Patents

Literature

75 results about "Tetrakis hydroxymethyl phosphonium sulfate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Toxicology & Carcinogenesis Studies of Tetrakis(hydroxymethyl)phosphonium sulfate (THPS) and Tetrakis(hydroxymethyl)phosphonium chloride (THPC) in F344/N Rats and B6C3F1 Mice. Technical Report Series No. 296 (1987) NIH Publication No. 87-2552 U.S. Department of Health and Human Services, National Toxicology Program, National Institute of ...

Rapid method for removing chromium in waste water

ActiveCN101348298AEasy to removeCheap sourceWater contaminantsWater/sewage treatment by sorptionFiltrationSulfide

A method for quick removal of chromium from waste water relates to a method for the treatment of waste water or sewage, in particular to a method for preparing a quick chromium removing agent for the treatment of chromium-containing waste water. The method takes iron sulfide as a chromium removing agent, and is characterized in that the chromium removing process comprises the following steps that (1) iron sulfide is crushed and sieved by a 300 mesh sieve, and the sieved fine powder is taken out; (2) water is added in the fine powder obtained at step (1), and the paste is mixed till solid-liquid weight ratio is between 1 to 3 and 1 to 4; moreover, pH value is adjusted to between 4 and 6 and then the paste is stirred and boiled; (3) tetrakis hydroxymethyl phosphonium sulfate (THPS) is added in the solution obtained at step (2) with the adding quantity accounting for 0.1 to 0.4 of the weight of iron sulfide solid, and then the mixture is stirred and heated to 80 to 95 DEG C; (4) heating is stopped when solid-liquid weight ratio is between 1 to 1 and 1 to 2, and then filtration is carried out to obtain solid and filtrate; and (5) the filtrate obtained at step (4) is used as a chromium removing agent, and is added in waste water to remove chromium. The chromium removing agent has the advantages of simple preparation method, cheap raw materials and extremely strong treatment capacity and excellent treatment effect on chromium-containing waste water.

Owner:JINDUICHENG MOLYBDENUM CO LTD

Halogen-free flame-retardant extinguishing agent

InactiveCN102793995ARaw materials are cheap and easy to getLow costFire extinguisherSurface-active agentsBoron

The invention discloses a halogen-free flame-retardant extinguishing agent, which is characterized by comprising the following components in percentage by weight: 10-40% of water, 20-50% of phosphorous compound, 10-30% of boric compound, 5-10% of tetrakis hydroxymethyl phosphonium sulfate, 5-15% of phosphorylated castor oil, 5-12% of zinc oxide, and 0.5-5% of surface active agent, preferably, 35-48% of the phosphorous compound and 17-26% of boric compound. The halogen-free flame-retardant extinguishing agent disclosed by the invention has the advantages that raw materials are cheap and easily obtained, the cost is low, pollution is not generated, the seepage force of products is strong, open fire can be extinguished only by simply spraying and sprinkling, and extinguishment can be up to the B1 level.

Owner:SUZHOU CUIZHI NEW TECH DEV

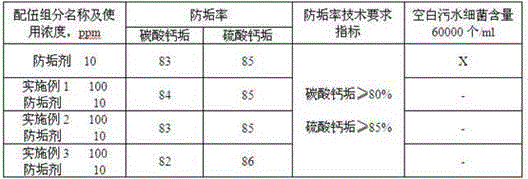

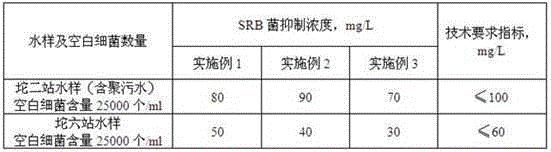

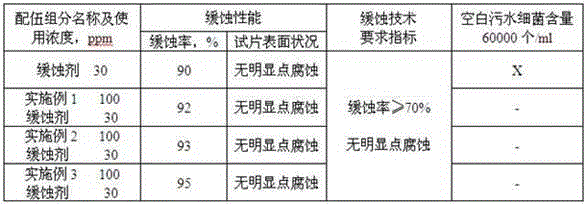

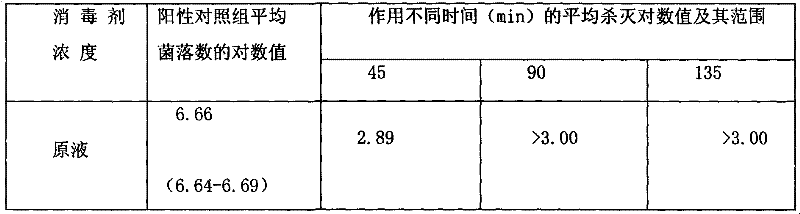

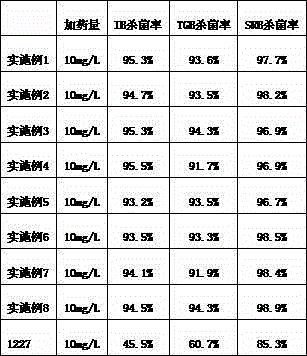

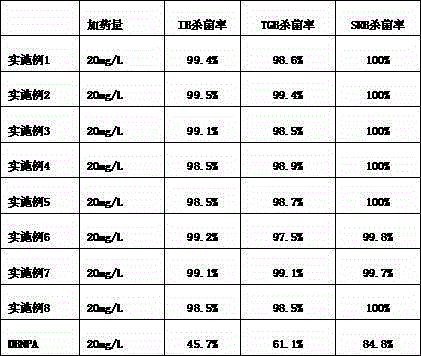

Preparation technology of improved oil field composite bactericide

ActiveCN105010387AAddressing drug resistanceImprove the bactericidal effectBiocideDisinfectantsSolubilityPolyhexamethylene guanidine

The invention relates to a preparation technology of an improved oil field composite bactericide. The technical scheme is that the preparation technology comprises the following steps in parts by weight: (1) adding 15-20 parts of BC-2 multiple quaternary ammonium salt bactericide, 8-10 parts of polyhexamethylene guanidine , 8-10 parts of tetrakis hydroxymethyl phosphonium sulfate, 2-5 parts of methylisothiazolinone, 1-3 parts of medical metronidazole, 1-3 parts of dithiocyano-methane, 8-10 parts of glutaraldehyde, 1-2 parts of isopropanol, 1-2 parts of ethylene glycol and 0.1-0.5 part of nonylphenol polyoxyethylene ether-10 into a preparation kettle, then adding 30-40 parts of water, and sufficiently stirring; and (2) adding a sodium hydroxide aqueous solution, and adjusting the pH value to be between 7 and 9. The preparation technology has the beneficial effects that the bactericide also reaches the following requirements while solving the problem of bacterial resistance: (1) the bactericide is high in bactericidal ability and low in lethal concentration; (2) the bactericide is wide in application range and can be resistant to polymer-contained sewage; (3) the bactericide is good in water solubility, convenient to add and good in compatibility with other water treatment agents; and (4) the bactericide is low in cost.

Owner:DONGYING DONGFANG CHEM IND

Washing liquid used for removing iron sulfides scale, and preparation method and applications thereof

ActiveCN107541198AImprove clearanceHigh scale inhibition rateDrilling compositionSodium saltBalance water

The invention discloses a washing liquid used for removing iron sulfides scale, and belongs to the field of chemical descaling. The washing liquid comprises 5 to 30% of an organic phosphorus chelatingagent, 1 to 6% of an ammonium salt chelating auxiliary agent, 2 to 8% of an inorganic oxidizing agent, 2 to 6% of a sulfur removing dispersant, and the balance water; the organic phosphorus chelatingagent is Tetrakis hydroxymethyl phosphonium sulfate and / or Tetrakis(hydroxymethyl)phosphonium Chloride. The sulfur removing dispersant is prepared via following steps: triazine, a polyol, and clear water are introduced into a reaction vessel, an obtained mixture is heated to 30 to 50 DEG C, and is reacted for 20 to 40min with stirring; Diethylenetriaminepenta(methylenephosphonicacid) sodium salt,an anionic surfactant, and clear water are added, the temperature is reduced to 25 to 35 DEG C, and stirring reaction is carried out under constant temperature conditions for 25 to 35min; wherein themass ratio of triazine, the polyol, and clear water is controlled to be 1:10-25:35-50, the mass ratio of the anionic surfactant, Diethylenetriaminepenta(methylenephosphonicacid) sodium salt, and clear water is controlled to be 1:1-4:10-24, and the mass amount of the anionic surfactant accounts for 0.5 to 4% of that of the sulfur removing dispersant. The washing liquid is high in clearing rate andscale inhibition rate, is safe, is friendly to the environment, and is high in biodegradability.

Owner:PETROCHINA CO LTD

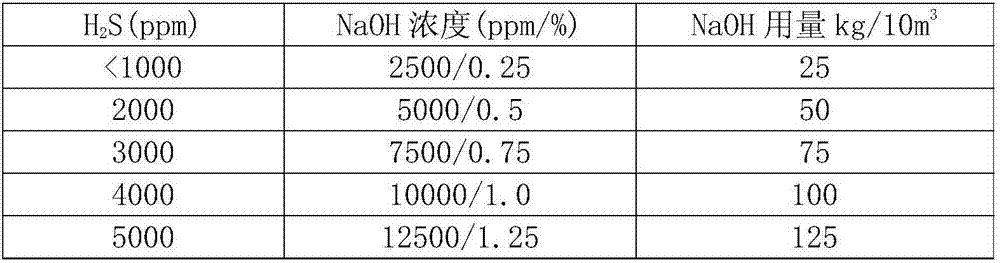

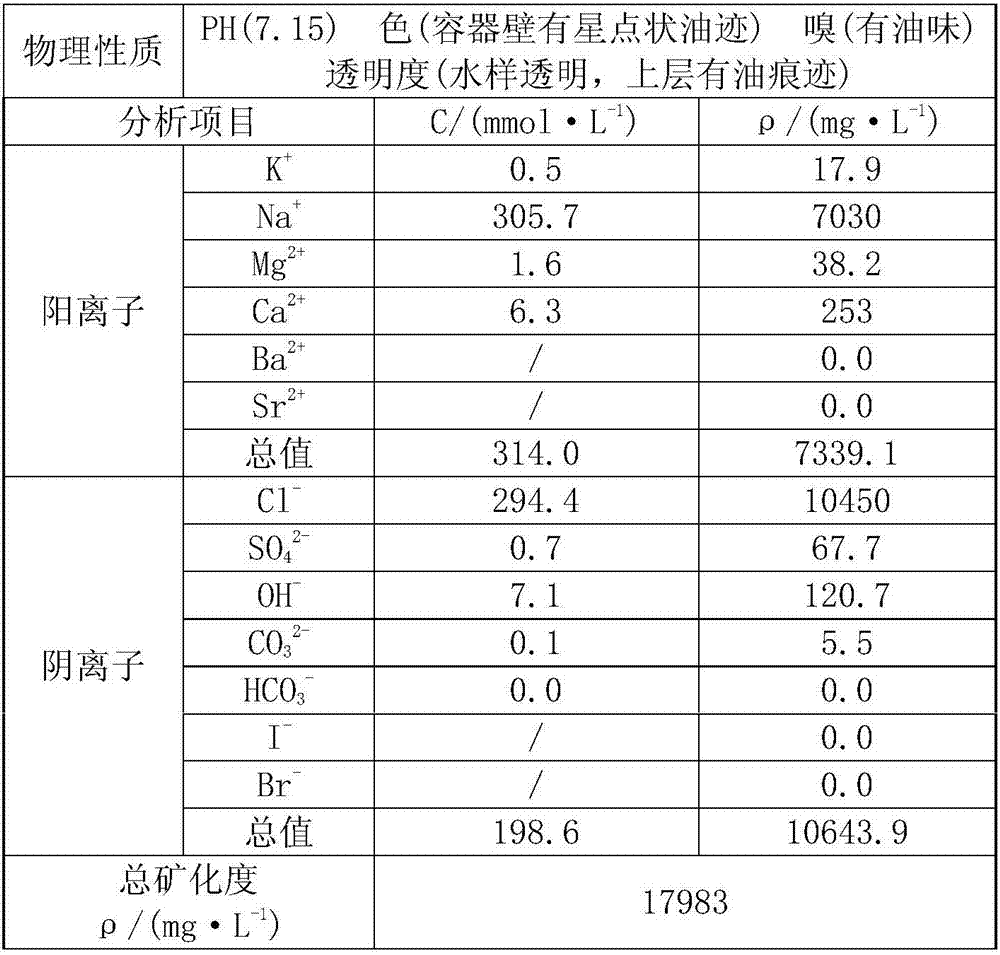

Method for treatment of hydrogen sulfide in oil well

ActiveCN106968639AEfficient removalGrowth inhibitionSurveyFlushingSulfate-reducing bacteriaOperability

The invention discloses a method for treatment of hydrogen sulfide in an oil well. The method comprises the following steps that (1) a hydrogen sulfide treatment technological pipe column is placed down; (2) a sodium hydroxide solution is used for well washing firstly, and then water is used for well washing; (3) a water reagent is used, and the water absorbing index is figured out under the pressure intensity of 18 MPa; (4) a sulfate reducing bacterium inhibitor solution is injected in a squeezed mode, water is injected for substituting, and the treatment radius of the oil well is 2-4 m; (5) a tetrakis hydroxymethyl phosphonium sulfate (THPS) bactericide solution is injected in a squeezed mode, and water is injected for substituting; and (6) the well is closed to conduct reaction for 10 days, and the well is opened to conduct normal production. According to the method for treatment of the hydrogen sulfide in the oil well, hydrogen sulfide gas and ferrous sulfide scale can be effectively eliminated, growth of sulfate reducing bacteria in a stratum can be effectively inhibited, and thus the oil can recover normal production; and the blank that due to water injection, the hydrogen sulfide content of the stratum exceeds the standard, and treatment is conducted is filled up, and the method has the advantages of being simple, high in operability, effective, practical and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Anti-aging and anti-twisting wind power cable

InactiveCN105778469AGood flexibility at low temperatureHigh tensile strengthInsulated cablesPower cablesCopper conductorFiber

The invention discloses an anti-aging and anti-twisting wind power cable. The anti-aging and anti-twisting wind power cable comprises a copper conductor, wherein an insulation layer is coated at the exterior of the copper conductor, a winding layer is coated at the exterior of the insulation layer, and a protective sheath layer is coated at the exterior of the winding layer; the protective sheath layer is made of polyurethane composite material; the polyurethane composite material is prepared form the following raw materials in parts by weight: 50 to 80 parts of polyurethane, 20 to 35 parts of nylon, 10 to 20 parts of ABS (acrylonitrile-butadiene-styrene) resin, 3 to 12 parts of diphenyl-methane-diisocyanate, 2 to 10 parts of montmorillonoid, 3 to 12 parts of kaolin, 2 to 10 parts of talcum powder, 3 to 12 parts of zinc borate, 3 to 15 parts of aluminium hydroxide, 10 to 25 parts of carbon fiber, 2 to 4 parts of silane coupling agent, 0.5 to 2 parts of antioxidant, 5 to 15 parts of phosphorus-containing flame retardant, and 0.2 to 1.5 parts of lubricant; the phosphorus-containing flame retardant is formed by reacting para aminobenzoic acid and tetrakis hydroxymethyl phosphonium sulfate. The anti-aging and anti-twisting wind power cable has the advantage that the anti-aging, anti-twisting and flame-retardant properties are excellent.

Owner:王社兵

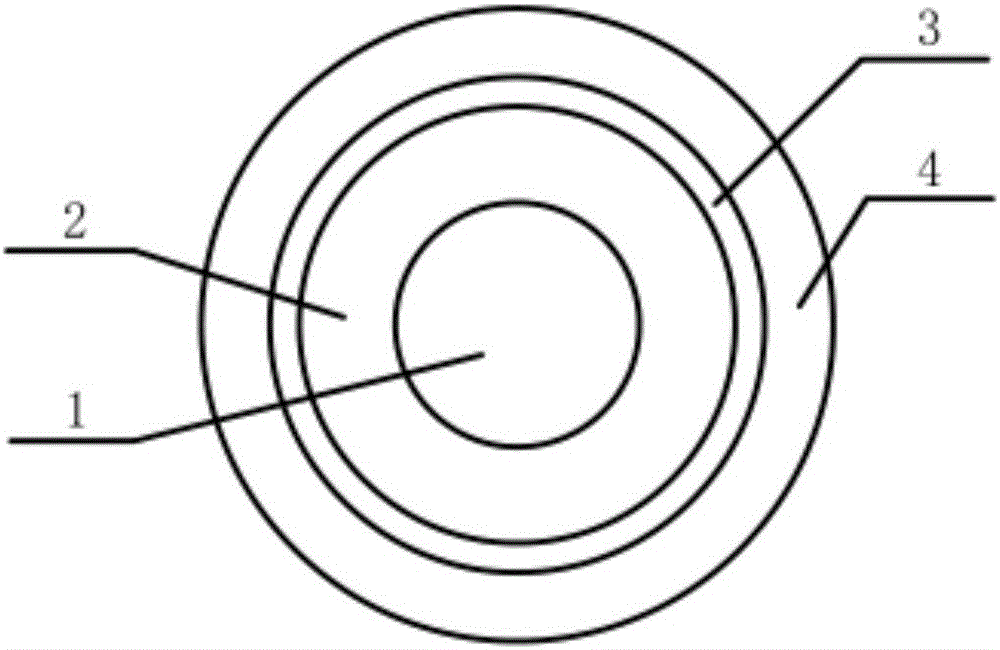

Compound orthophthalaldehyde disinfectant

The invention relates to compound orthophthalaldehyde disinfectant, and a preparation method and application thereof. The compound orthophthalaldehyde disinfectant is prepared from orthophthalaldehyde (1), tetrakis hydroxymethyl phosphonium sulfate (2), inositol phosphate (3), a penetrating agent (4), ampholyticsurfactant (5) and deionized water (6). The compound orthophthalaldehyde disinfectant is characterized by that each 1000ml compound orthophthalaldehyde disinfectant comprising 1.0 to 102.4g of the orthophthalaldehyde and 1.3 to 133.3g of inositol phosphate. The compound orthophthalaldehyde disinfectant can kill enteropathogenic bacteria, pyogenic cocci, hepatitis virus, avian influenza virus, various epidemic diseases, bacterial spore and the like, and is applicable to performing sterilization on articles in farms, environments, air, ground, water, epidemic focus, health and epidemic prevention and the like.

Owner:陈义平 +2

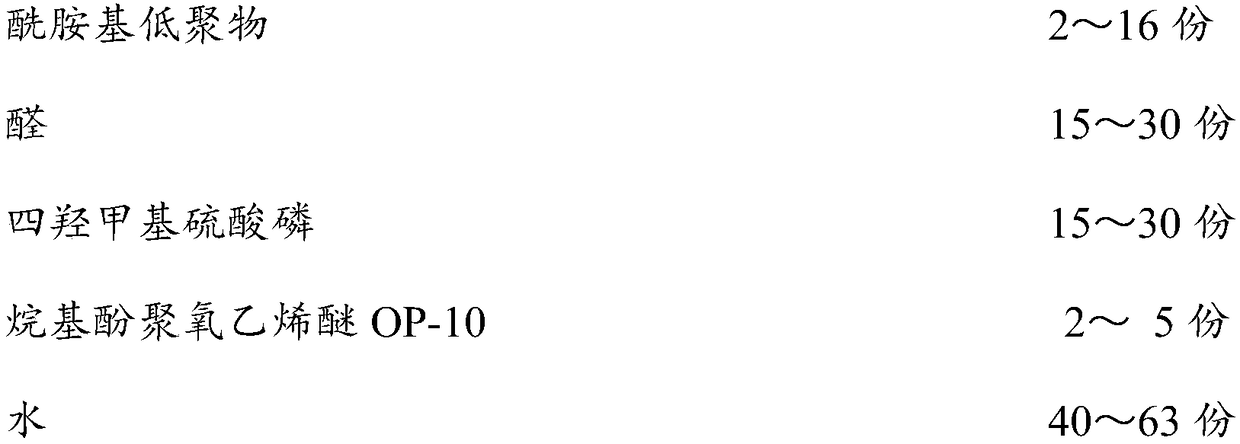

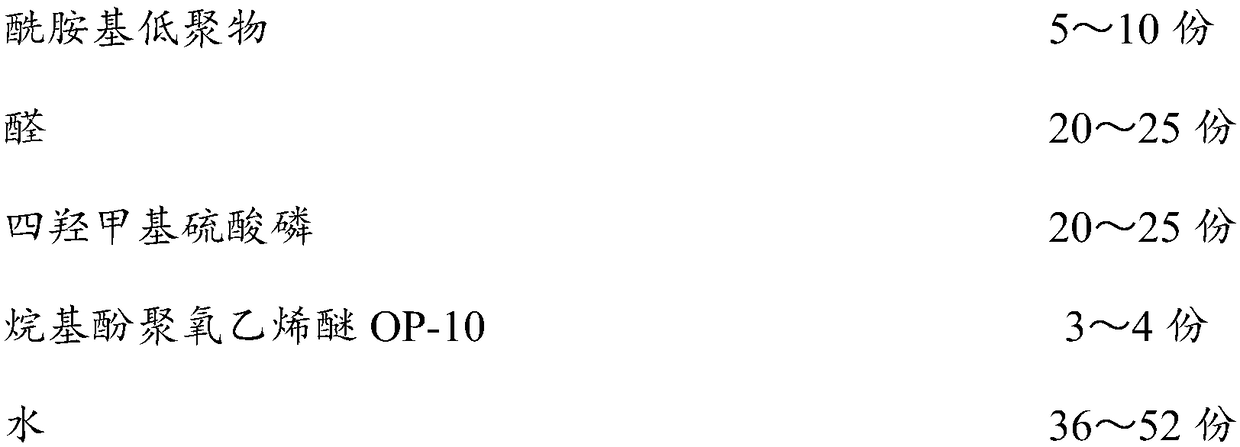

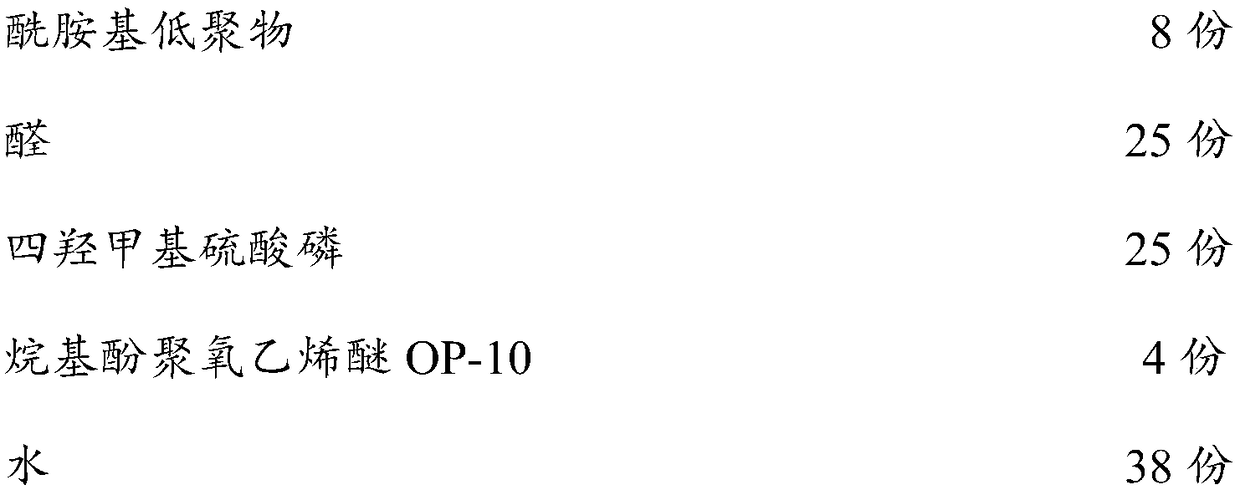

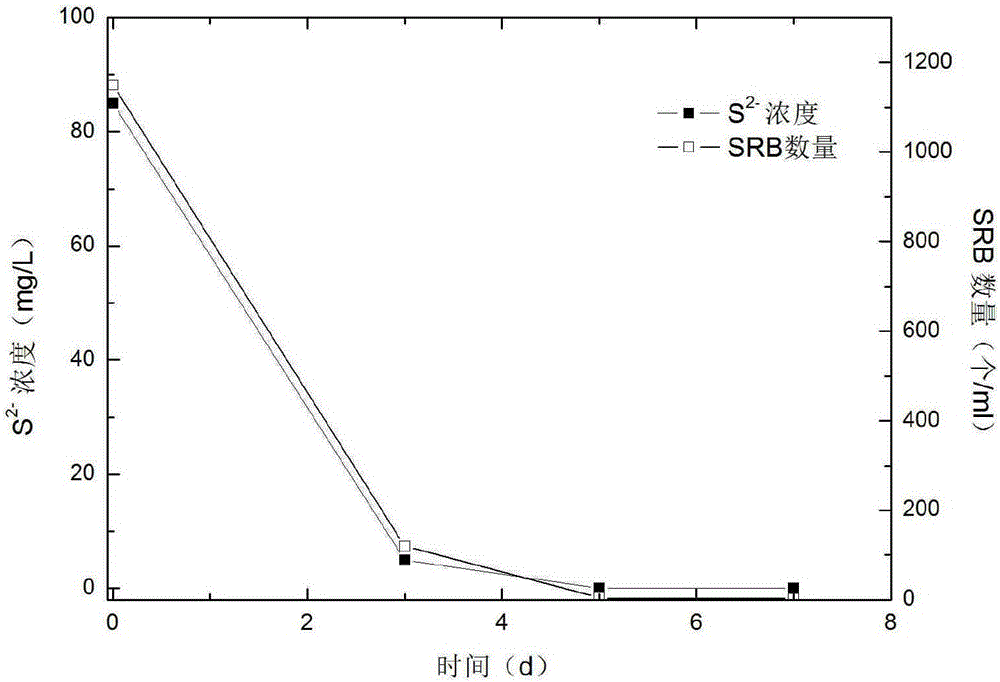

Corrosion-inhibiting bactericide for shale gas field

ActiveCN108641695AReduce dosageGood corrosion inhibition effectBiocideDisinfectantsOligomerAlkylphenol

The invention discloses a corrosion-inhibiting bactericide for a shale gas field. The corrosion-inhibiting bactericide for the shale gas field is prepared from the following components in parts by weight: 2 to 16 parts of amido oligomer, 15 to 30 parts of aldehyde, 15 to 30 parts of tetrakis hydroxymethyl phosphonium sulfate, 2 to 5 parts of alkylphenol polyoxyethylene OP-10 and 40 to 63 parts ofwater, wherein the amido oligomer is copolymerized by acrylamide, sodium acrylate and alkyl allyl quaternary ammonium salt. Compared with the prior art, the corrosion-inhibiting bactericide has the characteristics that the lasting period is long, the usage amount is small, and the corrosion-inhibiting sterilizing effect is good; the corrosion-inhibiting bactericide can be used for the corrosion inhibiting and sterilizing of gas collecting pipelines and water pipelines for shale gas collection, and sterilizing and corrosion inhibiting of pressure test water and production water of oil gas fieldpipelines; the strong killing effect on anaerobic bacteria and oxygen bacteria is realized.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

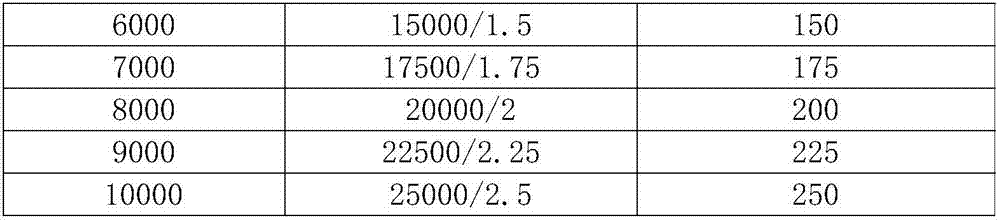

SRB (sulfate reducing bacteria) inhibitor for oil storage tank and use method of SRB inhibitor

ActiveCN105145631AExtended service lifeReduce corrosionBiocideDisinfectantsSulfate-reducing bacteriaStorage tank

An SRB (sulfate reducing bacteria) inhibitor for an oil storage tank comprises components in parts by mass as follows: 60-100 parts of glutaraldehyde or acrolein aldehydes, and or 30-70 parts of dodecyl dimethyl benzyl ammonium bromide or dodecyl dimethyl benzyl ammonium chloride, 15-20 parts of lysozyme, 20-30 parts of protease, 10-20 parts of diorthophthalic ethanediamine acetate and / or 10-20 parts of ethylene diamino-disuccinic acid salt and 5-10 parts of tetrakis hydroxymethyl phosphonium sulfate. The invention further discloses a method for using the SRB inhibitor for the oil storage tank, that is, the inhibitor is added according to the concentration of S<2-> in sedimentation water and mineralization degree. The inhibitor has the characteristics of small dosage, convenience in use, wide sources, low toxicity and the like and has double effects of sterilization and corrosion prevention.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

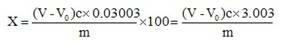

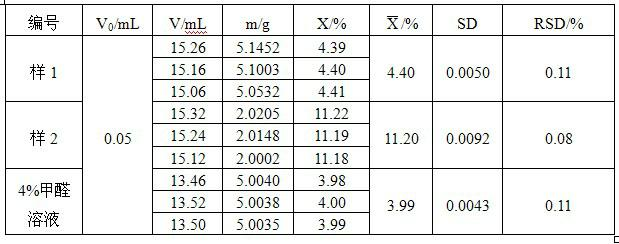

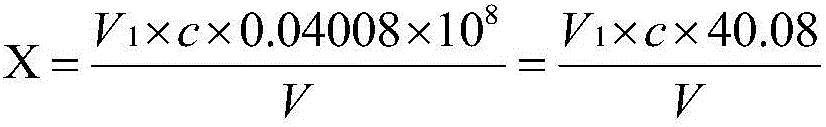

Method for measuring formaldehyde content in tetrakis hydroxymethyl phosphonium sulfate

InactiveCN102507560AExtend the lifespanEasy to prepareMaterial analysis by observing effect on chemical indicatorSulfite saltDistilled water

The invention discloses a method for measuring formaldehyde content in tetrakis hydroxymethyl phosphonium sulfate, which comprises the steps of: weighing 2-5 g of sample and putting the sample in a 250 mL conical flask, adding 50 mL of distilled water therein, dripping 5 drops of thymolphthalein indicator, adjusting the test solution to microscopic blue by sodium hydroxide solution or hydrochloric acid solution; adding 50 mL of sodium sulfite solution and immediately titrating the solution to an end point by a standard hydrochloric acid titration solution; and performing a blank test in the same method. Compared with the method of measuring formaldehyde content by an instrument, the method of the invention has the advantages of utilizing acid-base titration and optimizing the conditions, thereby having few utilized reagents, simple preparation, long service life of reagents, simple and convenient operation and low detection cost.

Owner:HUBEI XINGFA CHEM GRP CO LTD

Antibacterial agent for compound fabric and application of antibacterial agent

InactiveCN105220469AImprove securityGood antibacterial effectVegetal fibresAntibacterial agentCholine chloride

The invention discloses an antibacterial agent for compound fabric and an application of the antibacterial agent and belongs to the technical field of functional design of textile. The antibacterial agent comprises components in parts by weight as follows: 0.7-1.5 parts of tetrakis hydroxymethyl phosphonium sulfate, 2-4 parts of sodium hypophosphite, 1-2 parts of sodium hexametaphosphate, 0.1-0.2 parts of sodium carboxymethylcellulose, 0.1 parts of choline chloride and 80-100 parts of water. The antibacterial agent is applied to the antibiotic finish process of pure cotton fabric and comprises finish steps as follows: step one, the pure cotton fabric is soaked in a sodium citrate solution, taken out and drained; step two, the drained pure cotton fabric is subjected to double dipping and double rolling in the antibacterial agent, the pick-up is 30%, and the pure cotton fabric is dried, baked, washed with soap and aired. The antibacterial agent doesn't contain heavy metal or organic halogen, doesn't have poor effect on the environment and has high safety; the heat resistance is higher, and the antibacterial effect lasts long; meanwhile, the preparation cost is low, a process is simple, and industrial popularization is facilitated.

Owner:HUZHOU SHENXIANG SILK

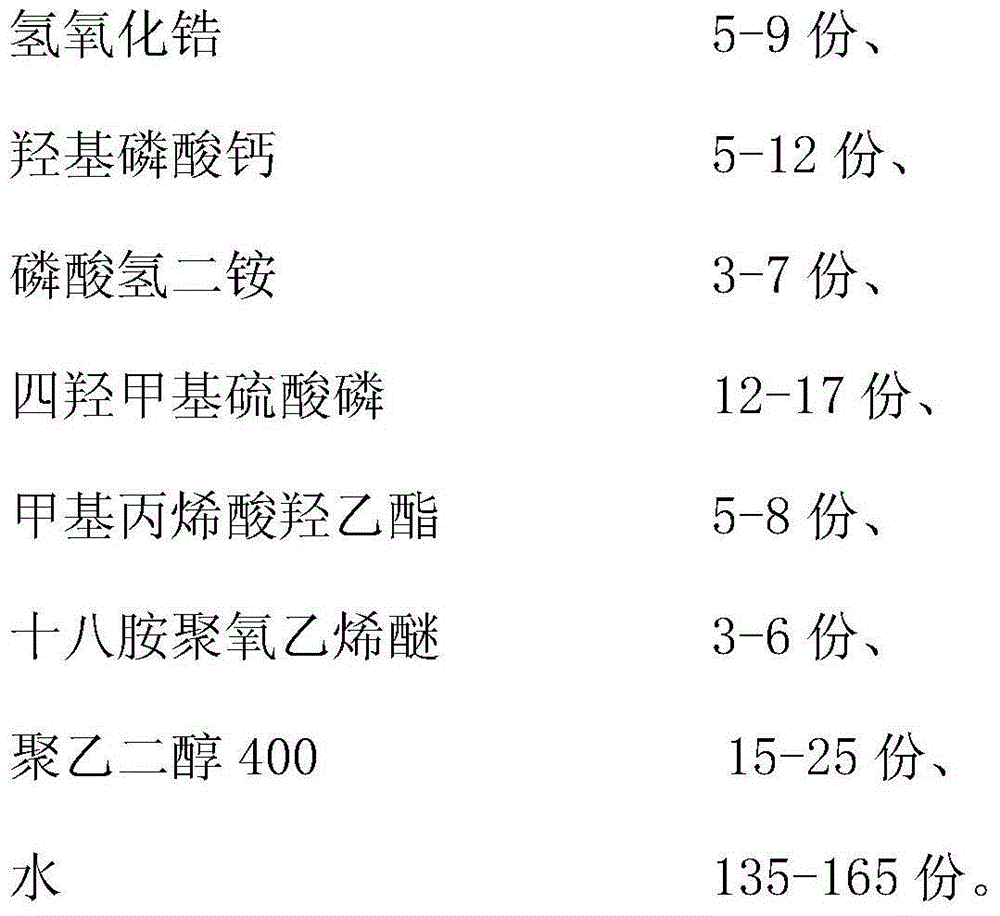

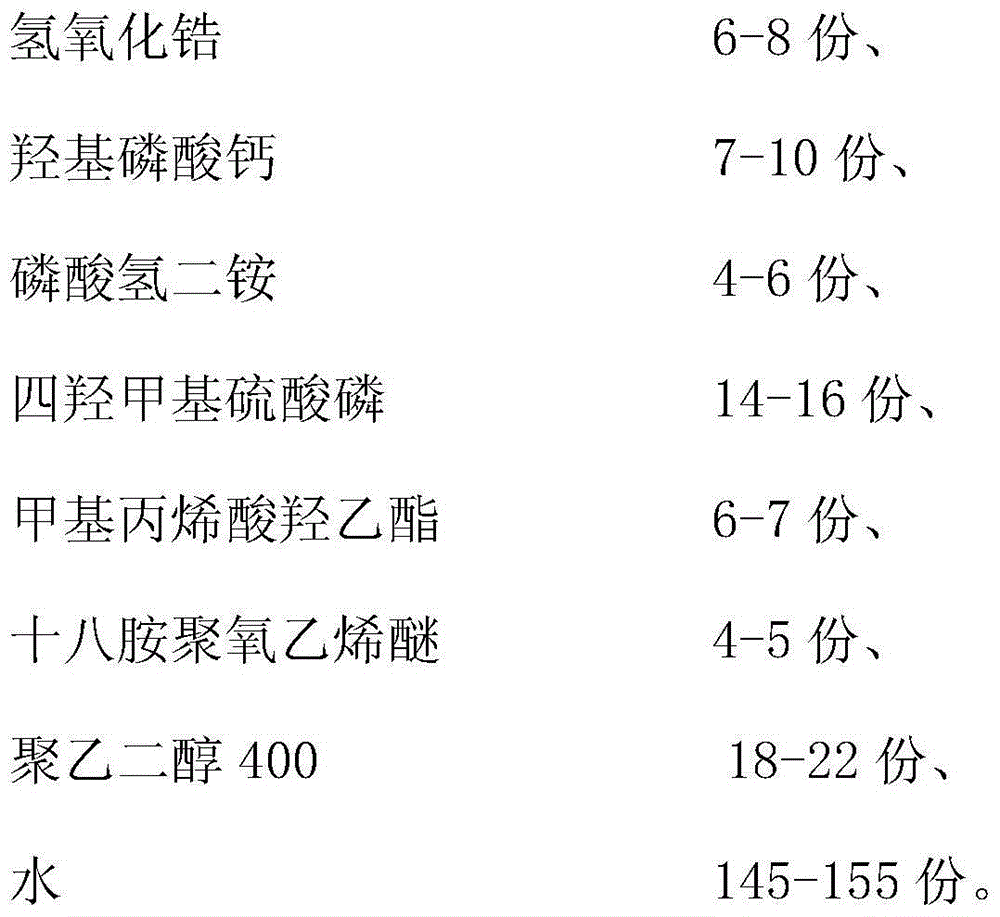

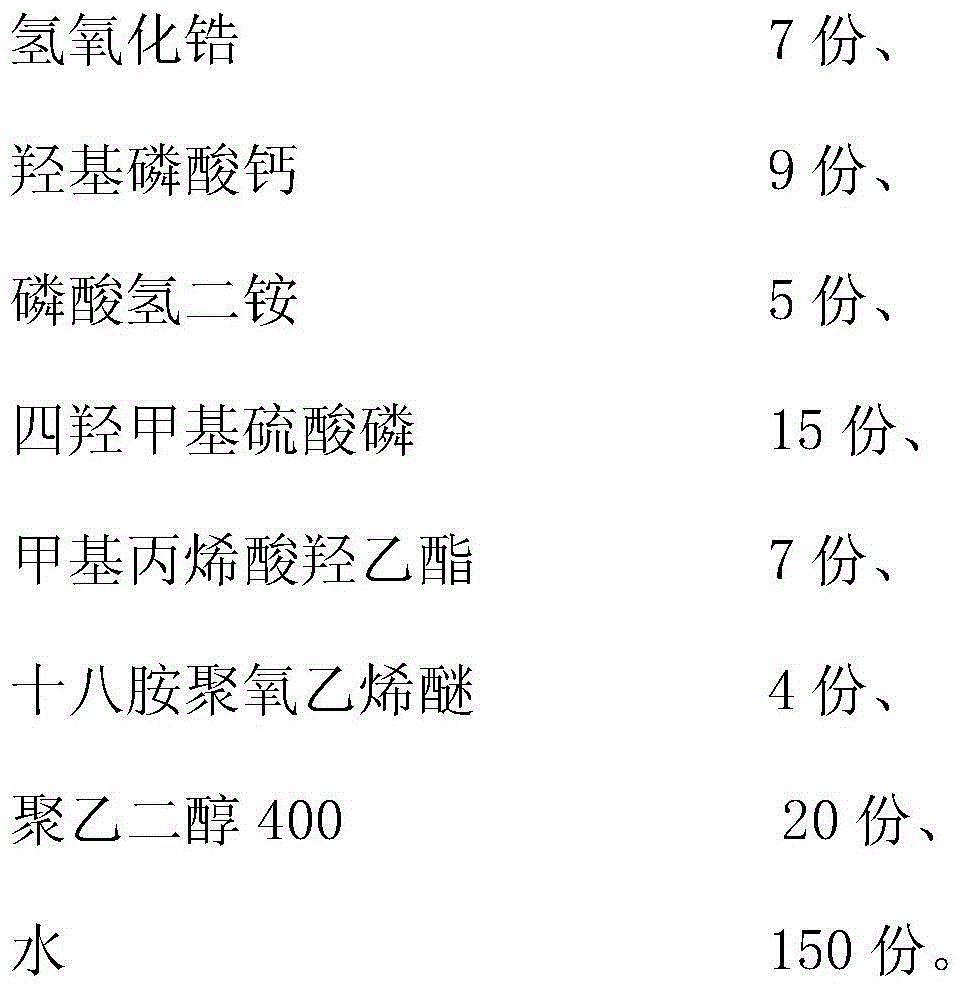

Halogen-free flame-retardant finishing agent and preparation method thereof

ActiveCN104562695AHigh limiting oxygen indexHigh flame retardant gradeFibre treatment(Hydroxyethyl)methacrylatePhosphate

The invention discloses a halogen-free flame-retardant finishing agent and a preparation method thereof. The finishing agent comprises 5-9 parts of zirconium hydroxide, 5-12 parts of calcium hydroxyl phosphate, 3-7 parts of diammonium hydrogen phosphate, 12-17 parts of tetrakis hydroxymethyl phosphonium sulfate, 5-8 parts of hydroxyethyl methacrylate, 3-6 parts of octadecylamine polyoxyethylene ether, 15-25 parts of polyethylene glycol 400 and 135-165 parts of water. The preparation method comprises the following steps: (1) mechanically grinding zirconium hydroxide, calcium hydroxyl phosphate and diammonium hydrogen phosphate; and (2) taking the materials comprising 5-9 parts of zirconium hydroxide, 5-12 parts of calcium hydroxyl phosphate, 3-7 parts of diammonium hydrogen phosphate, 12-17 parts of tetrakis hydroxymethyl phosphonium sulfate, 5-8 parts of hydroxyethyl methylacrylate, 3-6 parts of octadecylamine polyoxyethylene ether, 15-25 parts of polyethylene glycol 400 and 135-165 parts of water, stirring, and preserving to obtain the halogen-free flame-retardant finishing agent.

Owner:吴江市林虹纺织有限公司

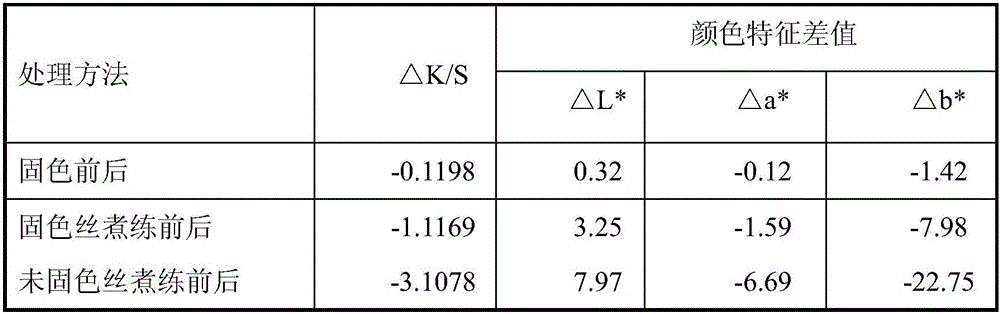

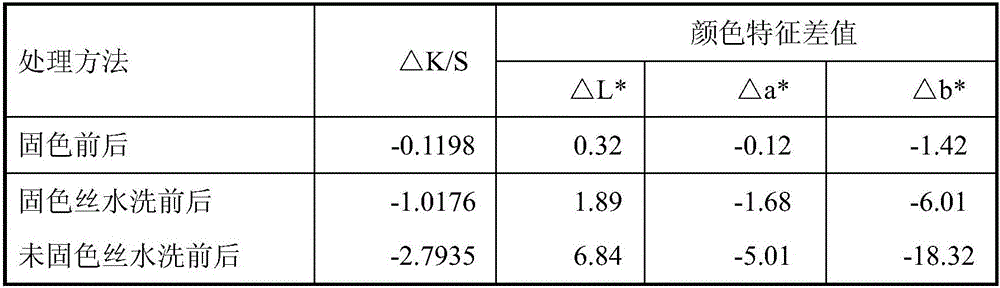

Color fixation method for natural colored silk

ActiveCN105696390ARetain pigmentIncrease resistance to scouringDyeing processCross-linkFixation method

The invention discloses a color fixation method for natural colored silk. The method comprises the following steps that water is added to tetrakis hydroxymethyl phosphonium sulfate serving as a cross-linking agent to be prepared into an aqueous solution, the pH is adjusted with a NaOH solution with the concentration of 0.1 mol / L to 2.0 mol / L, and then heating is carried out to form a treatment solution; the natural colored silk is put in the treatment solution to be subjected to heat preservation and dipping for 1-60 seconds, and after natural colored silk is taken out, the natural colored silk is cooled and stacked to fully react to achieve color fixation; or, the natural colored silk is directly placed in the treatment solution for heat preservation soaking to achieve color fixation; the natural colored silk obtained after color fixation is washed with clear water and dried, and the color-fixed colored silk is obtained.

Owner:ZHEJIANG SCI-TECH UNIV

Method for preparing ammonia-nitrogen removers

InactiveCN106832116AImprove production efficiencyShort processWater/sewage treatmentTrimethylolpropaneMaleic acid

The invention discloses a method for preparing ammonia-nitrogen removers. The method includes adding 10-18 parts of trimethylolpropane into a reaction kettle and heating the trimethylolpropane until the trimethylolpropane is molten at the temperature of 60 DEG C; adding 3-5 parts of ethanolamine into the trimethylolpropane, and slowly completely adding 20-40 parts of maleic anhydride into the trimethylolpropane in 1-1.5 hours approximately to obtain mixtures; heating the mixtures until the temperatures of the mixtures reach 100-110 DEG C, carrying out reaction for 3-5 hours and cooling reaction products until the temperatures of the reaction products reach 80-85 DEG C; adding 100 parts of distilled water into the reaction products, dissolving the reaction products to obtain solution and then adding 1-3 parts of dodecanol sodium maleic acid ester into the solution; simultaneously completely dropwise adding 6-12 parts of hydroxypropyl acrylate, 18-30 parts of acrylamide aqueous solution and 3-5 parts of initiator solution into the solution at the temperature of 80-85 DEG C in 3 hours approximately; carrying out heat reaction for 2 hours to obtain first reaction products, heating the first reaction products until the temperatures of the first reaction products reach 90-92 DEG C, carrying out reaction for 0.5 hour to obtain second reaction products, and then cooling the second reaction products until the temperatures of the second reaction products reach 50-60 DEG C; adding 10-15 parts of tetrakis hydroxymethyl phosphonium sulfate-urea condensation products and 2-4 parts of sodium percarbonate into the second reaction products, carrying reaction for 1-1.5 hours to obtain third reaction products, cooling the third reaction products until the temperatures of the third reaction products reach the room temperature and discharging the third reaction products. Compared with the prior art, the method has the advantages that the method includes few technological processes and simple steps and is easy and convenient to implement, accordingly, the ammonia-nitrogen remover preparation efficiency can be improved, and the method has popularization and application value.

Owner:SHAANXI UNIV OF TECH

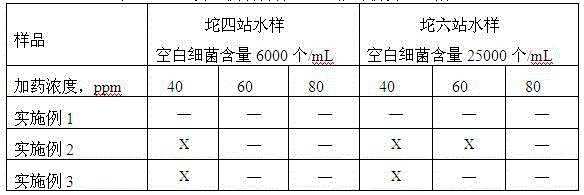

Fungicide for compound oilfield reinjection water, and preparation method therefor

ActiveCN105104420AReduce dosageThe dosage is lower than that of domestic existing oil field reinjection water fungicidesWaste water treatment from quariesBiocidePhosphonium saltBiology

The present invention relates to a treatment medicament for oilfield reinjection water, and particularly to a fungicide for compound oilfield reinjection water, and a preparation method therefor. A technical scheme of the invention is: a fungicide for compound oilfield reinjection water is prepared by quaternary phosphonium salt, dibromo nitrilo propionamide, 50% glutaraldehyde solution, and water, wherein the mass ratio of the quaternary phosphonium salt, the dibromo nitrilo propionamide, the 50% glutaraldehyde solution, and the water is 20-30: 10-20: 10-20: 30-60. The quaternary phosphonium salt is one of tetrakis hydroxymethyl phosphonium chloride and tetrakis hydroxymethyl phosphonium sulfate. The present invention provides a highly efficient fungicide for compound oilfield reinjection water.

Owner:WEIHAI XIANGYU TECH

Compositing and compounding process for bactericide for oilfield wastewater reinjection treatment

InactiveCN104782651AAvoid harmAddressing drug resistanceWaste water treatment from quariesBiocideHexamethylenediaminePolyhexamethyleneguanidine hydrochloride

The invention relates to a compositing and compounding process for a bactericide for oilfield wastewater reinjection treatment. The compositing and compounding process comprises steps as follows: (1), hexamethylenediamine is added to a reaction kettle, the temperature is raised in a stirring state, and iminourea hydrochloride is added; (2), the temperature is raised continuously, a thermostatic reaction is performed, and meanwhile, hydrochloric acid is added dropwise to serve as a catalyst; (3), the temperature is raised continuously, and a thermostatic reaction is performed; (4), after the reaction is finished, water and hydrochloric acid are added and uniformly stirred, and a product generated in the reaction is polyhexamethyleneguanidine chloride; (5), polyhexamethyleneguanidine chloride, tetrakis hydroxymethyl phosphonium sulfate, a biquaternary ammonium salt bactericide, nonylphenol polyoxyethylene ether-10, methylisothiazolinone and water are added to a preparation kettle and fully stirred; (6), a sodium hydroxide solution is added, and a pH (potential of hydrogen) value is adjusted to range from 7 to 9. The process has the beneficial effects that the character is stable; adding is simple; various agents are compounded, so that the problem of bacterial resistance is solved; the purpose of quickly killing bacteria in waste through the bactericide with lower concentration is achieved.

Owner:DONGYING DONGFANG CHEM IND

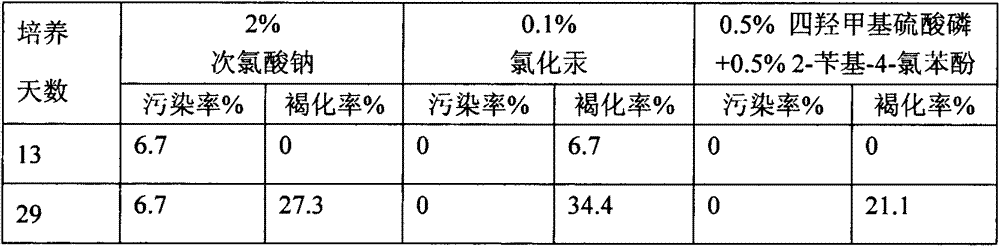

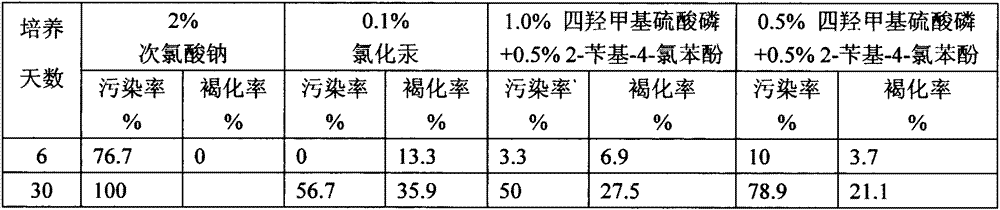

Anti-browning sanitizer for plant tissue culture explant

InactiveCN103891713ALow pollution rateLow costDead plant preservationPlant tissue culturePlant cellEthyl Chloride

The invention discloses an anti-browning sanitizer for a plant tissue culture explant, and belongs to plant tissue culture technologies in agriculture and forestry fields. A method in which the surface of the explant is sterilized with a reducible sterilant which replaces conventional mercuric chloride or sodium hypochlorite comprises steps of washing the tissue culture explant with flowing water, then sterilizing instantly with an ethanol solution, and soaking the explant respectively through tetrakis hydroxymethyl phosphonium sulfate and a 2-benzyl-4-chlorophenol solution in sequence. Compared with a conventional explant sanitizer, the reducible sterilant is efficient, has the broad spectrum, is mild to plant cells, inhibits browning while sterilizing the explant, improves the pretreatment efficiency of the explant, lowers the death rate of the tissue culture explant, is simple and convenient to operate, is safe to people, is convenient in popularization and application and has the environment-friendly effect.

Owner:SUBTROPICAL CROPS INST OF FUJIAN PROVINCE

Daily chemical product bacteriostat and preparation method thereof

InactiveCN106665649AIncreased toxicitySolve the shortcomings of depositionInorganic/elemental detergent compounding agentsBiocideChemical productsBoric acid

The invention belongs to the technical field of daily chemical product additives and particularly relates to a daily chemical product bacteriostat and a preparation method thereof. The bacteriostat is mainly prepared from components in percentage by mass as follows: 10%-15% of glyceryl monoricinoleate, 5%-10% of choline chloride, 7%-12% of pentanediol, 5%-10% of octanediol, 10%-15% of tetrakis hydroxymethyl phosphonium sulfate, 10%-15% of N-acetyl glucosamine, 5%-8% of sodium citrate, 5%-10% of potassium carbonate, 5%-10% of boric acid and 10%-15% of ethanol. The bacteriostat does not contain heavy metals, has small influence on the environment and is high in safety, raw materials are widely-sourced, and the daily chemical product bacteriostat can be applied to textile, fruit and vegetable cleaning or cleaning type daily chemical products.

Owner:JIANGXI YIXINTANG MEDICAL TECH

Preparation method of textile antibacterial agent

InactiveCN107523999AImprove antibacterial propertiesLong durationBiochemical fibre treatmentAntibacterial agentChemistry

The invention discloses preparation and application of a textile antibacterial agent. The antibacterial agent is prepared from the following raw materials in parts by weight: 5 to 15 parts of nano-silver composite particles, 10 to 30 parts of butyl-chitosan, 1 to 2 parts of tetrakis hydroxymethyl phosphonium sulfate, 1 to 2 parts of sodium hexametaphosphate, 1 to 5 parts of triethanolamine, 1 to 4 parts of sodium laurate, 1 to 5 parts of vaseline, 1 to 5 parts of a silane coupling agent and 80 to 100 parts of de-ionized water. The textile antibacterial agent disclosed by the invention has the advantages of good antibacterial effect and long lasting time and does not contain heavy metal and organic halogens so that harmful effects on the environment are not caused. Moreover, a preparation technology of the textile antibacterial agent is simple and industrialized popularization is easy to realize.

Owner:JIANGSU NEW REBA TECH CO LTD

Fireproof flame-retardant sound-absorbing cotton and preparation method thereof

The invention discloses fireproof flame-retardant sound-absorbing cotton, prepared from the following materials in parts by weight: 40 to 60 parts of polyester fiber, 15 to 25 parts of glass fiber, 10 to 20 parts of polysulfonamide fiber, 10 to 15 parts of ES fiber, 2 to 4 parts of tetrakis hydroxymethyl phosphonium sulfate, 1 to 2 parts of a silane coupling agent KH-550, 3 to 5 parts of zinc borate, 0.5 to 1 part of decabrominated dipheny ethane, 3 to 5 parts of simethicone, 0.1 to 0.2 parts of Turkey red oil and 10 to 15 parts of composite resin. The sound-absorbing cotton has better all-frequency sound-absorbing capacity, obviously improved acoustic performance and good fireproof flame retardance and high temperature resistance, and is good in usability, high in safety factor, wide in application scope and high in practicability.

Owner:WUHU HUANRUI AUTO INTERIOR DECORATION

Environment-friendly antiseptic floor and preparation method thereof

The invention discloses an environment-friendly antiseptic floor. The environment-friendly antiseptic floor is prepared from, by weight, 2-3 parts of casein, 3-4 parts of sodium carbonate, 6-8 parts of sericite powder, 1-2 parts of hexamethylphosphoramide, 17-20 parts of zirconylchloride octahydrate, 10-15 parts of 40-47% hydrochloric acid, 90-100 parts of 80-85% phosphoric acid, 3-4 parts of Tetrakis hydroxymethyl phosphonium sulfate, 4-7 parts of a 25-30% methylamine water solution, 5-7 parts of trifluoroethyl methacrylate, 0.2-0.4 part of octyl isothiazolinone, 0.06-0.1 part of ammonium persulfate, 0.01-0.02 part of divinyl benzene, 1-2 parts of azodicarbonamide, 1-2 parts of hexadecanoic acid, 140-200 parts of polyvinyl chloride, 6-9 parts of poly butyl acrylate and 0.4-1 part of zinc acetylacetonate. The floor is good in environmental protection, free of toxic and harmful substance volatilization and good in safety.

Owner:CHUZHOU YONGTONG TRAFFIC EQUIP

Nitrogen and phosphorus containing leather fire retardant and preparation method thereof

InactiveCN106498101AEasy to fillPerformance is not affectedLeather impregnationFiberPhosphonium salt

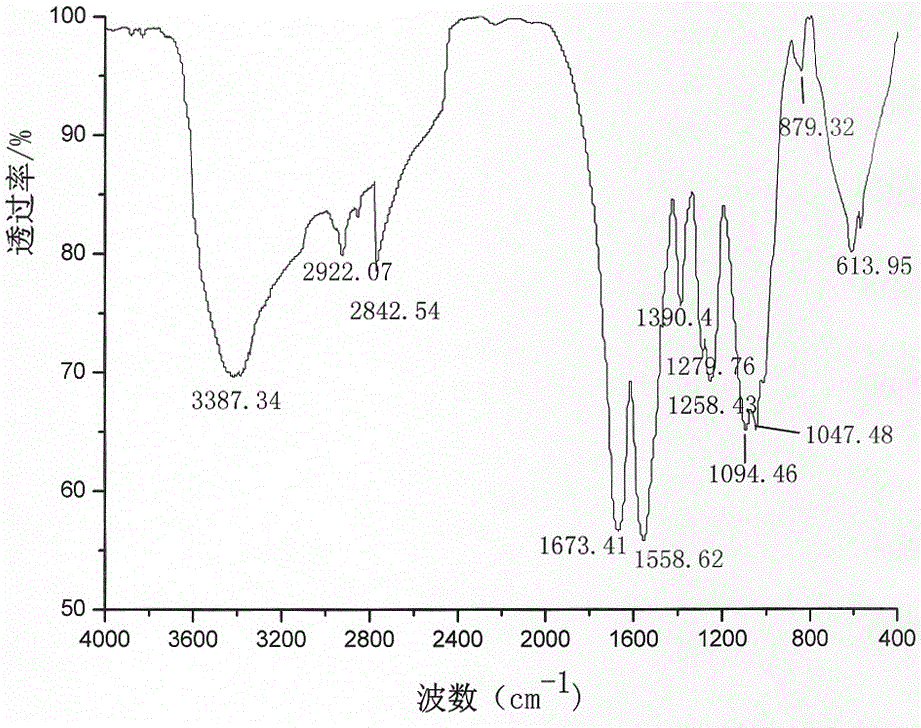

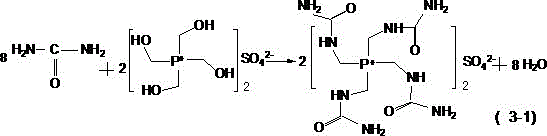

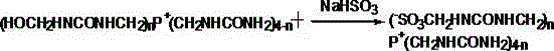

The invention discloses a nitrogen and phosphorus containing leather fire retardant and a preparation method thereof. The fire retardant is methylolation tetrakis hydroxymethyl phosphonium sulfate urea (M-THPS-U) of which the structural formula is (HOCH2HNCONH2)nP<+>(CH2NHCONH2)4-n (n ranges from 1 to 4). The preparation method comprises the following two steps: step 1, performing reaction on phosphonium salt and urea to generate THPS-U; and step 2, performing hydroxymethyl reaction on formaldehyde and THPS-U; and then sulfonating through a sulfonating agent to obtain a target product, namely, M-THPS-U. According to the preparation method, phosphonium salt, urea and formaldehyde are treated as the main raw materials to synthesize a leather fire retardant which contains nitrogen and phosphorus fire retarding elements, is high in leather filling performance and can be combined well with leather fibers. The preparation method is simple and convenient to popularize.

Owner:海宁皮革研究院

Anti-corrosion rosin floor and preparation method thereof

InactiveCN105504590AImprove heat stabilityPlay a barrier rolePhosphorus compoundsPhosphoric acidPolyvinyl chloride

The invention discloses an anti-corrosion rosin floor. The anti-corrosion rosin floor is prepared from, by weight, 5-7 parts of alkenyl succinate, 10-13 parts of expandable graphite, 1-3 parts of ammonium molybdate, 3-4 parts of maleated rosin, 17-20 parts of zirconium oxychloride octahydrate, 10-15 parts of 40-47% hydrochloric acid, 90-100 parts of 80-85% phosphoric acid, 4-7 parts of a 25-30% methylamine water solution, 5-7 parts of trifluoroethyl methacrylate, 0.2-0.4 part of 2-Octyl-3(2H)-isothiazolone, 0.06-0.1 part of ammonium persulfate, 0.01-0.02 part of divinyl benzene, 1-2 parts of azobisformamide, 130-200 parts of polyvinyl chloride, 3-4 parts of polyimide, 0.3-1 part of manganese isooctoate, 1-2 parts of stillingia oil and 3-4 parts of tetrakis hydroxymethyl phosphonium sulfate. The rosin added into the anti-corrosion rosin floor can effectively improve the compatibility between graphite and other fillers and polyvinyl chloride resin and improve the stability strength of a system and can reduce the plastic smell of traditional plastic floors.

Owner:CHUZHOU YONGTONG TRAFFIC EQUIP

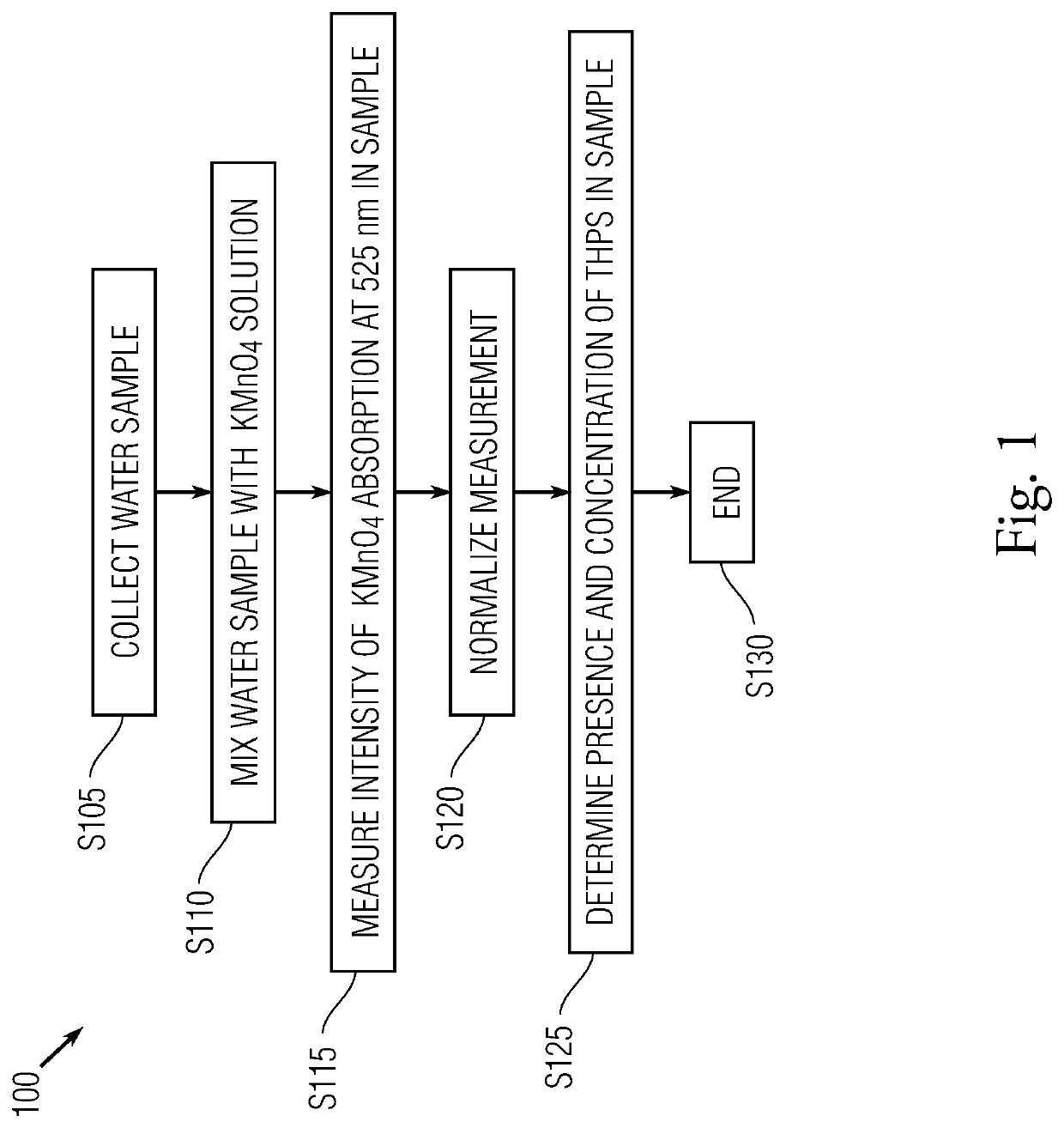

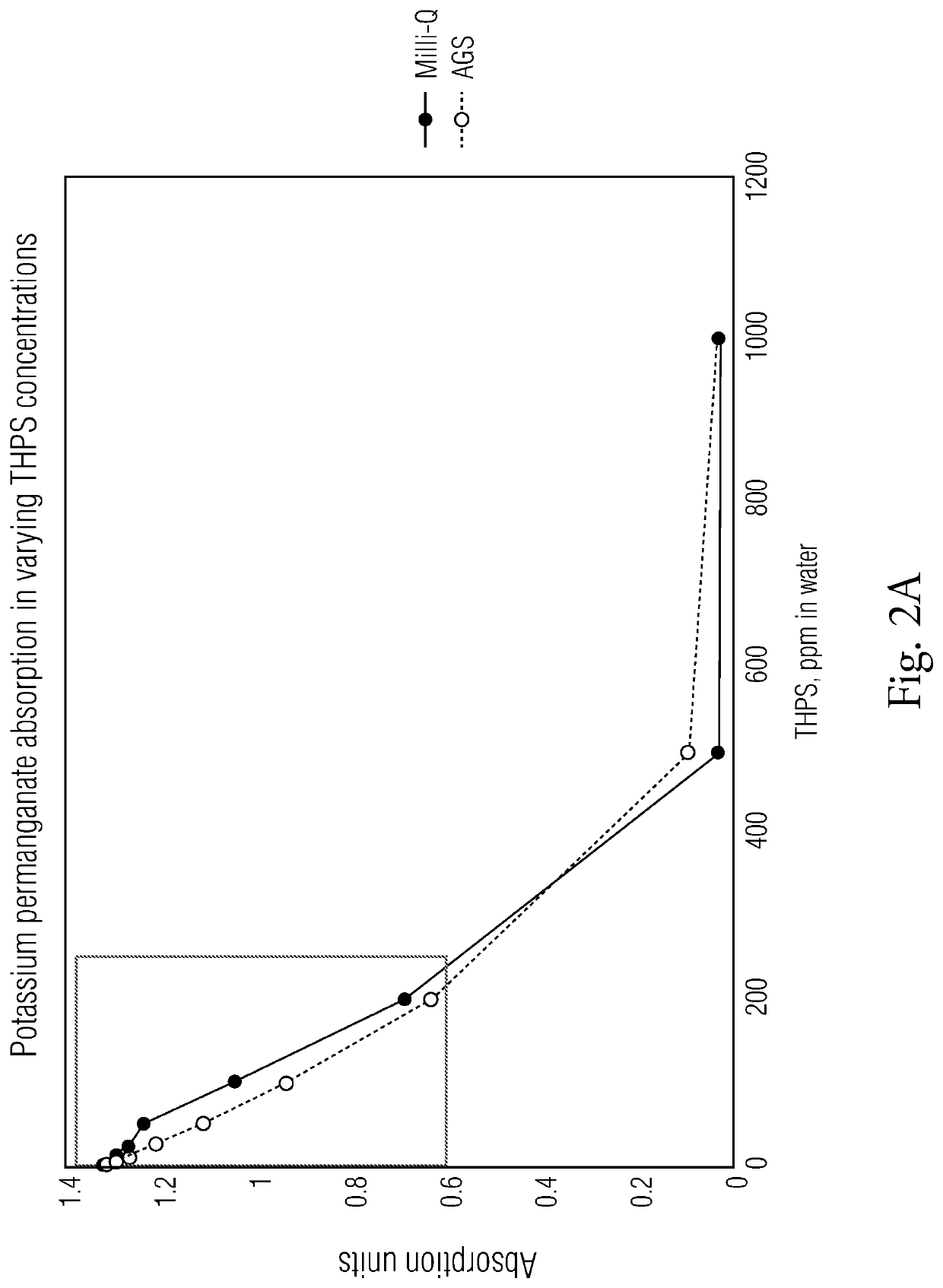

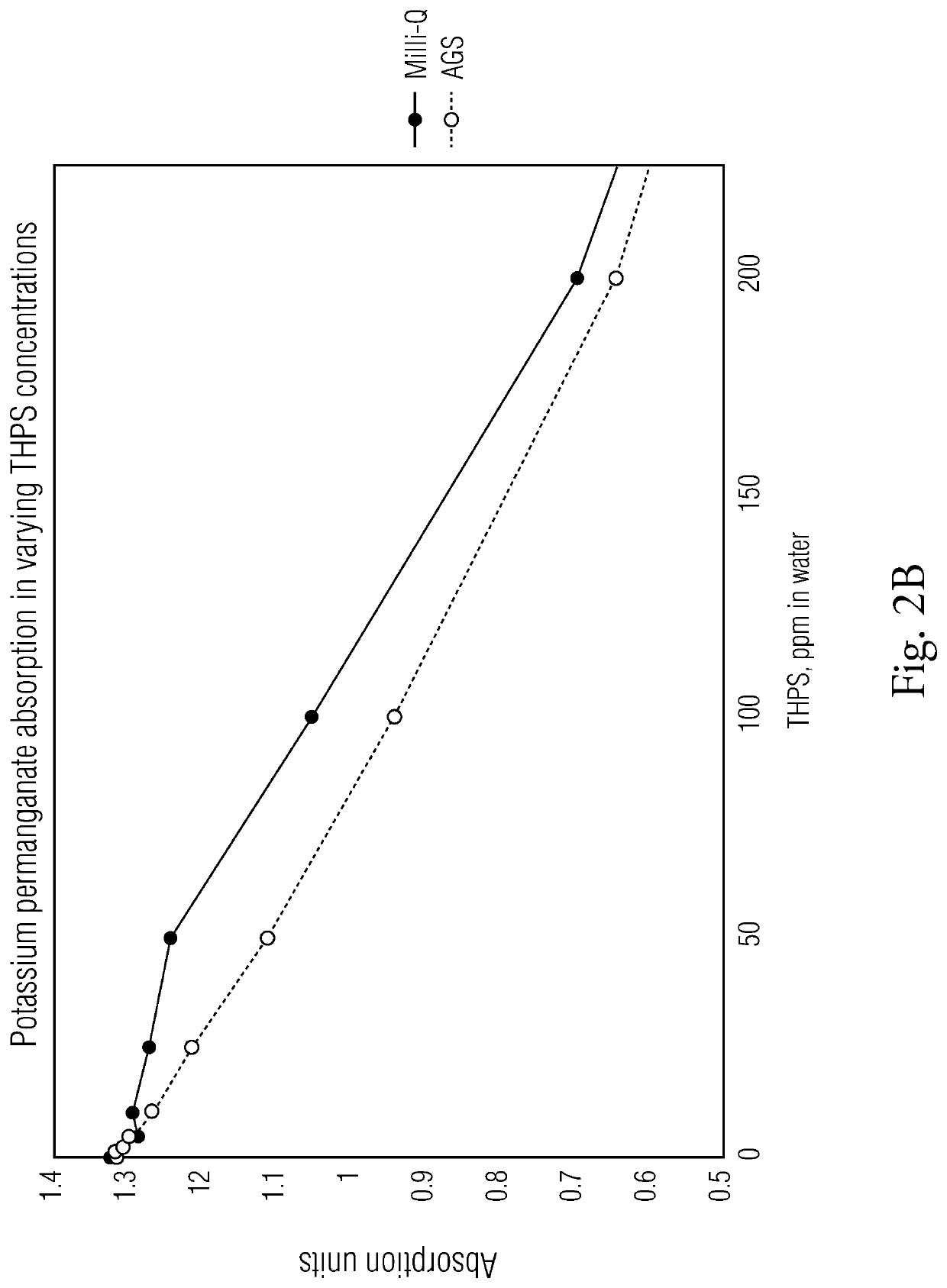

Methods for detecting and quantifying tetrakis(hydroxymethyl)phosphonium sulfate (THPS) in biocide products

The present application discloses methods for detecting and quantifying tetrakis(hydroxymethyl) phosphonium sulfate (THPS) in a water sample. In the methods, a water sample is mixed with a KMnO4 solution to form a mixture. An intensity of KMnO4 absorption in the mixture is then measured at a wavelength of 525 nm. The measured intensity is normalized by subtracting a background intensity at a wavelength of 650 nm. The presence and concentration of THPS in the water sample can then be determined by comparing the normalized intensity with intensity values of KMnO4 absorption of calibration samples comprising KMnO4 and known THPS concentrations.

Owner:SAUDI ARABIAN OIL CO

New type iron-biting bactericide

The invention discloses a new type iron-biting bactericide. The new type iron-biting bactericide comprises tetrakis hydroxymethyl phosphonium sulfate, water, sodium salt of diethylenetriamine penta and sodium hydroxide. The new type iron-biting bactericide disclosed by the invention has the beneficial effects that according to the iron-biting bactericide prepared by the formula and by the mixing effect of the tetrakis hydroxymethyl phosphonium sulfate and the sodium salt of diethylenetriamine penta, the dissolution rate of the ferrous sulfide is increased, and the consumption of the tetrakis hydroxymethyl phosphonium sulfate is reduced, so that the best ferrous-sulfide treating effect is achieved.

Owner:天津东大道科技有限公司

Preparation method of phosphatized anti-corrosive corrugated pipe

InactiveCN107418034AHas antibacterial and antiseptic propertiesFlame retardantBenzotriazoleHigh intensity

The invention discloses a preparation method of a phosphatized anti-corrosive corrugated pipe. According to the preparation method of the phosphatized anti-corrosive corrugated pipe, phosphatized anti-corrosive montmorillonoid achieves the antibacterial properties of 2-methyl-4-isothiazolin-3-ketone, sodium diacetate and benzotriazole, the fire-retarding property of tetrakis hydroxymethyl phosphonium sulfate as well as the high-strength characters of montmorillonoid, and meanwhile, obtains excellent surface activity and can effectively improve compatibility with polymer matrix and the anti-bacteria, fire-retarding and mechanical properties of finish pipe products.

Owner:马荧莹

Wood flame retarding modifier based on environmental protecting treatment

InactiveCN106142260AImprove the efficiency of the modification processImprove flame retardant performanceWood treatment detailsWood impregnation detailsEnvironmental resistancePhosphoric acid

The invention discloses a wood flame retarding modifier based on environmental protecting treatment. The wood flame retarding modifier is prepared by the following components in parts by weight: 40-100 parts of phosphoric acid, 20-50 parts of urea, 10-15 parts of melamine, 10-15 parts of tetrakis hydroxymethyl phosphonium sulfate, 2-6 parts of butanetetracarboxylic acid, 2-6 parts of iso-tridecanol polyoxyethylene ether, 1-3 parts of sodium alginate, 0.5-2 parts of catalyst, and the balance of water. The wood flame retarding modifier based on environmental protecting treatment can quickly penetrates in wood to improve the wood modifying efficiency in wood modifying treatment, so that the stock of flame retarding components of the wood flame retarding modifier in the wood is improved.

Owner:NANJING BOJUN NEW MATERIAL CO LTD +1

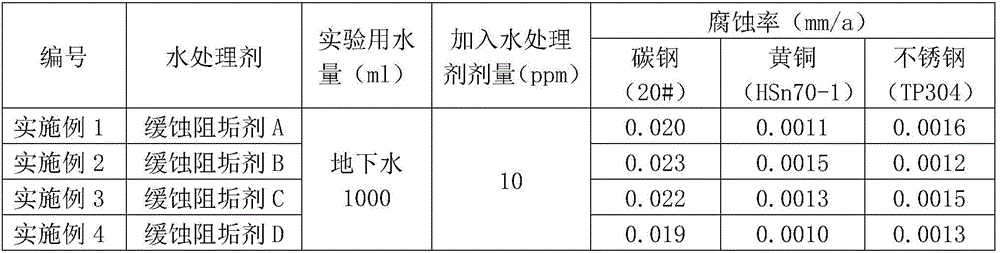

Composite scale and corrosion inhibitor containing sodium polyepoxysuccinate and preparation method thereof

InactiveCN106587398AGood corrosion inhibitionImprove the bactericidal effectSpecific water treatment objectivesScale removal and water softening(Hydroxyethyl)methacrylateIon

The present invention discloses a composite scale and corrosion inhibitor containing sodium polyepoxysuccinate, and the composite scale and corrosion inhibitor is composed of sodium polyepoxysuccinate, benzotriazole, sodium acrylate-hydroxyethyl methacrylate-methyl acrylate copolymer, tetrakis hydroxymethyl phosphonium sulfate, zinc sulfate and deionized water. A preparation process comprises the following steps: first deionized water is added into a container, then benzotriazole is added while stirring, sodium polyepoxysuccinate is added while stirring after even mixing and stirring are completed, then tetrakis hydroxymethyl phosphonium sulfate is added while stirring after even mixing and stirring are completed, then zinc sulfate is added while stirring after even mixing and stirring are completed, finally the sodium acrylate-hydroxyethyl methacrylate-methyl acrylate copolymer is added while stirring and the obtained mixture is allowed to stand after even mixing and stirring are completed, so as to obtain the scale and corrosion inhibitor. The scale and corrosion inhibitor disclosed by the present invention has obvious corrosion inhibition effect on carbon steel, brass and stainless steel metal; the scale inhibition rate is up to 97 percent or above; and the scale and corrosion inhibitor has a particularly strong bactericidal effect on heterotrophic bacteria and can kill microorganisms in water and slime.

Owner:陕西蔚然青科技有限公司

Tear-resistant hard plastic film and preparation method thereof

The invention discloses a tear-resistant hard plastic film, which comprises the following raw materials in parts by weight: 1-3 parts of vinyl carboxylate, 0.1-0.2 part of azodicarbonamide, 0.1-0.3 part of divinyl benzene, 0.5-1 part of zinc pyrithione, 120-140 parts of polytetrafluoroethylene, 3-5 parts of aluminum dihydrogen phosphate, 6-8 parts of isopropanol, 1-2 parts of ammonium ferrous sulfate, 2-4 parts of trichloroisocyanuric acid, 15-20 parts of silicon micropowder, 1-2 parts of magnesium stearate, 0.6-1 parts of Tetrakis hydroxymethyl phosphonium sulfate and 15-20 parts of a fiber dispersion. Esterified crosslinked fiber obtained can effectively improve the compatibility in the polytetrafluoroethylene, and the tear strength of the finished product can be further improved.

Owner:苏州工业园区汇统科技有限公司

Chlorine-resistant fiber cloth for swimsuits

The invention discloses long-acting chlorine-resistant fiber cloth for swimsuits. The chlorine-resistant fiber cloth comprises, by weight, 115 parts of polyester fibers, 15 parts of nanometer titanium dioxide, 1 part of tetrakis hydroxymethyl phosphonium sulfate, 2 parts of 5- hydroxy -1-tetralone, 2 parts of 4-cyclohexanone carboxylate, 1.5 parts of 2',4'-acetylphosphoramidothioate acetanilide, 3 parts of sodium pentanesulfonate, 2 parts of 4-isopropyl benzene sulfonyl chloride, 5 parts of 5-amino-2-methyl benzene sulfonic acid, 5 parts of sulfosuccinate butanedioic acid dioctyl phthalate sodium salt, 1 part of softener and 1 part of antioxidants.

Owner:JINJIANG HONGXING FASHION WEAVING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com