Green tung oil-based paint and preparation method thereof

A technology of tung oil and paint, applied in the direction of coating, etc., can solve the problems of VOCs, tung oil, long drying time, easy discoloration of paint film, etc., achieve the effect of low VOC content and avoid easy discoloration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

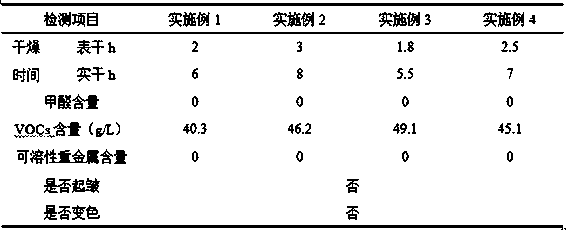

Examples

Embodiment 1

[0023] The green tung oil-based paint of this embodiment includes the following raw materials by weight: 40 parts of refined tung oil, 10 parts of polymerized linseed oil, 10 parts of catalpa oil, 20 parts of tung oil active diluent, 1 part of composite drier, antioxidant nano-oxidant Zinc 0.2 part, light stabilizer 4-hydroxy-2,2,6,6-tetramethylpiperidine-1-oxyl radical 0.2 part, ASD-YT paint antifungal agent 0.2 part, leveling agent polyether modification 0.1 part of polydimethylsiloxane and 0.1 part of modified organic silicone defoamer.

[0024] Refined tung oil is obtained from natural tung oil through deacidification and decolorization.

[0025] Tung oil active diluent, its preparation method: comprises the following steps:

[0026] (1) Preparation of tung oil fatty acid methyl ester: preheat tung oil at 65°C for 30min, add methanol equivalent to 40% of the mass of tung oil and KOH equivalent to 1.5% of the mass of tung oil, heat and stir at 65°C for reflux for 1 h, and ...

Embodiment 2

[0034] The green tung oil-based paint of this embodiment includes the following raw materials by weight: 45 parts of refined tung oil, 15 parts of polymerized linseed oil, 15 parts of catalpa oil, 30 parts of tung oil active diluent, 1.2 parts of composite drier, antioxidant nano-oxidant Zinc 0.25 part, light stabilizer 4-hydroxy-2,2,6,6-tetramethylpiperidine-1-oxyl radical 0.25 part, ASD-YT paint mildew inhibitor 0.2 part, leveling agent polyether modification 0.1 part of polydimethylsiloxane and 0.1 part of modified organic silicone defoamer.

[0035] Refined tung oil is obtained from natural tung oil through deacidification and decolorization.

[0036] Tung oil active diluent, its preparation method: comprises the following steps:

[0037] (1) Preparation of tung oil fatty acid methyl ester: preheat tung oil at 65°C for 30min, add methanol equivalent to 40% of the mass of tung oil and KOH equivalent to 1.5% of the mass of tung oil, heat and stir at 65°C for reflux for 1 h,...

Embodiment 3

[0045]The green tung oil-based paint of this embodiment includes the following raw materials by weight: 60 parts of refined tung oil, 10 parts of polymerized linseed oil, 10 parts of catalpa oil, 35 parts of tung oil active diluent, 1.5 parts of composite drier, antioxidant nano-oxidant 0.3 part of zinc, 0.3 part of light stabilizer N,N′-bis-(2,2,6,6-tetramethyl-4-piperidinyl) 1,6-hexanediamine, 2-octyl antifungal agent -0.3 part of 4-isothiazolin-3-one, 0.15 part of leveling agent polyether-modified polydimethylsiloxane, and 0.15 part of modified polysiloxane defoamer.

[0046] Refined tung oil is obtained from natural tung oil through deacidification and decolorization.

[0047] Tung oil active diluent, its preparation method: comprises the following steps:

[0048] (1) Preparation of tung oil fatty acid methyl ester: preheat tung oil at 65°C for 30min, add methanol equivalent to 40% of the mass of tung oil and KOH equivalent to 1.5% of the mass of tung oil, heat and stir a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com