Waterborne epoxy wall finish paint and preparation method thereof

An epoxy wall, water-based technology, applied in the direction of epoxy resin coating, coating, polyester coating, etc., can solve the problems of mildew and damp wall paint, etc., achieve the effect of eliminating air bubbles, better effect and preventing mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

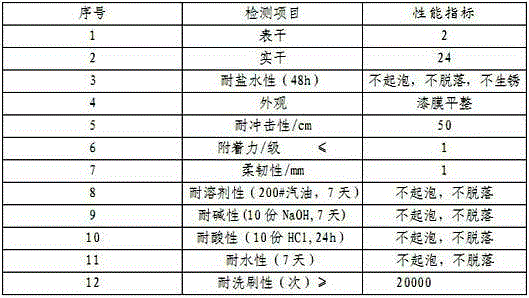

Image

Examples

Embodiment 1

[0027] Embodiment 1--make 1000 kilograms of waterborne epoxy wall paint:

[0028] Raw materials used:

[0029] Component A: 200 kg of water-based epoxy acrylic resin, 100 kg of water;

[0030] Component B: 150 kg of water-soluble saturated polyester resin, 50 kg of water-soluble amino resin, 2 kg of polyether modified siloxane, 200 kg of titanium dioxide, 100 kg of calcium carbonate, 80 kg of talcum powder, and 118 kg of water.

[0031] The production steps are as follows:

[0032] A component:

[0033] A, inject 200 kilograms of water-based epoxy acrylic resins and 100 kilograms of water into the reactor;

[0034] B. Start the mixer and stir the material for more than 20 minutes at a stirring speed of 400-600 rpm, and it will be completed after it is uniform;

[0035] B component:

[0036] A, first 150 kilograms of water-soluble saturated polyester resins, 50 kilograms of water-soluble amino resins and 118 kilograms of water are injected into the reactor;

[0037] B. ...

Embodiment 2

[0041] Embodiment 2--make 1100 kilograms of waterborne epoxy wall paint:

[0042] Raw materials used:

[0043] Component A: 300 kg of water-based epoxy acrylic resin, 50 kg of water;

[0044] Component B: 100 kg of water-soluble saturated polyester resin, 20 kg of water-soluble amino resin, 5 kg of polyether modified siloxane, 100 kg of titanium dioxide, 300 kg of calcium carbonate, 150 kg of talcum powder, and 75 kg of water.

[0045] Its production steps are as follows:

[0046] A component:

[0047] A, inject 300 kilograms of water-based epoxy acrylic resins and 50 kilograms of water into the reactor;

[0048] B. Start the mixer and stir the material for more than 20 minutes at a stirring speed of 400-600 rpm, and it will be completed after it is uniform;

[0049] B component:

[0050] A, first 100 kilograms of water-soluble saturated polyester resins, 20 kilograms of water-soluble amino resins, and 75 kilograms of water are injected into the reactor;

[0051] B. Star...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com