Ceramic glaze with antibacterial and mildew-proof effects as well as preparation method and application thereof

A ceramic glaze, antibacterial and antifungal technology, applied in the field of ceramics, can solve the problems of inability to achieve antibacterial and antifungal, unstable antibacterial performance, loss of antibacterial function, etc., and achieve significant antibacterial effect, strong antibacterial persistence, and antibacterial performance. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

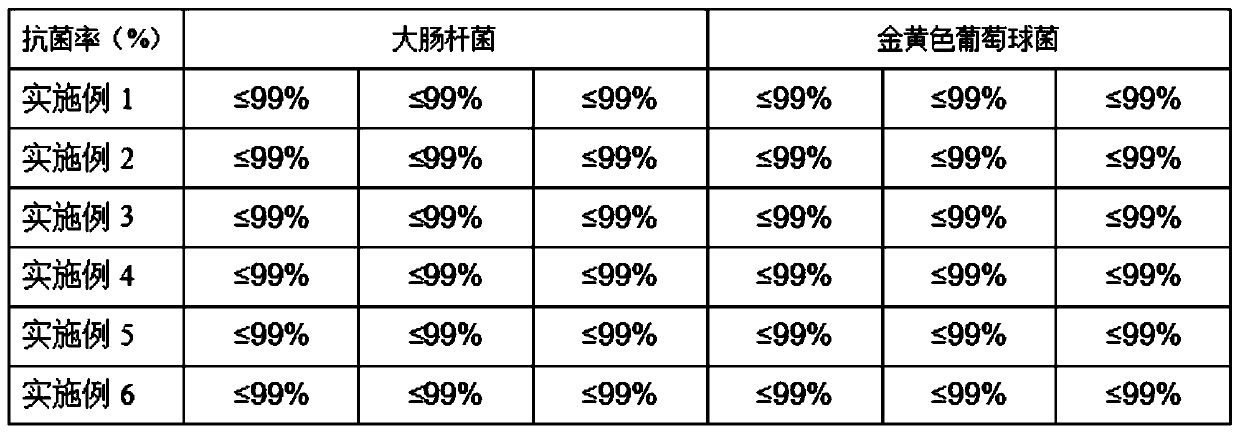

Examples

Embodiment 1

[0024] Wet 1Kg of nano-zinc oxide, 1Kg of nano-copper oxide and 2Kg of nano-titanium dioxide in water, disperse them into a suspension, and grind them while stirring to obtain component A; mix 3Kg of chitin, 0.2Kg of wasabi, and 0.3Kg of milt , Stir and mix to obtain component B; Mix component A and component B, grind while stirring, filter and dry to obtain antibacterial agent; mix 30Kg feldspar, 2Kg nano silver, 0.1Kg yttrium oxide, add 0.1Kg of antibacterial agent, 2Kg of sodium hexametaphosphate and 40Kg of calcium carbonate were mixed and ball milled to obtain a glaze slurry; the glaze slurry was fired at 800°C for 3 hours, and then it was fired into a frit and cooled to room temperature to obtain an antibacterial and antibacterial product. Mildew effect ceramic glaze.

Embodiment 2

[0026] Wet 1Kg of nano-zinc oxide, 1Kg of nano-copper oxide and 2Kg of nano-titanium dioxide in water, disperse them into a suspension, and grind them while stirring to obtain component A; mix 3Kg of chitin, 0.2Kg of wasabi, and 0.3Kg of milt , stir and mix to obtain component B; mix component A and component B, grind while stirring, and filter and dry to obtain an antibacterial agent; mix 40Kg feldspar, 2Kg nano silver, and 0.1Kg yttrium oxide, and add 1Kg of antibacterial agent, 2Kg of sodium hexametaphosphate and 40Kg of barium carbonate are mixed and ball milled to obtain a glaze slurry; the glaze slurry is fired at 800°C for 3 hours, then fired into a frit and cooled to room temperature to obtain an antibacterial and mildew-proof Functional ceramic glaze.

Embodiment 3

[0028] Wet 1Kg of nano-zinc oxide, 1Kg of nano-copper oxide and 2Kg of nano-titanium dioxide in water, disperse them into a suspension, and grind them while stirring to obtain component A; mix 3Kg of chitin, 0.2Kg of wasabi, and 0.3Kg of milt , Stir and mix to obtain component B; Mix component A and component B, grind while stirring, filter and dry to obtain antibacterial agent; mix 30Kg feldspar, 5Kg nano silver, 0.1Kg yttrium oxide, add 1g of antibacterial agent, 3Kg of sodium hexametaphosphate and 50Kg of calcium carbonate are mixed and ball milled to obtain a glaze slurry; the glaze slurry is fired at 1000°C for 4 hours, after being fired into a frit, cooled to room temperature to obtain an antibacterial and mildew-proof Functional ceramic glaze.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com