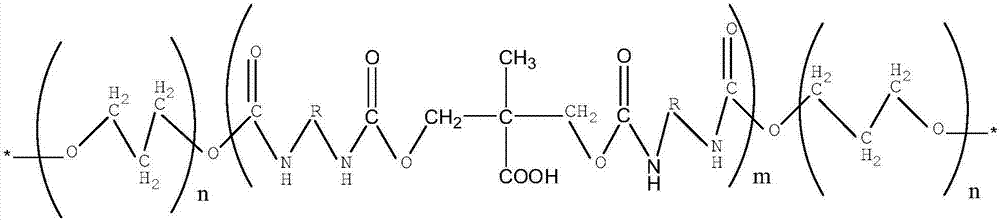

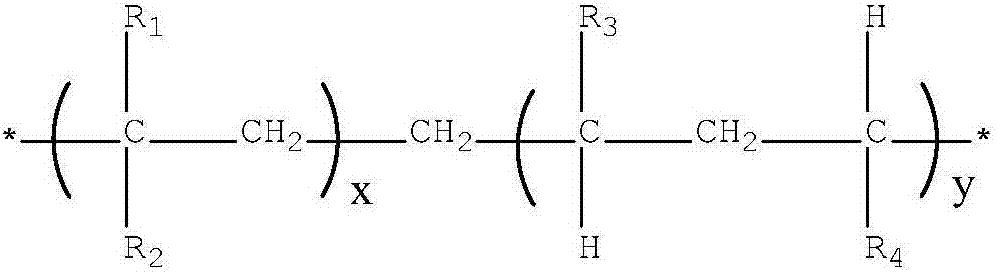

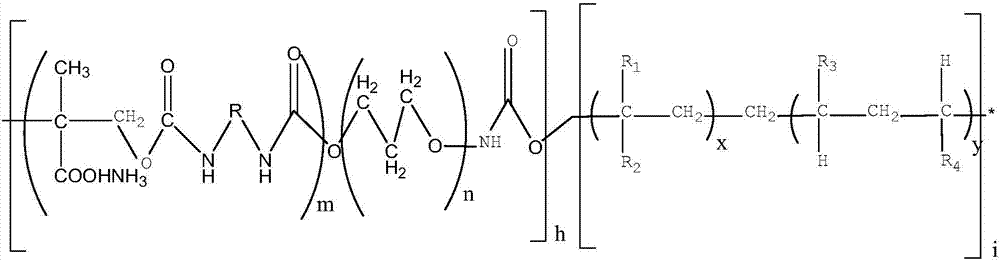

Waterborne acrylic modified polyurethane hybrid resin prepared by solvent-free method

A technology of water-based acrylic and hybrid resin, applied in the direction of coating, anti-corrosion coating, etc., to achieve the effect of excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A kind of waterborne acrylic acid modified polyurethane hybrid resin, its preparation process is as follows:

[0039] a), in a four-port reactor equipped with a thermometer, a condenser, and an agitator, 6.0 parts of polytetrahydrofuran diol, 3.0 parts of butanediol, 1.5 parts of trimethylolpropane, two 2.6 parts of hydroxymethylpropionic acid, heat up to 95-110°C, dehydrate under vacuum for 1.5-2.0 hours;

[0040] b), the temperature is lowered to 60-70°C, 16.0 parts of hexamethylene diisocyanate is added, and N 2 , dropwise adding 0.05 part of dibutyltin dilaurate, and then heating up to 80-82°C for 2-2.5 hours to obtain the hydrophilic polyurethane prepolymer;

[0041] c) Prepare 16.0 parts of methyl methacrylate and butyl acrylate mixed monomer in advance, take 8 parts of it and add it to the hydrophilic polyurethane prepolymer until the viscosity is moderate, cool down to 70°C, add hydroxyethyl acrylate 1.5 parts of ester, continue to react for 1.5h, and check un...

Embodiment 2

[0045] A kind of waterborne acrylic acid modified polyurethane hybrid resin, its preparation process is as follows:

[0046] a) In a four-port reactor equipped with a thermometer, a condenser, and an agitator, add 6.0 parts of polycarbonate diol, 4.0 parts of dipropylene glycol, and 2.0 parts of trimethylolpropane in sequence according to the weight percentage of the formula ,, 3.0 parts of dimethylolpropionic acid, heat up to 95-110°C, dehydrate under vacuum for 1.5-2.0 hours;

[0047] b), cooling down to 60-70°C, adding 17.0 parts of isophorone diisocyanate, passing through N 2 , dropwise adding 0.05 part of dibutyltin dilaurate, and then heating up to 80-82°C for 2-2.5 hours to obtain the hydrophilic polyurethane prepolymer;

[0048] c) Add 8 parts of methyl methacrylate monomer to the hydrophilic polyurethane prepolymer until the viscosity is moderate, cool down to 70°C, add 1.8 parts of hydroxyethyl acrylate, continue the reaction for 1.5 hours, and detect when Until th...

Embodiment 3

[0052] A kind of waterborne acrylic acid modified polyurethane hybrid resin, its preparation process is as follows:

[0053] a) In a four-port reactor equipped with a thermometer, a condenser, and an agitator, add 6.0 parts of polycarbonate diol, 4.0 parts of dipropylene glycol, 1.5 parts of glycerin, and dimethylol in sequence according to the weight percentage of the formula 3.5 parts of propionic acid, heated to 95-110°C, dehydrated under vacuum for 1.5-2.0 hours;

[0054] b), cooling down to 60-70°C, adding 15.0 parts of hexamethylene diisocyanate, passing through N 2 , drop 0.05 part of dibutyltin dilaurate, then raise the temperature to 80-82°C for 2-2.5 hours to obtain the hydrophilic polyurethane prepolymer;

[0055] c) Prepare 12.0 parts of mixed monomers of methyl methacrylate and butyl methacrylate in advance, take 7 parts of mixed monomers and add them to the hydrophilic polyurethane prepolymer until the viscosity is moderate, and cool down to 70°C , add 2.0 part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com