Preparation method of nano-copper

A technology of nano-copper and copper salt, which is applied in the field of nano-materials, can solve the problems of low product purity, and achieve the effects of simple process, mild reaction conditions and good product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

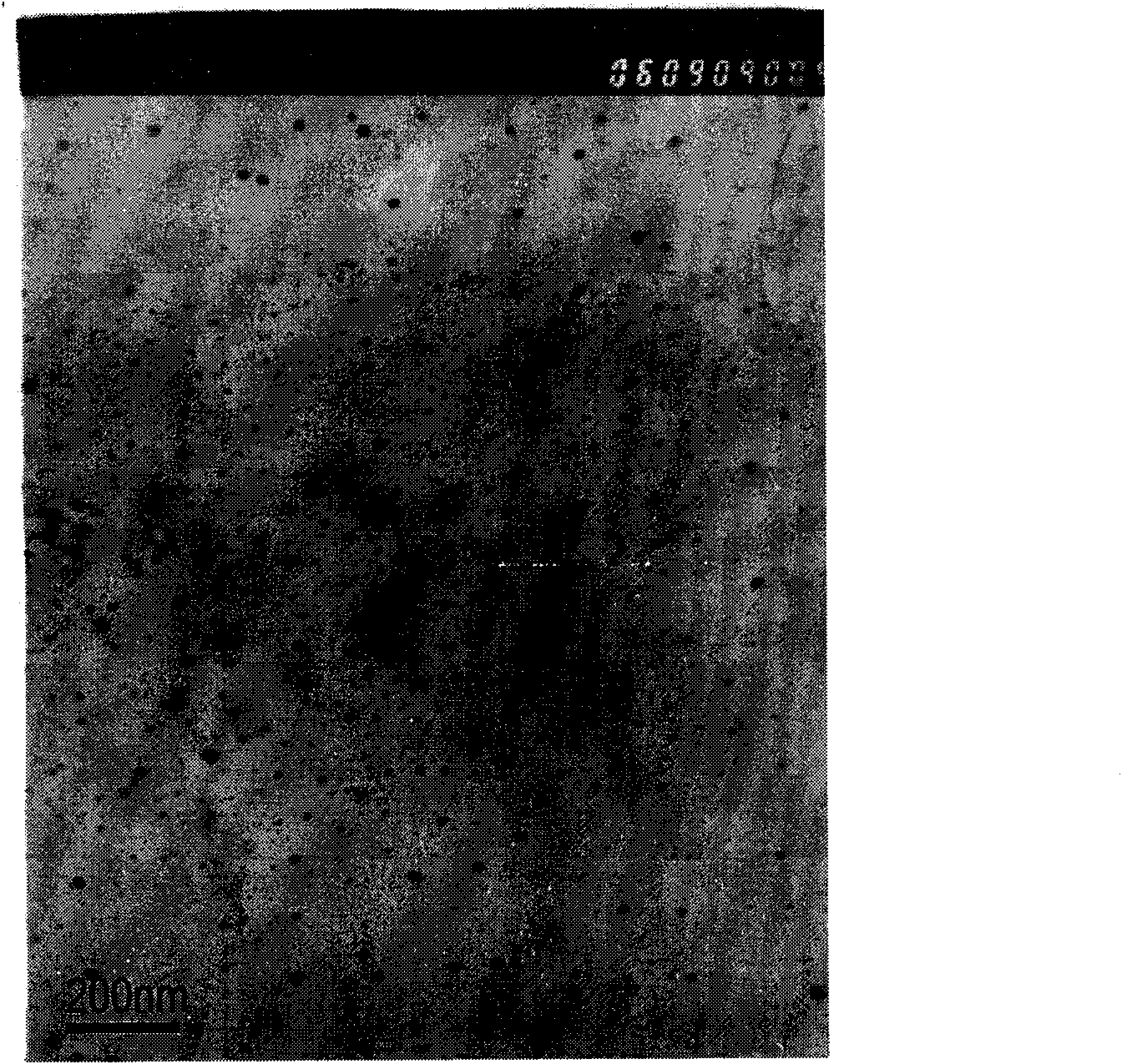

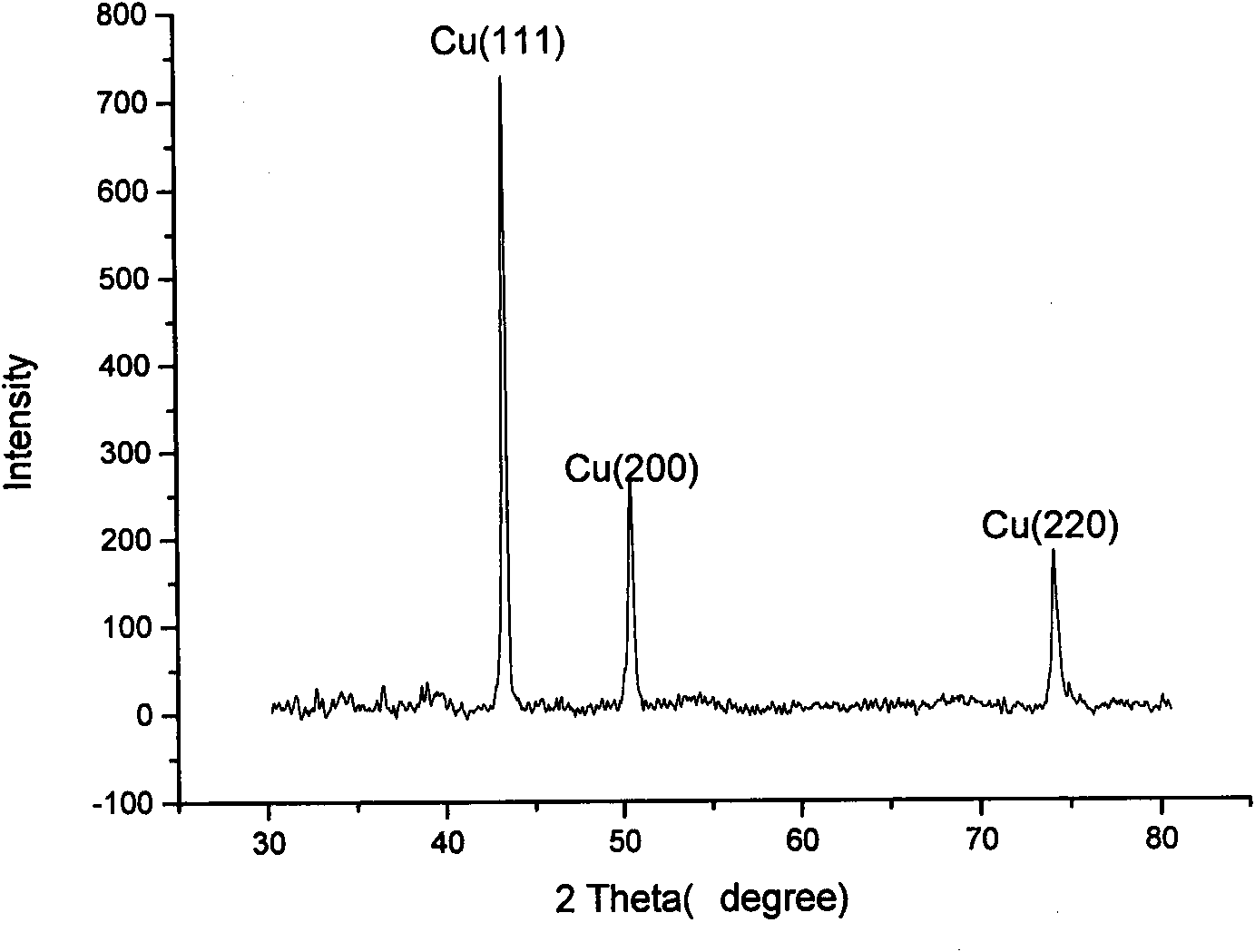

[0021] Example 1: Dissolve 0.01mol of copper acetate in 100ml of ethanol, add 5ml of oleic acid and 0.5g of polyethylene glycol 2000, stir to dissolve, and heat up to 50°C. Slowly add 10ml of hydrazine hydrate solution, stir vigorously, the solution gradually turns deep red, indicating the generation of nano-copper, and stop heating after 20 minutes. The cooled solution is left to stand and then centrifuged, and washed with ethanol and acetone repeatedly for more than three times to obtain pure nano-copper.

Embodiment 2

[0022] Example 2: Dissolve 0.01mol of copper sulfate pentahydrate in 100ml of diethylene glycol, add 0.5g of cetyltrimethylammonium bromide and 0.8g of polyvinyl alcohol 300,000, and raise the temperature to 100°C. Dissolve 0.02mol of sodium hypophosphite in 50ml of diethylene glycol, slowly add to the above solution and stir vigorously, the solution turns purple, indicating that nano-copper is formed, and stop heating after 20 minutes. Subsequent operations are the same as in Example 1.

Embodiment 3

[0023] Example 3: Dissolve 0.01 mol of copper nitrate in 100 ml of ethylene glycol, add 0.6 g of dodecyltrimethylammonium chloride and 2 g of polyvinylpyrrolidone (K30), and heat up to 40 degrees. Dissolve 0.01mol sodium borohydride in 50ml ethylene glycol, slowly add to the above solution and stir vigorously, the solution turns yellowish brown, indicating the production of nano-copper, and the reaction stops after 20 minutes. Subsequent operations are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com