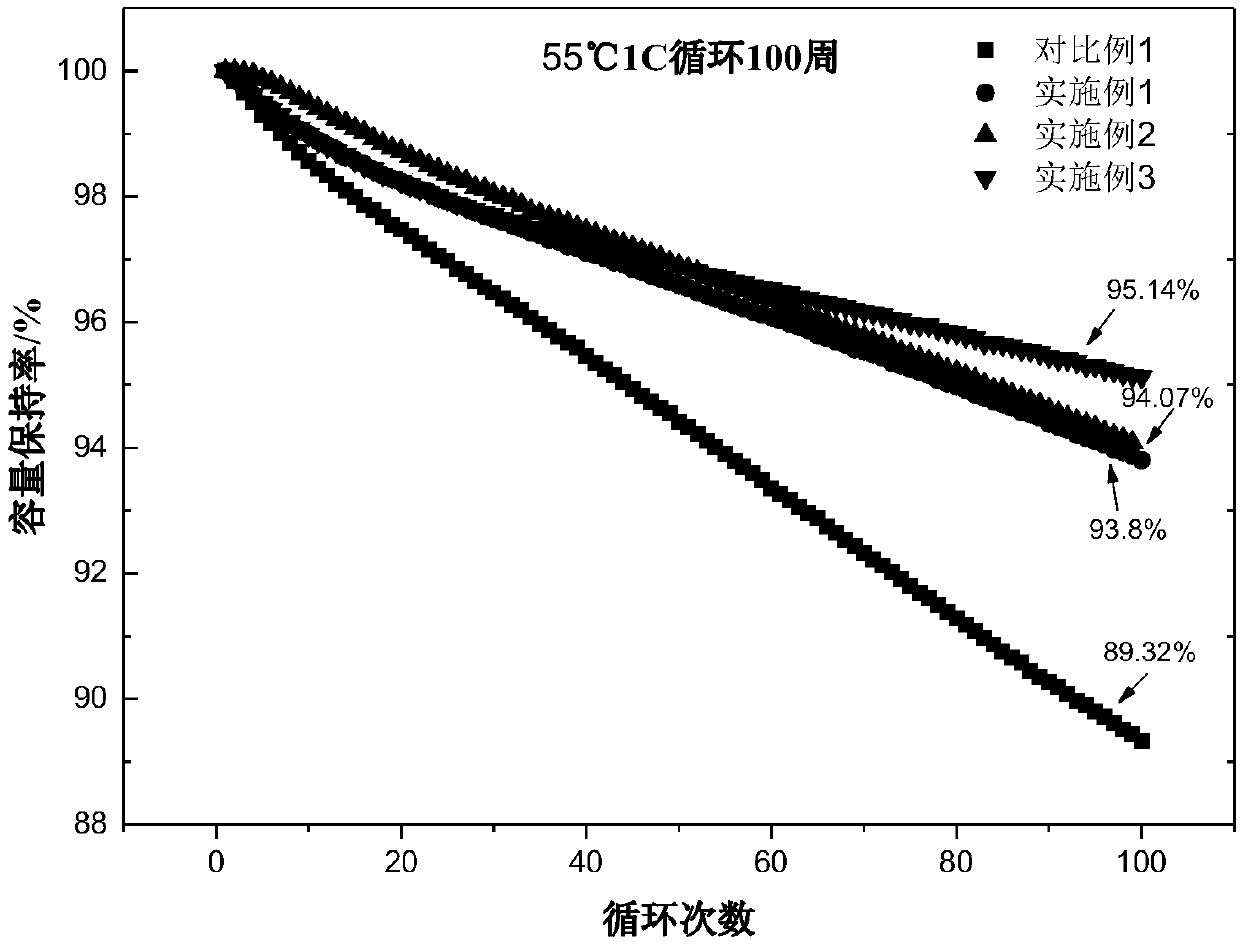

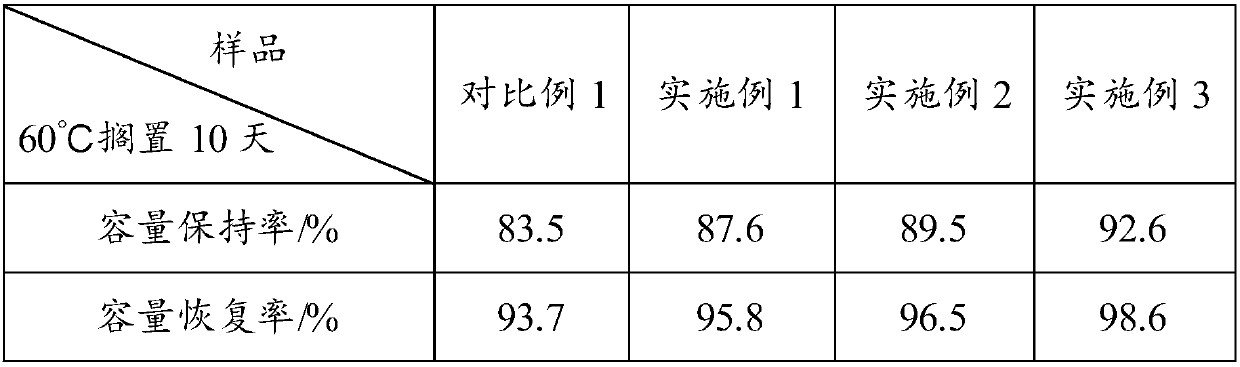

Embodiment 1

[0030] It is basically the same as the implementation of Comparative Example 1, except that 2% by mass of allyl isothiocyanate is added on the basis of Comparative Example 1.

Embodiment 2

[0032] The embodiment is basically the same as that of Comparative Example 1, except that 5% by mass of ethyl 3-trimethylsilyl propionate is added on the basis of Comparative Example 1.

Embodiment 3

[0034]It is basically the same as the implementation of Comparative Example 1, except that on the basis of Comparative Example 1, 2% of allyl isothiocyanate by mass percentage and 5% by mass of allyl isothiocyanate are added simultaneously Silyl propionate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| D50 | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com