Formula and preparation method of anti-mildew coating

A paint and anti-mildew technology, which is applied in the direction of anti-fouling/underwater paint, cement paint, coating, etc., can solve the problems of mildew and peeling off, and achieve the effect of strong adhesion, strong adaptability and good construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

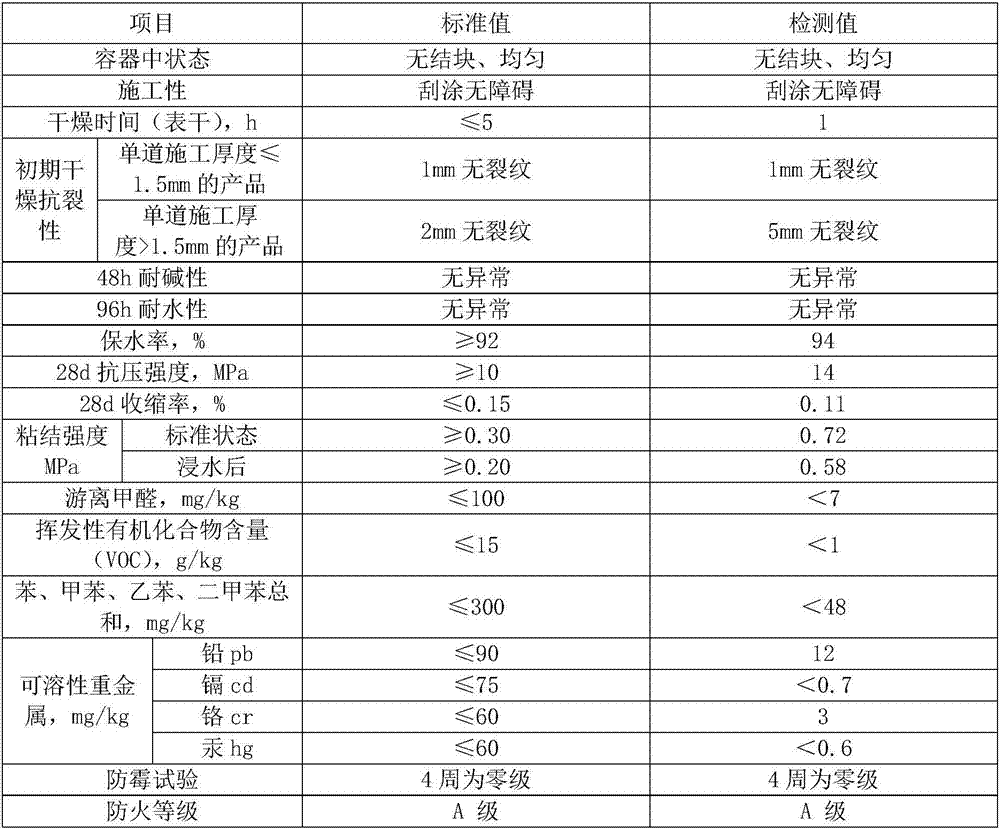

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with specific embodiments.

[0029] The invention relates to a formula of anti-mildew paint, which is prepared by cement, quartz sand, heavy calcium powder, light calcium carbonate, ash calcium powder, talcum powder, anti-cracking fiber and additives in a certain proportion. The weight ratio of each component is 19% of cement, 28% of quartz sand, 29% of heavy calcium powder, 6% of light calcium carbonate, 12% of lime calcium powder, 4% of talcum powder, 1.5% of anti-cracking fiber and 0.5% of additive. The particle size of quartz sand is 80-120 mesh; the additives are hydroxypropyl methylcellulose, preservative (cetyl ammonium bromide), antifungal agent (titanium-loaded zinc composite hydroxyapatite powder) and light-stabilized agent (hindered amine light stabilizer 662), the weight ratio of the four is 8.0:1.0:0.5:0.5.

[0030] Preparation method: equipment cleaning→quartz sand sieving and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| ignition point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com