Method for preparing nano copper powder and copper slurry

A technology of nano-copper powder and copper paste, which is applied in the field of preparation of anti-oxidation nano-copper powder and copper paste. Good performance and dispersibility, easy separation and collection, simple preparation conditions and processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

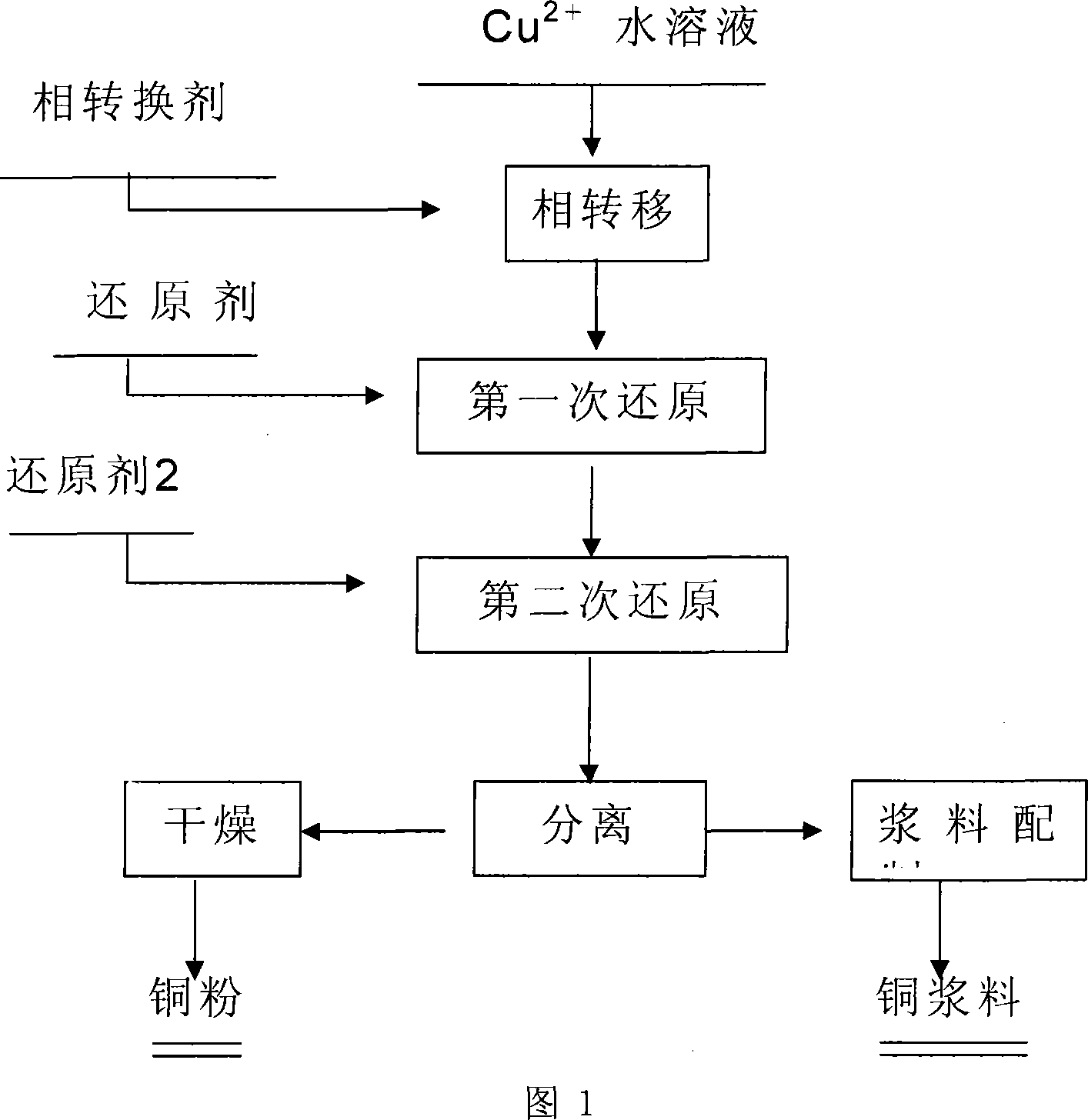

Method used

Image

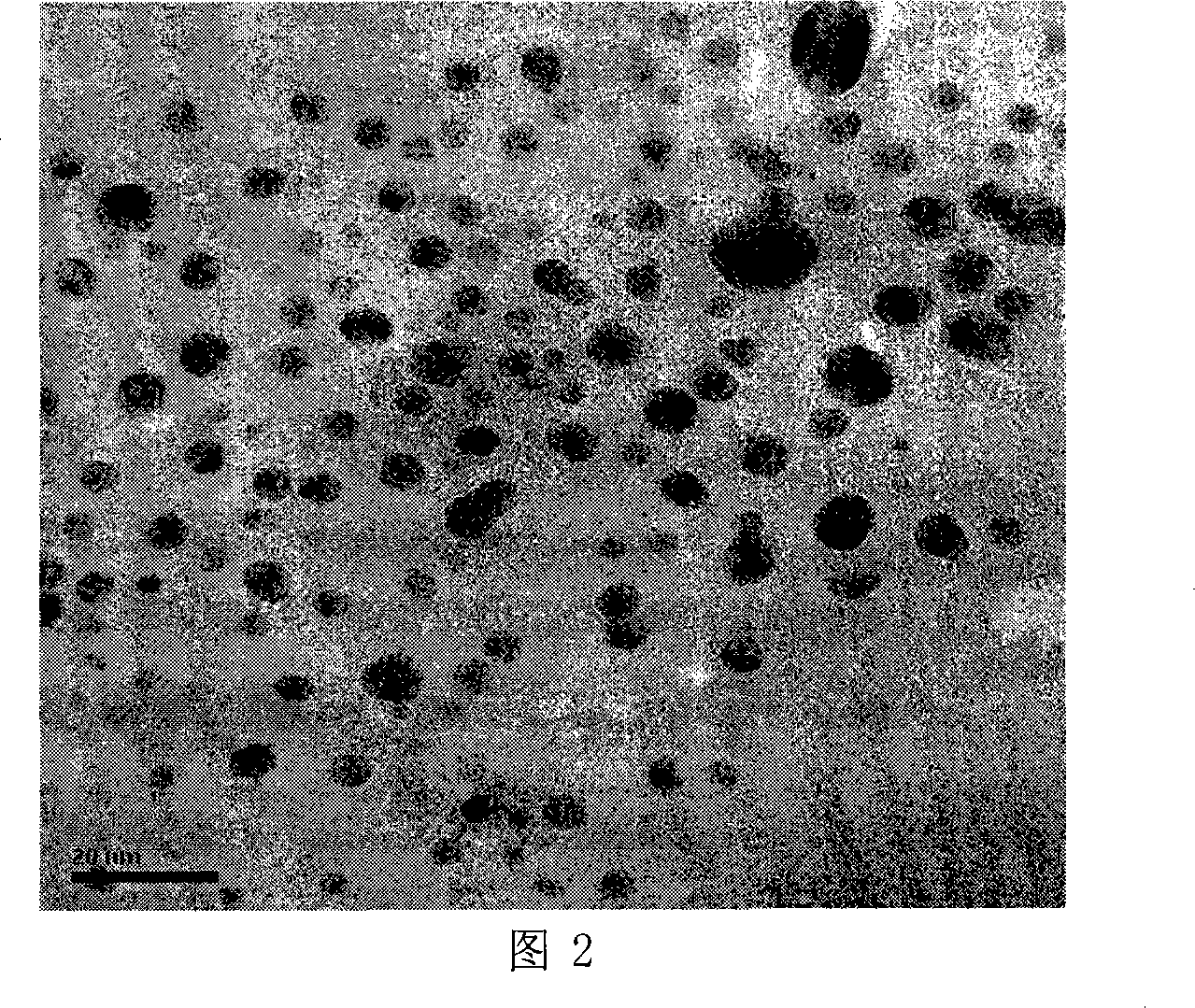

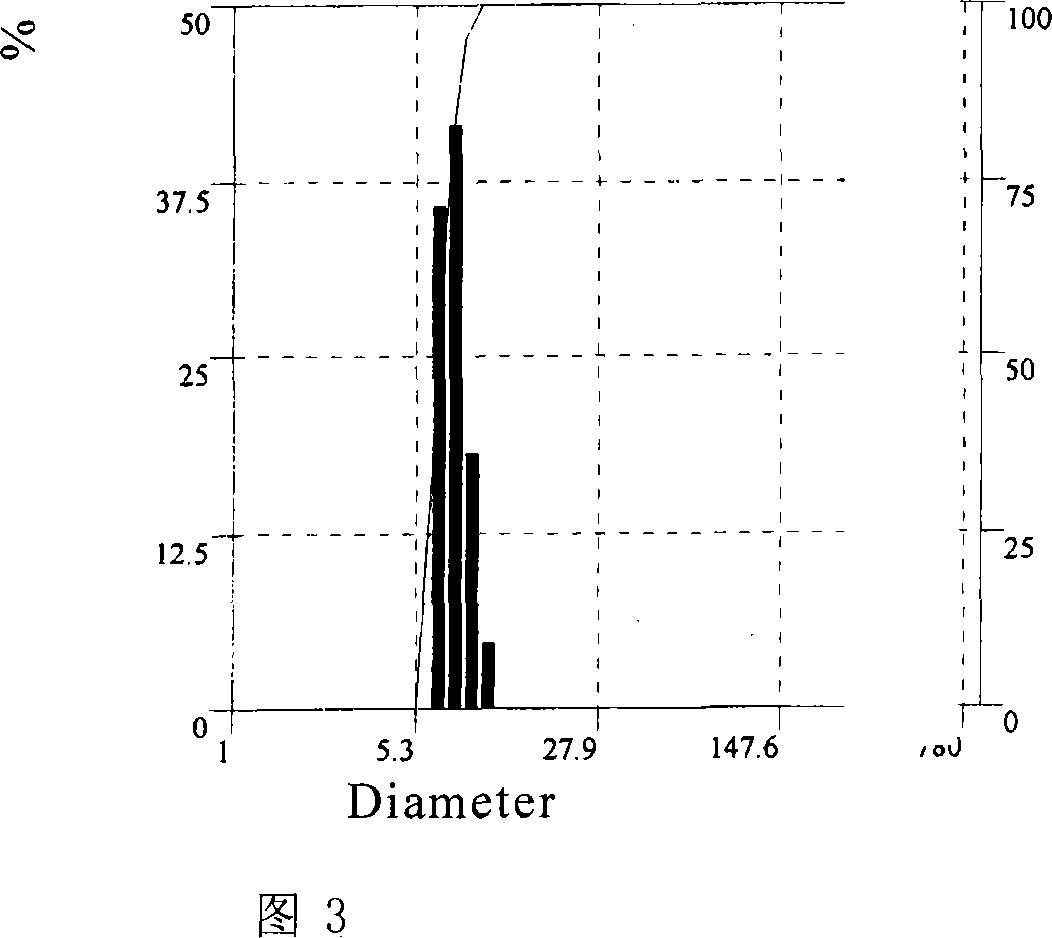

Examples

Embodiment 1

[0033] (1) Configure 0.5~1.0mol·L -1 Cu 2+ 200ml of aqueous solution, then add 5~10ml of stearic oleic acid into the above aqueous solution and shake vigorously for about 30min; (2) Add 0.5~0.8mol·L -1 50ml of glucose solution, heated in a water bath, and carried out the reduction reaction at a temperature of 40-60°C for about 15 minutes; (3) continue to add 0.5-0.8mol.L -120ml of ascorbic acid was reacted for 30min; cooled down to room temperature, and aged for 60min, the organic phase was separated and collected by overturning method; (5) the separated organic phase was washed with 20-40ml of ethanol and dried to obtain Nano-copper powder; or the organic phase of the coated copper obtained by separation is prepared according to the following formula (weight percentage) to obtain copper conductive paste,

[0034] Organic coated copper 2~20%

[0035] Dispersant (triethanolamine or polyethylene glycol) 0.1~5%

[0036] Stabilizer (sodium carboxymethyl cellulose or sodium car...

Embodiment 2

[0041] (1) Configure 0.5~1.0mol.L -1 Cu 2+ 2000ml of aqueous solution, then add 25-50ml of trans-oleic acid into the above-mentioned aqueous solution and shake vigorously for about 30min; (2) Add 0.5-0.8mol.L -1 500ml of glucose solution, heated in a water bath, and carried out the reduction reaction at a temperature of 40-60°C for about 15 minutes; (3) continue to add 0.5-0.8mol.L -1 200ml of formaldehyde was reacted for 30min; (4) Cool down to room temperature, and after aging for 60min, the organic phase was separated and collected by overturning; (5) The separated organic phase was washed with 50-100ml of acetone and dried to obtain dispersibility and anti-oxidation Nano-copper powder with good properties; or the coated copper organic phase obtained by separation is prepared according to the following formula (weight percentage) to obtain copper conductive paste,

[0042] Organic coated copper 2~20%

[0043] Dispersant (sodium polyacrylate or polyvinylpyrrolidone) 0.1~5...

Embodiment 3

[0049] (1) Configure 0.5~1.0mol·L -1 Cu 2+ 200ml of aqueous solution, then add 5-10ml of oleic acid mixture (volume ratio of stearic oleic acid to trans oleic acid is 1:1) into the above aqueous solution and shake vigorously for about 30min; (2) add 0.5-0.8mol L -1 50ml of glucose solution, heated in a water bath, and carried out the reduction reaction at a temperature of 40-60°C for about 15 minutes; (3) continue to add 0.5-0.8mol.L -1 40ml of hydrazine hydrate was reacted for 30min; (4) cooling down to room temperature, and after aging for 60min, the organic phase was separated and collected by overturning method; (5) the separated organic phase was washed with 20-40ml of ethanol, and after drying, the dispersibility and anti-resistance Nano copper powder with good oxidizability; or the organic phase coated copper obtained by separation is prepared according to the following formula (weight percentage) to obtain copper conductive paste,

[0050] Organic coated copper 2~20%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com