Original ecology separation and redispersion method of nano metallic colloid

An original ecological and re-dispersion technology, applied in the field of nanomaterials, can solve the problems of easy agglomeration, single shape, and difficult industrial production, and achieve the effects of mild reaction conditions, short reaction time, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

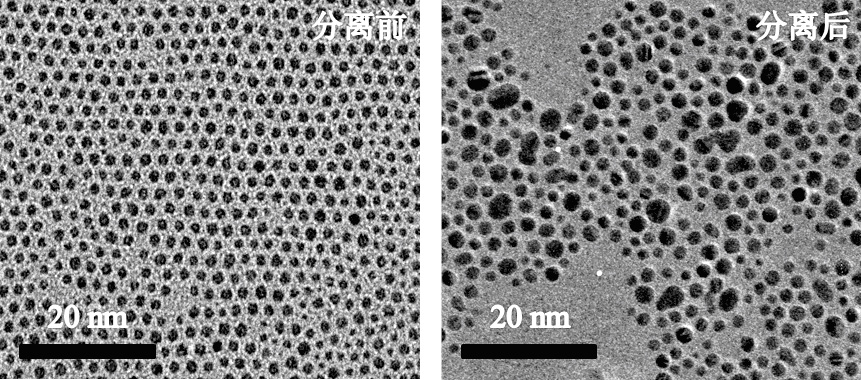

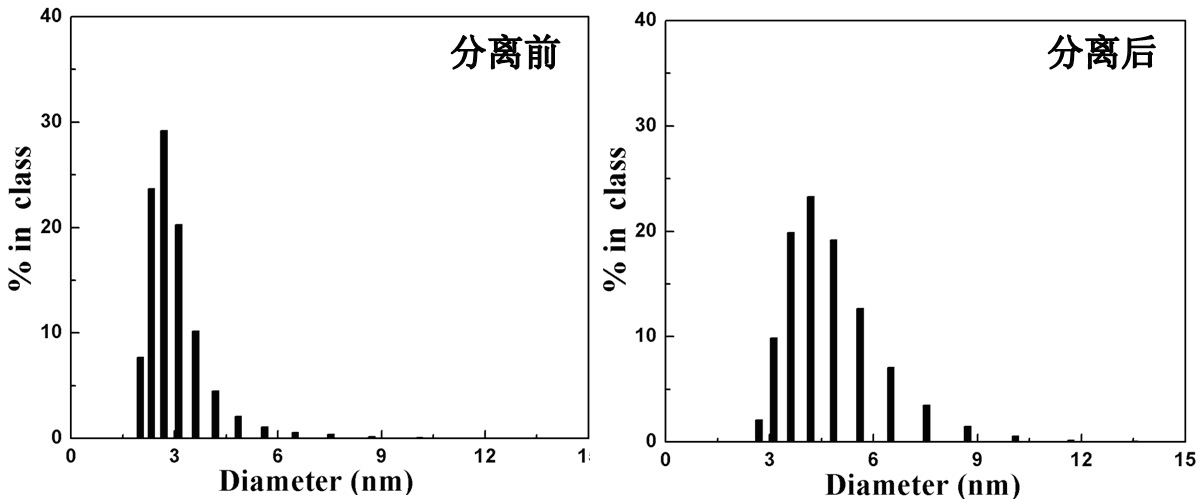

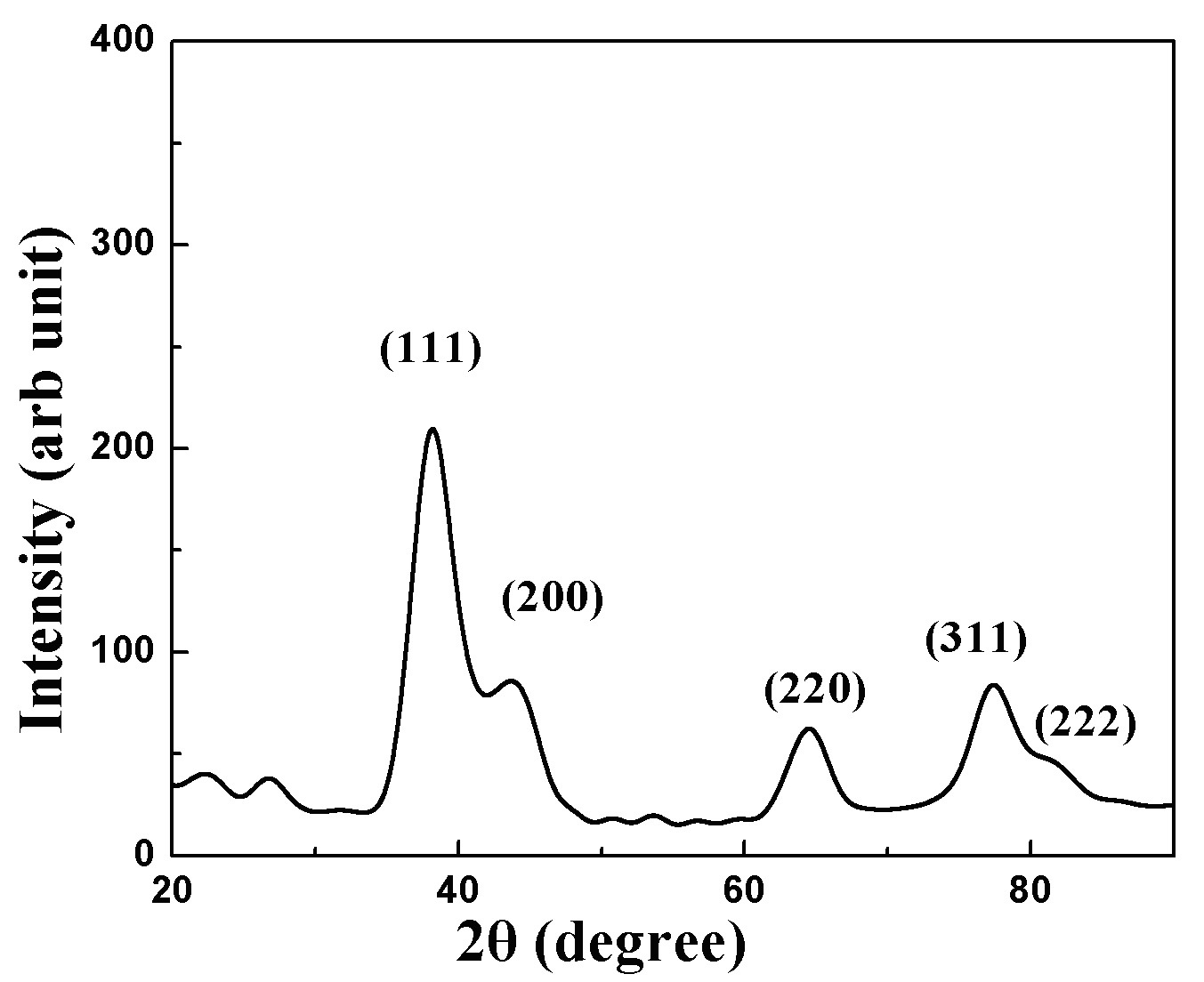

Image

Examples

Embodiment 1

[0028] Example 1: 0.020g silver acetate, 0.04g dodecanoic acid, a certain amount of deionized water and ethylene glycol, and adjust the pH value to 9~10 with potassium hydroxide, gradually raise the temperature to 90~120°C, and quickly Add 0.025g of ascorbic acid, and keep stirring for 20-30 minutes, the solution turns brown-black, and stable nano-silver colloid can be obtained; adjust the pH value of the solution to 6-7 with hydrochloric acid, and flocculent precipitates appear, and Brinell The funnel is separated, washed and dried to obtain nano-silver powder;

Embodiment 2

[0029] Example 2: 0.35g silver laurate, 0.7g sodium citrate, a certain amount of deionized water and isopropanol, and adjust the pH value to 9~10 with sodium hydroxide, and gradually heat up to 90~120°C for several minutes Add 0.05 g of hydrazine hydrate quickly, and continue to stir for 20 to 30 minutes. After the reaction, the solution turns brownish black, and stable nano-silver colloid can be obtained; adjust the pH value of the solution to 6 to 7 with sodium bisulfate, and flocculation occurs. Precipitate, separated by Buchner funnel, washed and dried to obtain nano-silver powder;

Embodiment 3

[0030] Example 3: 0.52g silver nitrate, 0.87g polyvinyl alcohol, a certain amount of deionized water, and adjust the pH value to 9~10 with sodium bicarbonate, gradually heat up to 90~120°C, and add hydration rapidly after a few minutes Hydrazine 0.07g and after 20-30 minutes of continuous stirring reaction, the solution turns brownish black, and stable nano-silver colloid can be obtained; the pH value of the solution is adjusted to 6-7 with phosphoric acid, and flocculent precipitation occurs, and the Buchner funnel separates, After washing and drying, nano-silver powder can be obtained; take some obtained nano-silver powder and disperse it directly in xylene, and ultrasonically disperse for several minutes to obtain yellow-green nano-silver colloid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com