Anti-aging and anti-twisting wind power cable

A twist-resistant and aging-resistant technology, which is applied in the direction of power cables, insulated cables, cables, etc., can solve the problems of poor aging resistance and twist resistance, can not meet the requirements of wind power cables, and limit the application of wind power cables, etc., to achieve Excellent heat resistance, improved viscosity and workability, and improved compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

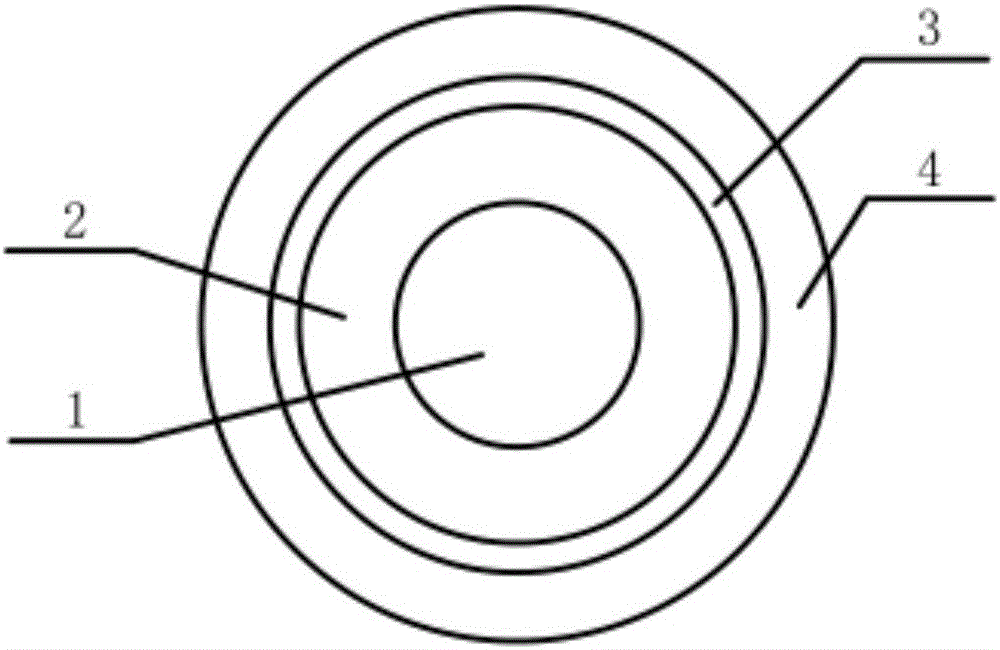

[0018] figure 1 It is a structural schematic diagram of the aging-resistant and twist-resistant wind power cable of the present invention. refer to figure 1 , an aging-resistant and twist-resistant wind power cable proposed by the present invention, comprising a copper conductor 1, an insulating layer 2 is coated on the outside of the copper conductor 1, and a wrapping layer 3 is coated on the outside of the insulating layer 2. The wrapping layer 3 is covered with a sheath layer 4; wherein, the sheath layer 4 is made of a polyurethane composite material, and the raw materials of the polyurethane composite material include by weight: 80 parts of polyurethane, 20 parts of nylon, ABS 25 parts of resin, 3 parts of diphenylmethane diisocyanate, 10 parts of montmorillonite, 3 parts of kaolin, 10 parts of talc, 3 parts of zinc borate, 15 parts of aluminum hydroxide, 10 parts of carbon fiber, 4 parts of vinyltriethoxysilane parts, 0.5 parts of antioxidant, 15 parts of phosphorus-con...

Embodiment 2

[0021] refer to figure 1 , an aging-resistant and twist-resistant wind power cable proposed by the present invention, comprising a copper conductor 1, an insulating layer 2 is coated on the outside of the copper conductor 1, and a wrapping layer 3 is coated on the outside of the insulating layer 2. The wrapping layer 3 is covered with a sheath layer 4; wherein, the sheath layer 4 is made of a polyurethane composite material, and the raw materials of the polyurethane composite material include by weight: 50 parts of polyurethane, 35 parts of nylon, ABS 10 parts of resin, 12 parts of diphenylmethane diisocyanate, 2 parts of montmorillonite, 12 parts of kaolin, 2 parts of talc, 12 parts of zinc borate, 3 parts of aluminum hydroxide, 25 parts of carbon fiber, -aminopropyltriethoxy 1.2 parts of silane, 0.8 parts of γ-(methacryloyloxy)propyltrimethoxysilane, 2 parts of lanthanum stearate, 5 parts of phosphorus-containing flame retardant, 1.5 parts of stearic acid amide;

[0022] Wh...

Embodiment 3

[0024] refer to figure 1 , an aging-resistant and twist-resistant wind power cable proposed by the present invention, comprising a copper conductor 1, an insulating layer 2 is coated on the outside of the copper conductor 1, and a wrapping layer 3 is coated on the outside of the insulating layer 2. The wrapping layer 3 is covered with a sheath layer 4; wherein, the sheath layer 4 is made of a polyurethane composite material, and the raw materials of the polyurethane composite material include by weight: 65 parts of polyurethane, 28 parts of nylon, ABS 21 parts of resin, 5.5 parts of diphenylmethane diisocyanate, 8.5 parts of montmorillonite, 7 parts of kaolin, 7 parts of talcum powder, 8 parts of zinc borate, 10 parts of aluminum hydroxide, 15 parts of carbon fiber, 0.5 parts of vinyl triethoxysilane Parts, 1 part of γ-aminopropyl triethoxysilane, 0.8 parts of γ-(methacryloyloxy)propyl trimethoxysilane, 1.2 parts of γ-glycidyl etheroxypropyl trimethoxysilane, four ( 0.3 parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com