Patents

Literature

278results about How to "Meet the requirements of green production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flame retardant cellulose fiber and preparation method thereof

InactiveCN101608348ASuitable for processingEasy to useFlame-proof filament manufactureMonocomponent cellulose artificial filamentMass ratioCellulose fiber

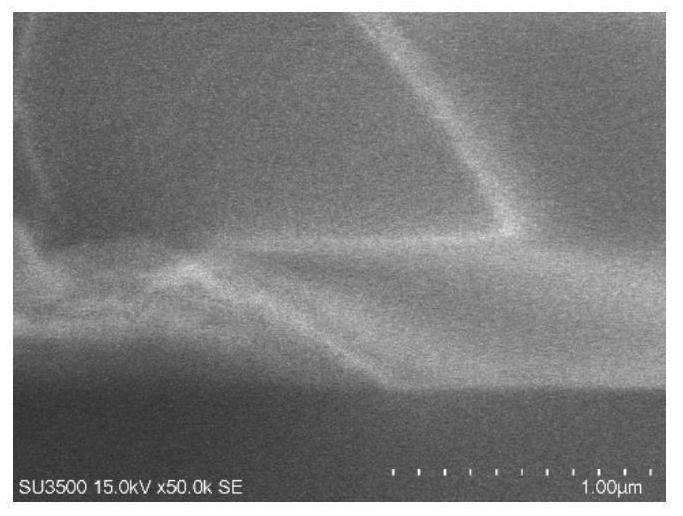

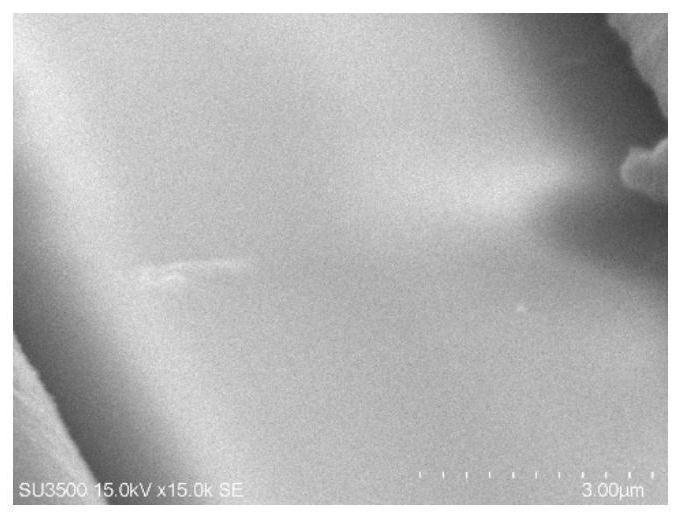

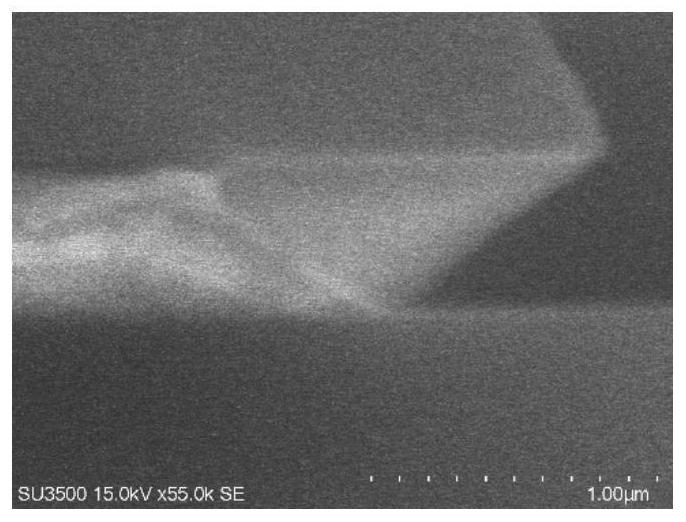

The invention discloses a flame retardant cellulose fiber and a preparation method thereof. The fiber has the components of fire retardant and cellulose which have the mass ratio of 10-25:100; wherein the fire retardant is novel phosphorus fire retardant having the average grain diameter being less than 1mum; the cellulose is wood pulp or cotton pulp having the polymerization degree of 400-1000 and alpha-cellulose content being more than or equal to 90%. According to the components with the mass ratio of the fiber, the preparation method of the fiber comprises the technique as follows: 1. preparation of flame retardant spinning solution as the following: according to the mass ratio, firstly adding the fire retardant into ionic liquid at the normal temperature, and leading the fire retardant to be uniformly dispersed in the ionic liquid under mechanical agitation; then adding the cellulose into the mixed ionic liquid to be fully dissolved with the dissolving temperature of 70-110 DEG C to prepare flame retardant spinning solution; ensuring the mass ratio between the cellulose and the ionic liquid to be 5-35:95-65: 2. preparation of the flame retardant cellulose fiber: preparing the flame retardant cellulose fiber according to the conventional spinning process flow.

Owner:TIANJIN POLYTECHNIC UNIV

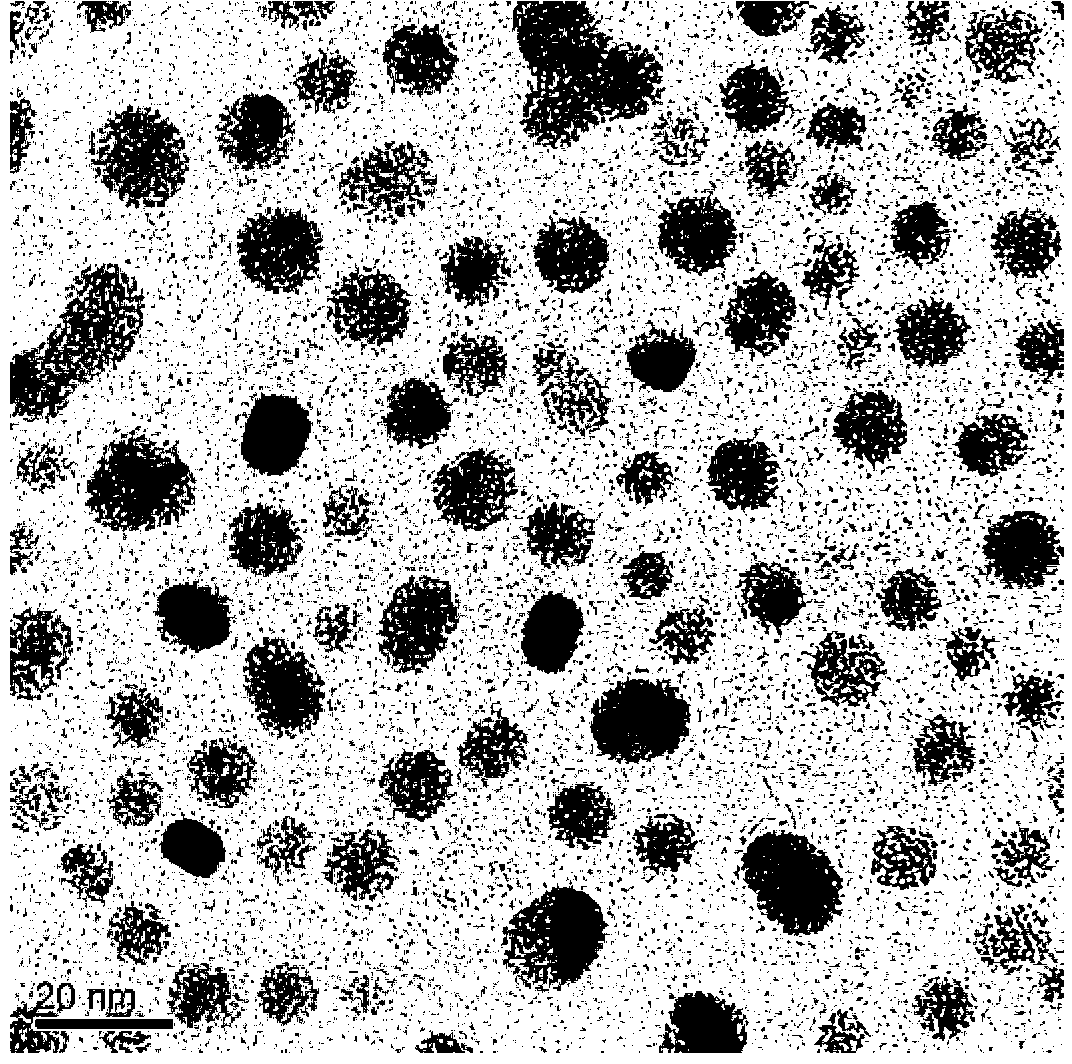

Nano-copper conductive ink preparation method

InactiveCN101608077ASimple processMild reaction conditionsInksNon-conductive material with dispersed conductive materialDistillationSolvent

The invention belongs to the nanometer material technical field, in particular to a nano-copper conductive ink preparation method, comprising the following steps: dissolving copper salt and organic protective agents in a solvent, heating the solution to 30-100 DEG C, simultaneously adding reducing agent in the reaction system to react while stirring for 20-30min, then cooling gradually; finally obtaining stable nano-copper conductive ink through electrodialysis separation and reduced pressure distillation. The invention has simple process, mild reaction conditions and short reaction time; the conductibility of the product is good, the particle size of nano-copper is 20-70nm, the nano-copper can not be oxidized for one month in the air; the production cost is low and no hazardous waste can be generated, thus meeting the demand of 'green production'.

Owner:FUDAN UNIV

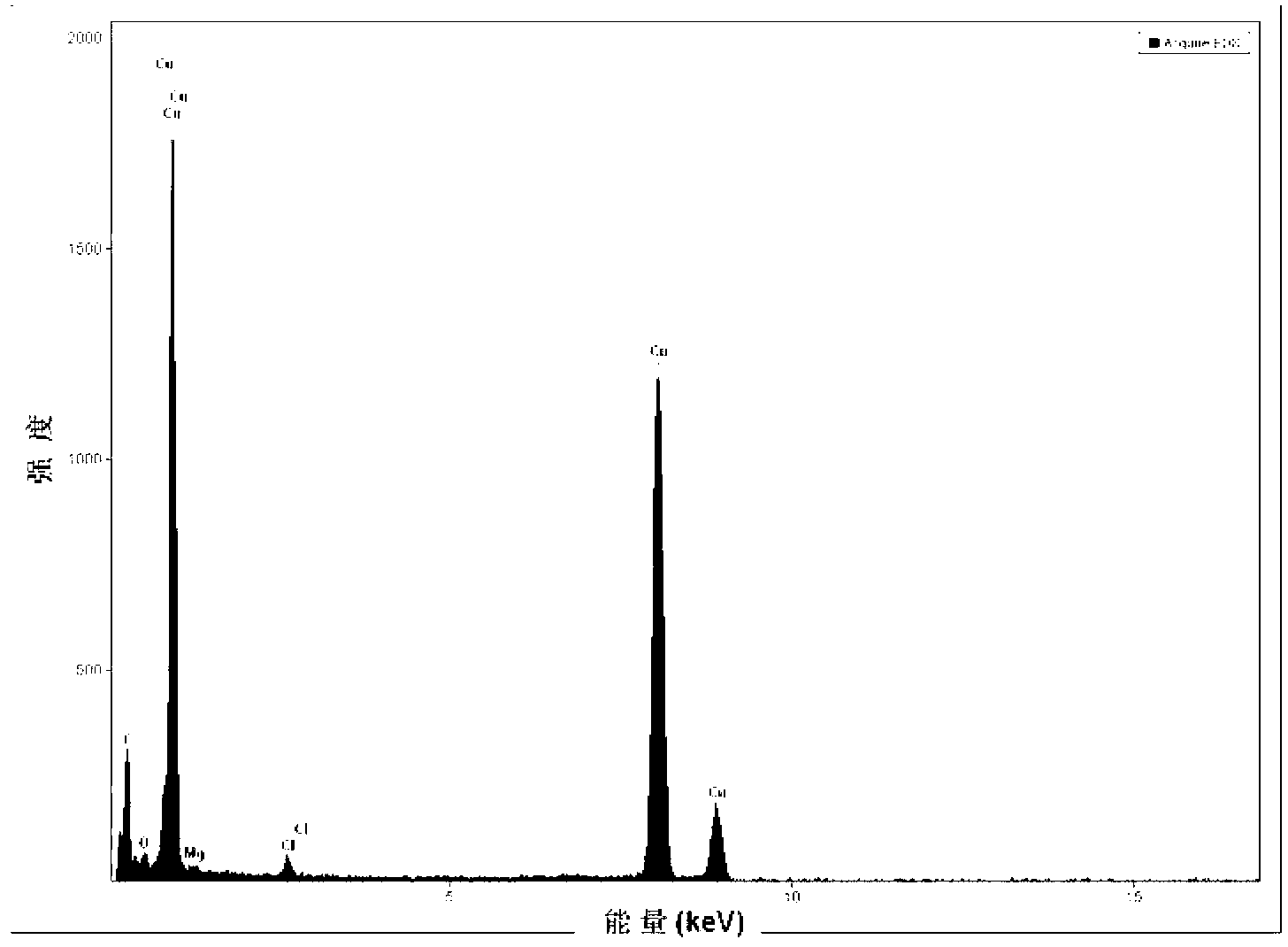

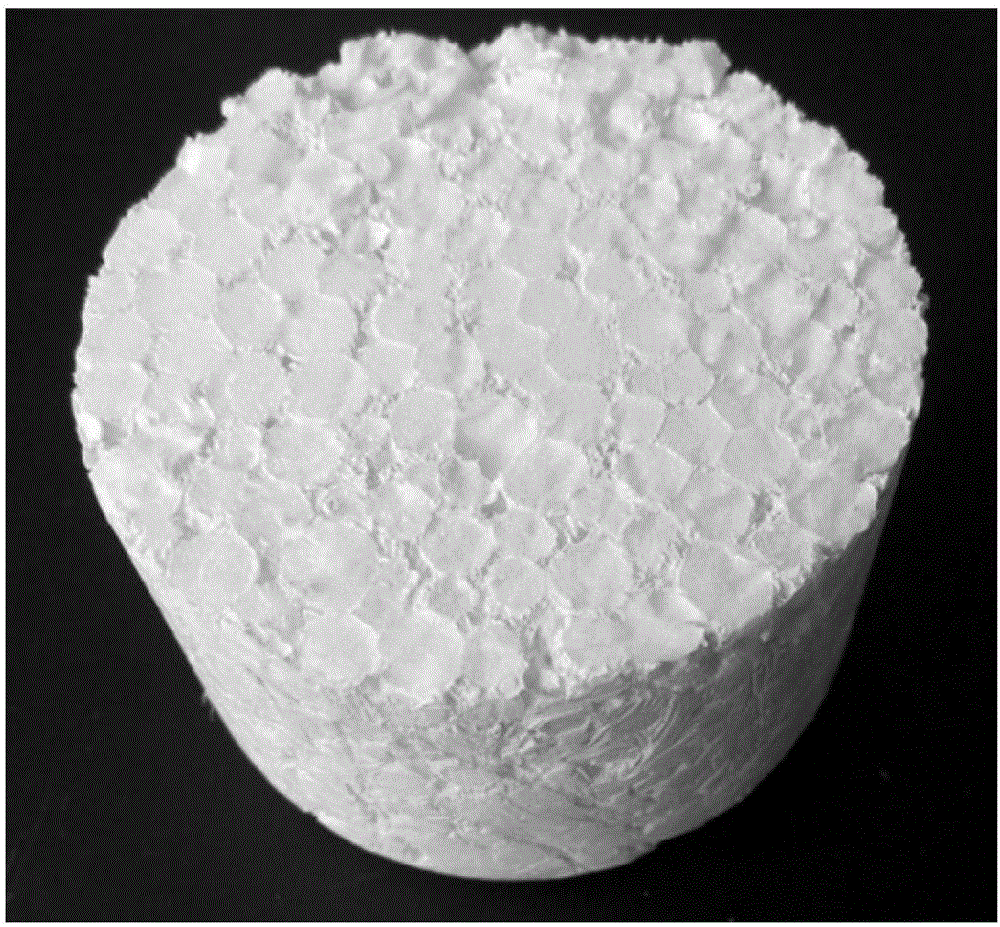

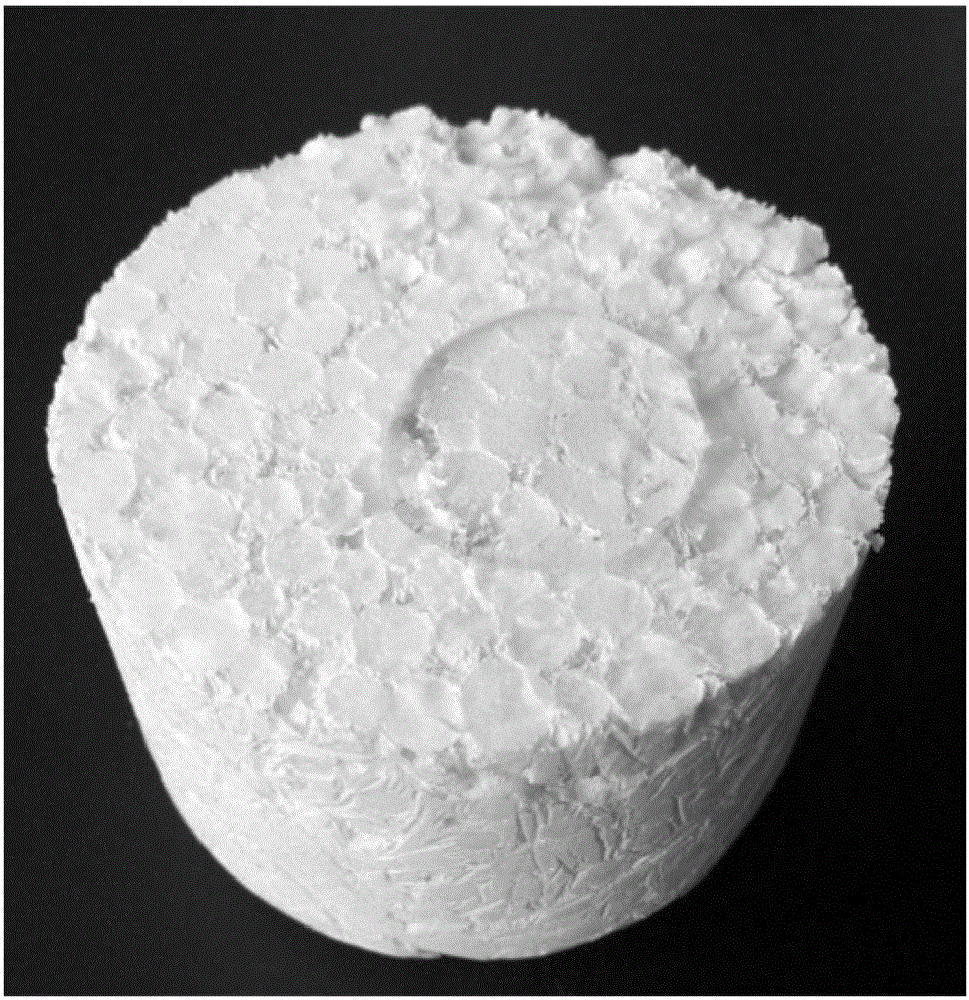

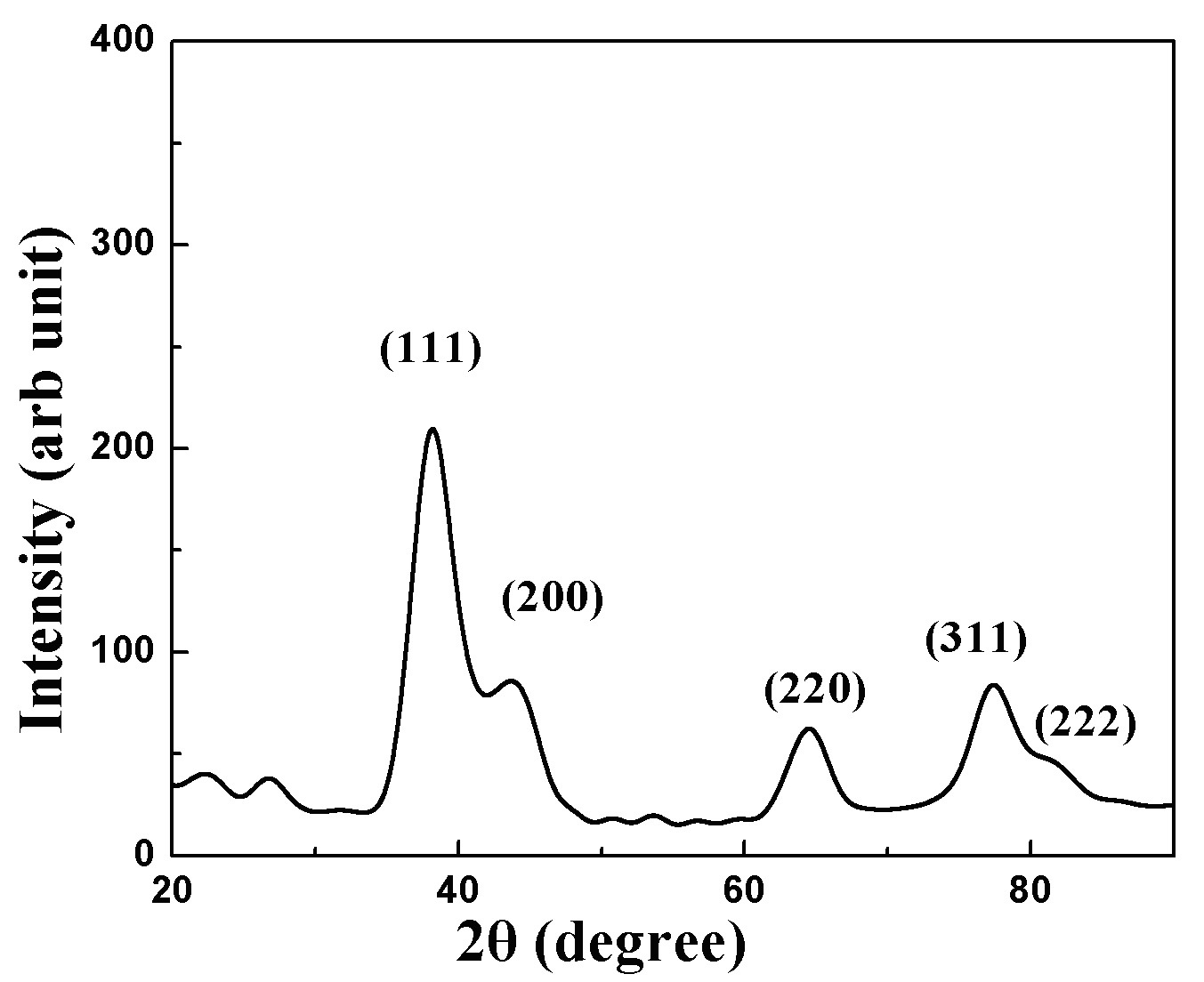

Method for preparing metal nanoparticles

The invention provides a method for preparing metal nanoparticles. By a dealloying method, firstly, precursor alloy solid fine materials containing target metal elements are prepared, secondly, the precursor alloy solid fine materials and acid solution containing hydrogen ions are in dealloying reaction under the condition of violent oscillation, the concentration of the hydrogen ions in the acid solution is controlled in the reaction process, magnesium, rare earth and other relatively active atoms preferentially react with the hydrogen ions and change into ions entering the solution, target metal atoms are freed out, and porous self-assembly and conglobation trend of the target metal atoms is effectively restrained under the condition of violent oscillation, so that uniformly scattered target metal nanoparticles are obtained. Compared with an existing method, the method is low in cost, simple in operation, green, environmentally friendly, high in preparation efficiency, high in by-product value and suitable for large-scale production, and accordingly has a fine application prospect.

Owner:赵远云

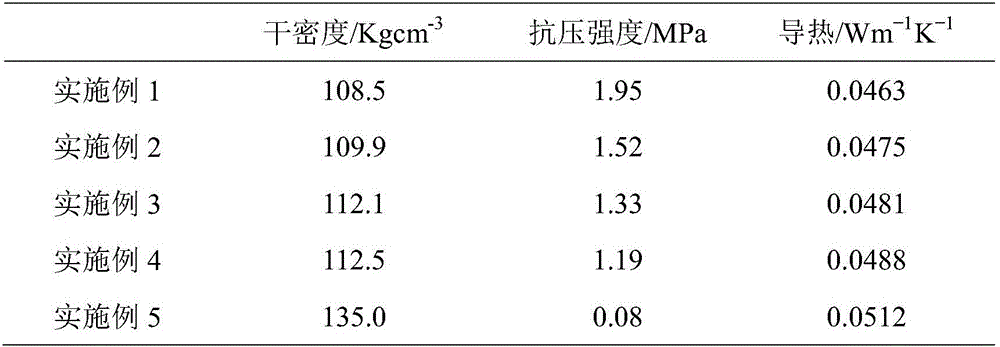

Water-proof inflammable coal ash/metakaolin-based insulation board

InactiveCN106747621AIncreased efficiency of hydration reactionsHigh densitySolid waste managementCement productionHydration reactionPolystyrene

The invention belongs to the field of building heat-insulating materials, and particularly relates to a production method for a water-proof inflammable coal ash / metakaolin-based insulation board. According to the preparation method, aggregate is metakaolin and coal ash, and polymerization is performed under the activation of an alkali activator, so that the hydration reaction efficiency of a geopolymer is increased greatly; a foaming agent is aluminum powder, so that the decomposing rate and foam producing amount are increased greatly in an alkaline environment, cost is lowered, and high economic efficiency is achieved. A selected polystyrene material has high density, high heat-insulation efficiency and a good waterproof effect. Moreover, reaction conditions are relatively mild, a reaction is easy to control, operation is easy, and the whole process flow meets the requirement of environmentally-friendly production. The prepared heat-insulating material has the advantages of light weight, high strength, good heat-insulation effect, superior waterproofness and inflammability.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

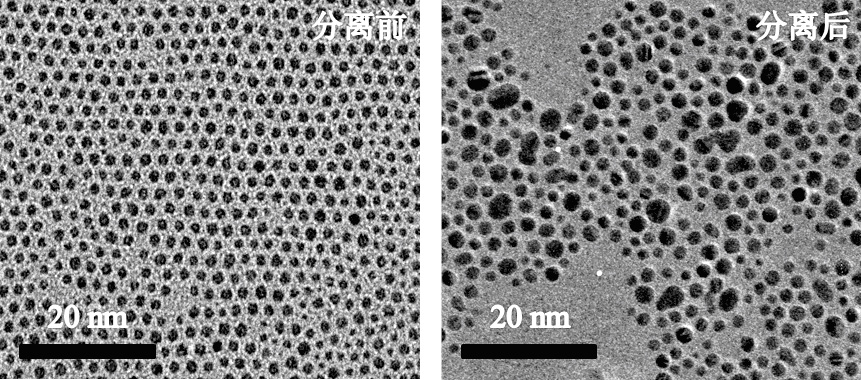

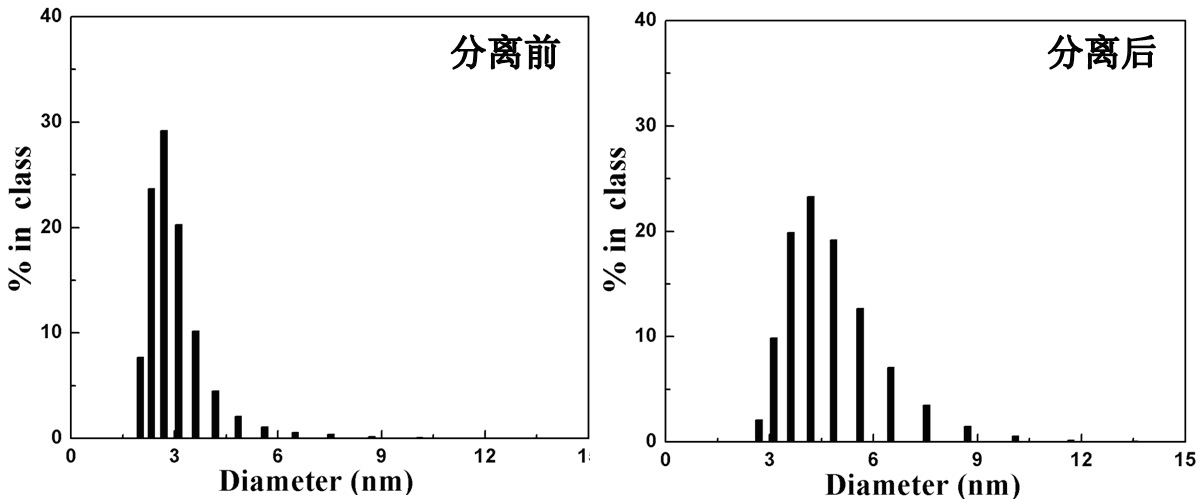

Original ecology separation and redispersion method of nano metallic colloid

The invention belongs to the technical field of nano, in particular to an original ecology separation and redispersion method of a nano metallic colloid. By taking spherical nano silver as an example, the method comprises the following steps: stirring and reacting silver salts under the existence of an organic protective agent and a reducing agent to obtain a nano silver colloid; adjusting the pH value of the nano silver colloid with acid, and continuously stirring and reacting until the colloid solution gradually appears flocks to obtain nano silver particles; and dispersing the nano silver particles in an organic solvent, and dispersing by ultrasonic to obtain the nano silver colloid dispersed in an original ecology mode. The invention can realize original ecology separation and redispersion repeatedly based on the interactive relationship among a dispersing agent, nano particles and the solution. The invention has the advantages of simple process, mild operation condition, short reaction time, little changes in particle size and appearance after repeated separation and dispersion, low preparation cost and no generation of harmful waste, and conforms to the requirement of green production.

Owner:FUDAN UNIV

Method for extracting nickel or cobalt from nickel ore with chloridizing roasting-leaching method

InactiveCN101550491ALow heating temperatureImprove heat utilizationProcess efficiency improvementExhaust gasNon-ferrous metal

The present invention relates to a technique for extracting non-ferrous metal, and specifically to a method for extracting nickel or cobalt from nickel ore with chloridizing roasting-leaching method. The aim of the invention is to settle the technical problem for extracting nickel or cobalt from nickel ore. The method of the invention comprises the following steps: grinding the dried powder of nickel ore, mixing the nickel ore with ammonium chloride, then putting the mixed compound into a sealed kiln for calcining, directly leaching the roasted product, adjusting the pH value of leaching liquid with the ammonia water recycled from end gas in the kiln, and controlling the pH value to 6.5-7.5 for recycling the nickel or cobalt. The grade of nickel or cobalt concentrate recycled by deposition according to the invention is high and can obtain more than 30% of nickel content. The subsequent processing and utilizing are facilitated. No exhaust gas or wastewater is discharged in the industrial process. The requirement of green production is satisfied.

Owner:谢永巨 +2

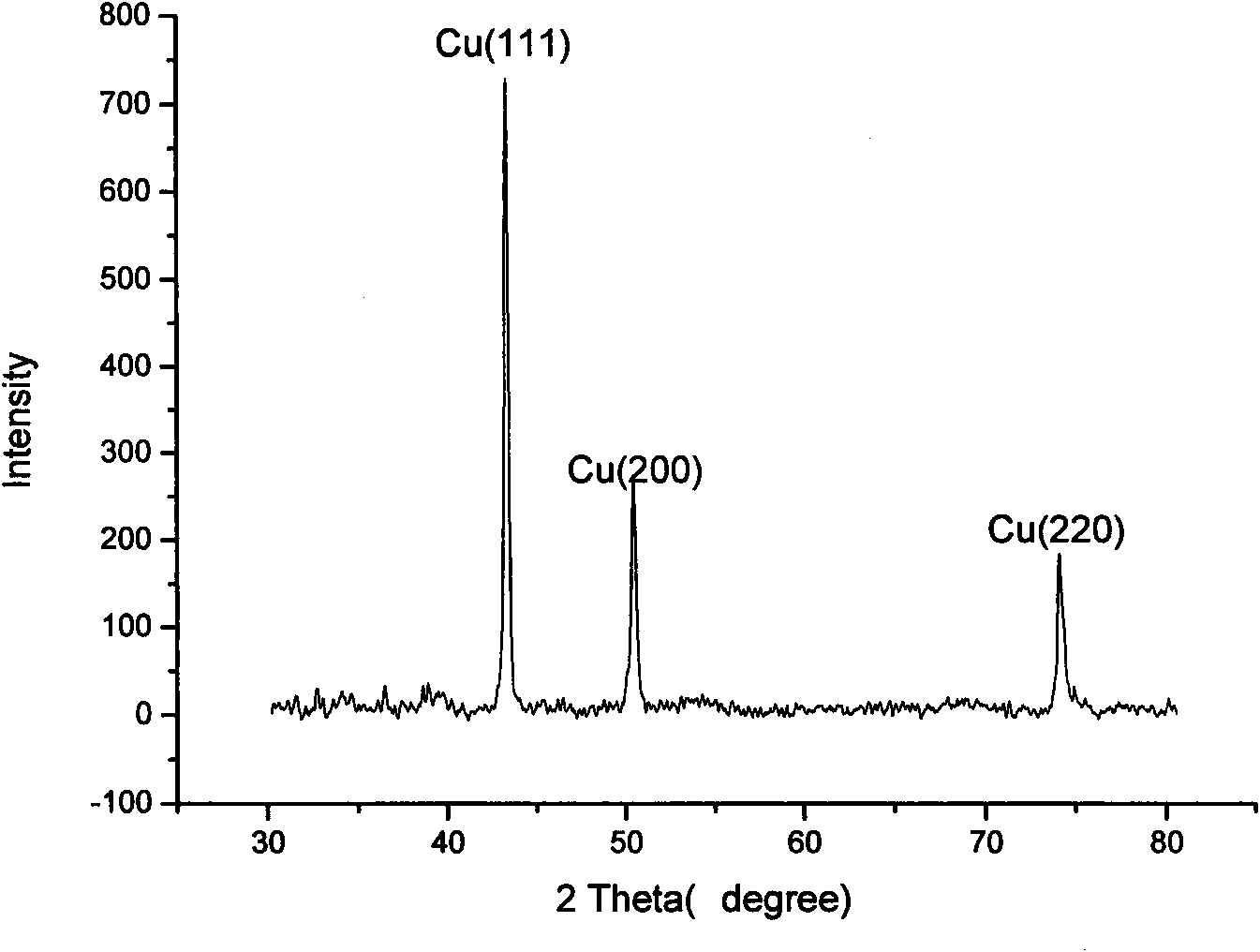

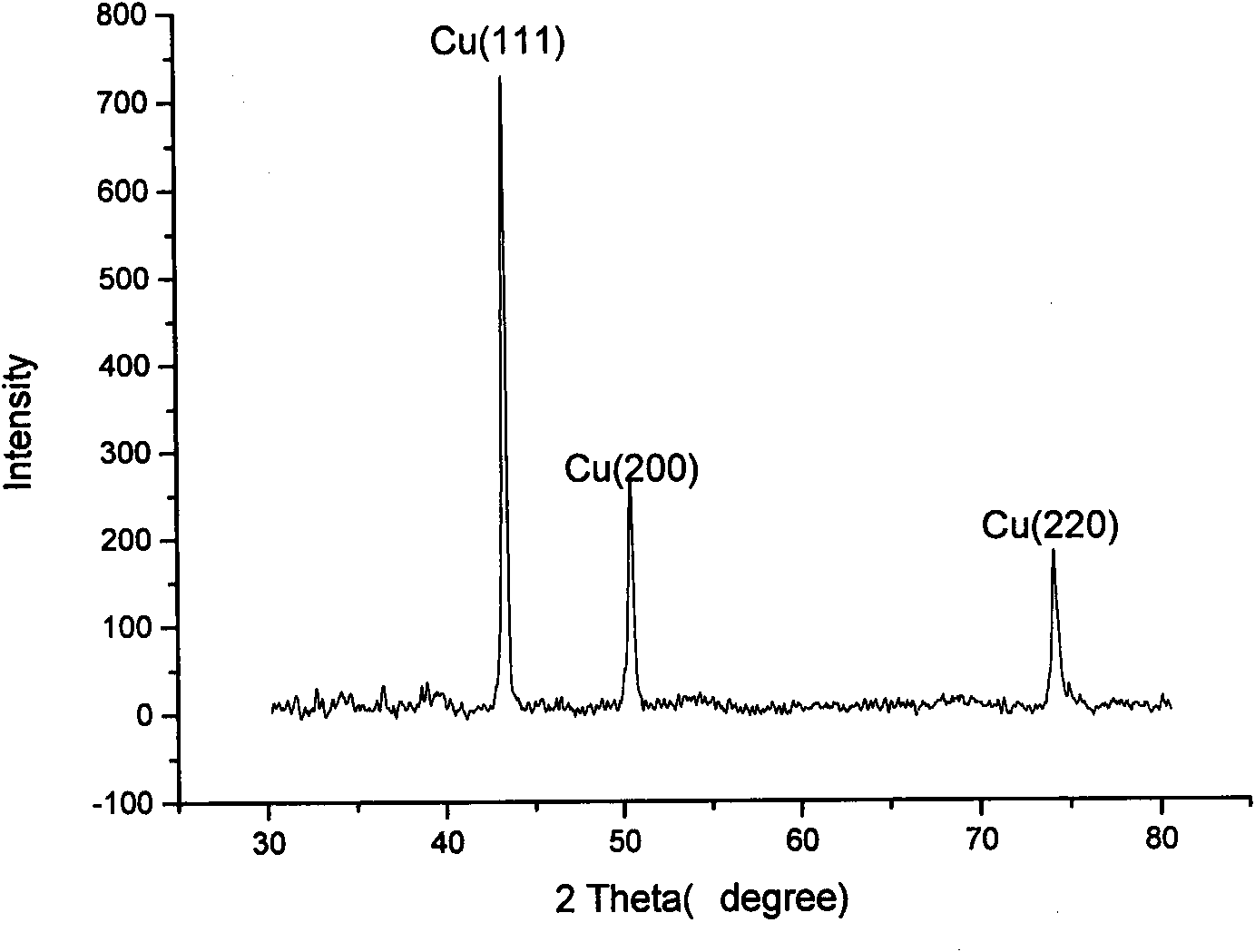

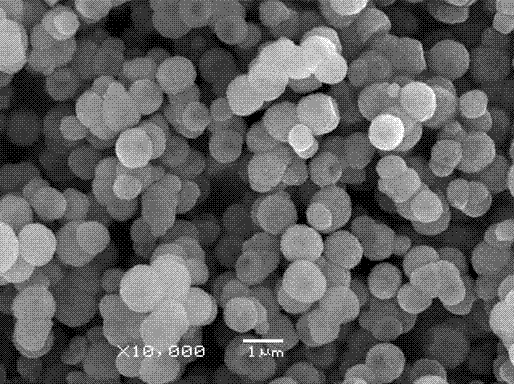

Preparation method of nano-copper

The invention belongs to the nanometer material technical field, in particular to a preparation method of nano-copper, comprising the following steps: dissolving copper salt and organic protective agents in a solvent, heating the solution to 30-100 DEG C, simultaneously adding reducing agent in the reaction system to react while stirring for 20-30min, then cooling gradually; standing the cooled solution, and then centrifuging and finally washing the solution with ethanol and acetone repeatedly to obtain pure nano-copper. The invention has simple process, mild reaction conditions and short reaction time; in the reaction process, two protective agents are both adopted to prevent the growth and oxidation of nano-copper; the product performance is good, the particle size of nano-copper is less than 20nm, the nano-copper can not be oxidized for one month in the air; the production cost is low and no hazardous waste can be generated, thus meeting the demand of 'green production'.

Owner:FUDAN UNIV

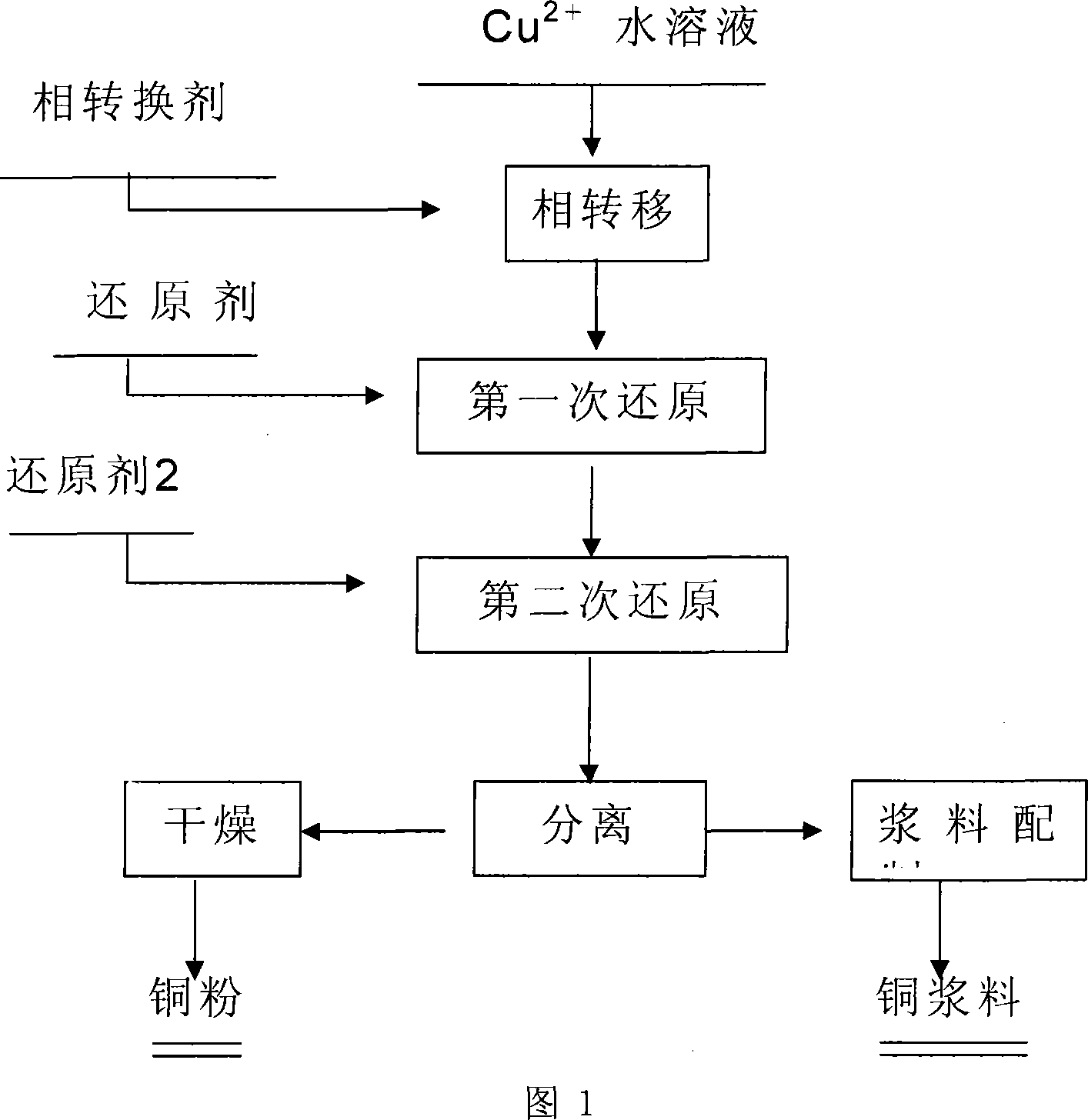

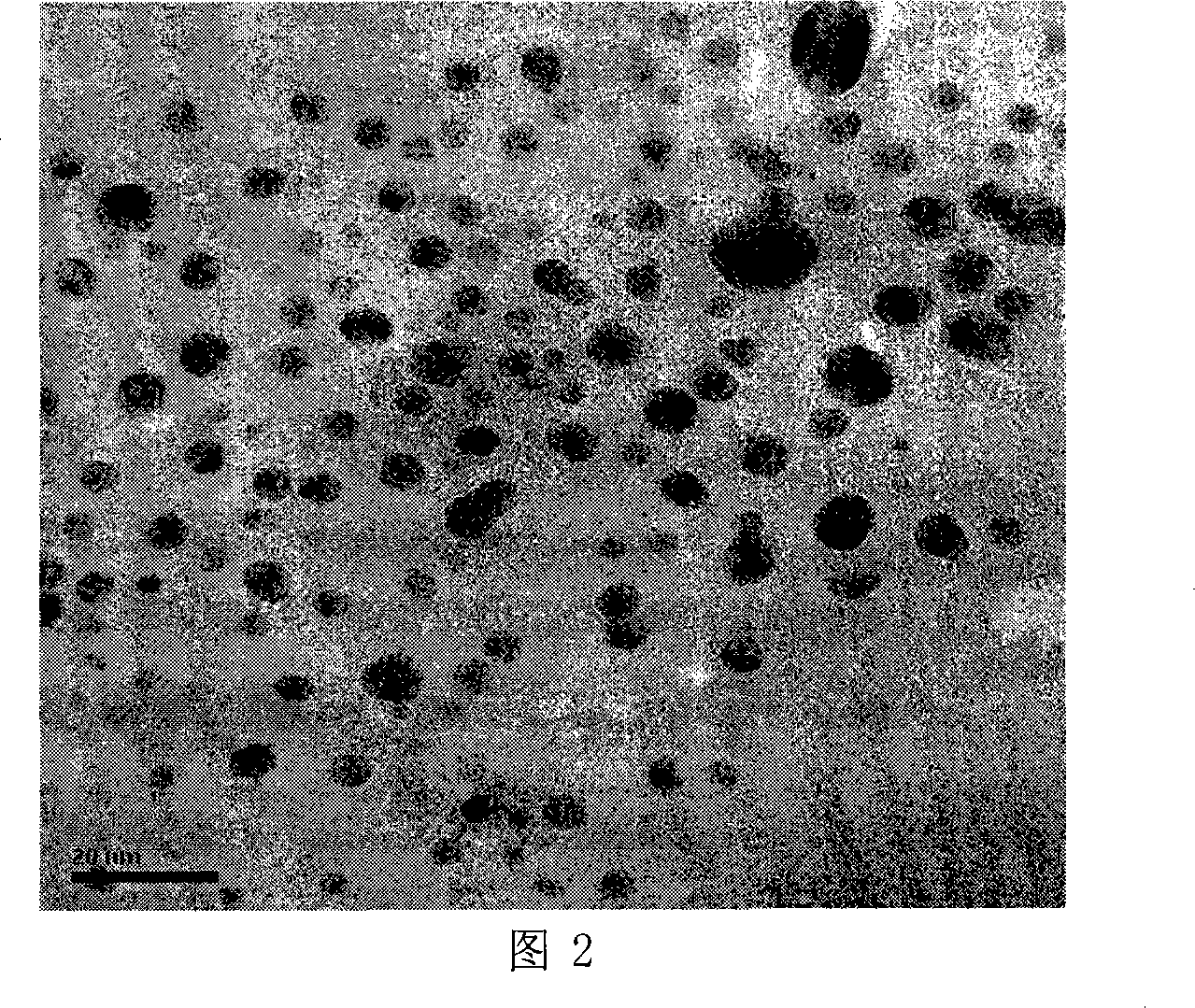

Method for preparing nano copper powder and copper slurry

InactiveCN101077529ASmall particle sizeImprove antioxidant capacityChemical compositionCeramic capacitor

The present invention is process of preparing nanometer copper powder and copper slurry with high antioxidant performance. The process includes solvent replacement, the first reduction, the second reduction, separation, drying and other steps. The present invention has the features of simple preparation process at normal temperature and normal pressure, low production cost, the effective protection of produced nanometer copper particle in organic phase, small copper powder size, environment friendly preparation process, etc. The prepared nanometer copper powder and copper slurry may be applied in producing large scale PCB, conducting ink, multilayer ceramic capacitor, etc.

Owner:CENT SOUTH UNIV +1

Method for preparing cellulose fiber

InactiveCN101838861AReduce usageIncrease productivityArtificial filaments from cellulose solutionsMelt spinning methodsYarnHydrogen

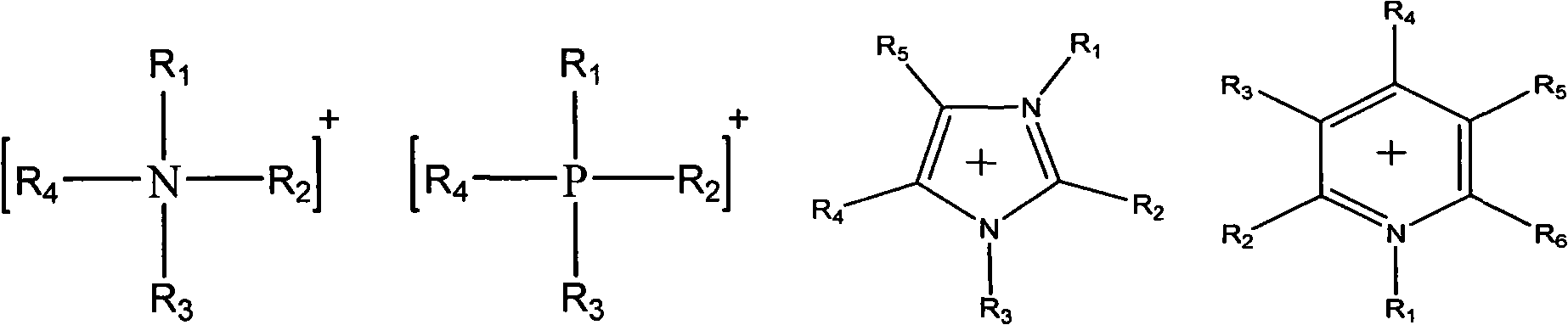

The invention discloses a method for preparing cellulose fiber. By using melting spinning technology, the method comprises the following steps of: 1, mixing cellulose and ionic liquid in a mass ratio of 5-8:5-2 to obtain an uniform mixture, wherein the cellulose is wood pulp, cotton pulp or bamboo pulp with degree of polymerization of 400 to 1,000; the ionic liquid consists of cations and anions; the cations are substituent-containing alkyl imidazole ions, wherein the substituent is more than one of hydrogen, C1 to C6 alkyl group, ethyl, propenyl, butenyl, ethoxyl, hydroxypropyl and alkoxy groups; the anions are halogen ions, BF4-, PF4-, SCN-, CN-, OCN-, CNO-, CF3SO3-, CFCOO-, CH3COO-, and (CF3SO2)2N- or (CF3SO2)2Cl-; 2, feeding the mixture into a double-screw extruder for melting spinning and stretching the extruded yarn by 0.5 to 6 times; and 3, washing, performing thermal forming and winding to obtain the cellulose fiber.

Owner:TIANJIN POLYTECHNIC UNIV

Method for dissolving and processing wood/cotton bamboo hemp fibre by employing ionic liquid

InactiveCN101225552ANon-volatileEasy to recycleConjugated cellulose/protein artificial filamentsWet spinning methodsCelluloseTotal solid content

The invention relates to a dissolving and processing method for wood, cotton, bamboo and hemp fiber with ionic liquid, which is characterized in that: (1) the pulverized wood or the pulverized cotton, the pulverized bamboo and the pulverized bast pulp are uniformly mixed with the ionic liquid; the spinning solution of the total solid content of 3 to 40% is formed through dissolving and deaerating for 1 to 120 hours at 35 to 160 degrees centigrade; wherein the weight ratio of the wood or the cotton, the bamboo and the bast is 30 to 80% : 7 to 60% : 10 to 60% ; (2) the spinning and the concreting bathing solidification are carried out after being filtered and deaerated; (3) the oiling and the drying process are carried out after being pulled, rinsed and bleached, so as to obtain a composite fiber. The dissolving and processing method for wood, cotton, bamboo and hemp fiber with ionic liquid has the advantages that: due to use the ionic liquid, the productivity is high, the recovery is easy, the requirement of the green production is satisfied and the prepared composite fiber has good mechanical strength; simultaneously the different fiber characteristics of a plurality of materials such as the wood or the cotton, the bamboo and the bast are synthesized; the source of the material is wide; the cost is low; and the advantages of various natural celluloses can be synthesized according to the requirement.

Owner:DONGHUA UNIV

Method for producing fermented fish paste

The invention discloses a method for producing fermented fish paste. The method for producing the fermented fish paste mainly comprises the steps of low-value fish raw materials, pretreatment (removal of scales, head, tails, internal organs and vertebras), soaking in salt vinegar water, draining, soaking in ozone water, draining, defibrination, salt addition, in-jar fermentation, seasoning, mixedhomogeneity and obtaining of finished products. The method adopts a salt vinegar water soaking method to remove fishy-smell substance, is scientific, easy to operate and good in effect. The salt vinegar water is used for soaking fish slices, and acetic acid promotes solubility of the fishy-smell substance (trimethylamine oxide and dimethylamine oxide) in water with the assist of the salt water and enables the fishy-smell substance to be solved in the water, thereby achieving the removal purpose. Ozone solution produced by an electrolysis type ozone generator is used for soaking and disinfection, sundry fungus pollution and usage of preservatives are reduced, and the requirement for green production is met. Self enzyme of fishes is utilized to perform natural fermentation, thereby ensuringgood taste and special flavor of the fish paste.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Preparation method of cellulose acetate fiber

ActiveCN103014892AAvoid pollutionImprove production environmentArtificial filaments from cellulose derivativesMelt spinning methodsPolymer scienceCellulose acetate

The invention relates to a preparation method of cellulose acetate fiber, in particular relates to a method for preparing cellulose acetate fiber after the cellulose acetate fiber is plasticized and modified by taking ionic liquid as a plasticizer. The method comprises the following steps of (1) evenly mixing and extruding the cellulose acetate fiber and the ionic liquid; (2) conducting vacuum drying on spinning materials; (3) conducting melt spinning: spinning the spinning materials through a metering pump and a spin sprayed plate, stretching through a hot roll, extracting liquor and washing; and (4) conducting oiling, drying and winding procedures to obtain cellulose acetate fiber with fiber breakage strength of 2.2-6cN / dtex. By adopting the preparation method of cellulose acetate fiber, the problems that the fiber mechanical property is poor, the breakage strength is low, and due to seeping or volatilization of the plasticizer, high fragility of cellulose acetate fiber grafted copolymer and difficulty of processing in the process of plasticizing and melt spinning cellulose acetate fiber, the fiber fineness is larger and the strength is low, and the like in the dry spinning process of cellulose acetate fiber in the prior art can be solved.

Owner:DONGHUA UNIV

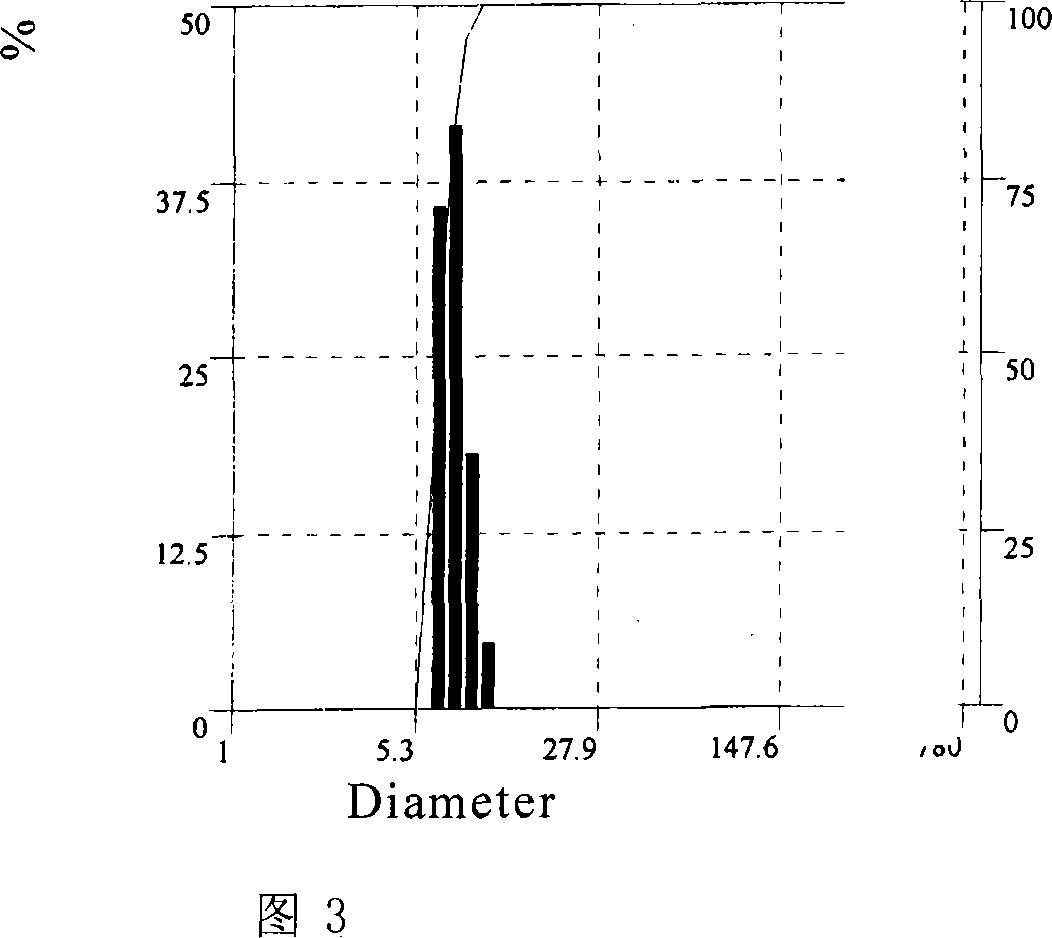

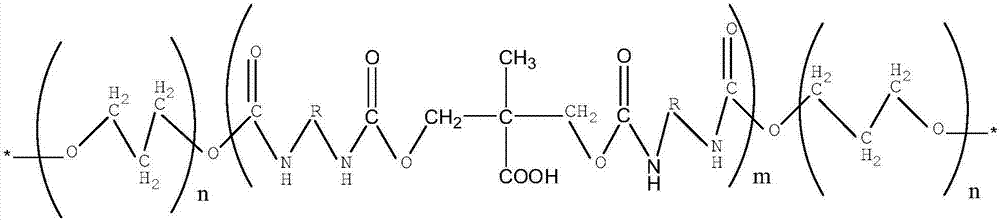

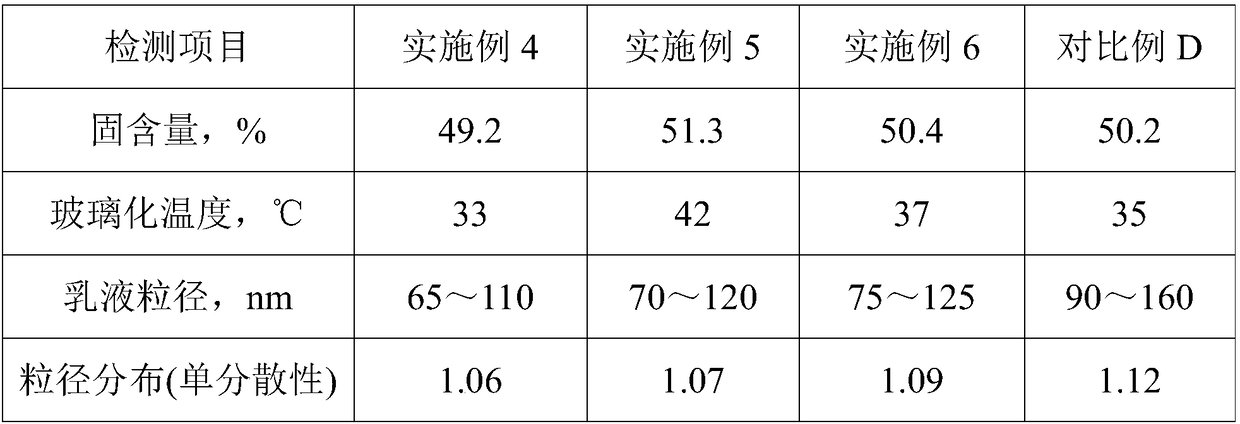

Waterborne acrylic modified polyurethane hybrid resin prepared by solvent-free method

InactiveCN107446457AUniform and stable dispersionStrong adhesionAnti-corrosive paintsPropanoic acidPolymer science

The invention relates to waterborne acrylic modified polyurethane hybrid resin. The waterborne acrylic modified polyurethane hybrid resin is composed of a polyurethane copolymer chain segment and an acrylic copolymer chain segment and is prepared from the following components: diisocyanate, oligomer polyol, polyol, dihydromethyl propionic acid, organic tin, hydroxyethyl acrylate, an acrylic monomer, ammonium persulfate, a neutralizer and de-ionized water. A solvent-free preparation method of the waterborne acrylic modified polyurethane hybrid resin, provided by the invention, meets green production requirements. The waterborne acrylic modified polyurethane hybrid resin prepared by the solvent-free preparation method, has the glass transition temperature Tg of 35 DEG C to 70 DEG C, the molecular weight of 4500 to 5500, the emulsion grain diameter of 150nm to 280nm, the pH (Potential of Hydrogen) of 7.5 to 8.5 and zero VOC (Volatile Organic Compounds) and has good adhesion force, water resistance, alkali resistance, ageing resistance and salt fog resistance; the waterborne acrylic modified polyurethane hybrid resin is widely applied to waterborne wood coating, waterborne anticorrosive coating, waterborne steel-structure coating, waterborne engineering coating and the like.

Owner:UNION FOSHAN CHEM +1

Solvent preparation of cellulose fiber releasing anion and use thereof

InactiveCN101230495ANon-volatileEasy to recycleMonocomponent cellulose artificial filamentWet spinning methodsTotal solid contentCellulose fiber

The invention relates to a method of preparing a cellulose fibre releasing anions by using the solvent method and the application. The method has the following steps: firstly, the comminuted cellulose, tourmaline powder and addition agent are well mixed with an ironic liquid, dissolved at a temperature of 35 to 160 DEG C, deaerated for 1 to 120 hours and a homogeneous and stable spinning solution with a total solid content of 3 to 30 percent is formed, wherein, the mixed mass ratio of the tourmaline powder is 0.01 to 20 percent and the added mass ratio of the addition agent is 0 to 10 percent; secondly, the spinning solution is filtered, deaerated, spinned and solidified through a coagulation bath; and thirdly, a composite fibre of cellulose and tourmaline powder is obtained after the procedures of stretching, water cleaning, bleaching, oiling and drying. The composite fibre has the functions of releasing anions, generating far infrared radiation, generating biocurrent and suppressing bacteria and is applicable to the fields of garments, ornaments and medical textiles. The ironic liquid used in the invention has high production efficiency, is easy for callback and conforms to the requirement of a green production. The prepared composite fibre has excellent mechanical strength and mechanical property, and the fabric made of the composite fibre can release anions, resist bacteria and prevent mildew.

Owner:DONGHUA UNIV

Method for separating corncob cellulose by using ionic liquid

InactiveCN102733224AEfficient enzymatic hydrolysisEliminate the effect of enzymatic hydrolysisPaper material treatmentCelluloseEngineering

The invention relates to a method for separating corncob cellulose by using ionic liquid. According to the invention, an ionic liquid 1-allyl-3-methylimidazole chlorine salt is synthesized with raw materials of allyl chloride and 1-methylimidazole; and with the high solubility of the ionic liquid upon cellulose, the ionic liquid is used for separating and extracting cellulose in corncob. The method comprises the steps of corncob pretreatment, lignin removing, cellulose separation, cellulose extraction, and the like. The extraction rate of corncob cellulose is approximately 18.35%. With the method, the purity of the extracted corncob is high, and the film-forming property of the cellulose is good. According to the invention, a green solvent which is the ionic liquid is used as a dissolving medium. The solvent can be recovered and reused, such that the requirement of green production is satisfied.

Owner:HEFEI UNIV OF TECH

Method for preparing non-fried instant freshwater fish

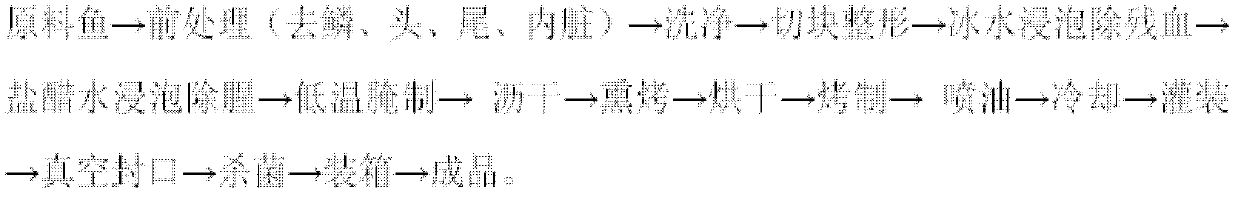

The invention provides a method for preparing a non-fried instant freshwater fish, comprising the concrete steps of preparing a raw material fish, carrying out pretreatment (scale, head, tail and innards removing), washing clearly, cutting and shaping, soaking in ice water, soaking in water containing salt and vinegar, curing at a low temperature, draining, performing roast smoking, stoving, baking, spouting oil, filling, carrying out vacuum seal and microwave sterilization, boxing up to obtain the finished product. The fish prepared by adopting the method for preparing the non-fried instant freshwater fish has the advantages of no fishy smell, good taste, no poisonous or harmful substance of fried foods, little oil content and capability of guaranteeing the product quality.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Production method of germinated milled rice

InactiveCN101617793AReduce pollutionReduce usageFood preparationMicroorganismGamma-Aminobutyric acid

The invention provides a production method of germinated milled rice, comprising the following steps: adopting milled germ-retaining rice that is produced by a special process as germinating materials, sterilizing the milled germ-retaining rice in water solution with the ozone concentration of 1.0-1.5mg / kg, coating by 1-2 percent of chitosan solution, soaking in clear water or 0.005-0.015 percent of gibberellin for 20-30 hours, culturing in the situation of 20-30 DEG C, and drying at 50-60 DEG C when the length of germs of germinated rice is 0.5-1.0 mm to obtain the germinated milled rice. In the production method, the germination ratio is more than 95 percent, Gamma-aminobutyric acid is more than 60mg every 100g of germinated rice, and the water content is 12-15 percent. The invention has simple process, reduces the microbial contamination in the germinating process and solves the difficult problems of brown stains, cracking, and the like in the drying process; and the germinated milled rice obtained by the method is better than germinated brown rice and milled germ-retaining rice on the taste, and has good colors, rich nutriments and strong heath care function.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Preparation method of durable PDMS (polydimethylsiloxane) bionic super-hydrophobic membrane

The invention belongs to the technical field of functional material preparation, aims to overcome defects of complicated process, higher cost, low efficiency and the like of conventional preparation of an intelligent super-hydrophobic material and provides a preparation method of a durable PDMS (polydimethylsiloxane) bionic super-hydrophobic membrane. The method comprises steps as follows: a stainless steel mesh is put in a hydrochloric acid solution and deionized water, is subjected to ultrasonic cleaning and then is air-dried; the air-dried stainless steel mesh is soaked in a SiO2 nanoparticle suspension, and a stainless steel mesh coated with SiO2 nanoparticles is prepared; a PDMS solution is poured on a substrate material and heated, and a PDMS substrate membrane is prepared; the stainless steel mesh coated with SiO2 nanoparticles is embossed on the surface of the PDMS substrate membrane, the stainless steel mesh is uncovered after curing, and the durable PDMS bionic super-hydrophobic membrane is obtained. The preparation method is simple and easy, has shorter period, and is suitable for large-scale production, a static contact angle for water is 150-160 degrees, and a rollingcontact angle is 5-10 degrees.

Owner:SHANXI UNIV

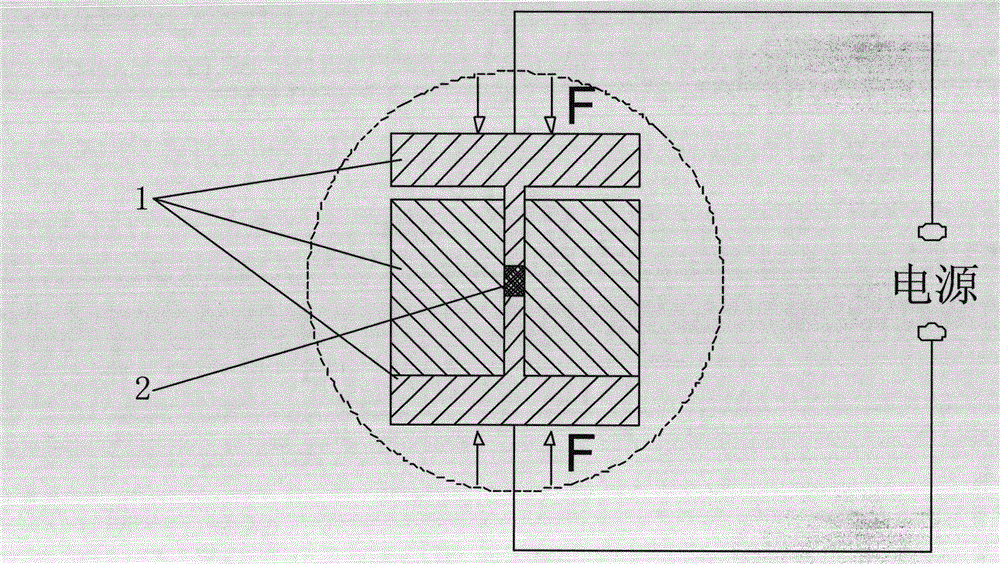

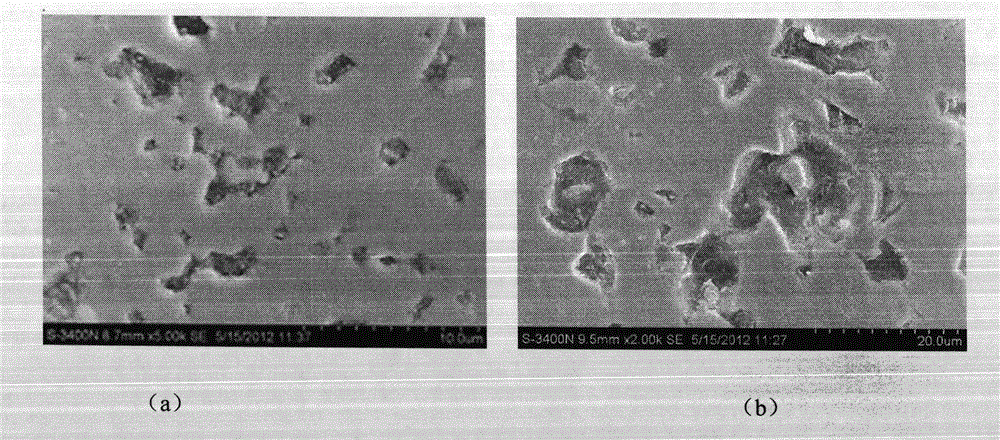

Method for preparing WC-Co hard alloy by rapid sintering under multi-physics coupling action

The invention discloses a method for preparing WC-Co hard alloy by rapid sintering under a multi-physics coupling action, which is characterized by comprising the steps of: evenly mixing powder of WC and Co, wherein the weight ratio of WC to Co is 84-94: 16-6; weighing and then filling into a mould; then, under the conditions that the heating speed is 15-100 DEG C / s and the vacuum degree is less than or equal to 0.01Pa, electrifying the mould containing the WC-Co powder with alternating current for rapid heating, and applying 10-200MPa acting force to the two ends of the mould; under the continuous action of electric field and force field, carrying out instant electric heating impact for different times when temperature rises to 800-1000 DEG C; and finally, cutting off the power, cooling with air and taking out the product. The electric heating impact comprises the following steps: cooling from the sintering temperature to 400 DEG C at the cooling speed of 15-100 DEG C / s and then heating to the sintering temperature at the heating speed of 15-100 DEG C / s; wherein the circulation time(s) is / are 1-10 time(s). The method simplifies the technological process, is rapid, efficient, energy-saving and environment-friendly, improves the quality of the hard alloy and is capable of replacing the existing preparation method of the hard alloy.

Owner:SICHUAN UNIV +1

Method for preparing pure titanium miniature parts on basis of multi-physical-field activated sintering

InactiveCN103447530ASimple processReduce processTurbinesOther manufacturing equipments/toolsPhysical fieldAlternating current

The invention discloses a method for preparing pure titanium miniature parts on the basis of multi-physical-field activated sintering. According to the method, pure titanium powder is weighed and is then filled into a mold, then, alternating current is introduced into the mold containing the titanium powder for carrying out fast heating under the sintering conditions that the temperature rise speed is 25 to 125 DEG C / s, and the vacuum degree is smaller than or equal to 0.01Pa, meanwhile, the acting force being 10 to 200MPa is exerted to the two ends of the mold, under the continuous effect of an electric field and a force field, the heat insulation is carried out for 0 to 10 minutes when the mold is heated to 800 to 1200 DEG C so that the titanium powder is formed in the mold, finally, the power is cut off, and the parts are cooled in the air and are then taken out. The method has the advantages that the technical flow process is simplified, the forming process can be easily controlled, no pollution is caused in the sintering process, the sintering time is shortened, the sintering temperature is lowered, and the product quality is improved.

Owner:SICHUAN UNIV

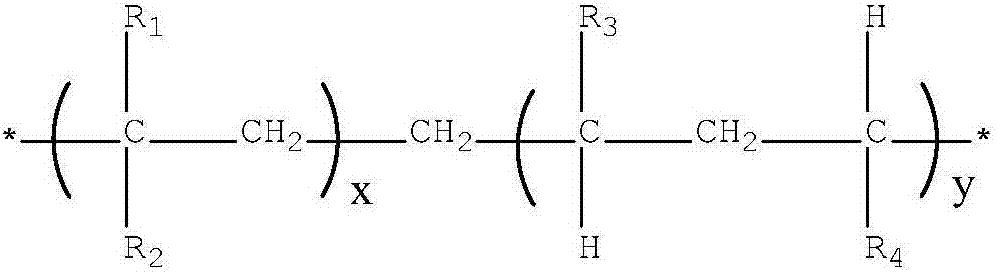

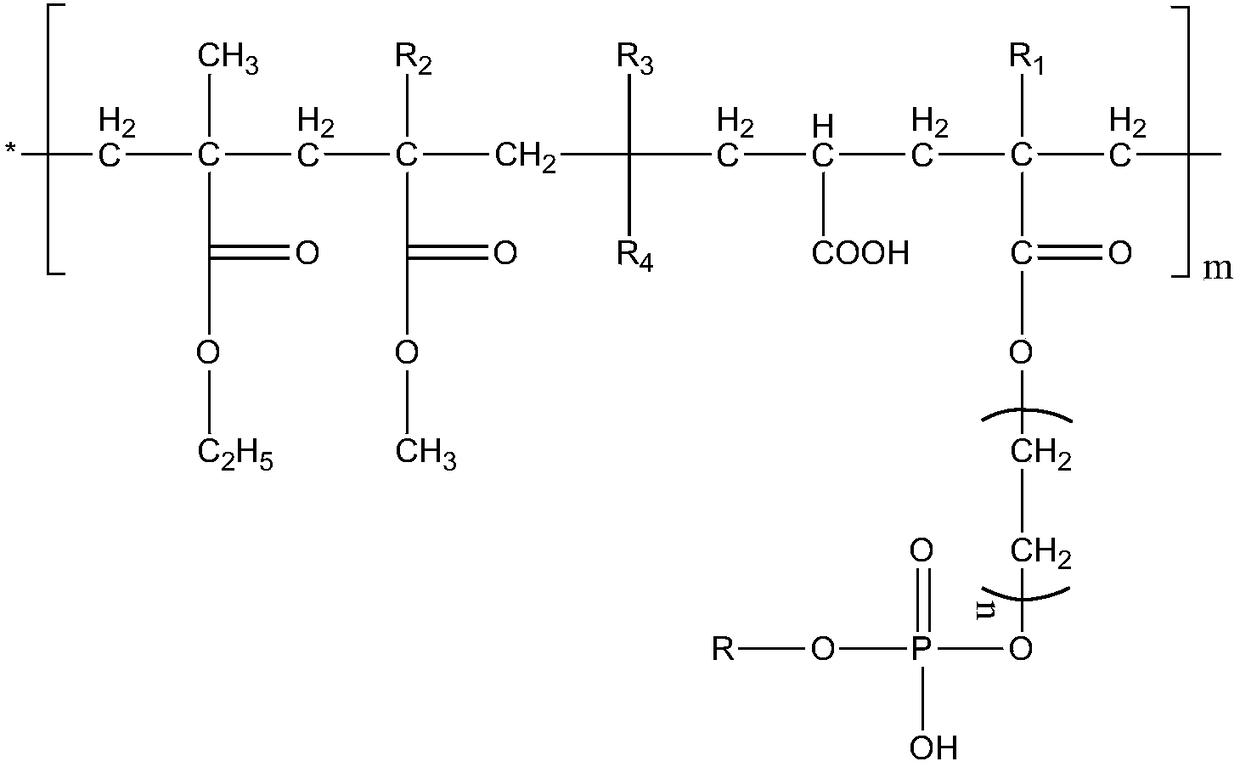

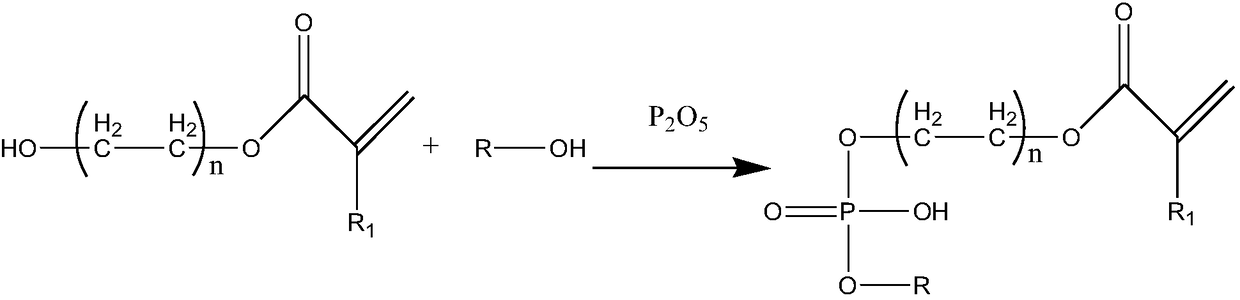

Phosphate modified acrylic core-shell emulsion with salt spray resistance

ActiveCN108250347AStrong adhesionImprove water resistanceGroup 5/15 element organic compoundsAnti-corrosive paintsWater basedAcrylic resin

The invention relates to a phosphate modified acrylic core-shell emulsion with salt spray resistance. A shell layer contains long-chain alkyl-acrylate phosphate diester functional groups; the components of the core-shell emulsion comprise acrylate soft and hard monomer, acrylic acid and long-chain alkyl-acrylate phosphate diester, a neutralizing agent, an initiator, an emulsifier and water; and the long-chain alkyl-acrylate phosphate diester is prepared from hydroxyl acrylate monomer, R6-10OH and phosphorus pentoxide through reaction. The invention also provides a preparation method of the phosphate modified acrylic core-shell emulsion with salt spray resistance. The phosphate modified acrylic core-shell emulsion has a glass transition temperature of 30-45 DEG C and a particle size of 60-150 nm; the phosphate modified acrylic core-shell emulsion provided by the invention has excellent adhesive force, water resistance, acid and alkali resistance, salt spray resistance, flash rust resistance and corrosion resistance, and is widely used for water-based antirust coating, water-based steel structure coating, water-based engineering coating, water-based concrete anticorrosive coating andthe like.

Owner:ZHUHAI JELEE CHEM ENTERPRISE CO LTD

Bamboo powder composite material and preparation method and application thereof

The invention provides a bamboo powder composite material, which is characterized by comprising the following components in part by weight: 30 to 60 parts of bamboo powder, 40 to 70 parts of melamine resin powder and 3 to 12 parts of hot melt adhesive powder, wherein the ratio of the bamboo powder to the hot melt adhesive powder is 10:1-2. The invention also provides a method for preparing the composite material, which comprises the following steps of: (1) preparing raw materials; (2) pretreating the raw materials; and (3) mixing the pretreated materials. The invention also provides a method for preparing a product of the composite material, which comprises the following steps of: (4) prefabricating a mold; (5) filling the composite material into the mold; (6) performing die casting on the composite material; (7) cooling the die-cast material; and (8) demolding the cooled material. The invention also provides application of the product in the field of manufacturing of sound boxes and the like. The bamboo powder composite material provided by the invention has high bamboo powder content and reasonable preparation process. The product can be particularly applied in specific fields and is in accordance with the concept of waste utilization, environmental friendliness, energy conservation and green production.

Owner:陈俊珂

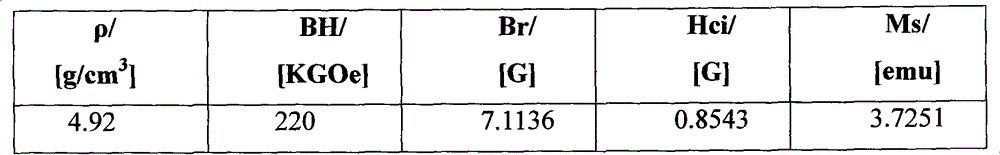

Method for preparing MnZn ferrite magnetic core by multi-physical field coupling

InactiveCN102976730AAccelerated solid phase diffusionHigh densityInorganic material magnetismInductances/transformers/magnets manufactureMultiphysics couplingPhysical field

The invention discloses a method for preparing an MnZn ferrite magnetic core by multi-physical field coupling. The method comprises the following steps of filling MnZn ferrite powder having particle sizes of 0.7 to 2.0 micrometers into a mold, directly powering on the mold with the MnZn ferrite powder to fast heat the mold at a heating rate of 5 to 200 DEG C / s under the pressure of 10<-2> Pa, simultaneously, applying an acting force of 50 to 100MPa to two ends of the mold, heating to a temperature of 600 to 1200 DEG C under the action of a continuous electric field, carrying out heat preservation for 2 to 10min so that the MnZn ferrite powder undergoes a solid-phase reaction in the mold and is molded fast, interrupting power supply, and taking out a sintered body. The method has the advantages that a heating rate is greatly improved so that diffusion between atoms is promoted; and through the pressure on the two ends of the mold, a MnZn ferrite magnetic core solid-phase reaction, compaction molding and compact sintering are carried out simultaneously so that performances of a molded magnetic core are guaranteed.

Owner:SICHUAN UNIV

Copper-containing laminated film etching liquid for liquid crystal panel and application thereof

The invention provides a copper-containing laminated film etching liquid for a liquid crystal panel and an application thereof. The etching liquid comprises a main agent and an auxiliary agent. A metal copper corrosion inhibitor in the main agent and the auxiliary agent is an amino carbazole metal corrosion inhibitor. According to the copper-containing laminated film etching liquid, the amino carbazole metal corrosion inhibitor is taken as the metal corrosion inhibitor in the main agent and the auxiliary agent, the product cost is lowered, and the etching liquid does not affect the electricalproperties of IGZO according to the corrosion inhibitor, so that the etching effect is better.

Owner:江苏和达电子科技有限公司 +1

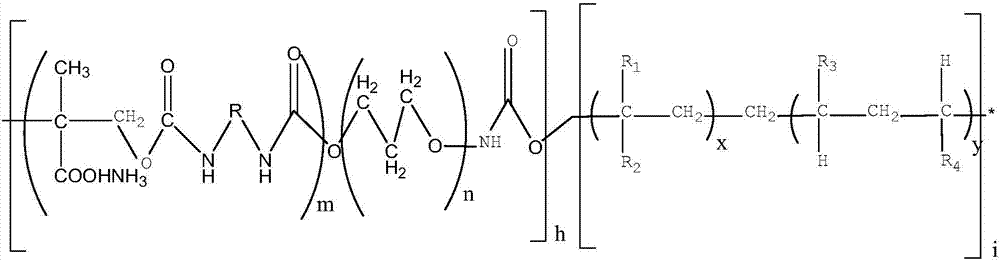

Method for preparing novel medical lubricating antibacterial catheter

The invention discloses a method for preparing a novel medical lubricating antibacterial catheter, which comprises the following steps of: blending and extruding high-concentration polypropylene-based nanometer silver antibacterial powder or antibacterial master batches and polylactic acid slices by using a screw extruder to prepare polylactic acid antibacterial master slices; and preparing the medical lubricating antibacterial catheter by using a precision melting extruder. The method is obvious in bacteriostatic effect, bacteria on the surface of the catheter can be inhibited from being propagated effectively, and the efficiency is more than 98 percent; and the catheter prepared by the method is high in biocompatibility, has surface self-lubricating property, and can be widely used for the water delivery and transfusion of patients and relevant instruments.

Owner:SHANGHAI LANGYI FUNCTIONAL MATERIALS

Method for preparing regenerated straw fiber by directly spinning straw

InactiveCN102146591AWide variety of sourcesSolve pollutionArtificial filaments from cellulose solutionsWet spinning methodsFiberYarn

The invention discloses a method for preparing regenerated straw fiber by directly spinning straw, belonging to the field of spinning of regenerated fiber. The method is characterized by comprising the following steps of: (1) washing straw with water, drying in the air, smashing, bleaching and filtering to obtain pretreated straw powder; (2) mixing the pretreated straw powder with chlorinated 1- butyl-3-methyl glyoxaline in the mass ratio of 1:30, preheating, swelling, dropwise adding dimethyl sulfoxide, adding 5 mL of dimethyl sulfoxide into every 0.5g of straw powder and stirring at controlled temperature to obtain high-viscosity spinning liquid; (3) filtering the high-viscosity spinning liquid, defoaming, spirally extruding, spraying by using a porous spinning head, drawing and curing in a coagulation bath to obtain fiber yarn, wherein the coagulation bath is water or an ion liquid aqueous solution with the concentration of 1-60 percent, the temperature of the coagulation bath is between 0 DEG C and 90 DEG C and the spinning speed is between 5 meters per minute and 150 meters per minute; and (4) drawing the fiber yarn, washing with water, applying oil and drying to obtain the regenerated straw fiber. The method has the characteristics of simple process, small equipment investment and low running cost.

Owner:WUHAN TEXTILE UNIV

Method for directly preparing membrane through wood fiber

The invention provides a method for directly preparing a membrane through wood fiber. The method includes the following steps: (1), mixing ion liquid and the wood fiber, and performing vacuum homogeneous emulsification cutting to enable the wood fiber to be dissolved in the ion liquid; (2), centrifuging a mixed solution to remove impurities and bubbles to obtain a wood fiber or ion liquid homogeneous phase solution system; (3), adding supernate after centrifuging into a die coated by polytetrafluoroethylene, horizontally standing, using deionized water for soaking after membrane liquid is basically solidified and formed, and uniformly smearing glycerin on the surface before drying. By the method, complex pretreatment is not needed, so that energy and time are saved, lignose and hemicellucose which are retained give functionality to the membrane, and the wood fiber is utilized comprehensively.

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI +1

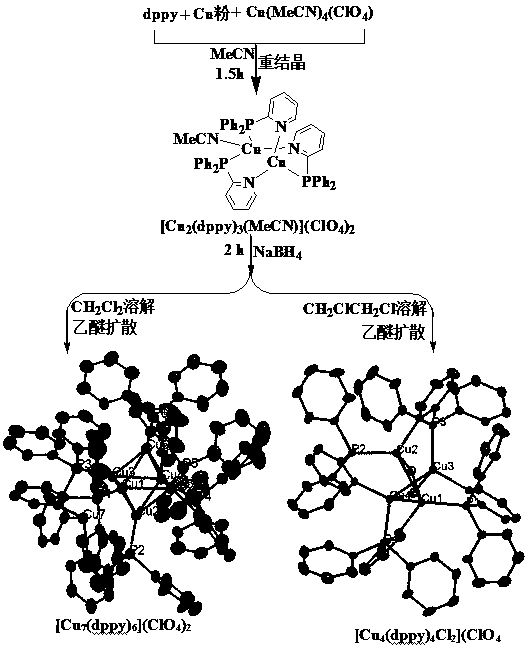

Organic phosphine copper nanocluster crystals and preparation method thereof

ActiveCN107652311AShort reaction timeHigh yieldGroup 1/11 organic compounds without C-metal linkagesOrganic chemistry methodsSolventPhosphine

The invention belongs to the technical field of metal nanoclusters, in particular to an organic phosphine copper nanocluster crystals and a preparation method thereof. With an organic phosphine coppercompound [Cu2(dppy)3(MeCN)](ClO4)2 as a precursor, NaBH4 as a reducing agent and CH2Cl2 and methanol as reaction solvents, after a stirring reaction is performed for 2h at room temperature, crystalswith two different structures, namely red [Cu7(dppy)6](ClO4)2 and yellow [Cu4(dppy)4Cl2](ClO4), can be obtained through recrystallization in different solvents respectively. A technology is simple, areaction condition is mild, and the reaction time is short; the two nanocrystals have unique structures and excellent light-emitting properties, have the particle sizes being smaller than 5 nanometers, and have potential application in light-emitting sensing and light-emitting devices; the preparation cost is low, no harmful waste is produced, and a requirement on environment-friendly production is met.

Owner:FUZHOU UNIV

Method for preparing cellulose/nanometer titanium dioxide blending material in ionic liquid solvent

InactiveCN101724929ALow process energy consumption and operating costsAvoid pollutionArtificial filaments from cellulose solutionsWet spinning methodsUltraviolet absorptionIon

The invention provides a method for preparing a cellulose / nanometer titanium dioxide blending material in an ionic liquid solvent, wherein a fiber consists of the cellulose and nanometer titanium dioxide particles. The ionic liquid solvent can directly dissolve the cellulose to avoid a complicated process for traditionally dissolving the cellulose; the nanometer titanium dioxide can be added to form uniform and stable spinning solution of cellulose / nanometer titanium dioxide; and the cellulose / nanometer titanium dioxide blending fiber material can be obtained through fiber spinning plasticizing, stretching, washing and drying. The composite material prepared by the method has the advantages of strong intensity, breaking elongation and flexibility, maintains the performance of regenerated cellulose filament, and has the functions of antibacterial activity and ultraviolet absorption. In the composite material prepared by the method, the cellulose is firmly combined with the nanometer titanium dioxide, and the nanometer titanium dioxide is evenly distributed and is difficult to run off. An ionic liquid is used as the solvent to prepare the cellulose composite material, so the method has the advantages of simple and convenient process, recyclable solvent, convenient operation and low cost, and is suitable for large-scale industrial application.

Owner:DALIAN POLYTECHNIC UNIVERSITY

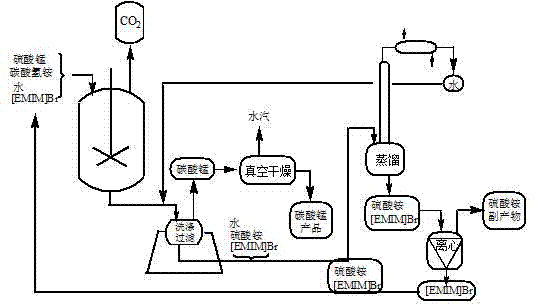

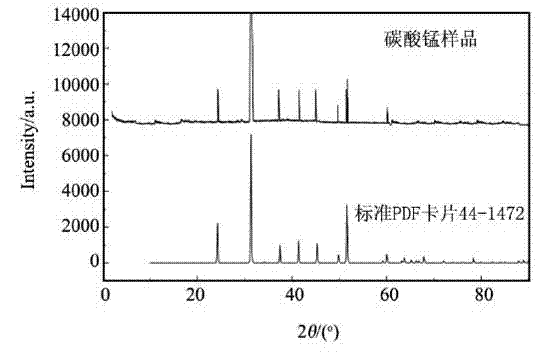

Method for synthesizing spherical manganese carbonate by use of ionic liquid

ActiveCN104724760AControllable shapeThe synthesis process is simpleBulk chemical productionManganese compoundsHydration reactionManganese sulphate

The invention provides a method for synthesizing spherical manganese carbonate by use of an ionic liquid. The method comprises the following steps: mixing an imidazole type ionic liquid, manganese sulfate monohydrate, ammonium bicarbonate and water together in the mass ratio of (6-9): (1-2): (1-2): (7-10), stirring for reacting at a reaction temperature ranging from 20-30 DEG C for 20-30 min, and meanwhile, collecting CO2 generated in the reaction process, after the reaction is ended, performing solid-liquid separation to obtain a solid and a filtrate, washing the solid, and drying in vacuum to obtain the spherical manganese carbonate product. Besides, the obtained filtrate is distilled and separated and then the ionic liquid and the solid are recovered, respectively; and the solid is ammonium sulfate or a sulfate mixture. According to the method, the imidazole type ionic liquid and water are taken as the solvents, and the imidazole type ionic liquid also serves as a template agent and is capable of controlling the precipitation reaction to obtain the spherical submicron-order manganese carbonate. The method is simple in synthesis process, and low in equipment and process operating costs; and the CO2, the ionic liquid and the ammonium sulfate or the sulfate mixture can be recycled to meet the requirement of green production.

Owner:DALIAN RUIYUANPOWER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com