Seamless spliced moisture-proof floor and preparation process thereof

A technology of seamless splicing and preparation process, applied in the field of mattresses and pillows, can solve problems such as easy deformation of wooden floors, and achieve the effect of obvious and lasting moisture-proof and waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Moisture-resistant and weather-resistant vegetable oil formula

[0038] Proportion by weight

[0039] Catalpa oil: Refined linseed oil: Refined tung oil: Tea seed oil: Sophora flavescens oil = 2:3:3:1:1

[0040] Among them: catalpa oil: relative density (25 / 25°C) 0.936-0.944, refractive index (25°C) 1.481-1.484, iodine value 169-190.

[0041] Refined linseed oil: relative density 0.92-0.98, iodine value 165-200gl2 / 100g, free acid content 2.1-2.6%, viscosity 8-10pa·s, refractive index 1.480-1.485.

[0042] Refined tung oil: relative density 0.940-0.943, iodine value 163-200gl2 / 100g, free acid content 5.5-8%, refractive index 1.510-1.520.

[0043] Tea seed oil: relative density 0.912-0.917, iodine value 80-90g / 100g, free fatty acid content 0.15-0.2%.

[0044] Sophora flavescens oil: relative density 0.90-0.912, refractive index 1.45-1.58.

Embodiment 2

[0046] The preparation process of the seamless splicing moisture-proof floor comprises the following steps:

[0047] first step:

[0048] The solid wood blanks with a moisture content of 9-14% are placed in an environment with an air humidity of 55-65% and a wind speed of 0.1-0.2m / s. The moisture content is controlled at 10.5-13.5%, and the difference between the moisture content of the front, middle and rear three stages of each blank and the moisture content of the upper, middle and lower layers does not exceed 3%.

[0049] The present invention adopts 60-90 days of balanced health preservation, so that the participating stress inside the wood is completely released.

[0050]The present invention reduces uneven moisture absorption and deformation of the floor through differential treatment of 3% moisture content.

[0051] Step two:

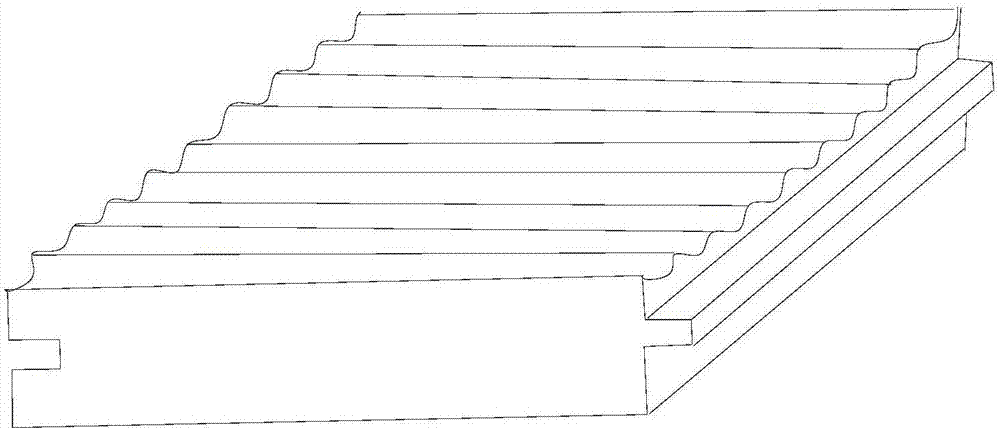

[0052] The above-mentioned billet is grooved and planed on four sides, and all the sides around it are opened in a right-angle shape; figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com