Preparation technology of improved oil field composite bactericide

A fungicide and compound technology, which is applied in the compounding process of improved oil field compound fungicides, can solve the problems of environmental pollution and cost, and achieve the effects of wide application range, low lethal concentration and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

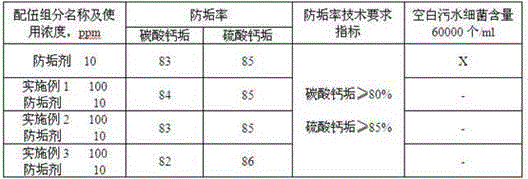

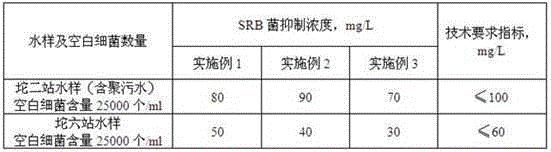

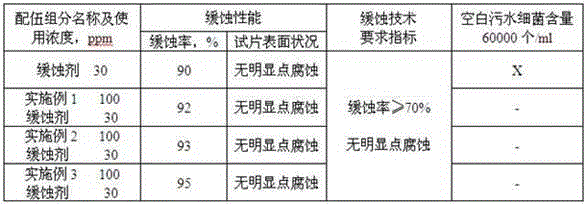

Examples

Embodiment 1

[0031] Embodiment 1: a kind of improved type oilfield composite fungicide mentioned in the present invention, its preparation method is:

[0032] 1) Add 5 parts of monomethylamine aqueous solution into the reaction kettle, add 8 parts of epichlorohydrin under stirring, raise the temperature to 50°C, and react at constant temperature for 4-6 hours;

[0033] 2) Continue to heat up to 70°C, add 25 parts of dodecyl tertiary amine, and react at constant temperature for 3-5 hours;

[0034] 3) Continue to heat up to 80°C, add 8 parts of benzyl chloride, and react at constant temperature for 1-3 hours;

[0035] 4) After the reaction is over, add 54 parts of water, stir evenly, and the product generated by the reaction is BC-2 multi-quaternary ammonium fungicide;

[0036] 5) Add 20 parts of BC-2 polyquaternary ammonium fungicide, 10 parts of polyhexamethyleneguanidine, 10 parts of tetrakis hydroxymethyl phosphorus sulfate, 5 parts of methylisothiazolinone, 3 parts of medical metr...

Embodiment 2

[0039] Embodiment 2: a kind of improved type oil field composite bactericide that the present invention mentions, its preparation method is:

[0040] 1) Add 7 parts of monomethylamine aqueous solution into the reaction kettle, add 10 parts of epichlorohydrin under stirring, raise the temperature to 50°C, and react at constant temperature for 5 hours;

[0041] 2) Continue to heat up to 70°C, add 30 parts of dodecyl tertiary amine, and react at constant temperature for 4 hours;

[0042] 3) Continue to heat up to 80°C, add 10 parts of benzyl chloride, and react at constant temperature for 2 hours;

[0043] 4) After the reaction is over, add 60 parts of water, stir evenly, and the product generated by the reaction is BC-2 multi-quaternary ammonium fungicide;

[0044] 5) Add 18 parts of BC-2 polyquaternary ammonium fungicide, 9 parts of polyhexamethyleneguanidine, 9 parts of tetrakis hydroxymethyl phosphorus sulfate, 4 parts of methylisothiazolinone, 2 parts of medical metronidaz...

Embodiment 3

[0047] Embodiment 3: a kind of improved type oilfield composite bactericide that the present invention mentions, its preparation method is:

[0048] 1) Add 6 parts of monomethylamine aqueous solution into the reaction kettle, add 9 parts of epichlorohydrin under stirring, raise the temperature to 50°C, and react at constant temperature for 5 hours;

[0049] 2) Continue to heat up to 70°C, add 28 parts of dodecyl tertiary amine, and react at constant temperature for 4 hours;

[0050] 3) Continue to heat up to 80°C, add 9 parts of benzyl chloride, and react at constant temperature for 2 hours;

[0051] 4) After the reaction is over, add 52 parts of water, stir evenly, and the product generated by the reaction is BC-2 multi-quaternary ammonium fungicide;

[0052] 5) Add 20 parts of BC-2 polyquaternary ammonium fungicide, 10 parts of polyhexamethyleneguanidine, 10 parts of tetrakis hydroxymethyl phosphorus sulfate, 5 parts of methylisothiazolinone, 3 parts of medical metronidazo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com