Novel injectable hydrogel for bone defect repair and preparation method thereof

A bone defect and water injection technology, which is applied in pharmaceutical formulations, prostheses, drug delivery, etc., can solve the problems of mismatching degradation rate, new bone formation, affecting the use effect, and low gel strength, so as to improve the repair effect of bone defects , easy operation and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Dissolve 10 g of dodecylamine in 250 mL of ethanol solution with a mass concentration of 70%, stir until dodecylamine is completely dissolved, then add 6 mL of tetraethyl orthosilicate, 0.34 mL of triethyl phosphate, 3.2 g of calcium nitrate tetrahydrate, 0.55g magnesium nitrate hexahydrate and 0.522g copper nitrate trihydrate, continue to stir for 3h; centrifuge and wash the product with deionized water, freeze-dry, and calcinate the dried powder in the air at 650°C for 3h to obtain magnesium- and copper-rich Bioactive glass.

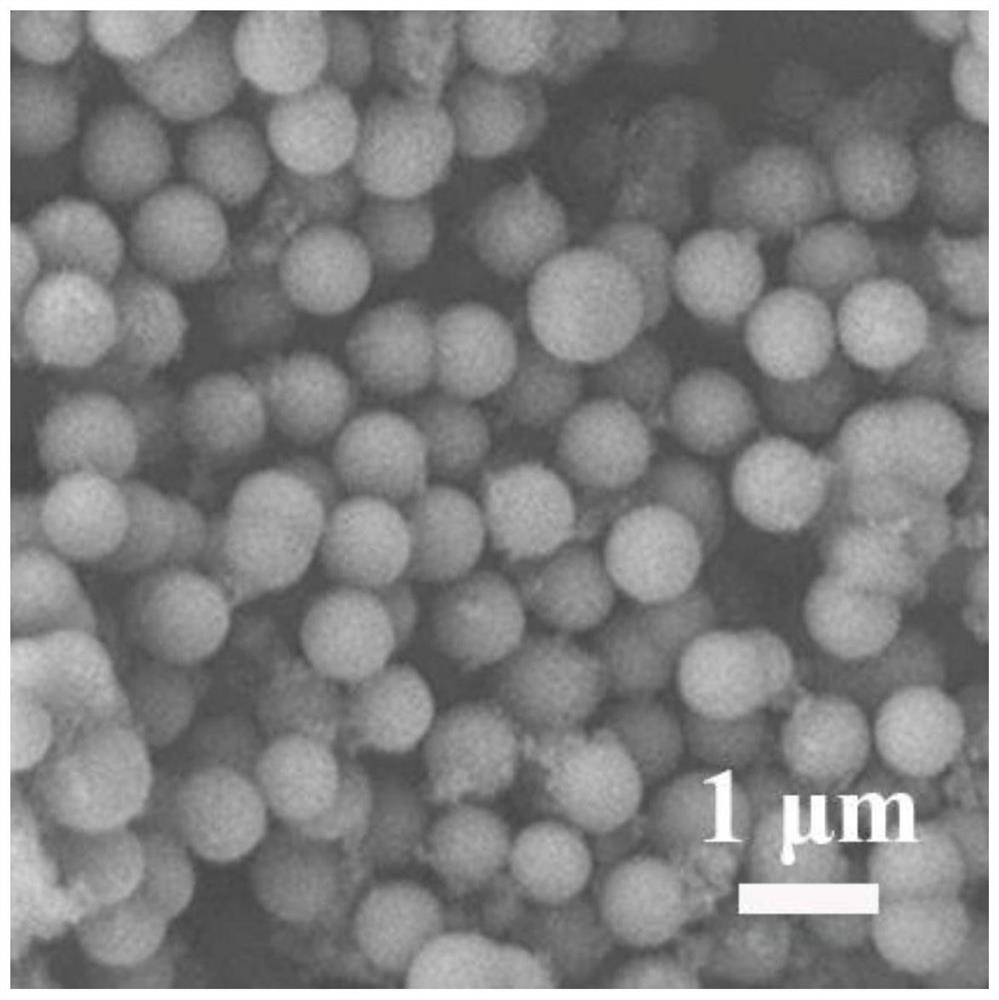

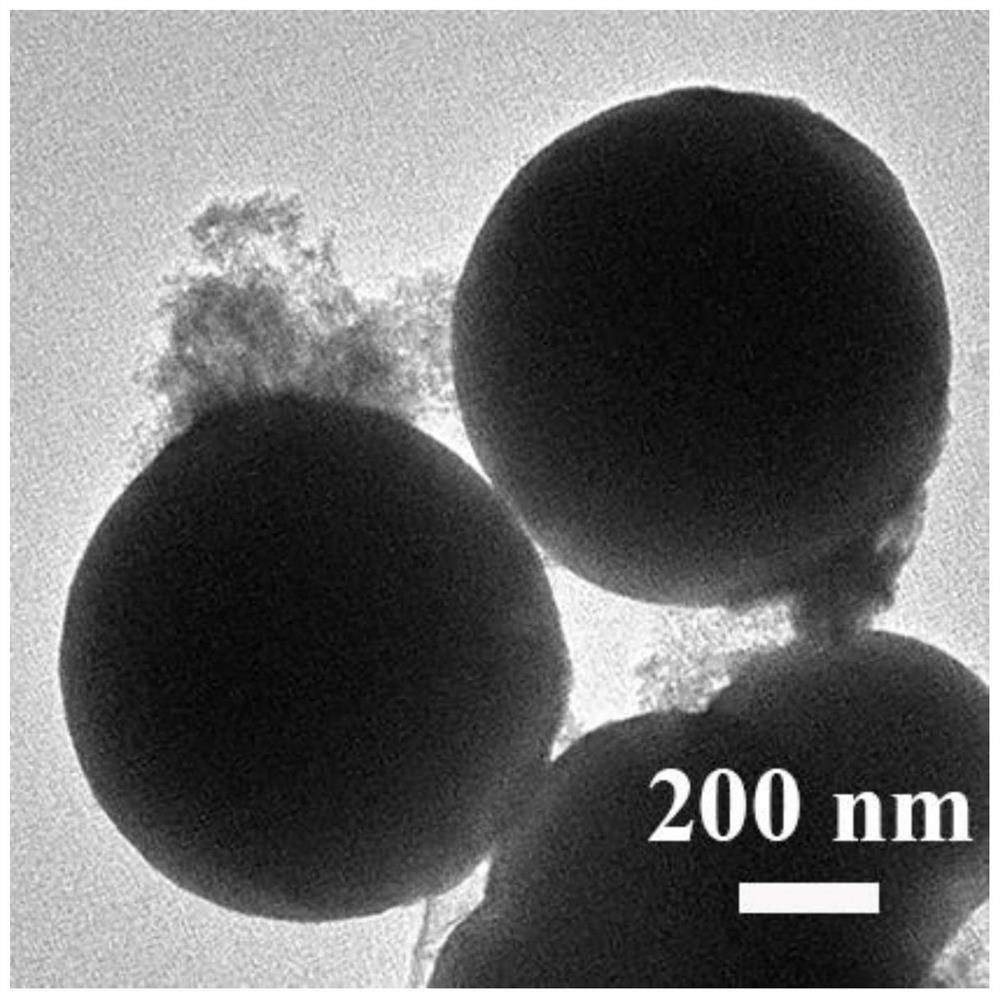

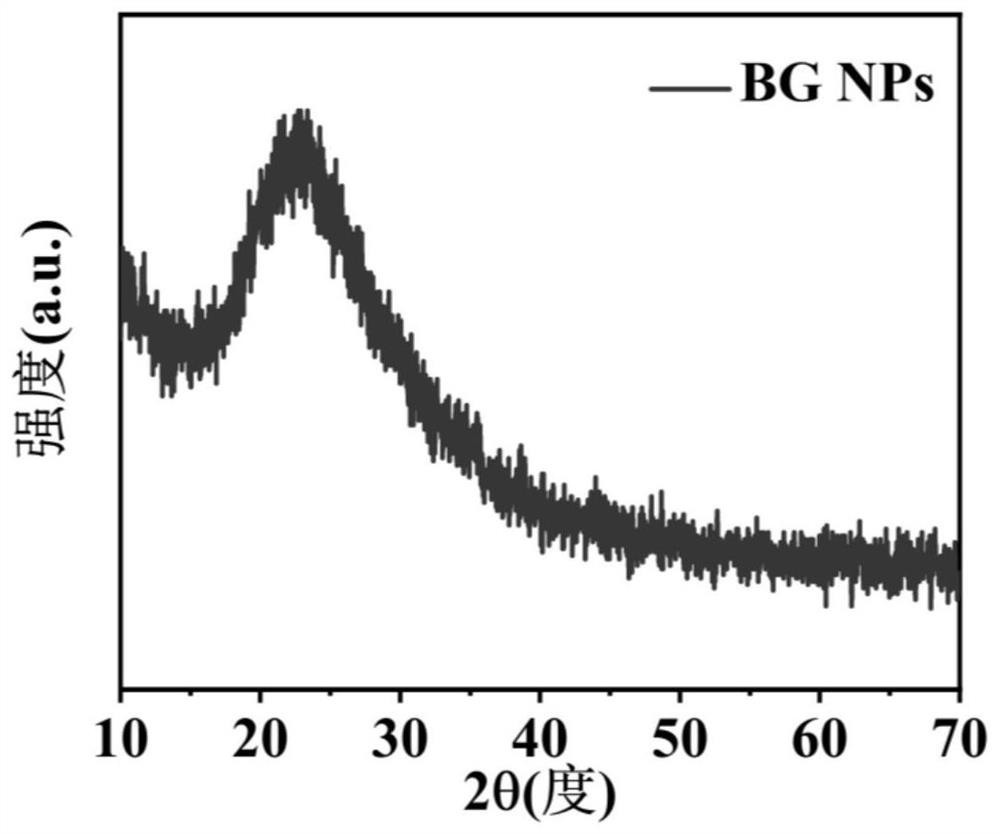

[0033] The product prepared by scanning electron microscopy is a nanosphere with a particle size of about 650nm to 750nm, such as figure 1 shown; the product nanospheres prepared by transmission electron microscope detection are solid structures, such as figure 2 Shown; The product prepared by X-ray diffraction detection is an amorphous structure, which is a typical feature of silicate glass, such as image 3 Shown; After the powder is immers...

Embodiment 2

[0035] Dissolve 10g of dodecylamine in 250mL of ethanol solution with a mass concentration of 80%, stir until dodecylamine is completely dissolved, then add 40mL of tetraethyl orthosilicate, 0.31mL of triethyl phosphate, 16g of calcium nitrate tetrahydrate, 0.8 g magnesium nitrate hexahydrate and 0.8 g copper nitrate trihydrate, continue to stir for 2 hours; centrifuge and wash the product with deionized water, freeze-dry, and calcinate the dried powder in the air at 600°C for 2 hours to obtain magnesium- and copper-rich bio Active glass, its physical and chemical properties are similar to Example 1.

Embodiment 3

[0037] Dissolve 10 g of dodecylamine in 250 mL of ethanol solution with a mass concentration of 90%, stir until the dodecylamine is completely dissolved, then add 60 mL of tetraethyl orthosilicate, 0.6 mL of triethyl phosphate, 25.5 g of calcium nitrate tetrahydrate, 1.38g magnesium nitrate hexahydrate and 1.3g copper nitrate trihydrate, continue to stir for 4h; centrifuge and wash the product with deionized water, freeze-dry, and calcinate the dried powder in the air at 700°C for 4h to obtain magnesium- and copper-rich Bioactive glass, its physical and chemical properties are similar to Example 1.

[0038] Preparation of injectable hydrogels

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| compressive stress | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com