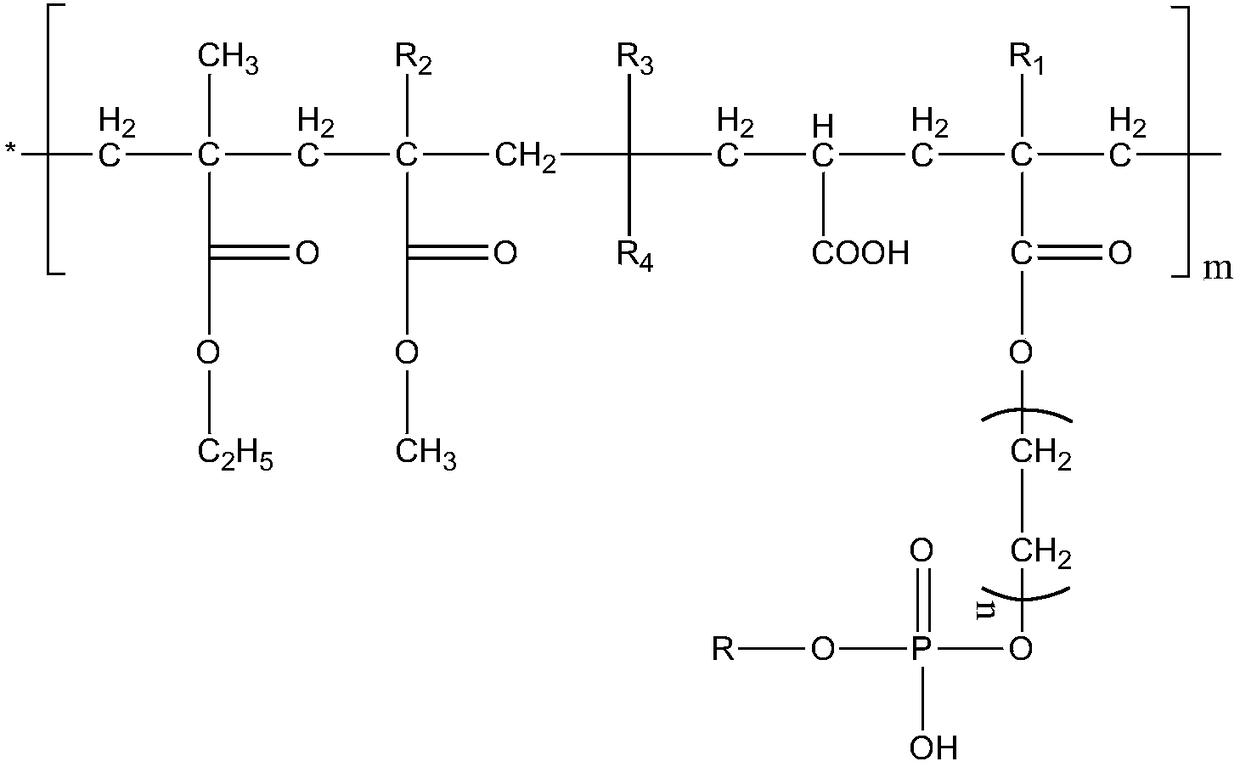

Phosphate modified acrylic core-shell emulsion with salt spray resistance

A technology of acrylic core and core-shell emulsion, which is applied in the fields of compounds, coatings, and organic chemistry of Group 5/15 elements of the periodic table, and can solve problems such as affecting film-forming performance, increasing application costs, and low alkyl carbon number. , to achieve the effect of excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

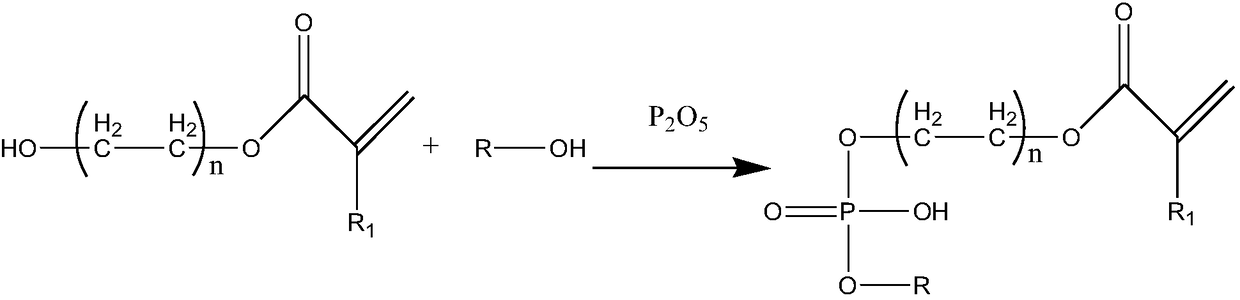

[0038] A kind of octyl-hydroxyethyl acrylate phosphodiester A, its preparation process is as follows:

[0039] In the reaction kettle, add 35.0 parts of hydroxyethyl acrylate and 0.2 parts of hydroquinone, stir evenly, raise the temperature to 50°C, add 28.0 parts of phosphorus pentoxide and 36.8 parts of octanol in batches, and complete the addition within 1.5 hours , and then raise the temperature to 82° C., keep the temperature for 3 hours, measure the acid value, cool down after passing the test, and discharge to obtain the octyl-hydroxyethyl acrylate phosphate diester A.

Embodiment 2

[0041] A kind of hexyl-hydroxyethyl methacrylate phosphodiester B, its preparation process is as follows:

[0042] In the reaction kettle, add 40.0 parts of hydroxyethyl methacrylate and 0.2 parts of hydroquinone, stir evenly, raise the temperature to 50°C, add 26.0 parts of phosphorus pentoxide and 33.8 parts of hexanol in batches, within 1.5h After the addition, the temperature was raised to 82°C, and the temperature was maintained for 3 hours to measure the acid value. After passing the test, the temperature was lowered, and the material was discharged to obtain the hexyl-hydroxyethyl methacrylate phosphodiester B.

Embodiment 3

[0044] A kind of octyl-acrylate hydroxypropyl phosphate diester C, its preparation process is as follows:

[0045] In the reaction kettle, add 38.0 parts of hydroxypropyl acrylate and 0.2 parts of hydroquinone, stir evenly, raise the temperature to 50°C, add 30.0 parts of phosphorus pentoxide and 31.8 parts of octanol in batches, and complete the addition within 1.5 hours , and then raise the temperature to 82°C, keep the temperature for 3 hours, measure the acid value, cool down after passing the test, and discharge to obtain the octyl-hydroxypropyl acrylate phosphate diester C.

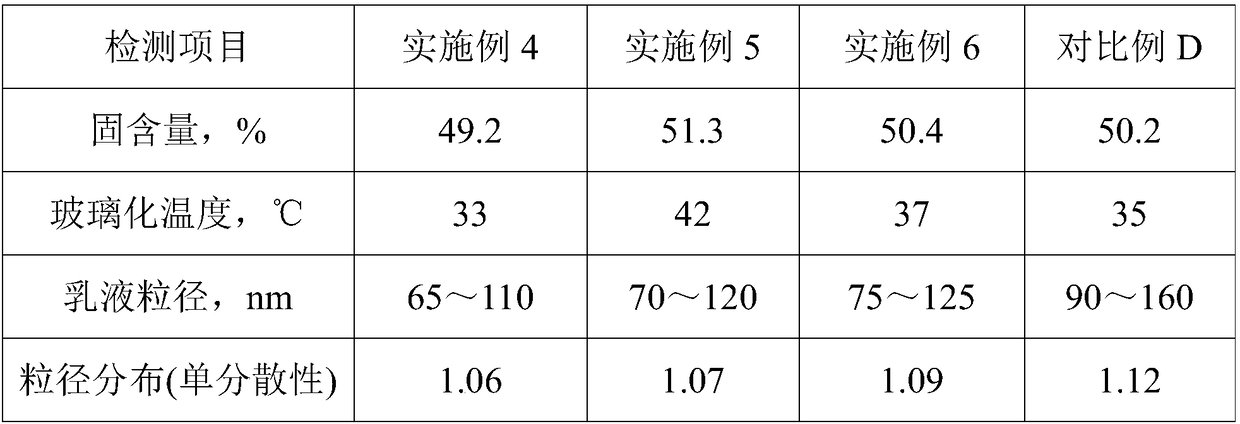

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com