Patents

Literature

51 results about "Stillingia oil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stillingia oil is gained by solvent from the plant seeds of the Sapium family such as, Sapium sebiferum (Chinese tallow tree) and Sapium discolor (Mountain tallow tree). It is used as a drying agent in paints and varnishes. It dries readily on a glass plate in 4–6 hours. Stillingia oil's properties, such as a high iodine value, and chemical components classifies it as a drying oil. Why it has the appropriate properties to be a drying oil remain disputed. Following are three different arguments from J. Devine (1950), A. Crossley with T.P. Hilditch (1953), and V. C. Batterson with W. M. Potts (1938)...

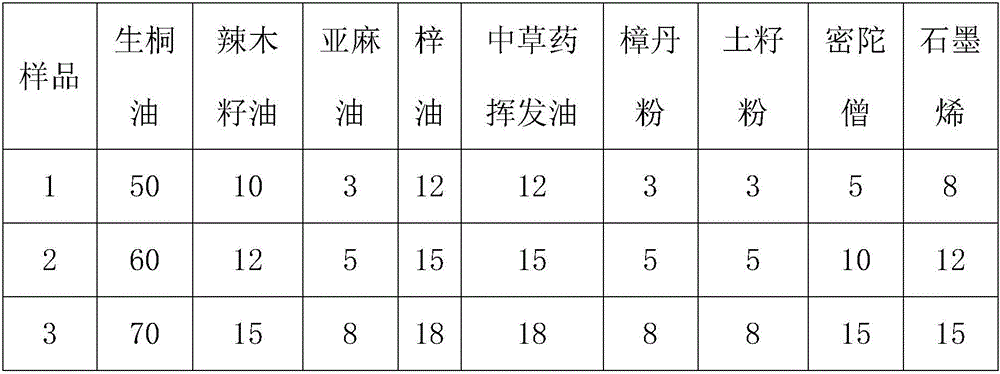

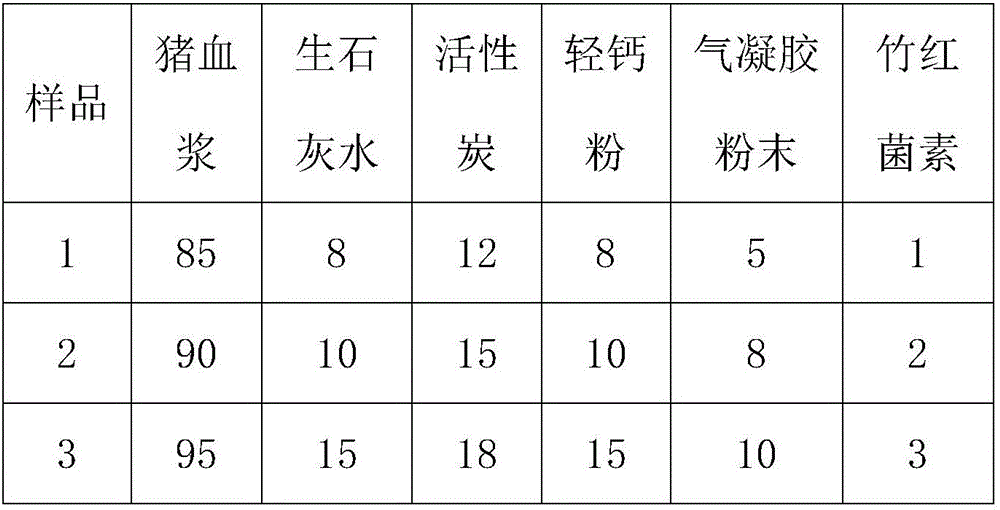

Ash oil putty for ancient architecture material and preparation method thereof

ActiveCN106189460AImprove anti-ultraviolet performanceImproves application continuityFilling pastesBrickPutty

The invention provides ash oil putty for an ancient architecture material and a preparation method thereof. The ash oil putty contains ash oil, a blood material and brick dust, wherein the mass ratio of the ash oil to the blood material to the brick dust is 1 to 1-3 to 5-10, the ash oil is prepared from raw tung oil, moringa seed oil, linseed oil, catalpa oil, Chinese herbal medicine volatile oil, minium powder, manganese dioxide metal drier, litharge, graphene and other raw materials. The blood material is prepared from pig plasma, quick lime water, activated carbon powder, light calcium powder, aerogel powder and hypocrellin. The brick dust is obtained by smashing oil-immersed black brick coarse granules. The ash oil, the blood material and the brick dust are mixed in proportion. The ash oil putty has good adhesion and toughness, increased tension, good coating continuity and is easy to construct. Dried ash oil putty does not crack, is easy to polish, also has excellent waterproof, anticorrosive, antibacterial and ultraviolet-proof properties, is especially suitable for repair and filling of the ancient architecture material, is especially used for ancient architecture wood materials and plays an excellent wood material filling effect.

Owner:BEIJING XINCHUZHIYUAN ENVIRONMENTAL PROTECTION TECH

Preparation method of alpha-linolenic acid with purity of 98%

ActiveCN104649895AWide coverageSufficient sourceOxygen-containing compound preparationPreparation by ester-hydroxy reactionMixed fatty acidStillingia oil

The invention discloses a preparation method of alpha-linolenic acid with the purity of 98%. The preparation method is characterized by comprising the following steps: removing free fatty acid from Chinese tallow kernel oil, or siritch (linseed oil), purple perilla seed oil, eucommia seed oil, kiwi seed soil and the like in anhydrous ethanol to obtain mixed fatty glyceride; then performing base catalysis ester exchange to obtain mixed fatty acid ethyl ester; performing urea inclusion and complex salt complexing to obtain 90% alpha-linolenic acid; and finally performing metal ion complexing and dissociation to obtain alpha-linolenic acid with the purity of 98%. The preparation method disclosed by the invention is stable and reliable, simple, convenient and feasible to operate, simple in equipment and suitable for large-scale production.

Owner:湖北华龙生物制药有限公司

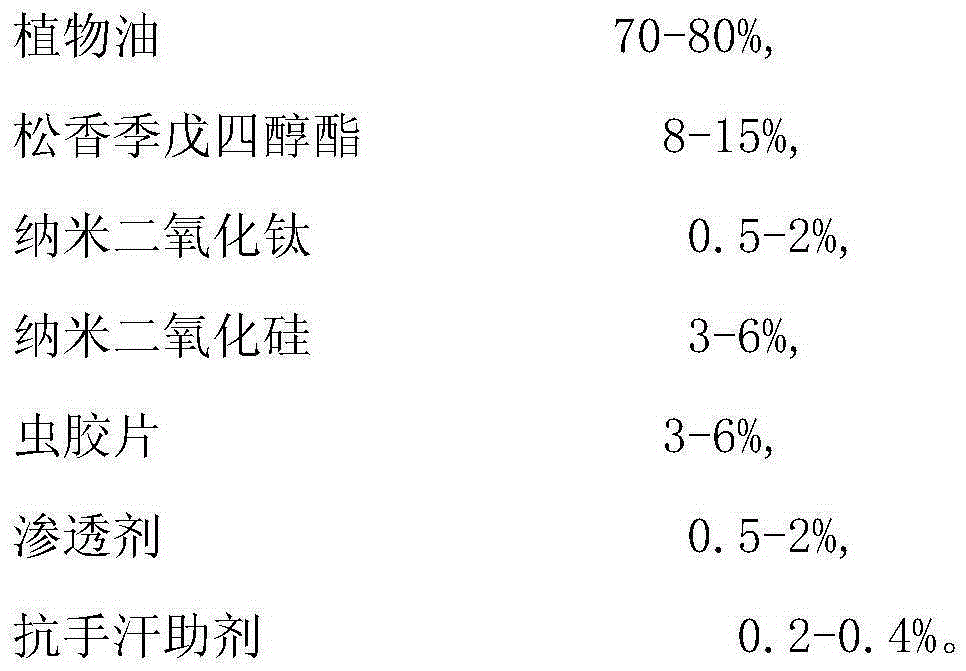

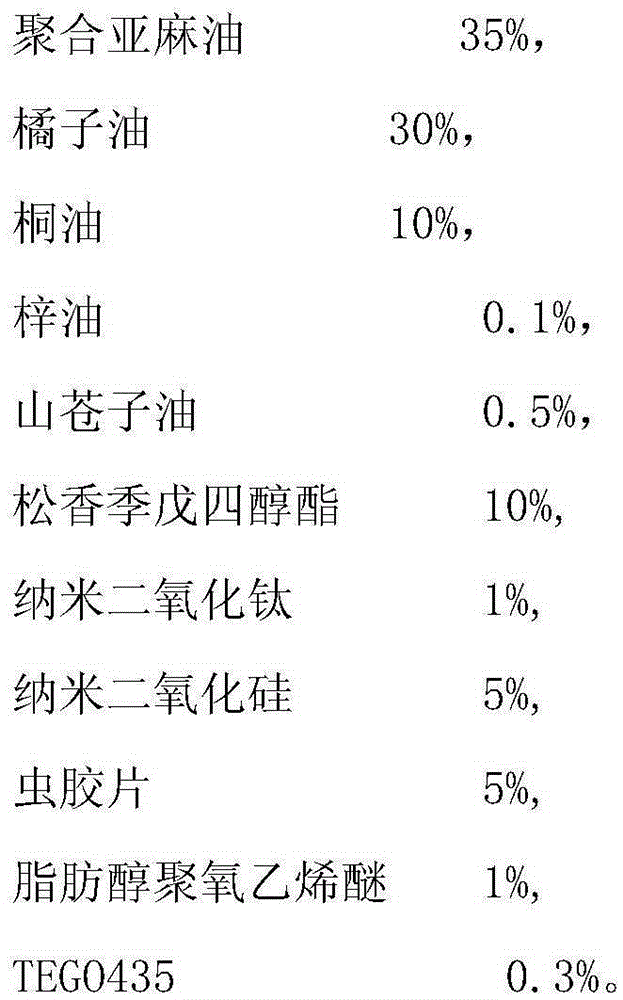

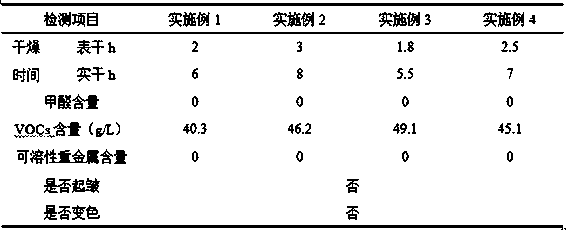

Stain-removing and furniture-servicing film plating oil and preparation method therefor

ActiveCN105238267AEasy to handleHigh hardnessAntifouling/underwater paintsPaints with biocidesVegetable oilShellac

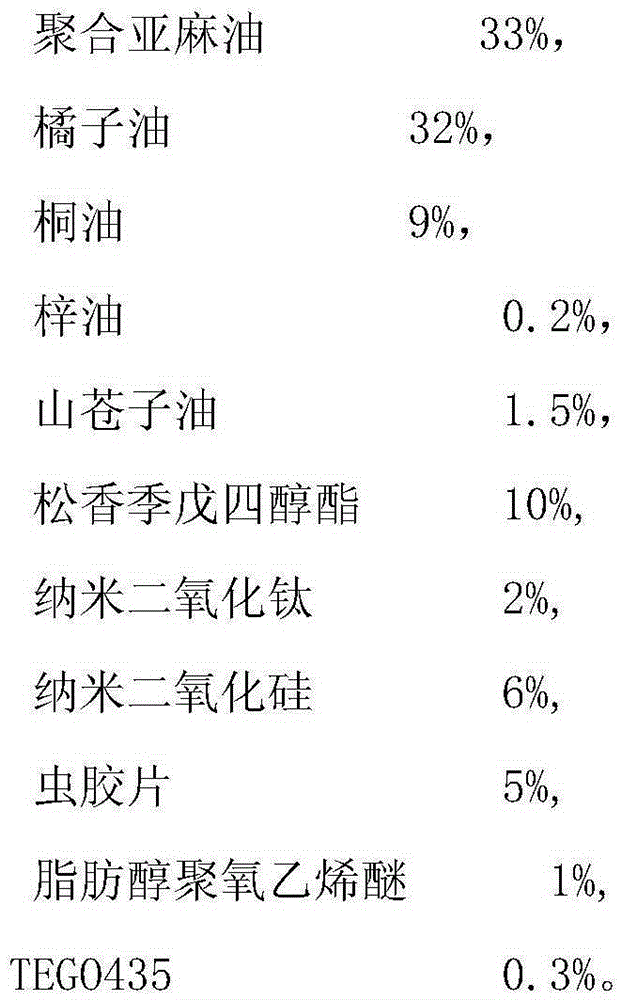

The invention discloses stain-removing and furniture-servicing film plating oil and a preparation method therefor. The film plating oil contains the following ingredients in percentage by weight: 70-80% of vegetable oil, 8-15% of pentalyn, 0.5-2% of nano titanium dioxide, 3-6% of nano-silica, 3-6% of flake shellac, 0.5-2% of penetrant and 0.2-0.4% of hand perspiration resisting assistant, wherein the vegetable oil consists of polymerized flaxseed oil, mandarin oil, tung oil, stillingia oil and litsea cubeba oil. The film plating oil disclosed by the invention is a novel material for cleaning, nursing and serving the surface of furniture, stains of the surface of the furniture can be rapidly and conveniently treated, and the hardness, hand feeling and glossiness of a coat surface can be improved; and meanwhile, the film plating oil can protect the surface of the furniture and plays roles in antisepticizing and mildew-proofing.

Owner:JIANGMEN GUOMEI CHEM

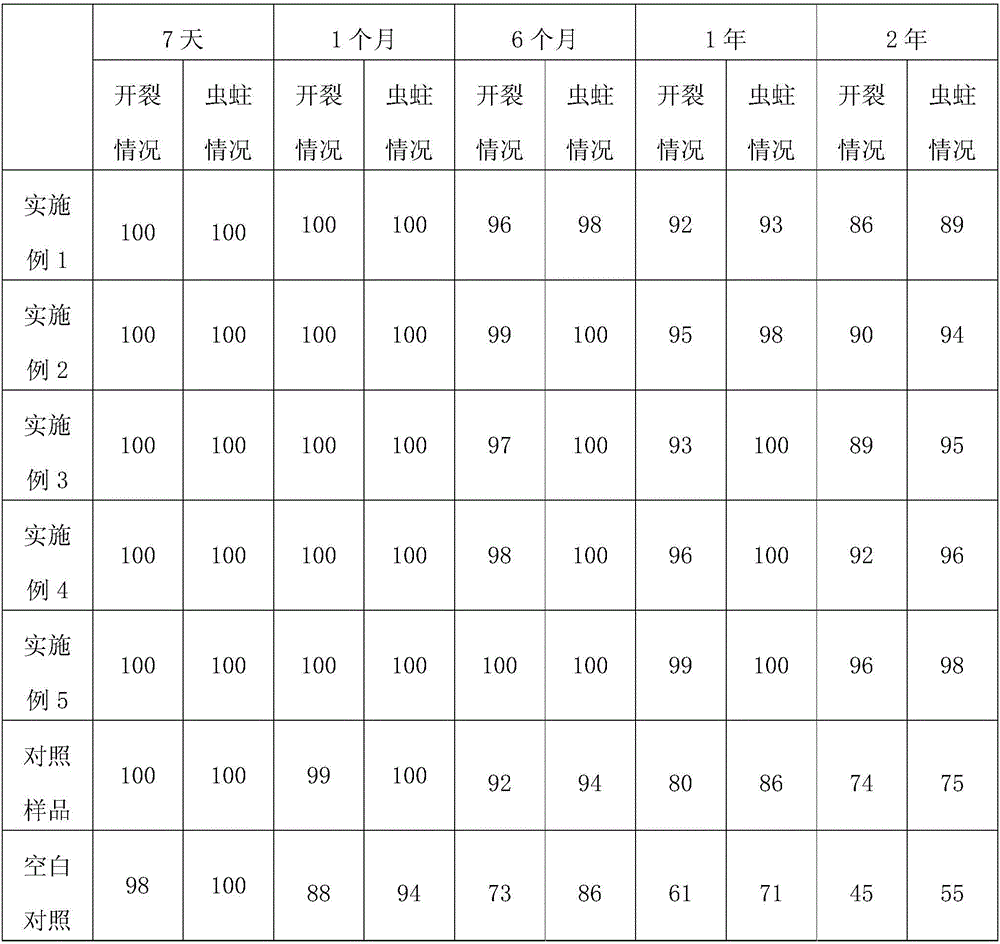

Wood anti-cracking agent

ActiveCN106584619ANothing producedMeet environmental protection requirementsWood impregnation detailsStillingia oilPolyvinyl alcohol

The invention relates to the technical field of wood processing treatment, in particular to a wood anti-cracking agent. The wood anti-cracking agent is prepared from, by weight, 30-55 parts of palm oil, 25-40 parts of pine oil, 15-30 parts of stillingia oil, 20-35 parts of tung oil, 10-20 parts of beewax, 0.5-2.5 parts of methylparaben, 10-20 parts of silicone oil, 1-5 parts of polyvinyl alcohol, 1-5 parts of glycerinum, 2-6 parts of Twain, 4-10 parts of cobalt iso-octoate, 0.5-2.5 parts of neem oil and 0.2-1.0 part of allicin. The wood anti-cracking agent has the advantages of being green, environmentally friendly, good in durability, capable of effectively preventing wood from cracking, and meanwhile capable of preventing worm damage and mildew.

Owner:GUANGXI NANYIZAI SCI & TECH CO LTD

Vacuum gold-plated primer

InactiveCN104559746ARaw materials are easy to getLow costPolyurea/polyurethane coatingsSolventSkin agent

The invention discloses a vacuum gold-plated primer which comprises the following components in percentage by mass: 55 to 60 percent of alcohol acid modified urethane oil, 20 to 25 percent of rosin modified phenolic resin, 1 to 2 percent of a dryer, 1 to 2 percent of an anti-skinning agent, 0.3 to 0.4 percent of organic modified nano SiO2, 0.2 to 0.3 percent of organic modified nano graphene and 11 to 22 percent of No.200 solvent oil. The alcohol acid modified urethane oil is prepared from the following components in percentage by mass: 5 to 10 percent of linseed oil, 1 to 5 percent of soybean oil, 10 to 15 percent of stillingia oil, 5 to 10 percent of pentaerythritol, 15 to 20 percent of toluene diisocynate and 40 to 64 percent of No.200 solvent oil. The vacuum gold-plated primer disclosed by the invention has the advantages of low cost, good adhesive force, high hardness, excellent heat resistance, controllable curing time, bright and full surface, high convenience in construction and the like and is suitable for industrial production.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Anti-cracking paint

InactiveCN103881573AIncrease stickinessWon't fall offRosin coatingsEpoxy resin coatingsBenzoic acidEpoxy

The invention relates to an anti-cracking paint which comprises the following components in parts by weight: 10-13 parts of tung oil, 4-7 parts of stillingia oil, 3-6 parts of linseed oil, 12-15 parts of rosin, 5-8 parts of benzoic acid, 4-6 parts of amber, 11-16 parts of pigments, 1-4 parts of white spirit, 2-4 parts of white alcohol, 5-8 parts of a curing agent, 7-12 parts of moisture-proof agent and 3-5 parts of epoxy resin gel. By adopting the epoxy resin gel, the anti-cracking paint disclosed by the invention does not fall off after being coated on a wall due to improved viscidity, no cracks are generated, and most of the adopted raw materials are organic raw materials which are friendly to the environment, energy-saving, safe and harmless to people.

Owner:SOUTHEAST UNIV

Method for preparing wax oil floor

InactiveCN105291236ASimple processAvoid local uneven moisture contentWood working apparatusCoatingsPerilla oilTurpentine

The invention relates to the field of furniture wood industries, in particular to a method for preparing a wax oil floor. Firstly, linseed oil, stillingia oil, perilla oil, pine oil, castor oil, rosin modified resins and beeswax which each account for 10%-30% of the total content of semi-finished wax oil are mixed and subjected to high-temperature polymerization at the temperature of 280-300 DEG C; turpentine is added into a polymerized mixture for dilution and filtering to form the semi-finished wax oil; a dryer is added into the diluted and filtered semi-finished wax oil for concoction, and after the concoction is finished, finished wax oil is formed; then the finished wax oil is smeared to the floor, and finally after the wax oil on the floor is blown dry, the wax oil floor is formed. The process is simple, the wax oil floor with the indexes identical to foreign indexes can be produced, the floor without harmful substances such as formaldehyde and benzene is achieved, and the requirement of environmental protection is met.

Owner:江苏徐家木业有限公司 +1

Wood mildewproof treatment method

InactiveCN107866885AHigh purityImprove antibacterial propertiesWood treatment detailsWood heatingPathogenic microorganismStillingia oil

The invention discloses a wood mildewproof treatment method and belongs to the field of wood processing. Mildewproof liquid prepared through the method is composed of clove oil and Cedrorana extract,wherein the clove oil is extracted through a microwave extracting technology with normal hexane as solvent, the extracted clove oil is high in purity, thus, the antibacterial property is high, the extracted clove oil is combined with the Cedrorana extract, due to the fact that lots of aromatic metabolic products are synthesized into the Cedrorana extract, the aromatic metabolic products have plantdefense mechanisms and can suppress growth and reproduction of pathogenic microorganisms, and the antibacterial effect is achieved, so that the mildewproof effect of the mildewproof liquid is furtherimproved. The problems that bactericidal effects of present physical methods are poor, durable protectability is not formed, and once treated wood is further processed or abraded and cracked and ambient environment is suitable, wood can be damaged by mold and decay fungi again is solved.

Owner:唐林元

Green tung oil-based paint and preparation method thereof

ActiveCN109054639AGuaranteed performanceSolve problems such as green environmental protectionCoatingsStillingia oilVegetable oil

The invention discloses green tung oil-based paint and a preparation method thereof. The green tung oil-based paint is mainly prepared from the following raw materials in parts by weight: 40-60 partsof refined tung oil, 10-15 parts of stand linseed oil, 10-15 parts of stillingia oil, 20-35 parts of reactive tung oil diluent, 1-2 parts of compound drier, 0.2-0.4 part of antioxidant, 0.2-0.4 part of light stabilizer, 0.2-0.3 part of mildew preventive, 0.1-0.2 part of flatting agent and 0.1-0.2 part of defoaming agent. The invention further discloses the preparation method of the green tung oil-based paint. The paint has the following advantages that the tung oil is used as a main body, compounding is conducted on the tung oil, the other vegetable oil, a biological solvent, auxiliaries and the like, a safe environment-friendly nontoxic tung oil-based paint product is developed, and under a situation of guaranteeing the paint performance, the current purposes of environmental friendlinessof the paint industry can be achieved.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

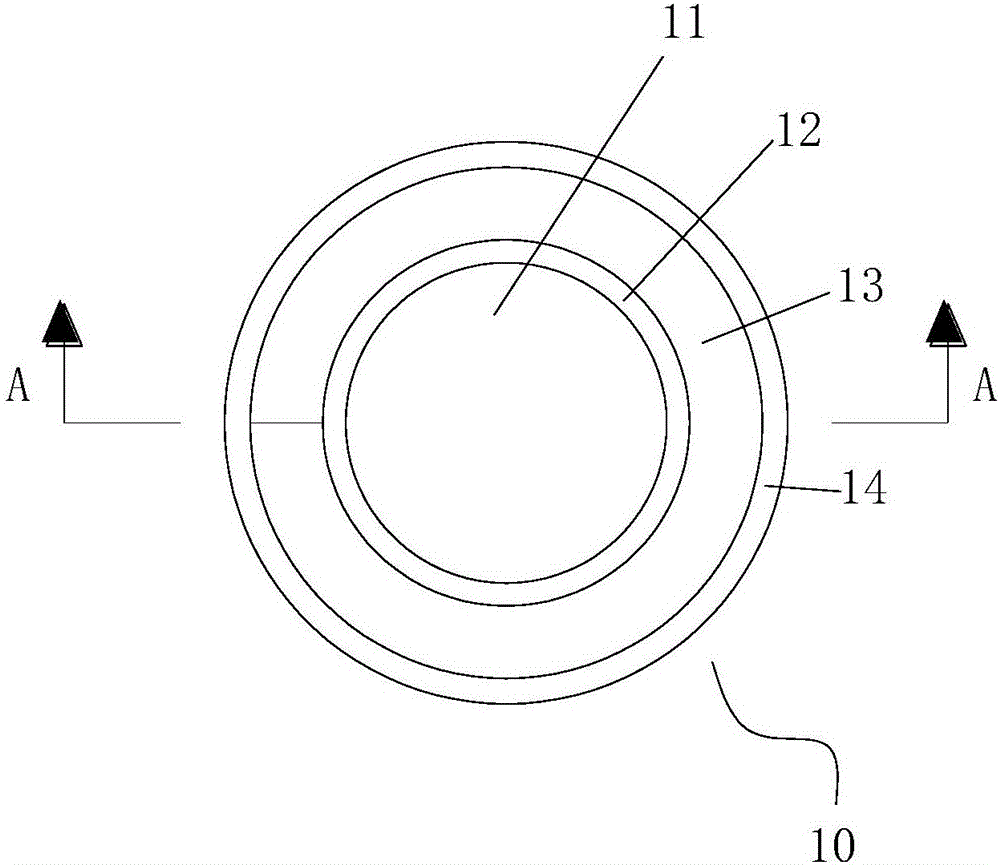

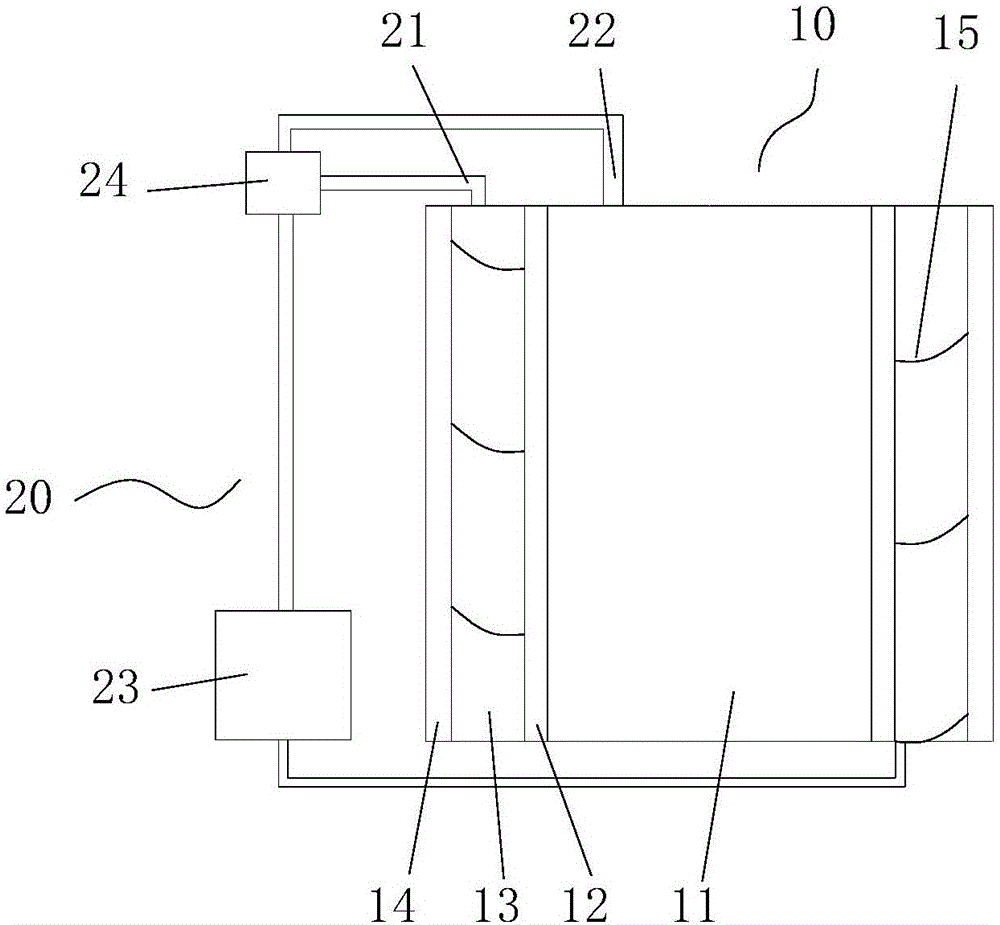

Gloss oil for historic building materials and preparation method thereof

ActiveCN106244001AImprove anti-ultraviolet performanceImprove wettabilityRosin coatingsAnti-corrosive paintsVegetable oilThermal insulation

The invention provides gloss oil for historic building materials and a preparation method thereof. The gloss oil is prepared from the following raw materials: raw tung oil, moringa oleifear seed oil, flax seed oil, stillingia oil, rosin, lithargite and aerogel powder. The preparation method of the gloss oil comprises the following steps: adding raw tung oil into a reaction tank, heating and carrying out thermal insulation, wherein it is ensured that raw tung oil is in an oxygen-enriched atmosphere during the process; adding other vegetable oil into raw tung oil, uniformly mixing, heating, adding rosin and aerogel powder, uniformly mixing, continuously heating, carrying out thermal insulation, adding lithargite, dissolving, and naturally cooling. In allusion to the above preparation method, the invention also provides a reaction device to guarantee full curing of raw tung oil and heating uniformity and further realize accurate control of parameters. The gloss oil of the invention is used for surface protection of historic building materials, especially protection of wood surface, has waterproof, corrosion resistant, ultraviolet-proof and sterilization effects, and can enhance surface glossiness, hardness and hand feeling.

Owner:BEIJING XINCHUZHIYUAN ENVIRONMENTAL PROTECTION TECH

Preparation methods of binding agent for casting and matched curing agent thereof

InactiveCN105085877ASimple production processMild responseFoundry mouldsFoundry coresStillingia oilAlcohol

The invention relates to preparation methods of a binding agent and a matched curing agent thereof, in particular to preparation methods of a binding agent for casting and a matched curing agent thereof. The preparation method of the binding agent for casting comprises the steps that stillingia oil and polyhydric alcohol are added in a reaction kettle, stirring is started, electrical heating is turned on, and nitrogen is introduced into the reaction kettle for protection; the temperature is increased to 130 DEG C, a catalyst is added, and when the material liquid temperature is increased to 210-225 DEG C, a timed reaction is performed for 3-4 hours; after heat preservation is finished, cooling water is introduced to lower the temperature, when the material liquid temperature is lowered to 100-130 DEG C, nitrogen is closed, polybasic acid and a water-carrying agent are added, and the temperature is increased; timing starts to be performed when refluxing occurs in the material liquid temperature increasing process, and a reflux reaction is kept for 0.5-2 hours; after refluxing is finished, cooling water is introduced to lower the temperature; when the material liquid temperature is lowered to 120 DEG C, solvent and a drier are added, the temperature is lowered below 70 DEG C, stirring is stopped, and discharging is performed. The preparation methods are unique and can effectively solve the problem that the stripping time is longer at low temperature, the influence on the usable time of casting sand at low temperature is less, and safety and reliability are achieved.

Owner:GANSU KOCEL CHEM

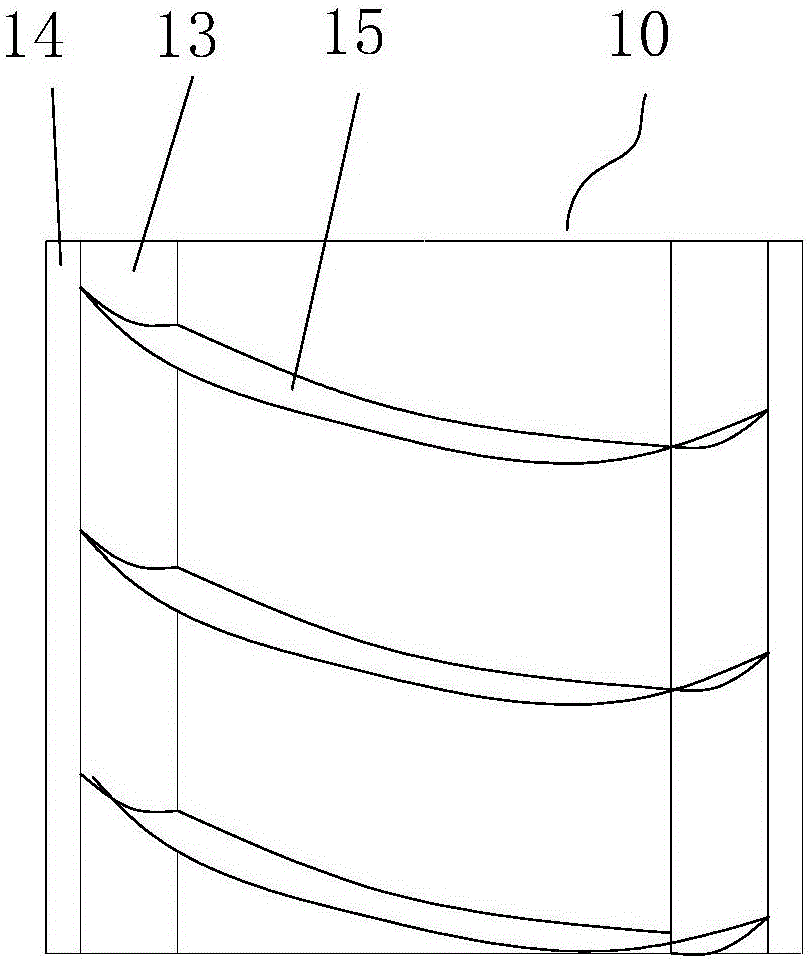

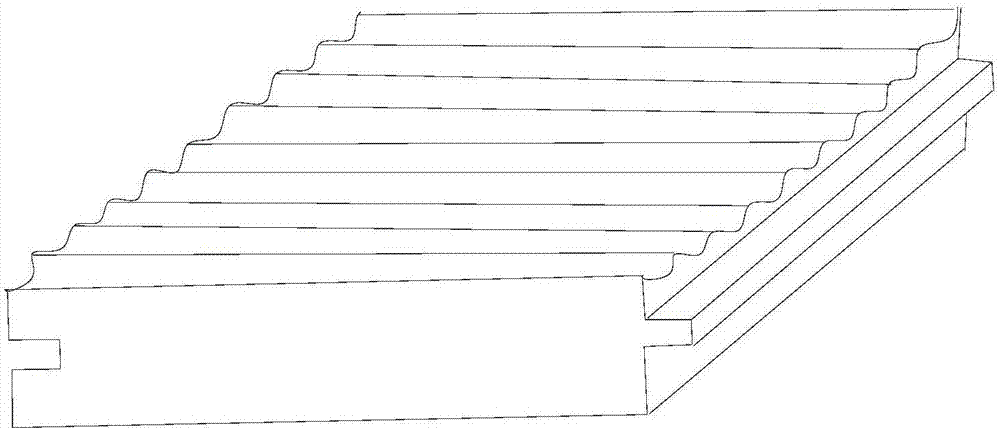

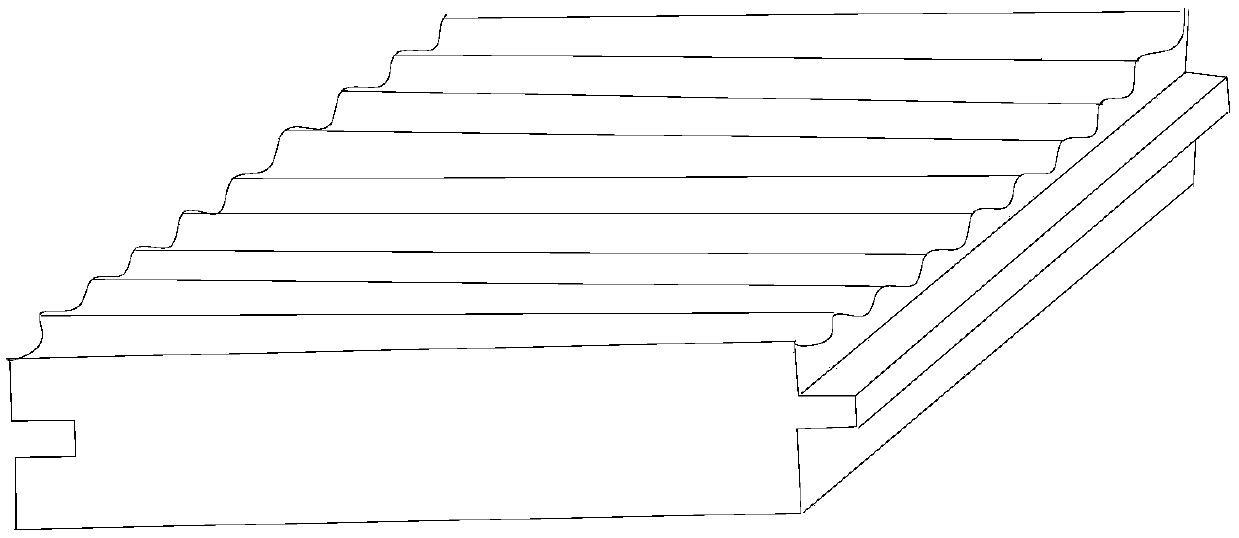

Seamless spliced moisture-proof floor and preparation process thereof

ActiveCN107042560APrevent intrusionImprove waterproof performanceWood treatment detailsPretreatment apparatusVegetable oilStillingia oil

The invention discloses a seamless spliced moisture-proof floor and a preparation process thereof. Dense micro corrugated grooves are formed in the back surface of the seamless spliced moisture-proof floor. The periphery of the seamless spliced moisture-proof floor is coated with moisture-proof and weather-proof vegetable oil. The moisture-proof and weather-proof vegetable oil comprises stillingia oil, refined linseed oil, refined tung oil, tea seed soil and sophora oil. The weight ratio of the stillingia oil to the refined linseed oil to the refined tung oil to the tea seed soil to the sophora oil is 2:3:3:1:1. According to the seamless spliced moisture-proof floor, no gap is retained in the upper and lower portions of spliced seams of the spliced floor, back water / moisture, dust, garbage and the like can be effectively prevented from invading from gaps in the side edges of the side surfaces or the back surface, and meanwhile, the seamless spliced moisture-proof floor is good in moisture-proof and weather-proof performance and not prone to being deformed.

Owner:杨明 +1

Melamine phenolic resin glass preparation method

The invention discloses a melamine phenolic resin glass preparation method. The preparation method comprises the following steps that 1, raw materials are weighed, SiO2, Al2O3, Na2SiO3, CaSiO3, Na2O, CaO and La2O30 are evenly mixed, the mixture is put in a crucible, heating is performed to reach 1650 DEG C, and heat-preservation reaction is performed for 5-6 hours; 2, stillingia oil modified melamine phenolic resin is added, heat preservation is performed for 2-3 hours for full melting and clarification; 3, melt is poured into a preheated graphite mold, irradiation is performed with ultraviolet light with the wavelength smaller than 50 nanometers for 1-2 minutes for forming; 4, nucleating and crystallization are performed to obtain glass. The melamine phenolic resin glass is strong in compressive strength and bending strength, due to the fact that ultraviolet light irradiation produces a certain physicochemical property change to the melt, and the glass prepared by adopting the preparation method is not likely to break under the effect of an impact force.

Owner:HANGZHOU TIANSHAN MEDICINE GLASS CO LTD

Micaceous iron antirust paint for medical use and preparation method therefor

InactiveCN104962163AImprove anti-corrosion performanceEasy to prepareAnti-corrosive paintsResin coatingMedical treatment

The invention discloses micaceous iron antirust paint for medical use and a preparation method therefor. The micaceous iron antirust paint is prepared from micaceous iron oxide, phenolic resin coating, calcium carbonate, talcum powder, zinc phosphate, barium sulfate, tung oil, zinc oxide, stillingia oil and cobalt naphthenate. The micaceous iron antirust paint is applied to the rust protection and anticorrosion of medical instruments, the appearance of a coating film is reddish-orange, and the micaceous iron antirust paint has the solid content of 82-88 percent and the viscosity of 85-125s; the corrosion resistance is good, the impact strength is 55-75cm, and the resistance to salt water meets the condition that the micaceous iron antirust paint does not bubble and does not fall off in 15-35 days; the time for surface drying is 2-6 hours, and the time for solid drying is 20-22 hours; the preparation method is simple, the raw materials are simply and easily obtained, and the micaceous iron antirust paint can be extensively produced and continuously replace the existing materials.

Owner:SUZHOU JONATHAN NEW MATERIALS TECH

Anti-corrosion rosin floor and preparation method thereof

InactiveCN105504590AImprove heat stabilityPlay a barrier rolePhosphorus compoundsPhosphoric acidPolyvinyl chloride

The invention discloses an anti-corrosion rosin floor. The anti-corrosion rosin floor is prepared from, by weight, 5-7 parts of alkenyl succinate, 10-13 parts of expandable graphite, 1-3 parts of ammonium molybdate, 3-4 parts of maleated rosin, 17-20 parts of zirconium oxychloride octahydrate, 10-15 parts of 40-47% hydrochloric acid, 90-100 parts of 80-85% phosphoric acid, 4-7 parts of a 25-30% methylamine water solution, 5-7 parts of trifluoroethyl methacrylate, 0.2-0.4 part of 2-Octyl-3(2H)-isothiazolone, 0.06-0.1 part of ammonium persulfate, 0.01-0.02 part of divinyl benzene, 1-2 parts of azobisformamide, 130-200 parts of polyvinyl chloride, 3-4 parts of polyimide, 0.3-1 part of manganese isooctoate, 1-2 parts of stillingia oil and 3-4 parts of tetrakis hydroxymethyl phosphonium sulfate. The rosin added into the anti-corrosion rosin floor can effectively improve the compatibility between graphite and other fillers and polyvinyl chloride resin and improve the stability strength of a system and can reduce the plastic smell of traditional plastic floors.

Owner:CHUZHOU YONGTONG TRAFFIC EQUIP

Micaceous iron antirust paint for metals

InactiveCN106010250AImprove anti-corrosion performanceHigh strengthAnti-corrosive paintsTalcPolyacrylamide

The invention discloses micaceous iron antirust paint for metals. Raw materials are micaceous iron, iron oxide red, aluminum paste, talc powder, zinc stearate, carbon black, tung oil, stillingia oil, polyacrylamide and potassium dichromate. The corrosion resistance is good, the viscosity is 85-125 s, and the covering powder is 260-300 g / cm<2>. The strength is high, adhesive force is at a first class, the micaceous iron antirust paint resists water for 20-40 d and has no abnormalities; and the micaceous iron antirust paint resists saline water for 10-30 d and does not bubble or drop. The surface dry requires 2-6 h, the hard dry requires 18-22 h, and the fineness is 10-30 microns. A preparation method is simple, the raw materials are simple and easy to obtain, and the micaceous iron antirust paint can be produced widely and replace existing materials continuously.

Owner:沈旭源

Method for preparing eugenol from clove oil plant

InactiveCN103819317ASimple extraction methodPractical extraction methodEther separation/purificationStillingia oilEugenol

The invention relates to a method for preparing eugenol from a clove oil plant, specifically to a method for preparing eugenol from clove oil extracted from a syringe plant, and belongs to the biochemical field. The invention relates to a simple, practical and efficient extraction method. Through HPLC detection, the content of the eugenol product extracted by the method reaches more than 98%.

Owner:王喜军 +1

Anti-cracking paint

The invention discloses an anti-cracking paint, which is composed of the following ingredients by mass fraction: 5-15 parts of ammonium polyphosphate, 12-14 parts of black ink, 6-10 parts of organic clay, 10-12 parts of water soluble resin, 1-3 parts of Baijiu, 6-8 parts of stillingia oil, 5-7 parts of benzoin, and 7-9 parts of cement. The anti-cracking paint provided by the invention has very high adhesive force, and significant improved self-strength, can prevent paint cracking, ensures and lasts the paint use effect, and prolongs the service life of the paint.

Owner:张咸佐

Vegetable oil printing ink and manufacturing method thereof

The invention relates to a vegetable oil printing ink, which is prepared from the following raw materials by weight percentage: 35%-40% of stillingia oil polymeric oil, 32%-42% of refined soybean oil,3%-6% of refined tung oil, 13%-18% of pigment, 3%-5% of filler, 1%-3% of auxiliary resin, 0.5%-1% of a drier, 1%-3% of micronized wax, 0.5%-1% of an antioxidant and 0.5%-1% of vanilla oil. Thus, through development of stillingia oil polymeric oil linked polymeric oil, the formula of vegetable-type ink can be formed, and the environment-friendly vegetable oil type printing ink with good safety, low harm to the human body and environment and relatively low cost can be developed.

Owner:宁波龙茂文教科技有限公司

High-lubricity stillingia oil-containing core-shell-structure nano-modified transformer oil and preparation method thereof

InactiveCN106433883AImprove performanceImprove insulation performanceAdditivesStillingia oilVinyltriethoxysilane

The invention discloses high-lubricity stillingia oil-containing core-shell-structure nano-modified transformer oil. The transformer oil is prepared from, by weight, 100-150 parts of naphthenic base oil, 10-15 parts of stillingia oil, 0.1-0.15 part of nano-titanium dioxide, 0.03-0.05 part of nano-aluminum nitride, 0.3-0.5 part of 2,6-butylated hydroxytoluene, 0.1-0.15 part of benzotriazole, 0.1-0.15 part of diglycolamide oleate borate, 0.015-0.025 part of ethyl orthosilicate, 0.015-0.025 part of vinyltriethoxysilane and 0.1-0.15 part of poly(alkylene glycol). The transformer oil has the good insulating property and heat dissipation property, is stable in property and long in service life, has the advantages of being good in lubricating property and dispersing property and is beneficial for steady running of a transformer system and high in practicability.

Owner:TONGLING RIKE ELECTRONICS

Delicate-fragrance basalt fiber reinforced wood plastic composite material

InactiveCN107353686AImprove adhesionPrevent disengagementAnti-corrosive paintsMechanical propertyMaterials science

The invention discloses a delicate-fragrance basalt fiber reinforced wood plastic composite material. The material is prepared from the following components in parts by weight: 2 to 3 parts of polypropylene oxide glycol, 1 to 2 parts of propyl gallate, 0.8 to 1 part of stillingia oil, 0.7 to 1 part of n-salicylanilide, 1 to 2 parts calcium lactate, 2 to 3 parts of palm wax, 3 to 4 parts of polypropylene adipate, 0.7 to 2 parts of polybenzimidazole, 5 to 7 parts of attapulgite, 10 to 13 parts of potassium feldspar powder, 100 to 140 parts of butyl acrylate, 160 to 200 parts of basalt fiber, 5 to 7 parts of walnut shell flour, 8 to 10 parts of triethanolamine, 6 to 8 parts of nanosilicon dioxide powder, 6 to 8 parts of aralia echinocaulis powder, 0.1 to 0.2 part of eaglewood powder, 4 to 6 parts of 3-hydroxybenzoic acid, 1 to 2 parts of lauryl alcohol sulfate, 4-6 parts of plant saponin, 0.1 to 0.2 part of terpineol and 1 to 3 parts of nano-scale kieselguhr. The basalt fiber reinforced wood plastic composite material obtained by the invention has the advantages of good weatherability, heat insulation, water resistance, corrosion resistance and the like, and the mechanical property is obviously improved compared with that of ordinary wood plastic composite materials.

Owner:安徽钰锦生态木材料有限公司

Making method of high-nutrient soybean oil

The invention discloses a making method of high-nutrient soybean oil. The high-nutrient soybean oil is made from the following raw materials in parts by weight: 115-120 parts of soybean oil, 3-5 partsof honey, 3-6 parts of fish oil, 0.1-0.3 part of a shiitake mushroom extract, 0.3-0.5 part of fruit raw powder, 0.2-0.4 part of curcumin, 1-3 parts of fennel oil, 0.1-0.3 part of rose essential oil,1-2 parts of edible clove oil, 10-15 parts of camellia oil, 0.1-0.3 part of ginsenoside and 0.1-0.2 part of Pseudo-ginseng sapinogenin. The making method comprises the following steps of performing stirring to prepare blend oil crude products, performing ultrasonic vibration, and performing temperature-raising and temperature-lowering treatment. The soybean oil made by the technical scheme not only is good in mouth feel and rich in nutrients, but also has the effect of improving flavor.

Owner:ANHUI HUAAN FOOD CO LTD

Cleaning fluid special for erasing small carbon black grains on white board

PendingCN107384644AExtended service lifeEfficient removalSurface-active detergent compositionsSurface-active non-soap compounds and soap mixture detergentsWhiteboardOrganic solvent

The invention provides cleaning fluid special for erasing small carbon black grains on a white board. The cleaning fluid comprises the following components by weight percent: 45%-70% of absolute ethyl alcohol, 5%-10% of a surfactant, 7%-13% of an organic solvent, 0.5%-3.5% of beta-cyclodextrin inclusion compound and 15%-30% of deionized water. The cleaning fluid is capable of effectively removing the small carbon black grains permeated into the white board gaps, cleaning the white board and prolonging the service life; wormwood oil, rhizoma atractylodis oil and clove oil are contained in the cleaning fluid, so that the sterilizing effect can be achieved; the cleaning fluid also can be used under a colder environment.

Owner:SHANXI UNIV

Wax oil special for decoration and preparation method of wax oil

InactiveCN106947390AGood colorHigh purityWax coatingsNatural resin coatingsHazardous substanceInsect pest

The invention relates to wax oil special for decoration and a preparation method of the wax oil. The wax oil is prepared from the following components in parts by weight: 15-25 parts of stillingia oil, 6-12 parts of linseed oil, 35-45 parts of carnauba wax, 10-15 parts of beewax, 6-15 parts of olive oil, 15-30 parts of plant resin, 6-8 parts of a rose extract, 5-8 parts of a tea tree essence, 6-12 parts of tung oil, 4-6 parts of thistle seed oil and 35-40 parts of absolute ethyl alcohol. The special wax oil is extracted by adopting a pure natural material and is nontoxic and harmless, no chemical substance is added, the special wax oil does not contain harmful substances such as heavy metals, is environment-friendly, can reach the edible level and is good in effect, high in extraction rate, resources are saved the cost is reduced, the extracted wax oil is high in purity, good in color, tasteless and good in permeability, effectively penetrates into wood, the wood is better protected, the surface hardness is strengthened, the wood does not easily crack, the original unique texture is reserved, the damage of insect pests is effectively blocked, the water resistance is good, cleaning is facilitated and the comprehensive economic efficiency is strengthened.

Owner:MAANSHAN RUNQI NEW MATERIAL SCI & TECH

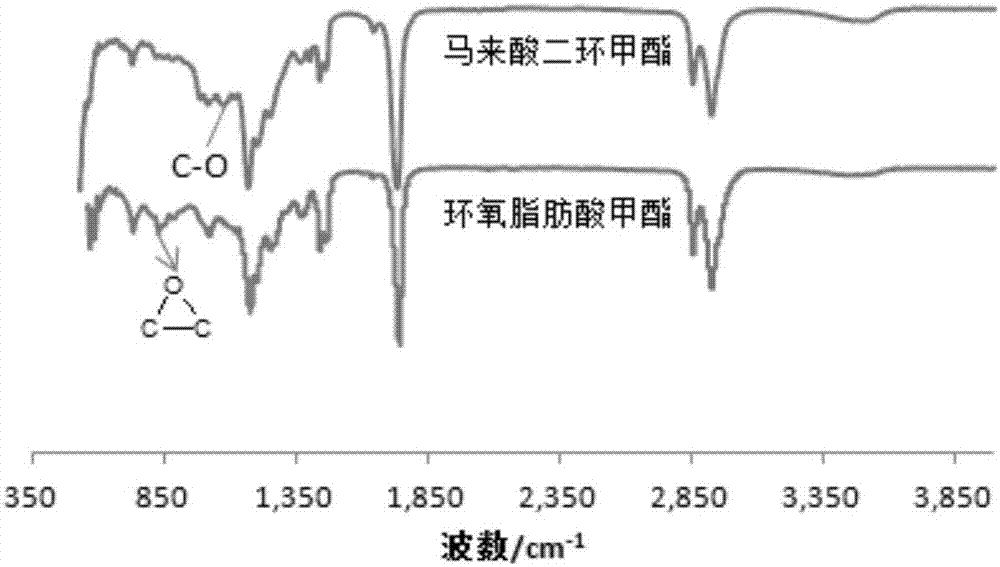

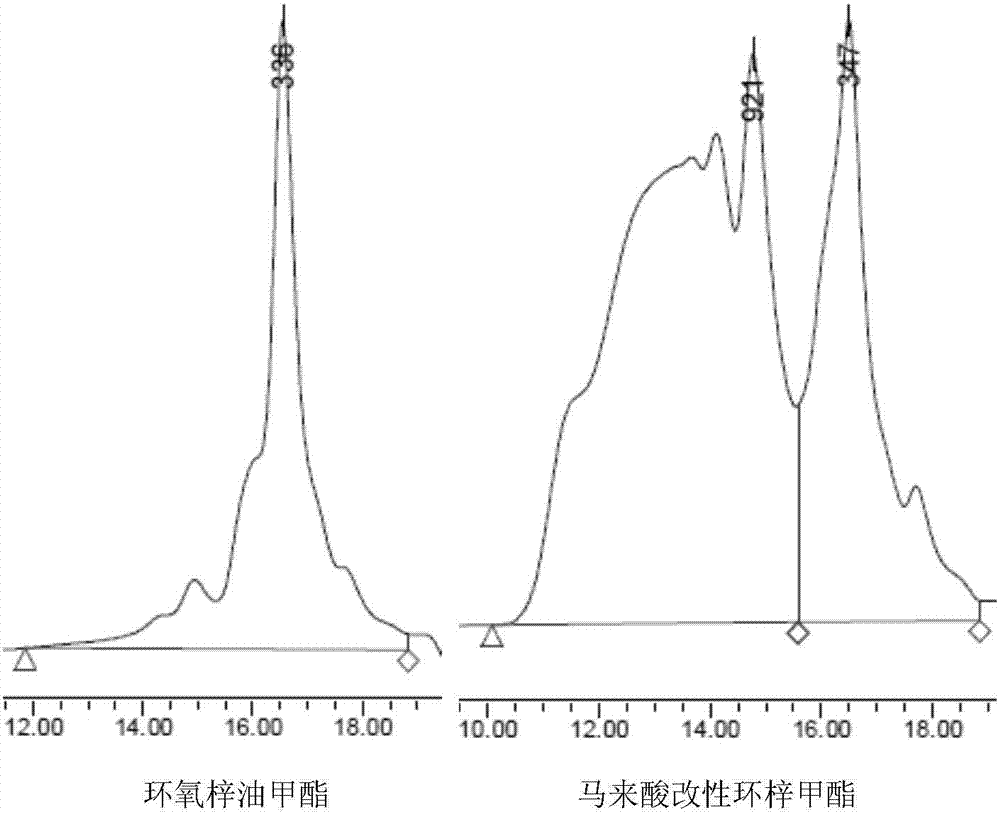

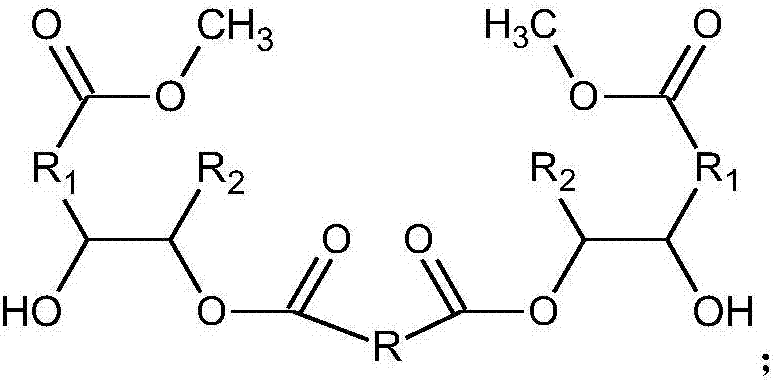

Dibasic acid modified epoxy stillingia oil methyl ester plasticizer and preparation method thereof

The invention relates to a dibasic acid modified epoxy stillingia oil methyl ester plasticizer and a preparation method thereof. Stillingia oil (or fatty acid methyl ester of stillingia oil), peroxides, and dibasic acid are taken as raw materials. At first, tallow seed oil is converted into epoxy stillingia oil methyl ester; and then catalytic ring opening and esterification of dibasic acid are carried out to generate epoxy fatty acid esters of dibasic acid. The preparation method can effectively reduce the content of short chain fatty acid esters (methyl 2,4-decadienoate) in stillingia oil methyl ester and increase the average molecular weight. The plasticizer has the characteristics of low volatility, mobility resistance, good durability, and high flash point. The plasticizer is suitable for being used as a co-plasticizer.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Internal noncongealable oil for reducer and preparation method of internal noncongealable oil

The invention discloses internal noncongealable oil for a reducer and a preparation method of the internal noncongealable oil. The internal noncongealable oil is characterized by comprising the following raw materials in parts by weight: 9-16 parts of allylamine, 18-24 parts of butanol, 25-31 parts of base oil, 15-22 parts of unsaturated fatty acids, 10-18 parts of epoxy resin, 14-20 parts of graphite powder, 8-15 parts of stillingia oil, 7-13 parts of sodium borate, 8-14 parts of urea, 6-12 parts of adipic acid, 8-14 parts of formic acid silicone oil, 7-12 parts of paraffin, 7-12 parts of sorbitol, 8-14 parts of tetradecane, 4-9 parts of an antirust agent and 10-16 parts of rosin. The internal noncongealable oil for the reducer provided by the invention can play a lubrication role when being injected into a closed box of the reducer, and can maintain relatively high chemical performance when the temperature is below zero in winter so as to ensure the normal operation of a gear and a worm of the closed box of the reducer.

Owner:安徽省含山县风华铸造厂(普通合伙)

Seamless splicing moisture-proof floor and its preparation process

ActiveCN107042560BPrevent intrusionWill not absorb water and swellWood treatment detailsPretreatment apparatusSoil scienceVegetable oil

The invention discloses a seamless spliced moisture-proof floor and a preparation process thereof. Dense micro corrugated grooves are formed in the back surface of the seamless spliced moisture-proof floor. The periphery of the seamless spliced moisture-proof floor is coated with moisture-proof and weather-proof vegetable oil. The moisture-proof and weather-proof vegetable oil comprises stillingia oil, refined linseed oil, refined tung oil, tea seed soil and sophora oil. The weight ratio of the stillingia oil to the refined linseed oil to the refined tung oil to the tea seed soil to the sophora oil is 2:3:3:1:1. According to the seamless spliced moisture-proof floor, no gap is retained in the upper and lower portions of spliced seams of the spliced floor, back water / moisture, dust, garbage and the like can be effectively prevented from invading from gaps in the side edges of the side surfaces or the back surface, and meanwhile, the seamless spliced moisture-proof floor is good in moisture-proof and weather-proof performance and not prone to being deformed.

Owner:杨明 +1

Anti-wearing oil paint used on municipal guardrail

The invention discloses an anti-wearing oil paint used on municipal guardrails. The anti-wearing oil paint is composed of following raw materials, by weight: 12-14 parts of long-oil-length linseed oil alkyd resin, 20-24 parts of thick oil from stillingia oil, 8-10 parts of paraffin chloride, 3-6 parts of hexamethyl cellulose, 1-2 parts of iron oxide red, 2.5-3.5 parts of bentonite, 0.5-1.5 parts of butyl acetate, 0.4-0.8 parts of a mixed dry-accelerating agent and 32-36 parts of 200 solvent oil. The oil paint is low in cost, is suitable for metal surfaces having rust, solid oxide skin or old paint film, is significantly improved in wearing resistance, can be used in some large metal structures, which are difficult to subject to surface treatment, such as bridges, traffic guardrails, large machinery, metal doors and windows and the like.

Owner:HEFEI LANTIAN FURNITURE MAKING CO LTD

Printing ink for pens

Printing ink for pens is composed of the following raw materials (by weight): 30-45 parts of activated carbon black, 20-30 parts of calcene, 1-3 parts of tetrafluoro isoindolinone, 30-40 parts of a binder, 1-4 parts of linolenic acid oil, 2-3 parts of 2-6-ditert-butyl-4-methylphenol, 1-3 parts of tributyl phosphate, 2-4 parts of Arabic gum, 1-4 parts of No. 101 gasoline and 2-4 parts of UV-531. The binder is composed of the following raw materials (by weight): 30-35 parts of rosin-modified p-tert-butylphenol resin, 10-15 parts of stillingia oil, 10-14 parts of tung oil, 5-8 parts of long oil alkyd resin, 25-30 parts of oil for printing ink (distillation range 270-290 DEG C), 6-10 parts of linseed oil, 2-5 parts of polyethylene wax, 1-3 parts of nitrocellulose and 0.2-0.5 part of cobalt naphtenate. In the prepared printing ink for pens, the resin in the binder is completely soluble in the oil for printing ink, and resin has good dissolvability in a solvent.

Owner:CHONGQING IND POLYTECHNIC COLLEGE

Low-temperature quick-dried paint with hard and durable paint film

The invention relates to paint, in particular to low-temperature quick-dried paint with a hard and durable paint film. The paint is characterized by being prepared from components in parts by mass asfollows: 11-13 parts of hydroxyethyl cellulose, 1-3 parts of bismuth oxychloride, 5-7 parts of talc powder, 4-6 parts of water-soluble resin, 1-5 parts of mica powder, 6-8 parts of butanol, 3-6 partsof butyl stearate, 3-5 parts of stillingia oil and 25-35 parts of water. Compared with the prior art, the low-temperature quick-dried paint is high in adhesion force and high in resistance to acid, base and water, and demands of people are met.

Owner:山东蓝盟防腐科技股份有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com