Patents

Literature

190results about How to "Improved resistance to twisting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

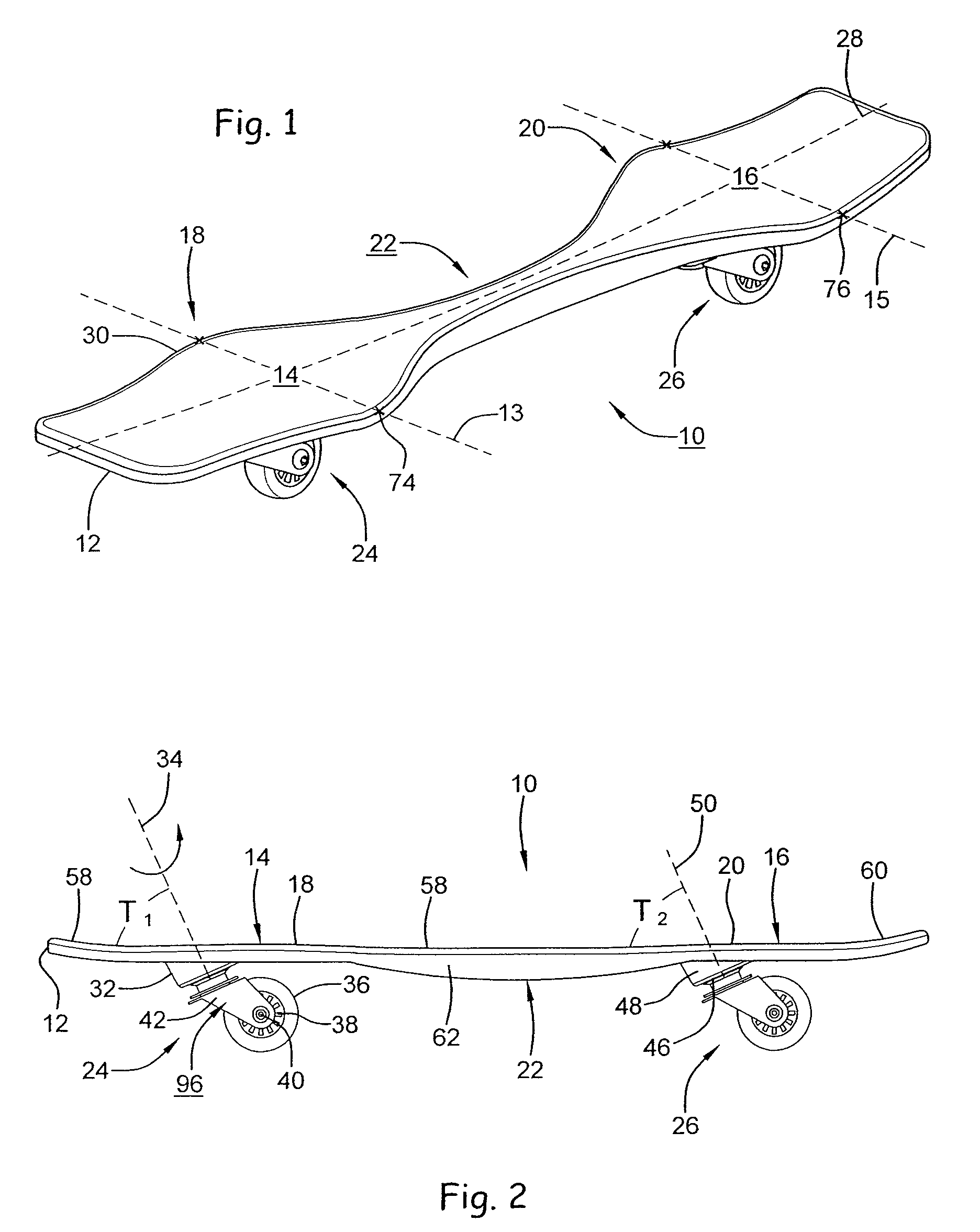

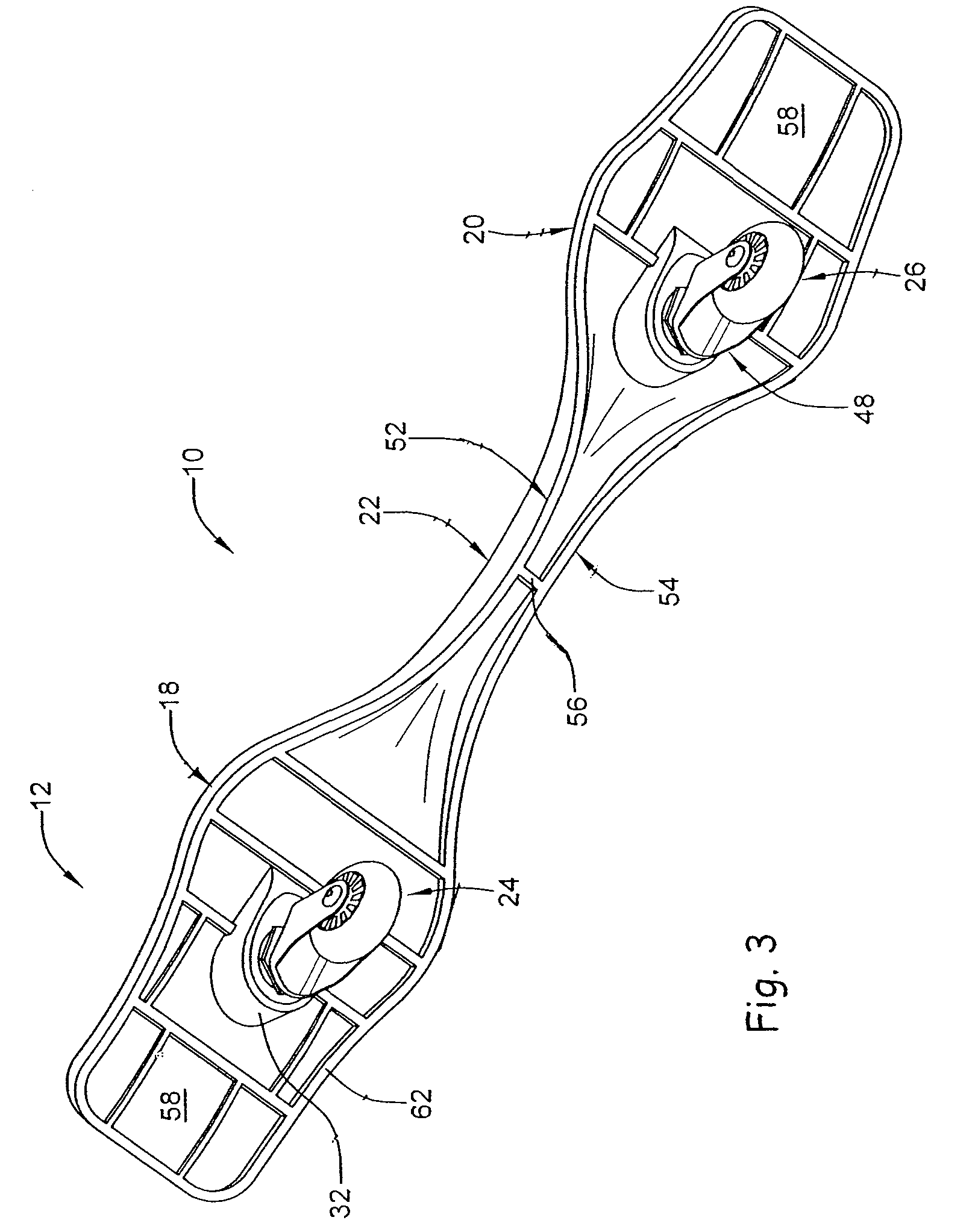

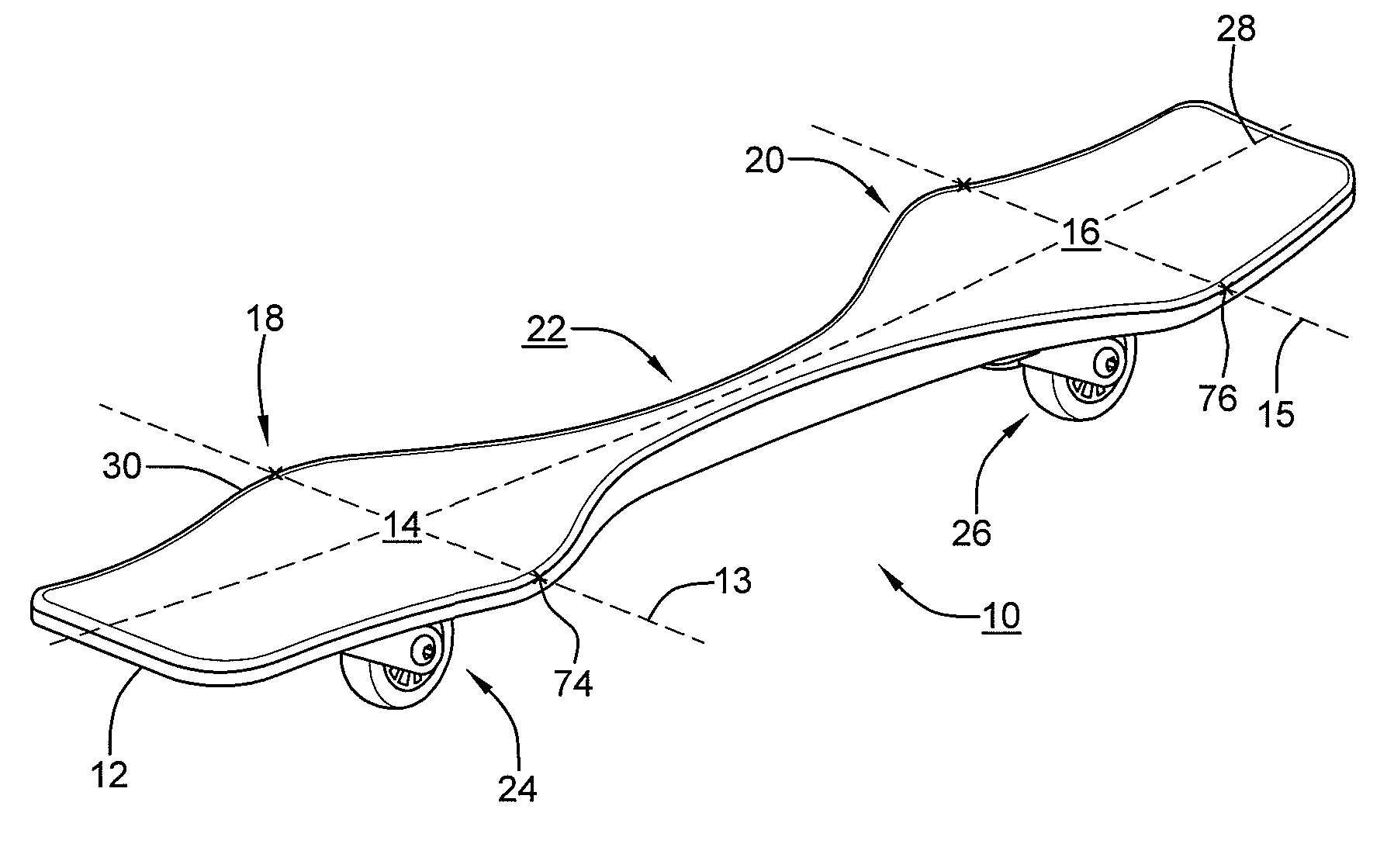

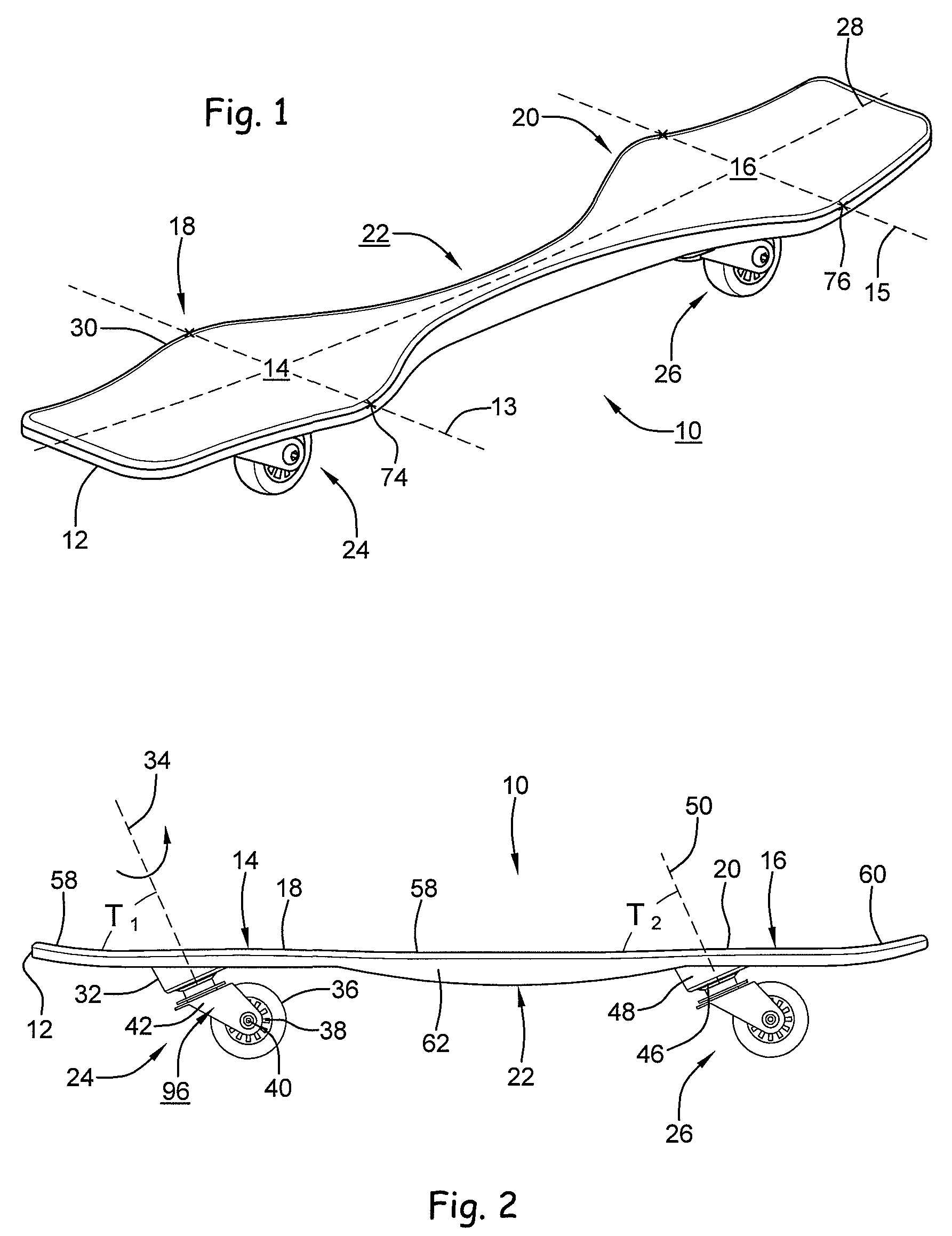

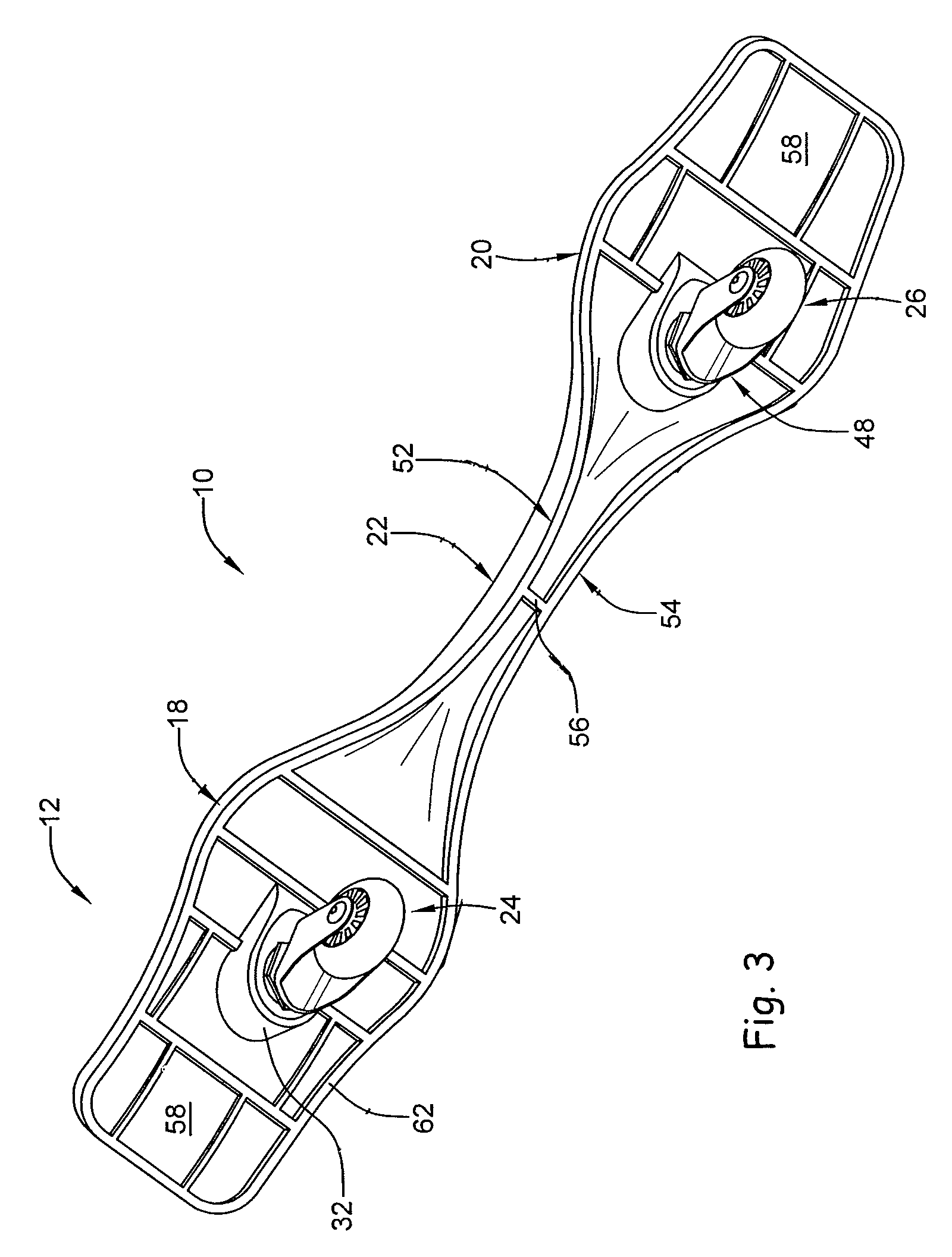

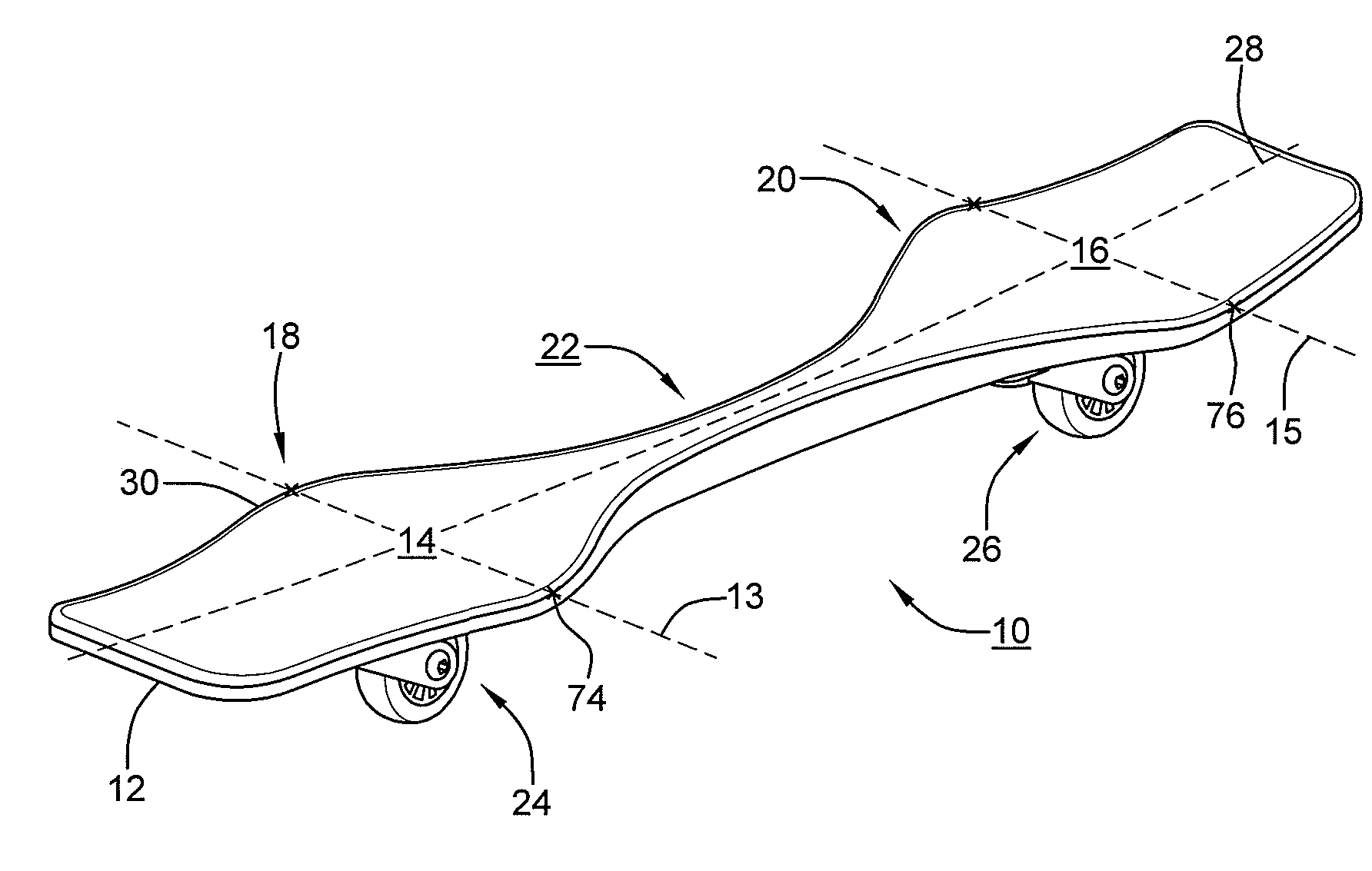

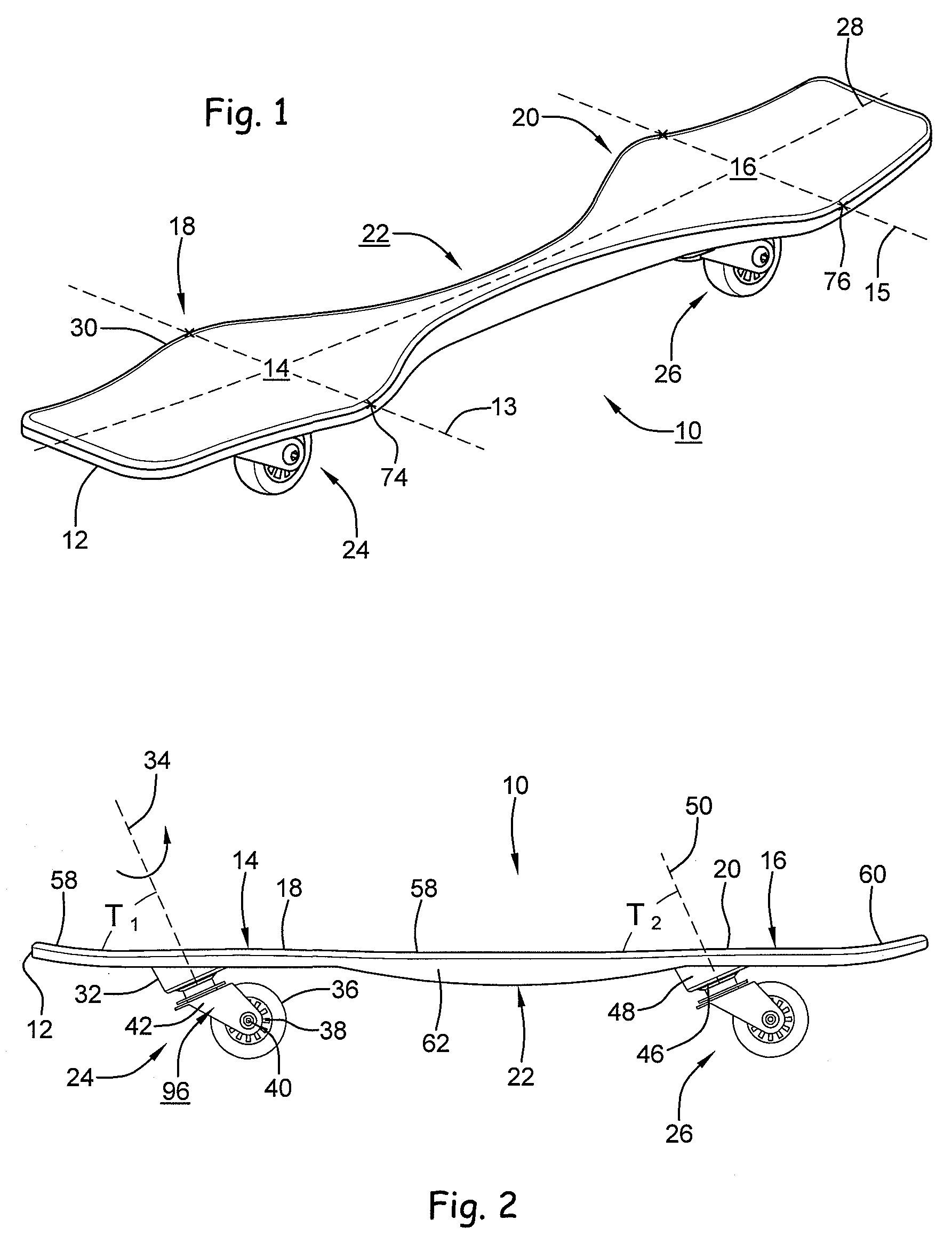

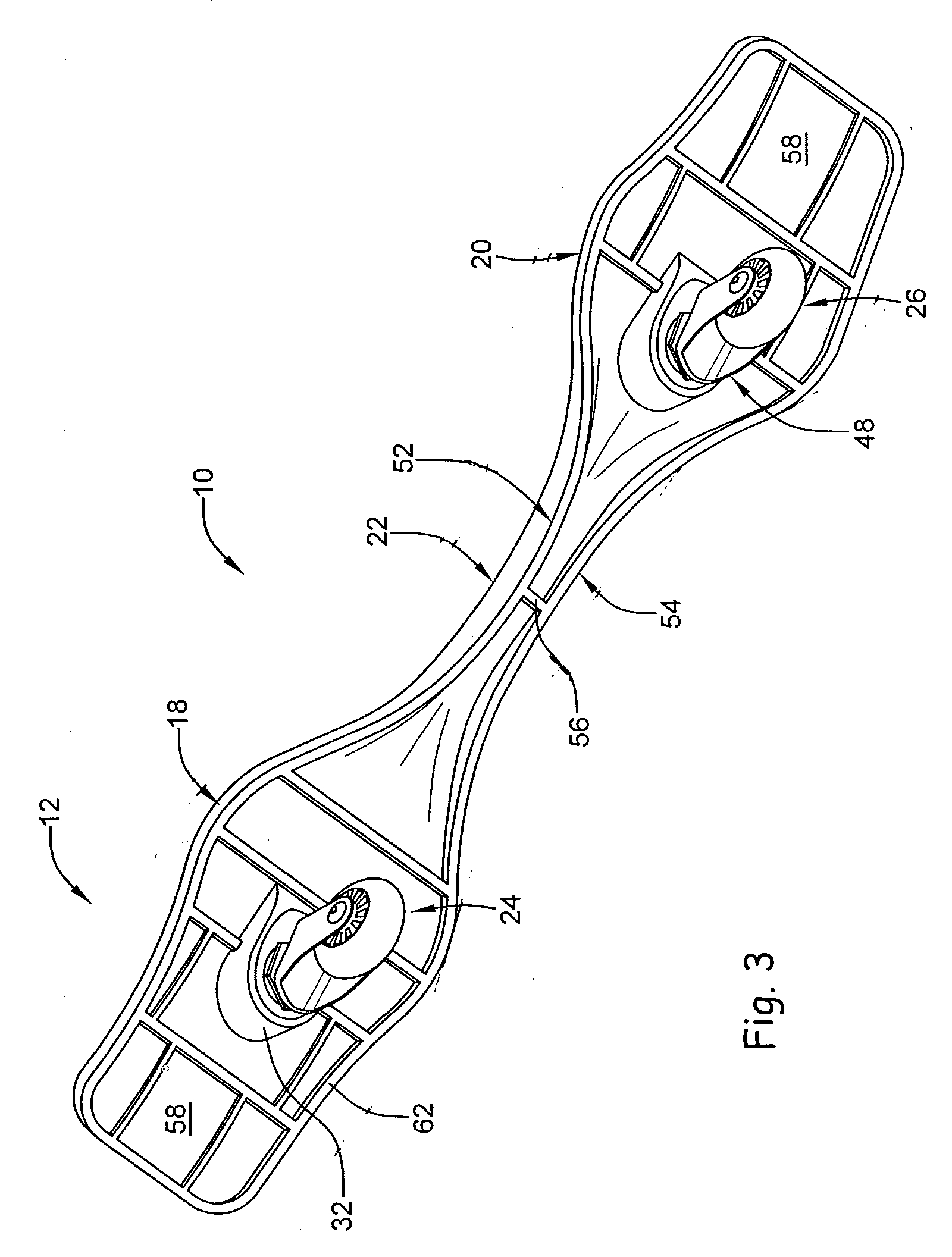

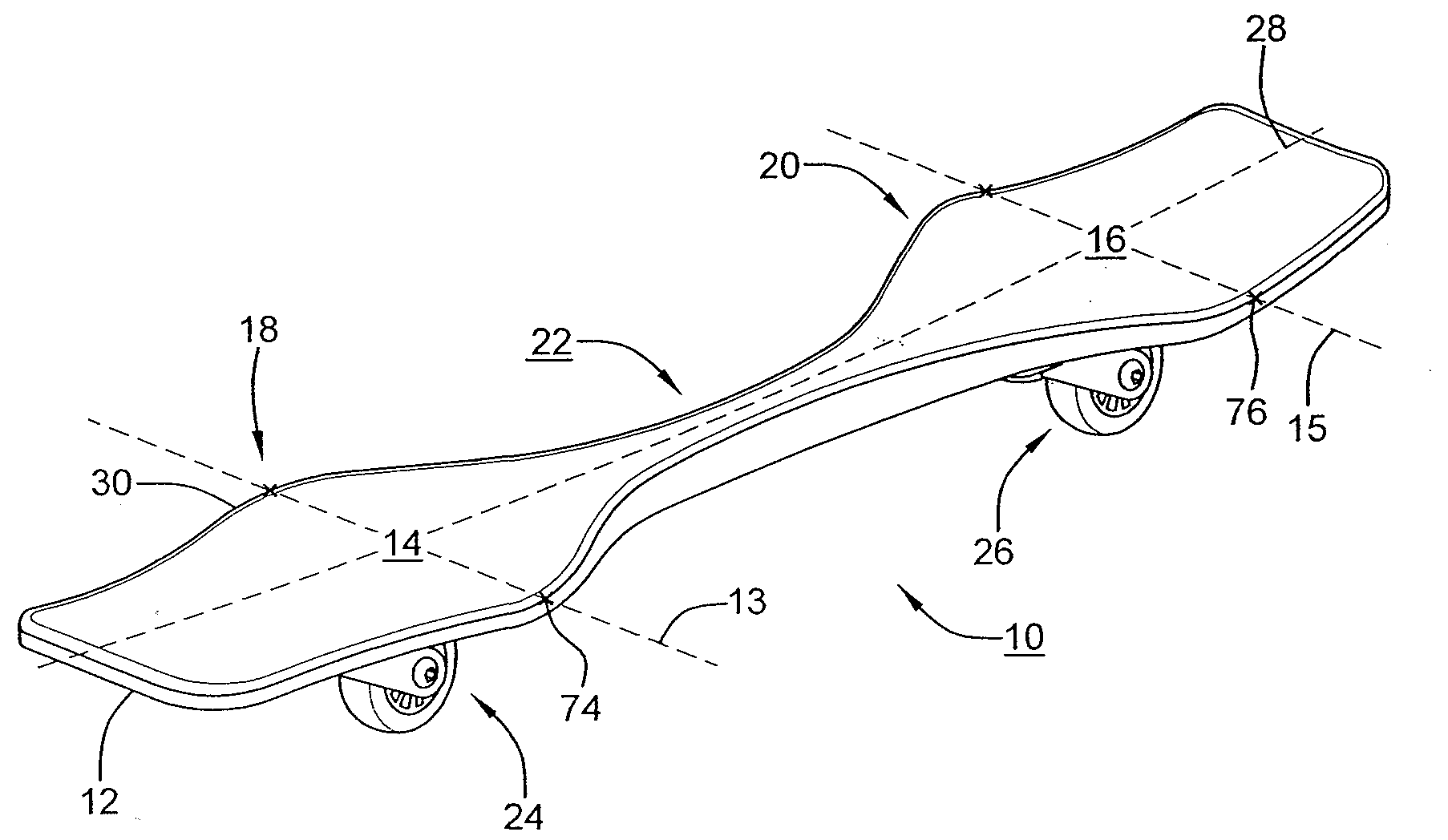

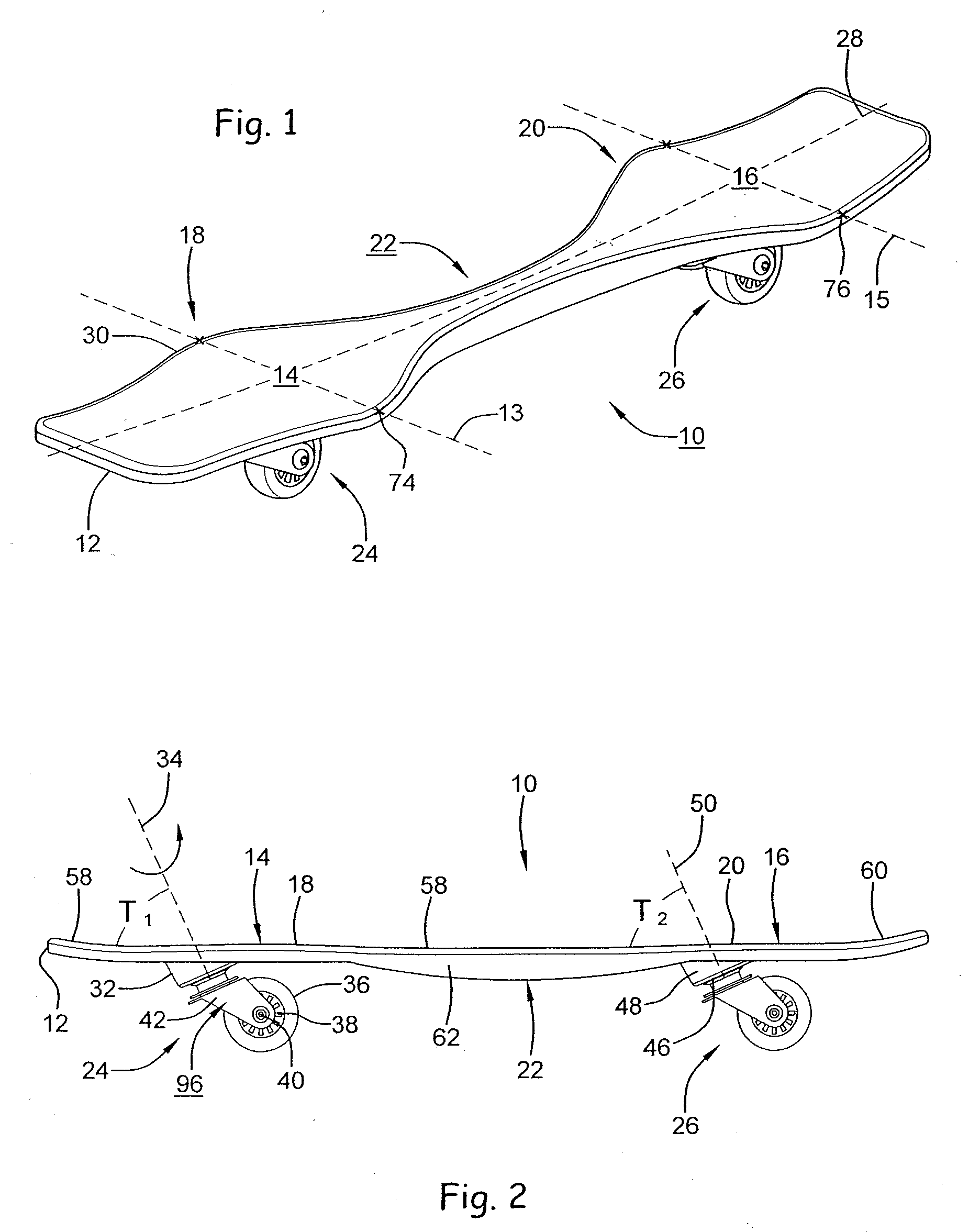

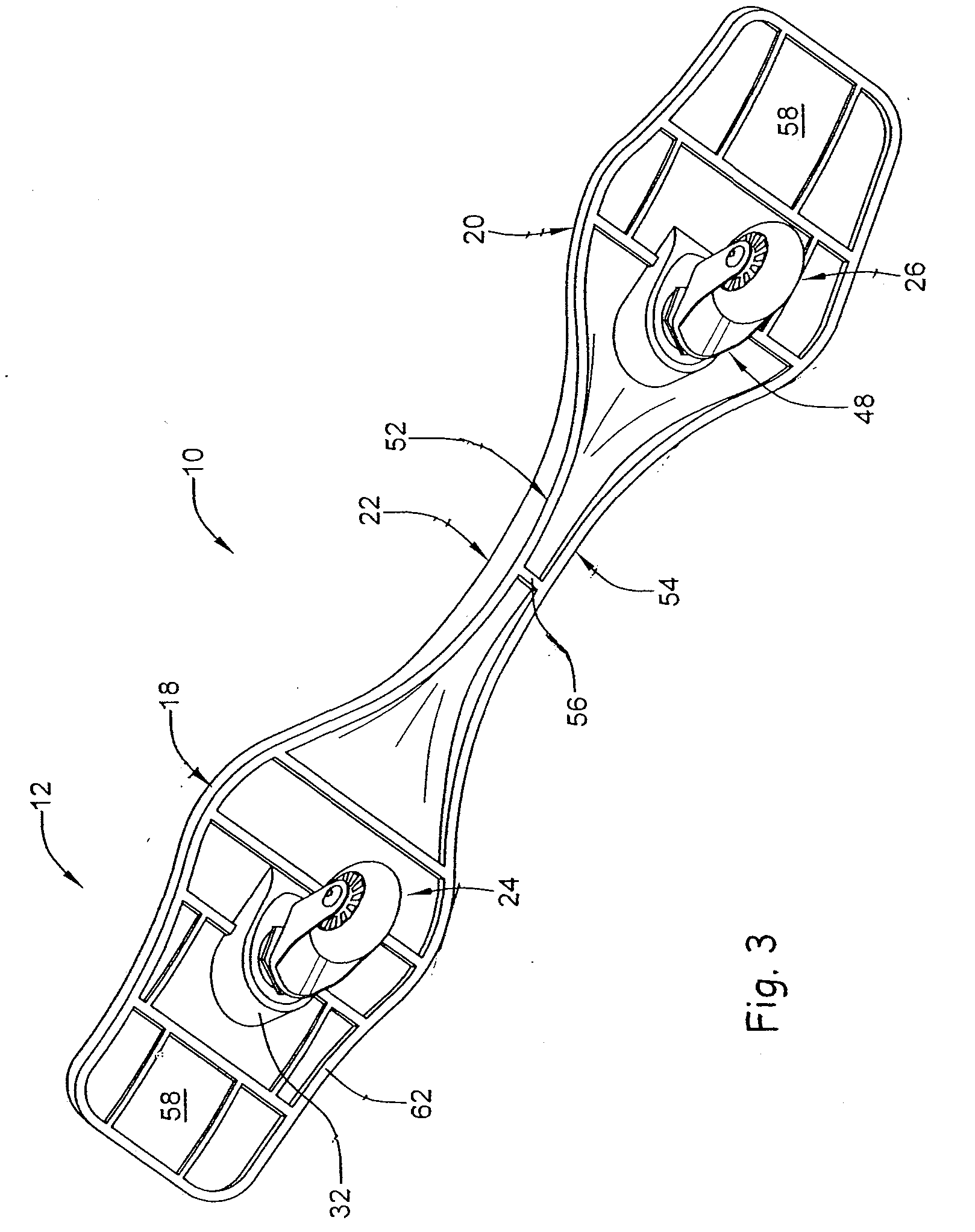

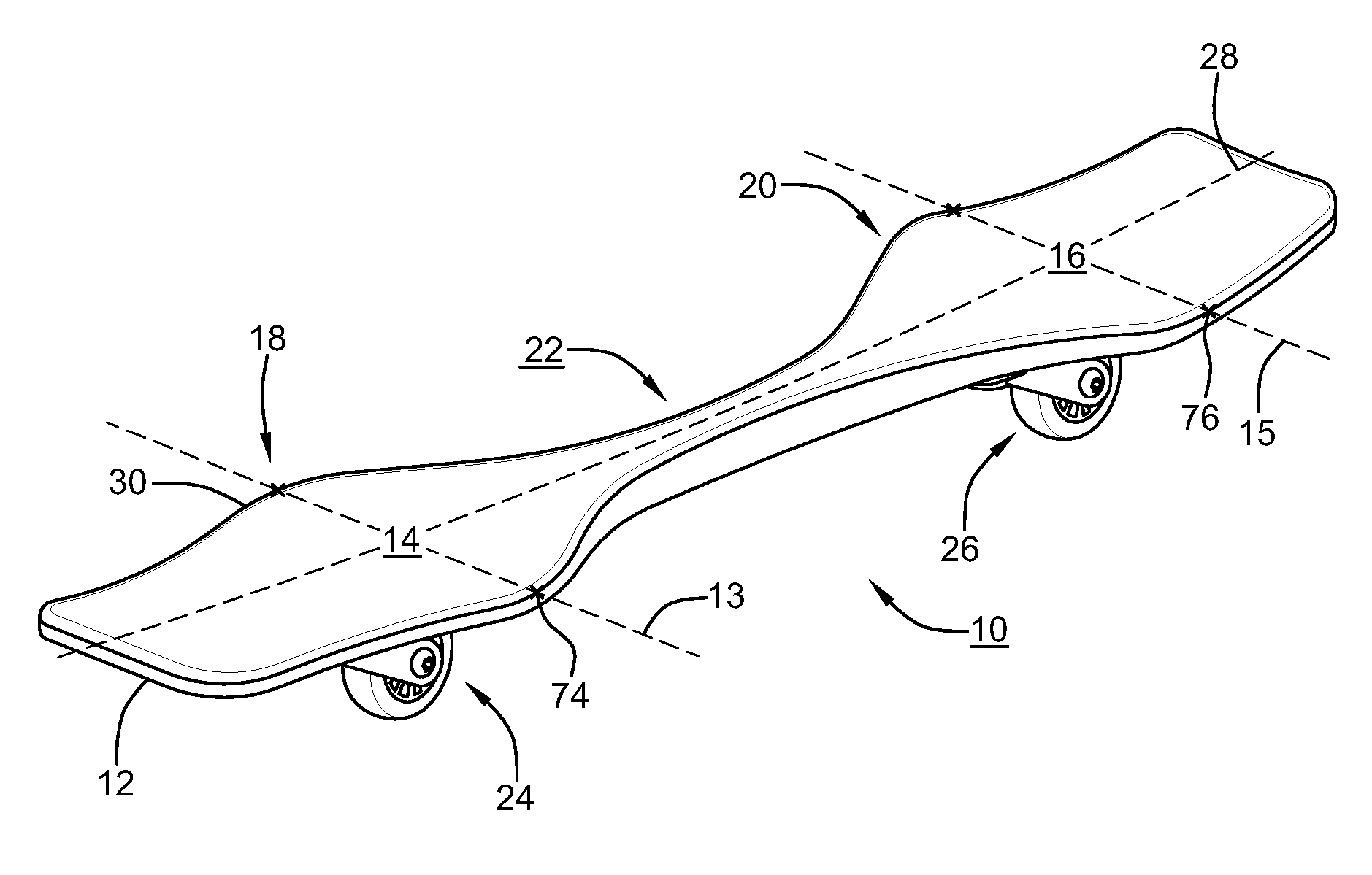

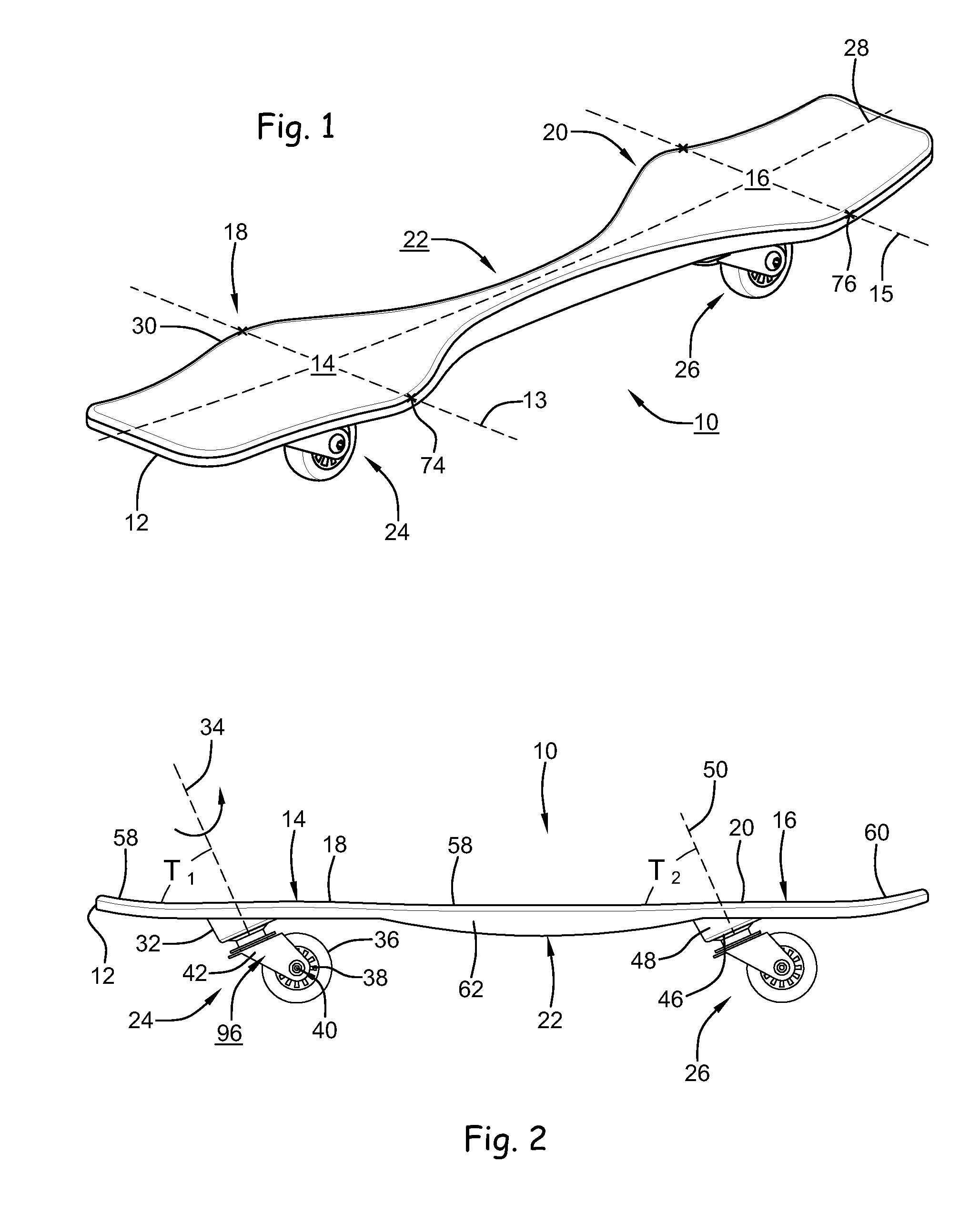

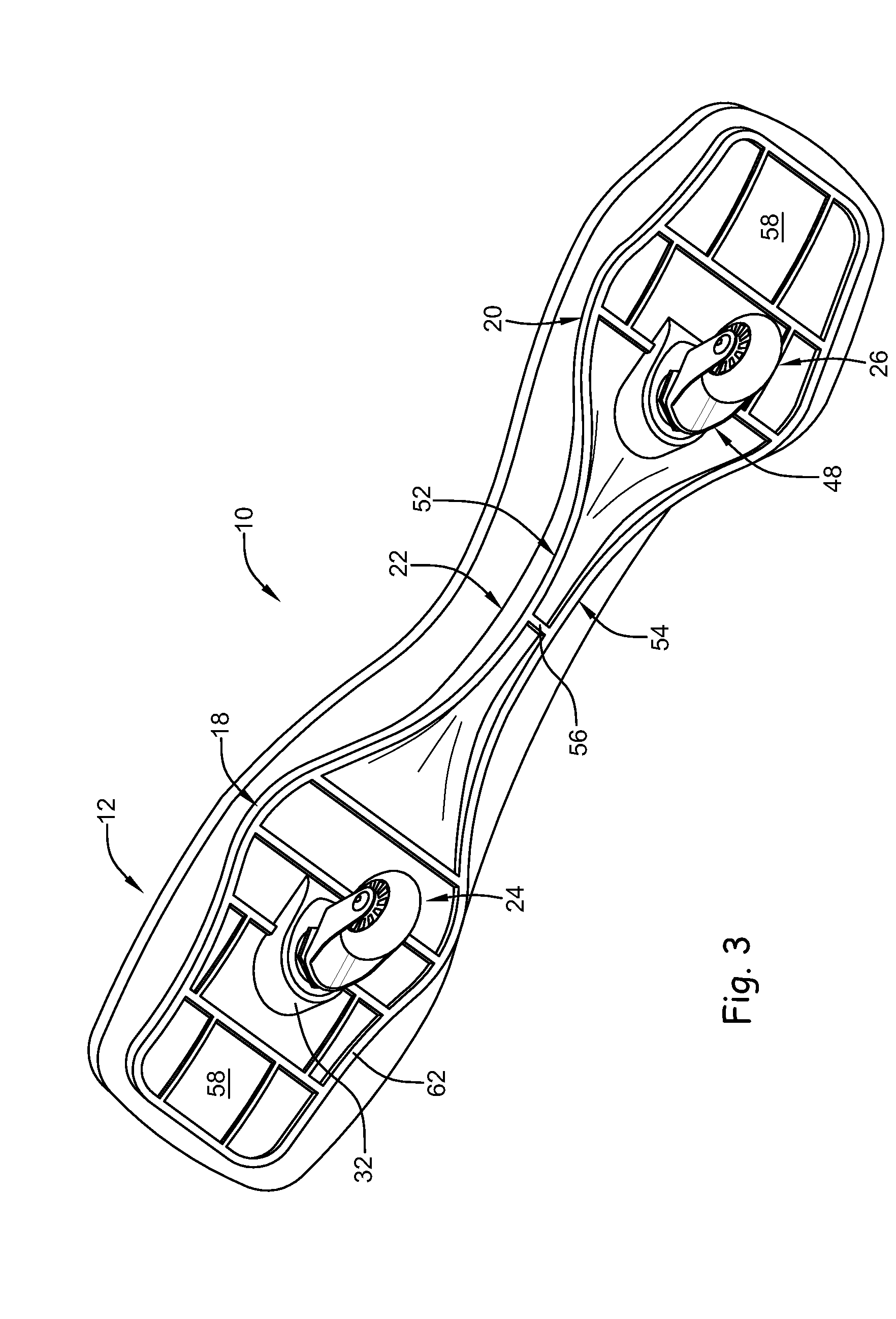

One piece flexible skateboard

ActiveUS7600768B2Sufficient resistanceWithout substantial bendingRider propulsionSkate-boardsFoot supportsEngineering

Owner:RAZOR USA

One piece flexible skateboard

ActiveUS7766351B2Sufficient resistanceWithout substantial bendingSnowboardsSkisFoot supportsEngineering

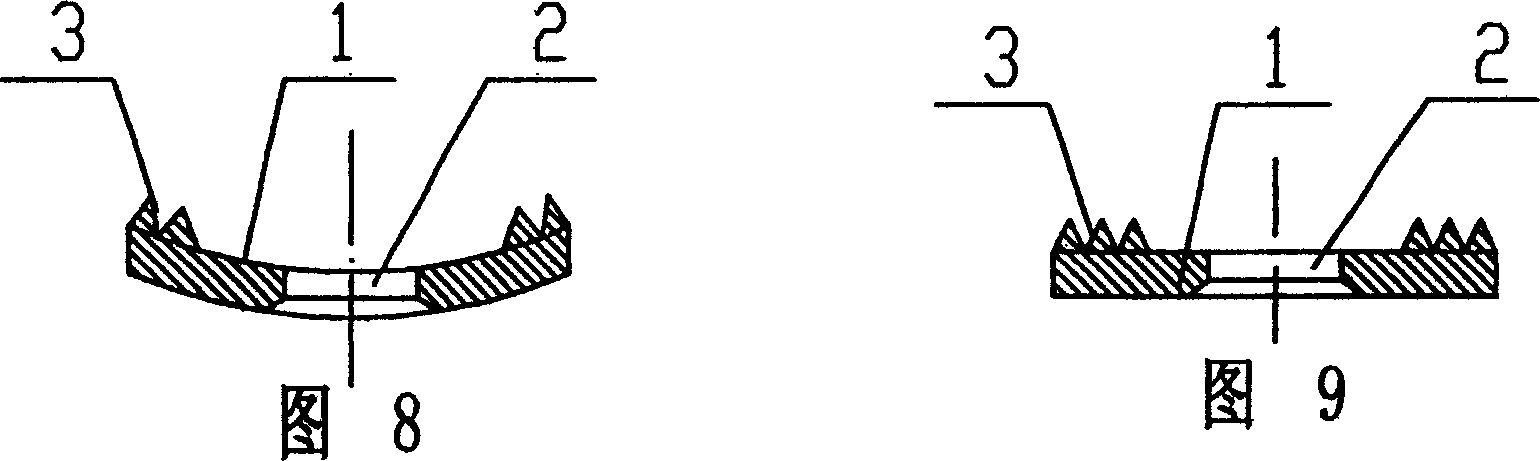

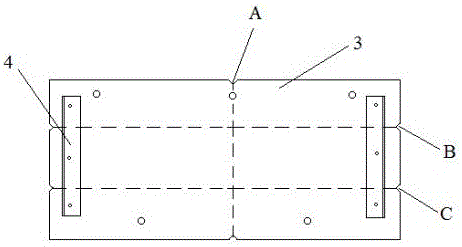

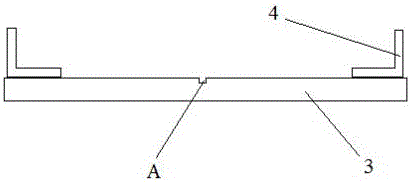

A flexible skateboard may include a pair of direction casters mounted for steering rotation on a twistable one piece skateboard. A center section may be made sufficiently narrower than outboard foot support areas so that the board may be twisted by a rider to add energy for rolling motion to wheels in the casters. The center section may also be made sufficiently resistant to bowing and twist so that the skateboard may be ridden as a conventional, non-flexible skateboard. Wells may be provided to resist twisting and provide gripping surfaces on the board for the rider's feet.

Owner:RAZOR USA

Working device setted on one place and engineering machinery using it

InactiveCN1831253AShorten the timeImprove operational skillsMechanical machines/dredgersVehiclesState of artEngineering

The invention is a working device arranged in some place, composed of two or above working devices arranged in some place, back-to-back, side-arranged, opposite, staggered, side-by-side, up and down, rotatable, inclinable, turnable, movable, liftable or in other form. And an engineering machine applying it is composed by arranging it in corresponding position on a corresponding vehicle or chassis or connecting it with the correspond position. And it can compose various engineering machines by various vehicles or chassises, compact, multifunctional, low-cost, high-efficiency and energy-saving, and having strong practicality.

Owner:姚实现

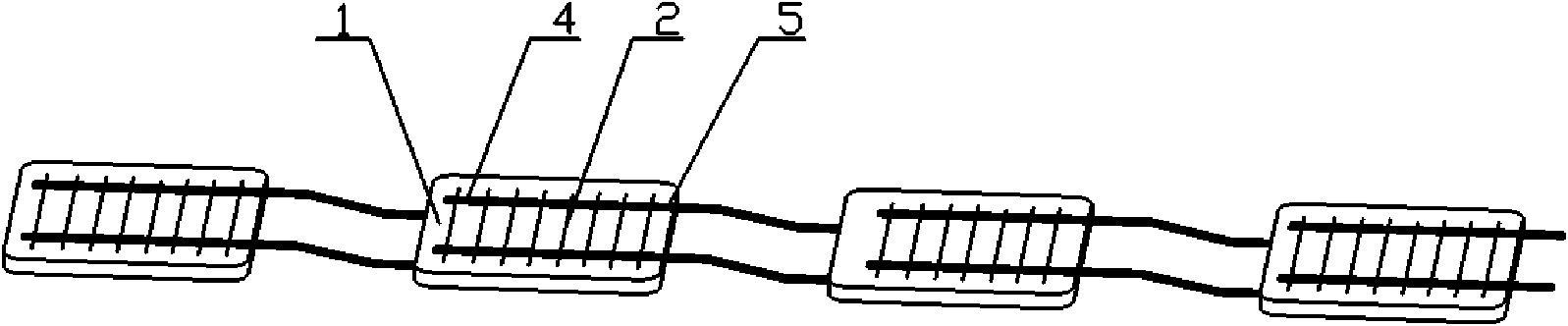

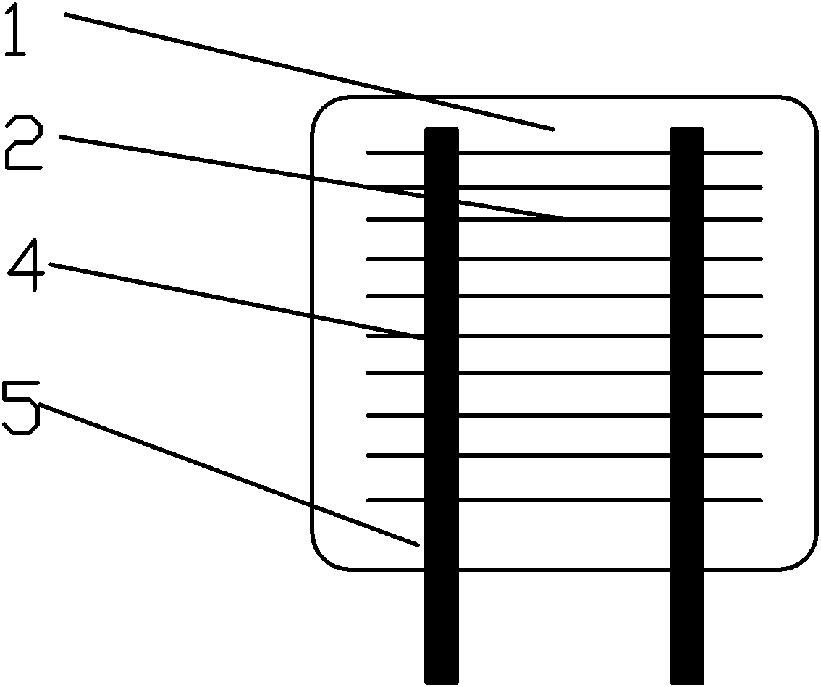

Solar photovoltaic component and welding process

InactiveCN101567402ASmall bridging stressImproved resistance to twistingSoldering apparatusPhotovoltaic energy generationAutomotive engineeringPressure resistance

A solar photovoltaic component and a welding process. The solar photovoltaic component comprises a group of solar cell plates. The front face of the solar cell plate is welded with the back face of the adjacent solar cell plate through a bus bar. A welding gap is arranged between the bus bar leading-off wire and the solar cell plate. The welding process comprises the following steps: preheating the welding bench, heating the electric iron; pasting the release paper on the bus bar; stably welding the front bus bar and the solar cell plate; putting the cell plate in a series welding platform; firstly welding the front bus bar leading-off wire, then welding the back bus bar. The invention effectively controls the welding start position and the welding direction by setting the welding gap on the structure and pasting the release paper in the welding process, reduces the bridge stress of the front face of the cell plate and the adjacent back face of the cell plate after welding, ensures the PN junction will not short out in the welding process, improves the wind resistance and static pressure resistance so as to enhance the solar photovoltaic component service life.

Owner:恒基光伏电力科技股份有限公司

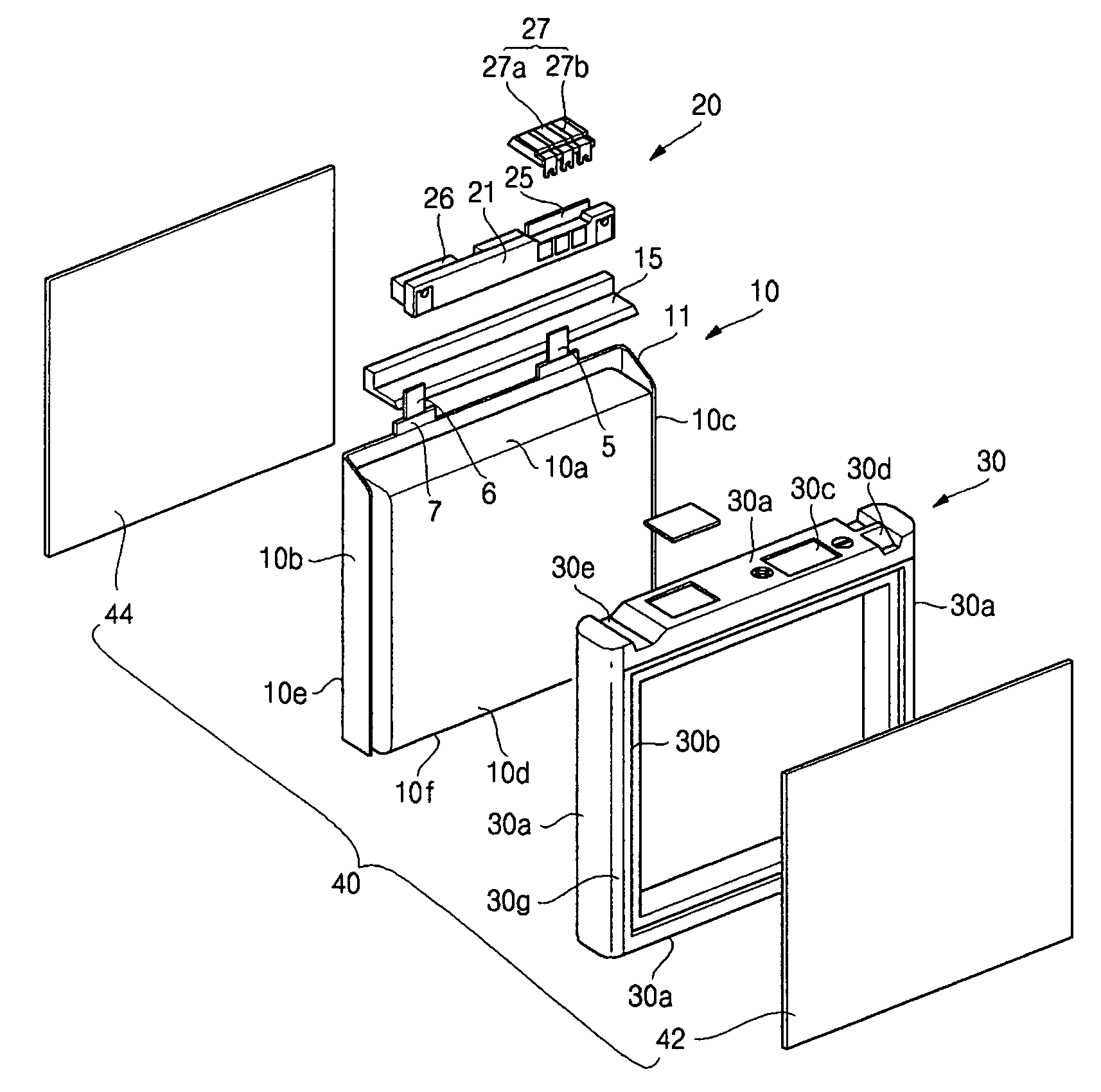

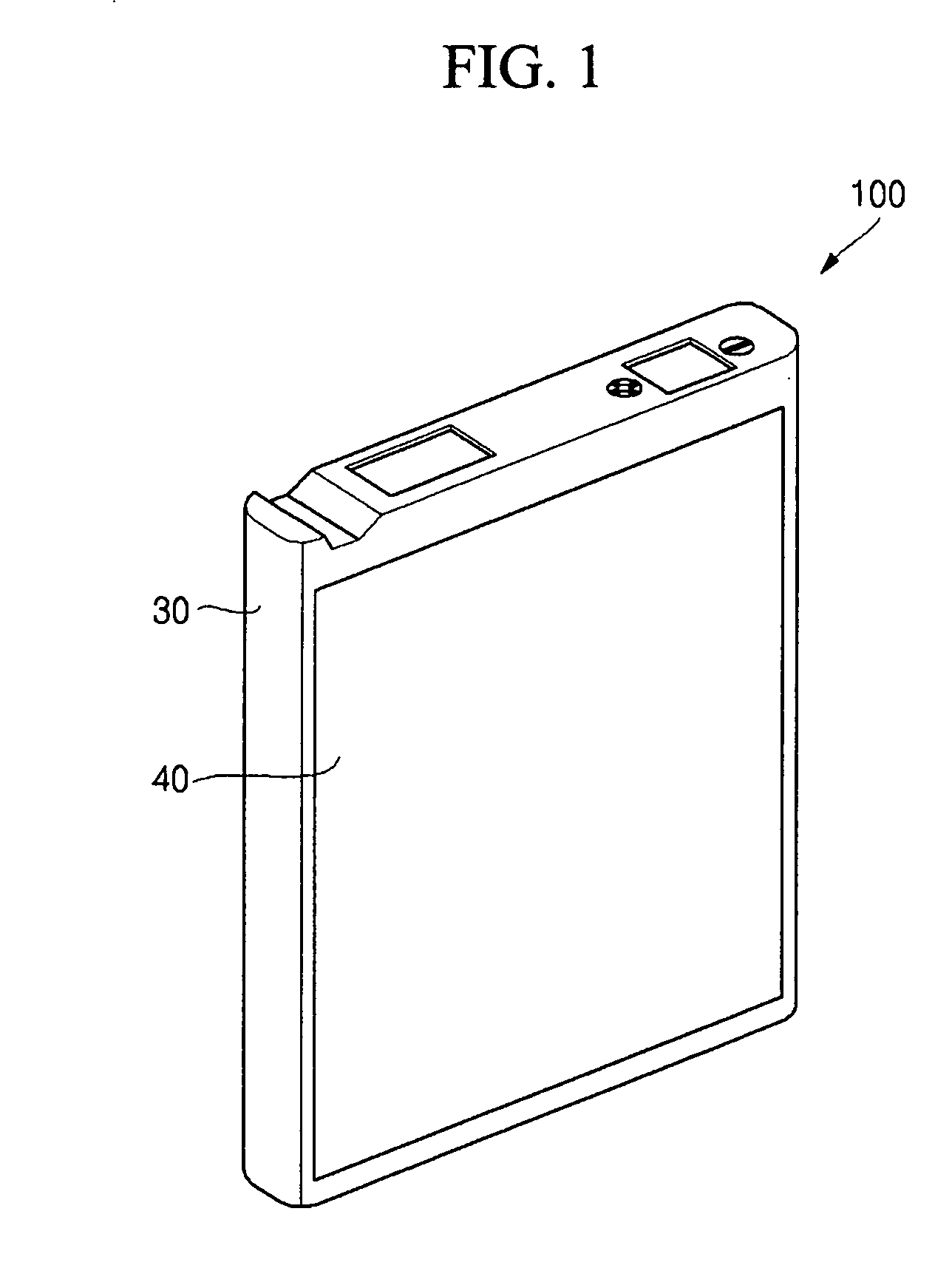

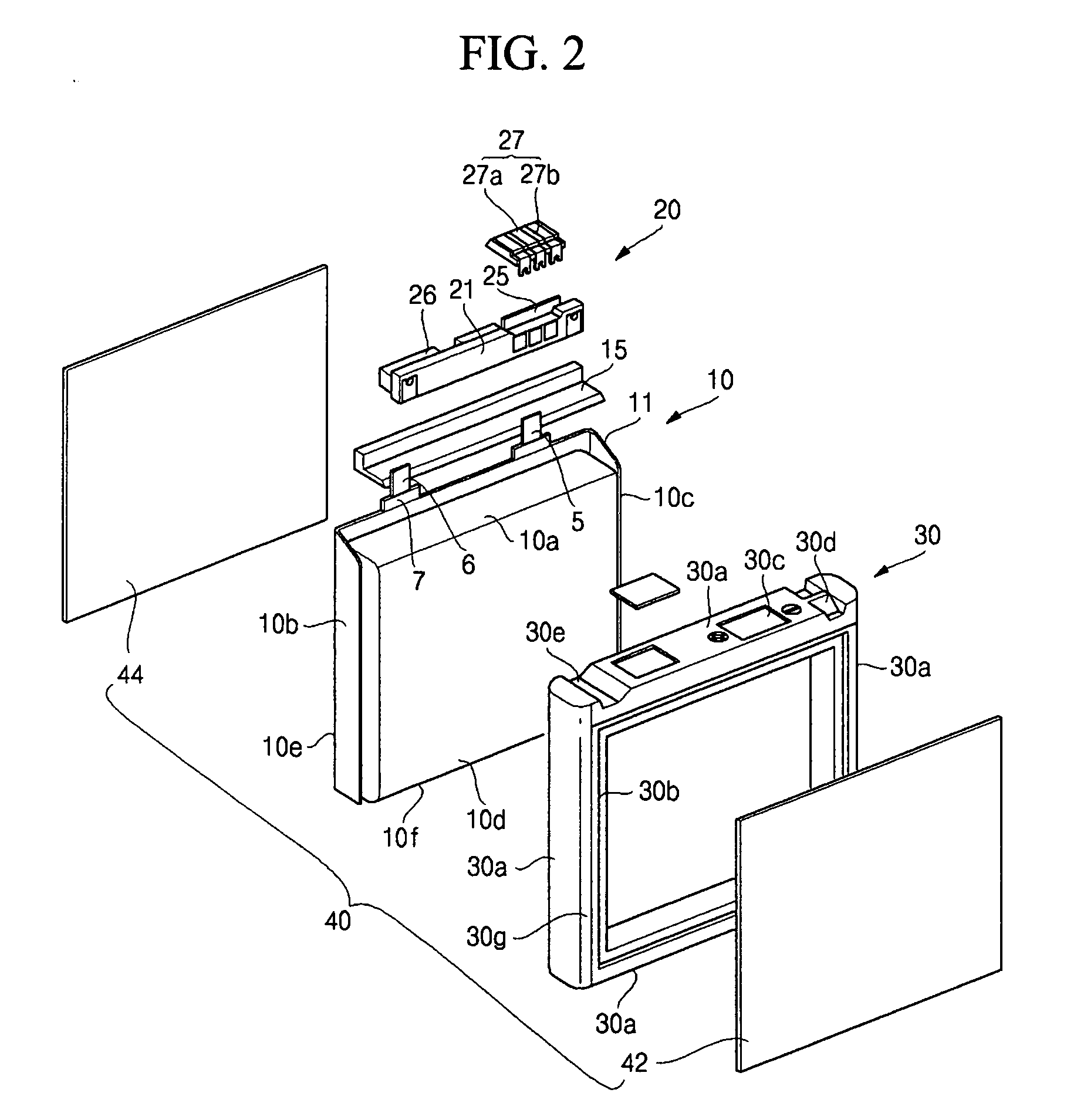

Battery pack

ActiveUS20090081485A1Small thicknessImproved resistance to twistingSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsEngineeringBattery pack

Disclosed is a battery pack that enables its outer case to be formed in small thickness regardless of formability and material property, and has enhanced twisting resistance. The battery pack includes a bare cell for generating electricity, a circuit member provided at an upper part of the bare cell and electrically coupled to the bare cell, a frame case formed so as to expose front and back parts of the bare cell externally while covering the bare cell including the circuit member, and a film sheet connected to the frame case so as to cover the front and back parts of the bare cell.

Owner:SAMSUNG SDI CO LTD

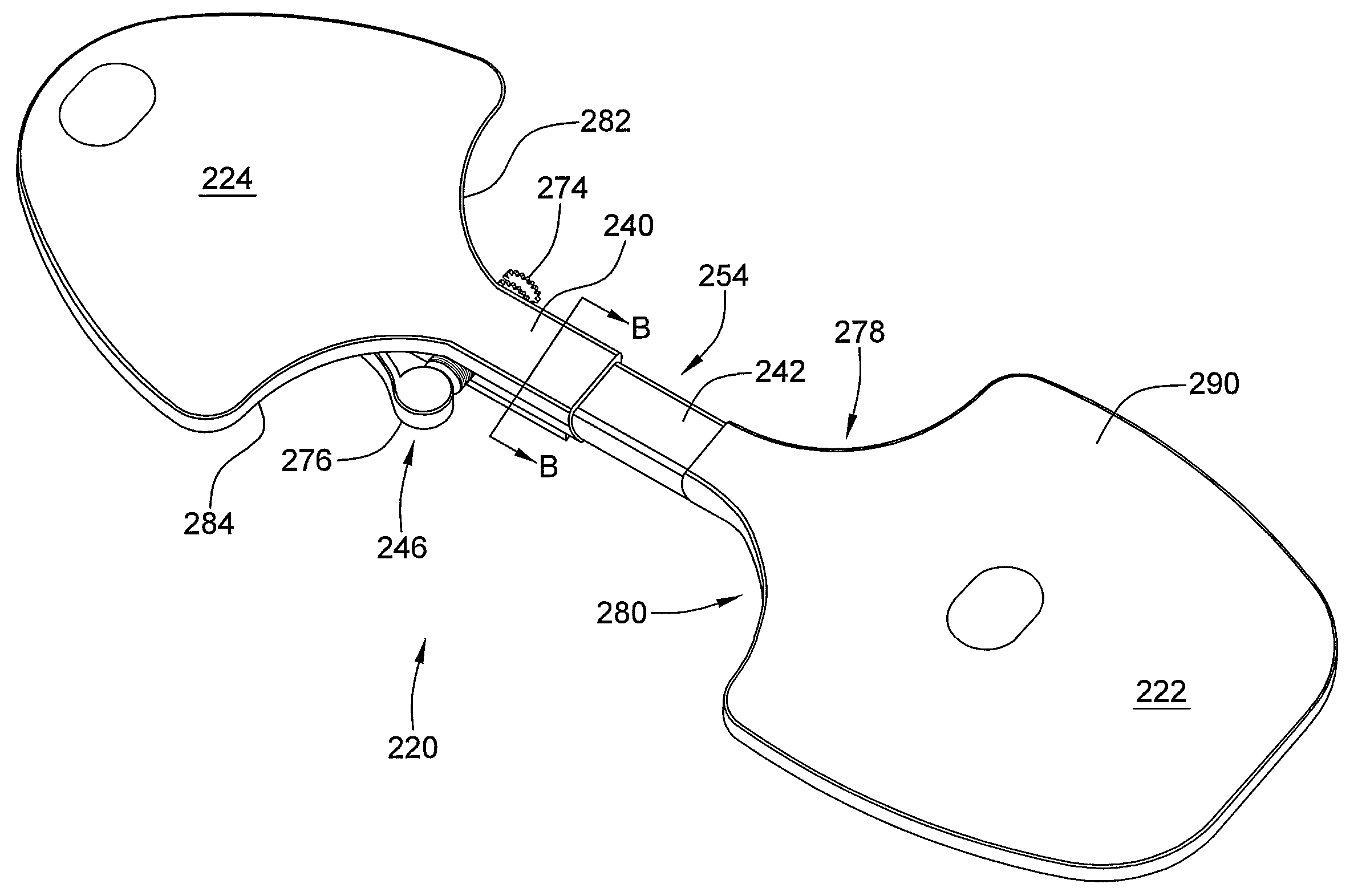

One piece flexible skateboard

ActiveUS20070252355A1Sufficient supportImprove rigidityRider propulsionSkate-boardsFoot supportsCaster

A flexible skateboard may include a pair of direction casters mounted for steering rotation on a twistable one piece skateboard. A center section may be made sufficiently narrower than outboard foot support areas so that the board may be twisted by a rider to add energy for rolling motion to wheels in the casters. The center section may also be made sufficiently resistant to bowing and twist so that the skateboard may be ridden as a conventional, non-flexible skateboard. Wells may be provided to resist twisting and provide gripping surfaces on the board for the rider's feet.

Owner:RAZOR USA

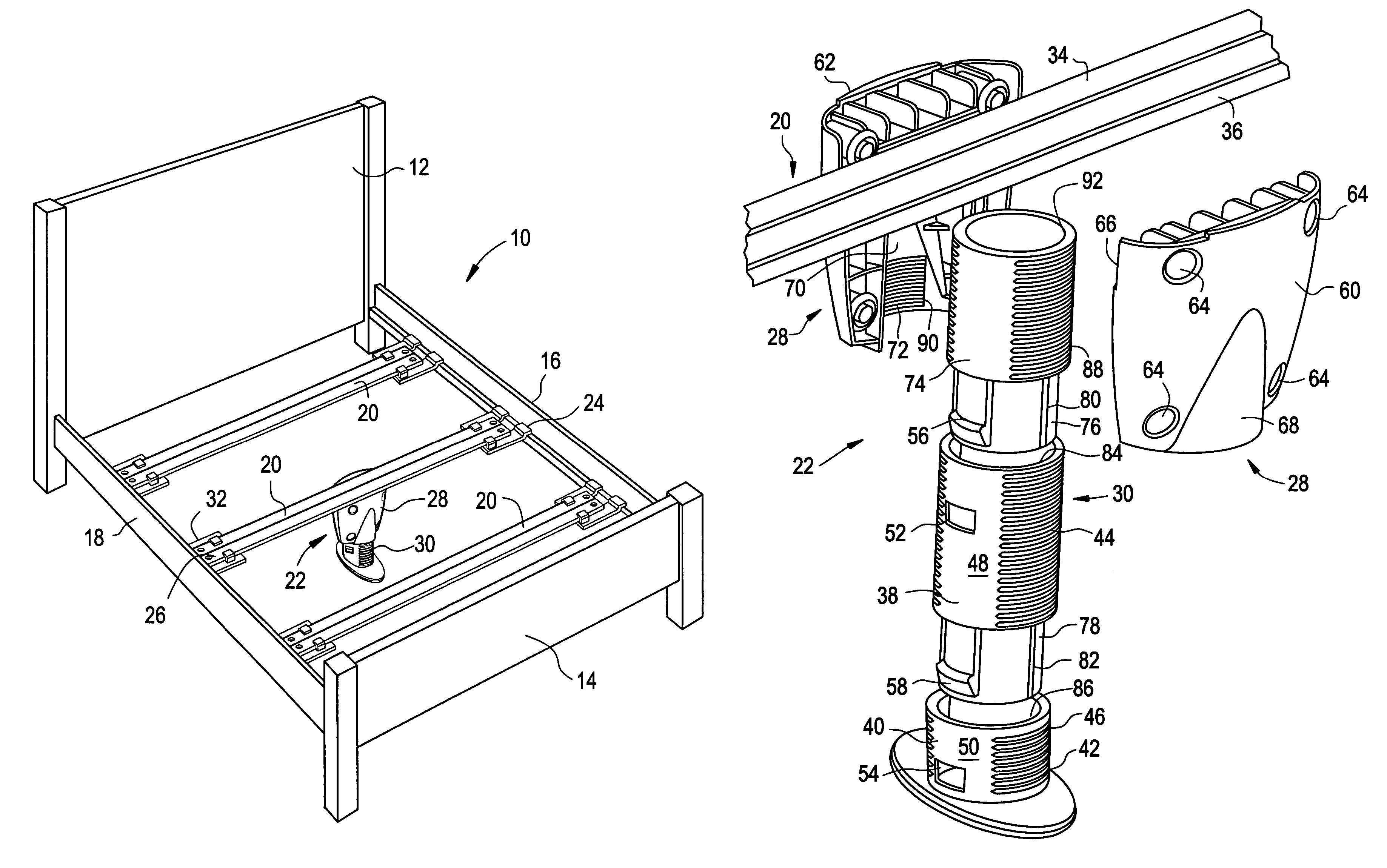

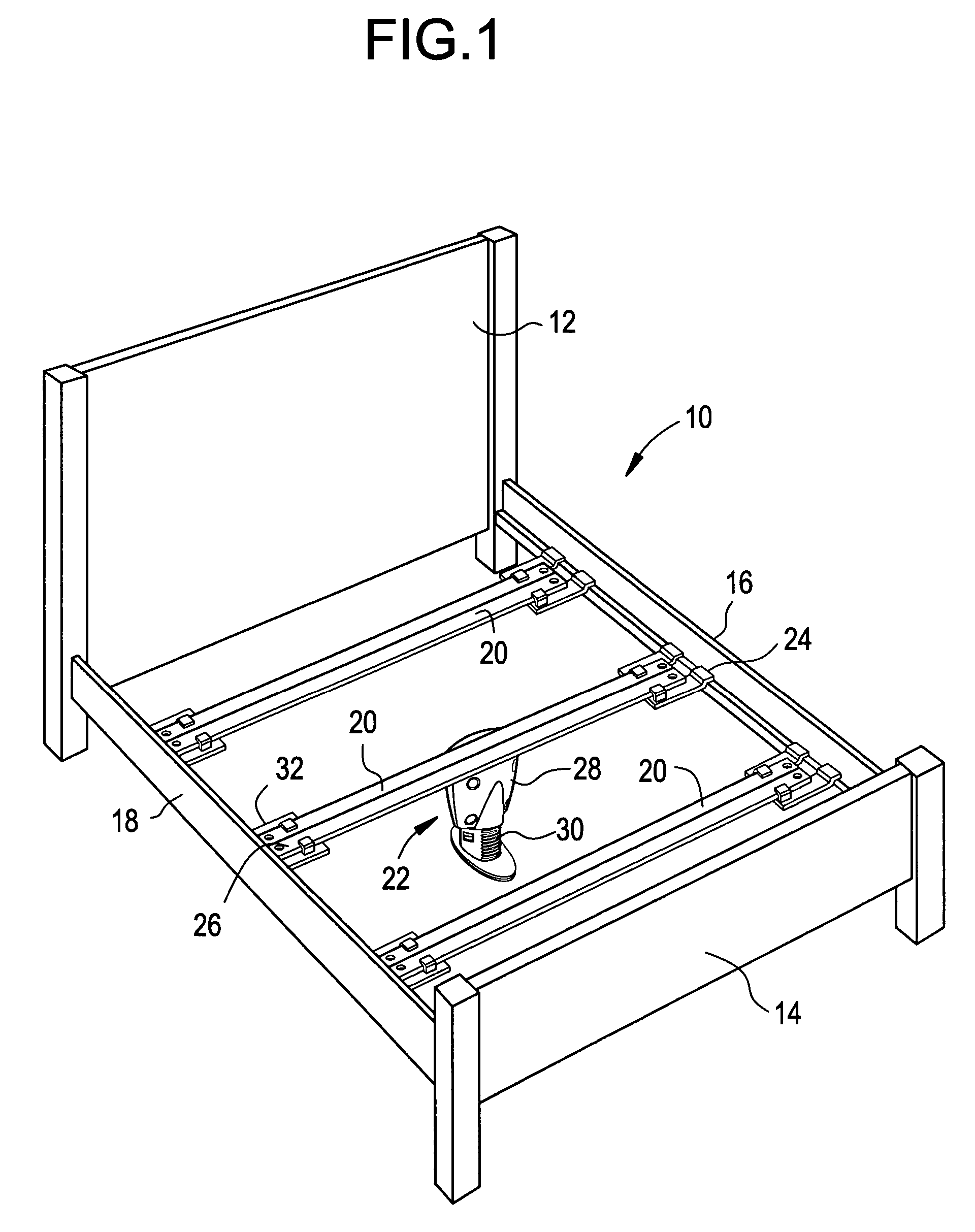

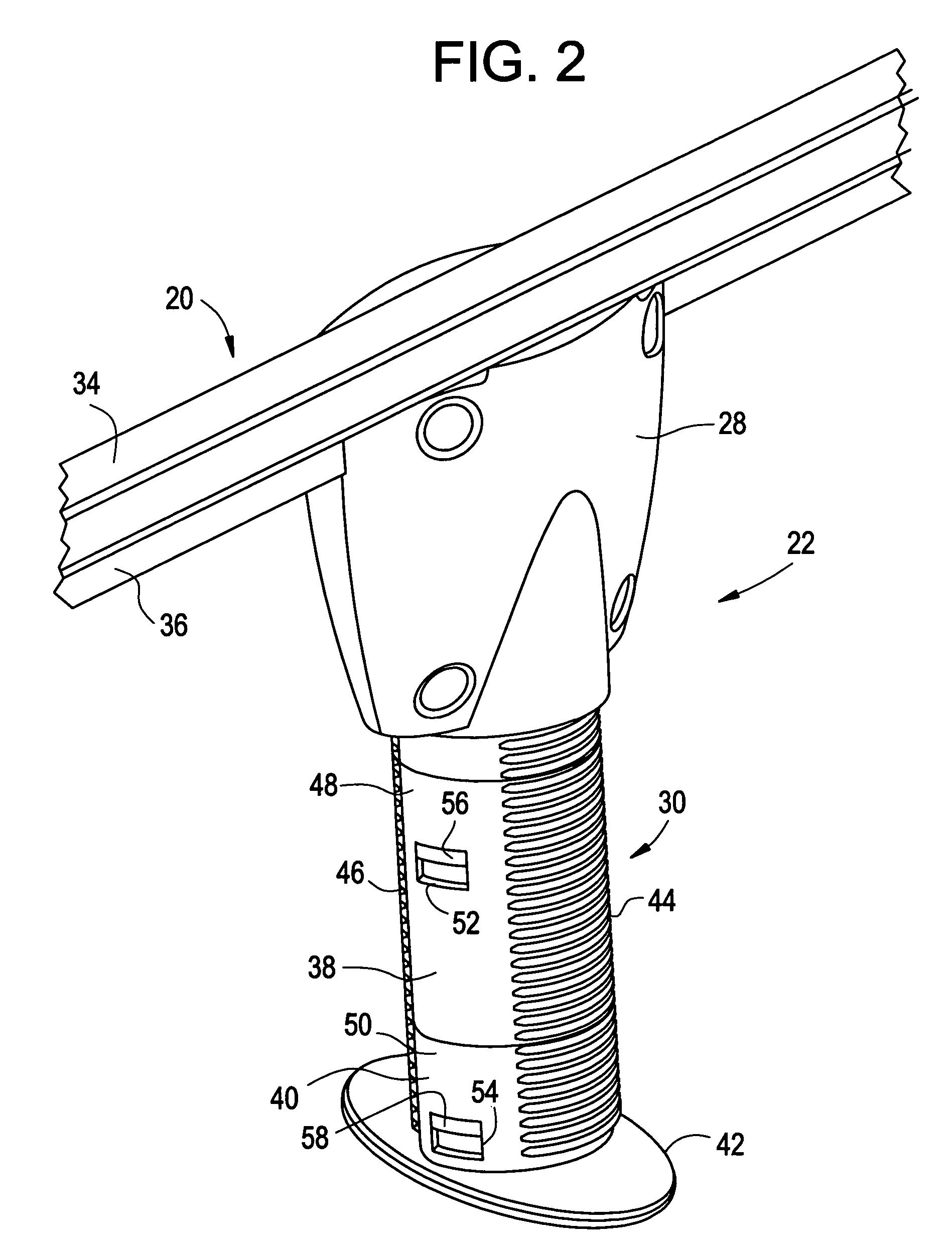

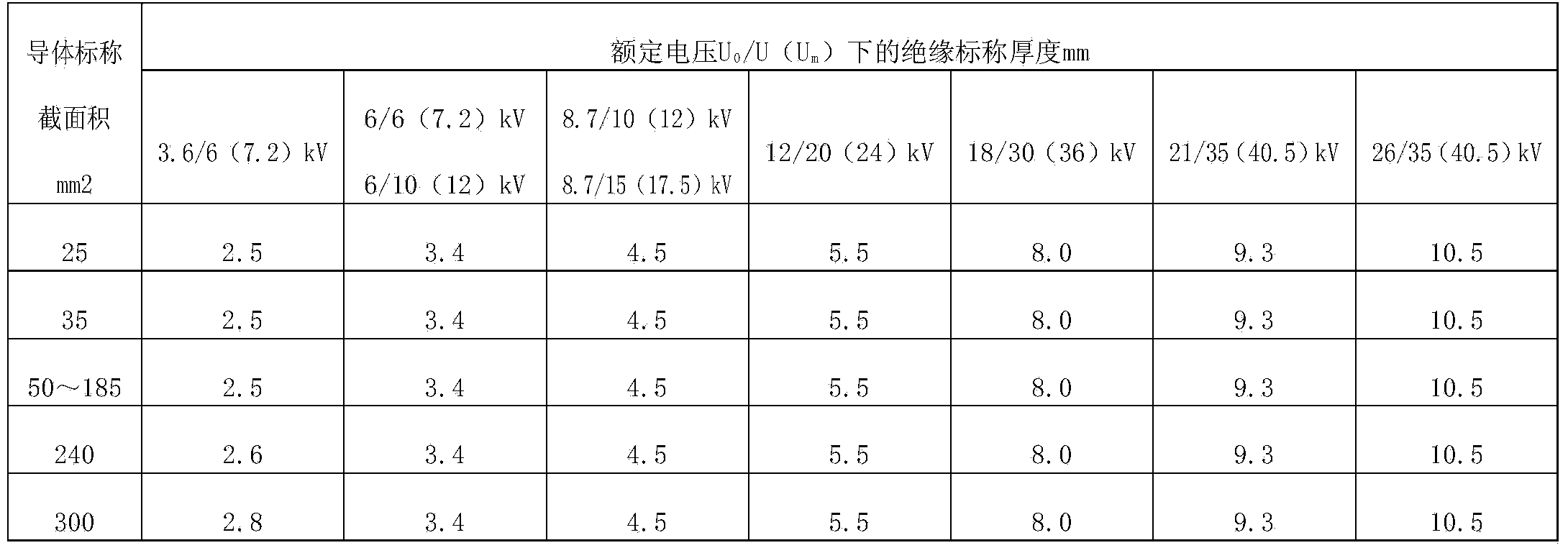

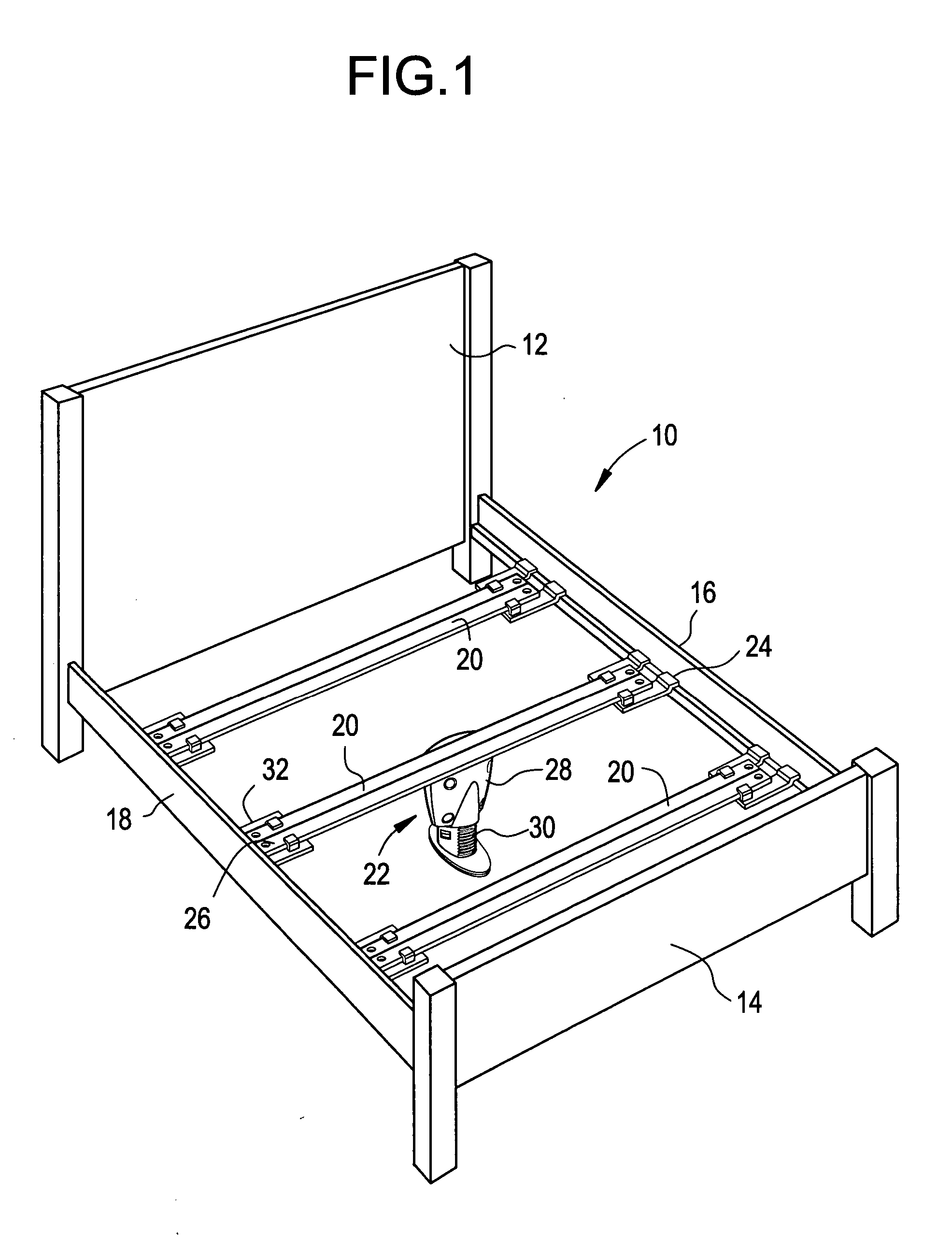

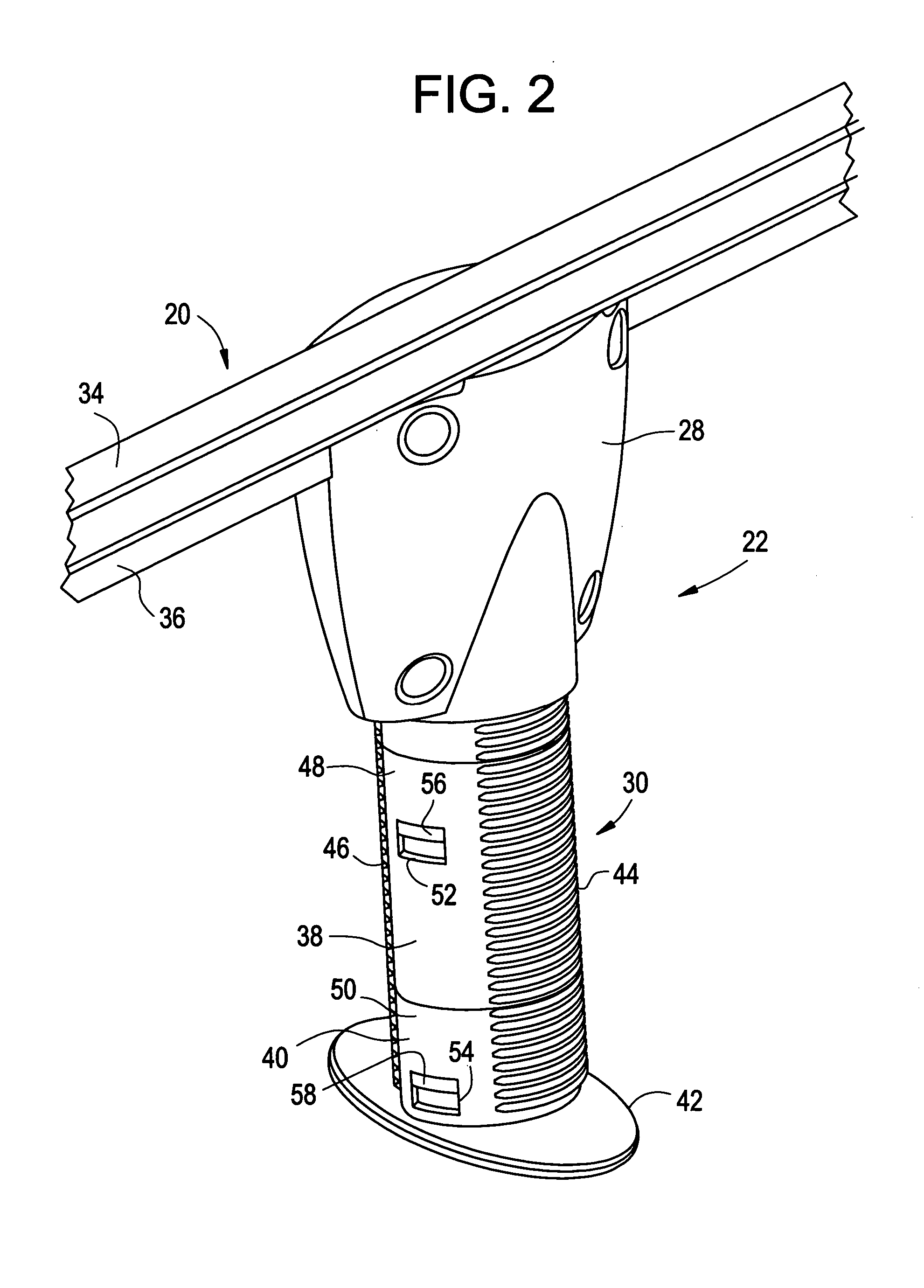

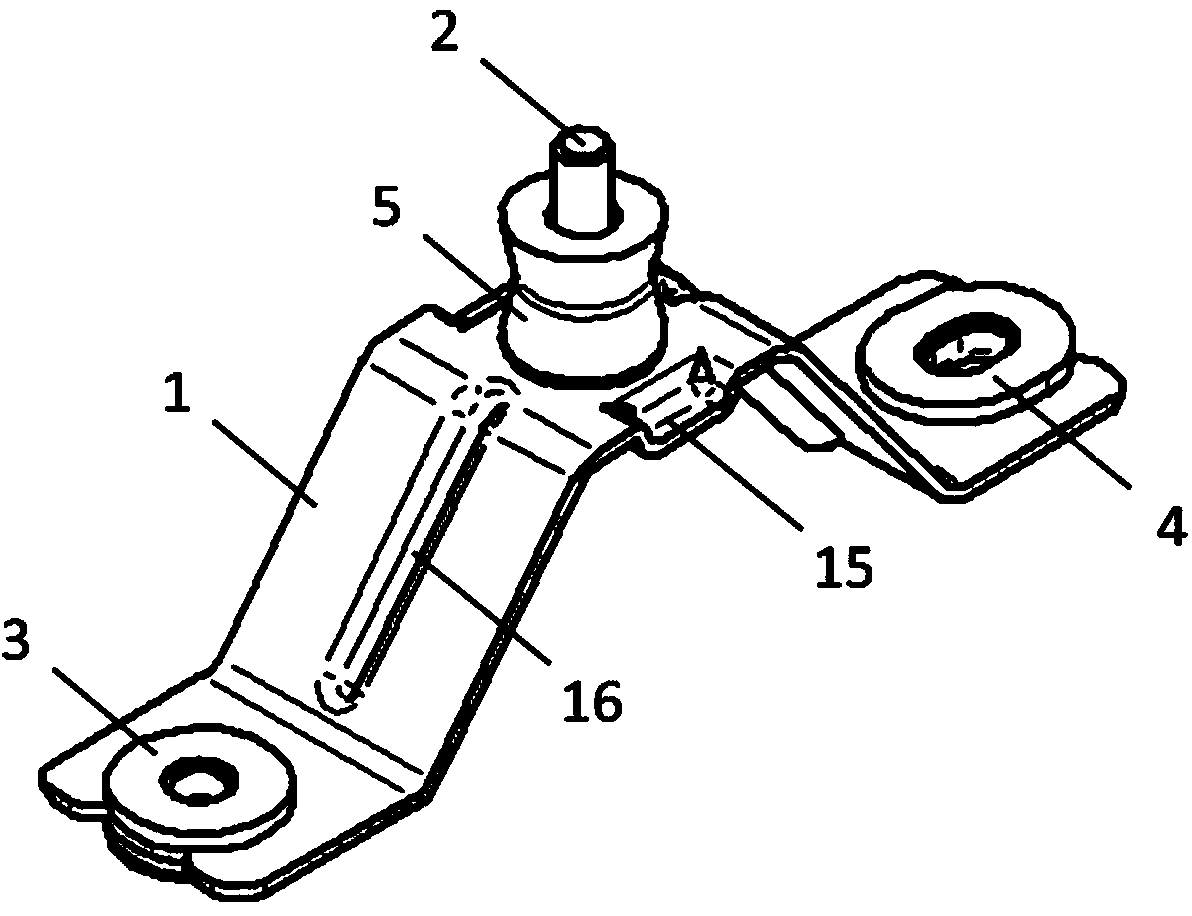

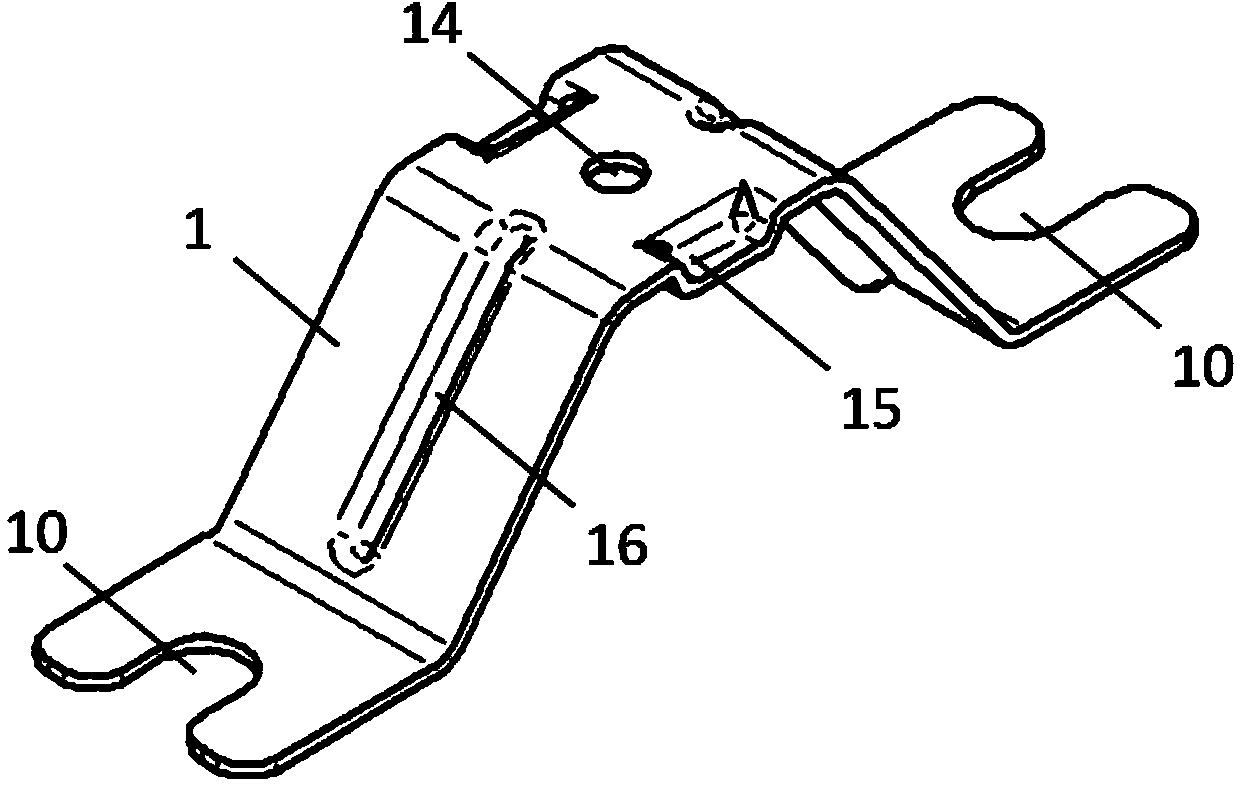

Support member for a bed frame

ActiveUS7219378B2Improved resistance to twistingReduces potential of damaging bendingSpring mattressesSofasEngineeringSelf adjusting

Owner:FINGER LAKES INTPROP

One piece flexible skateboard

ActiveUS20090058028A1Reduce distortionSufficient resistanceRider propulsionSkate-boardsEngineeringFoot supports

Owner:RAZOR USA

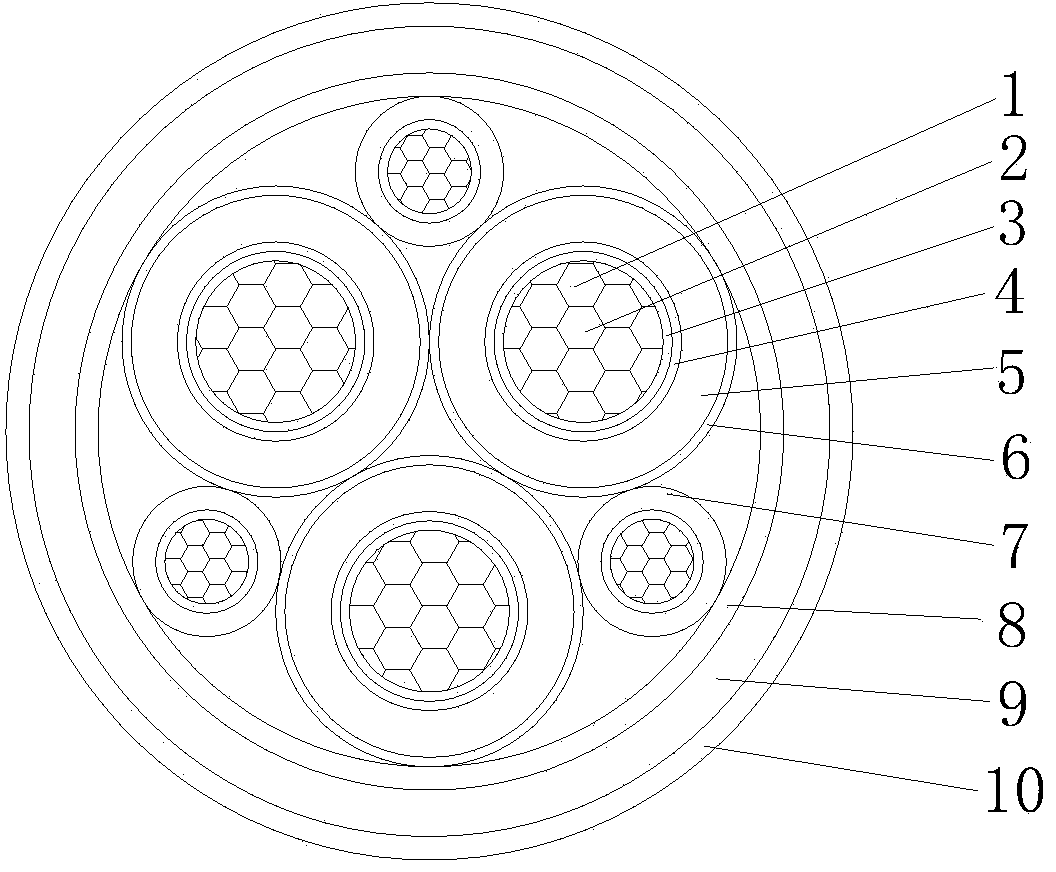

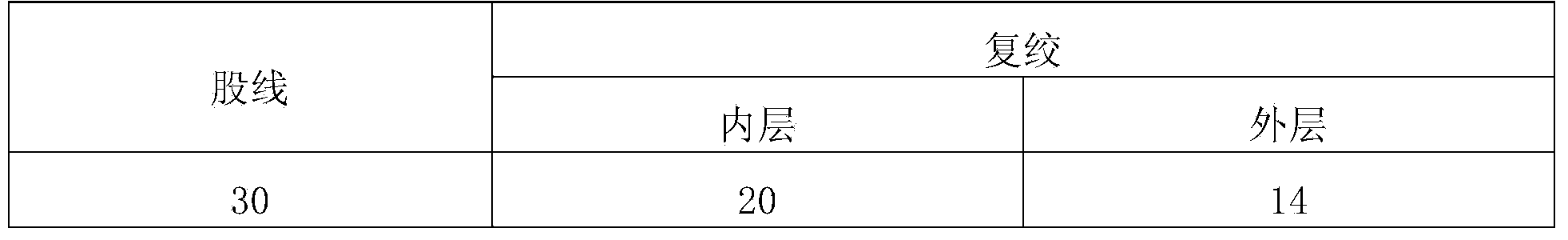

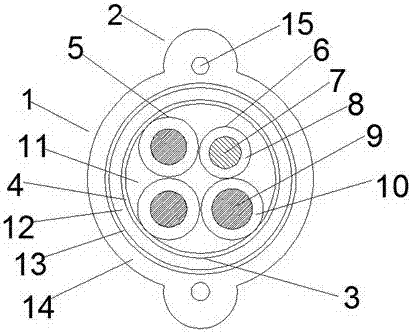

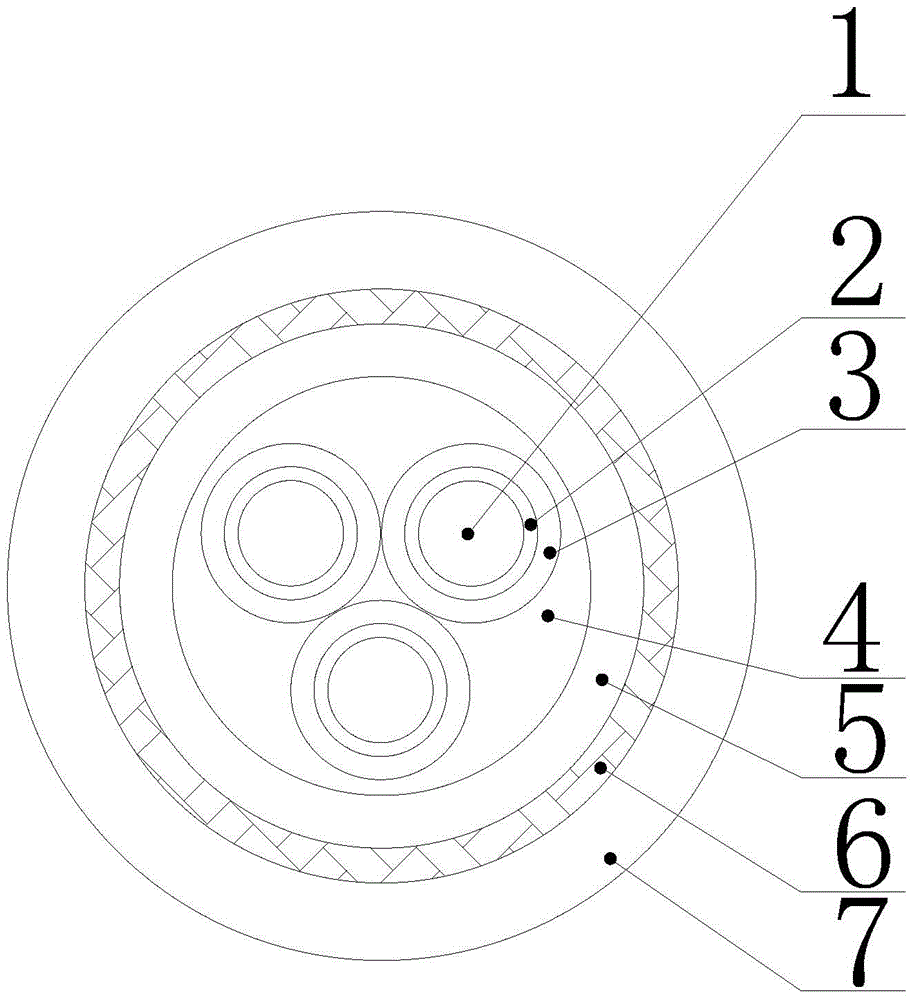

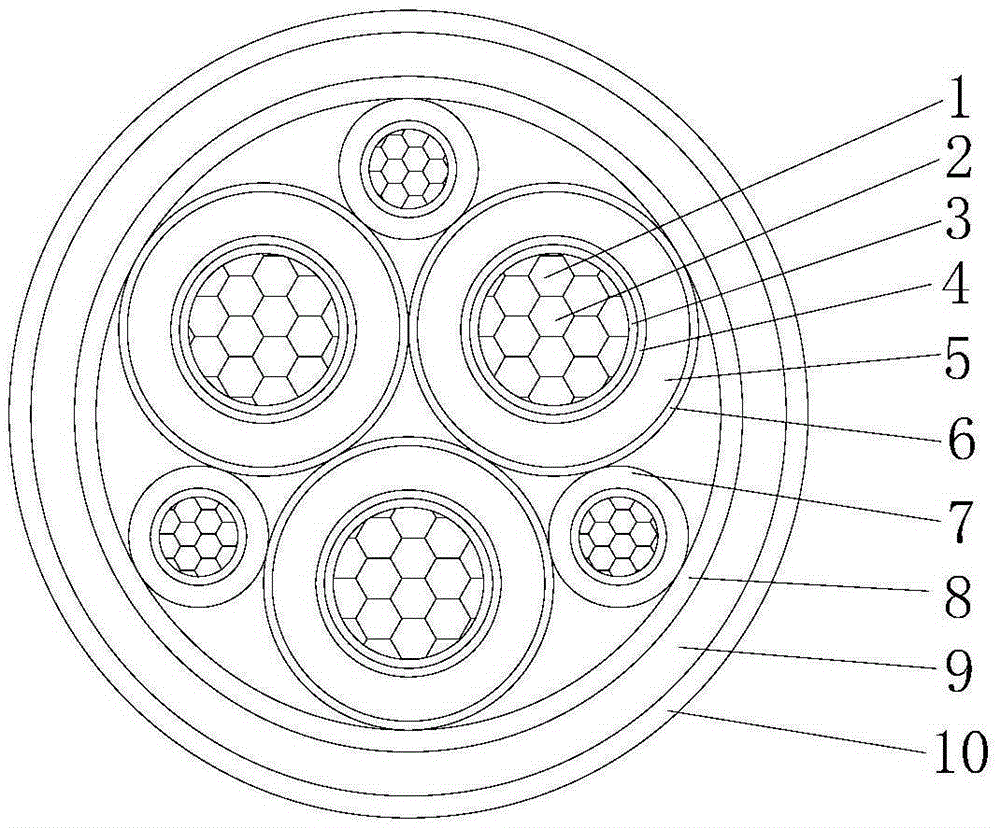

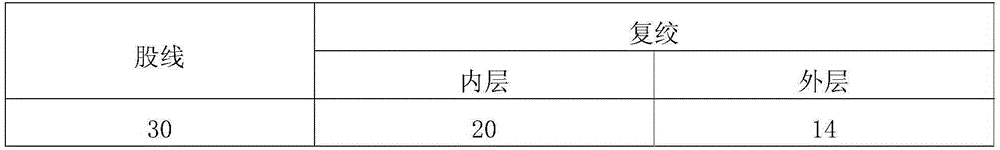

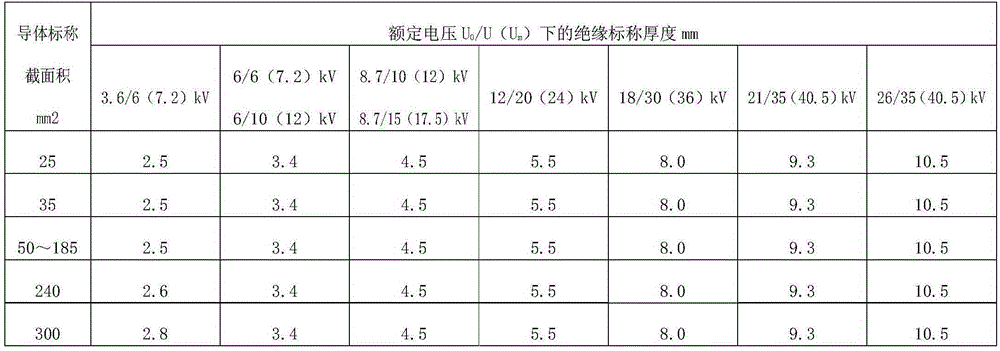

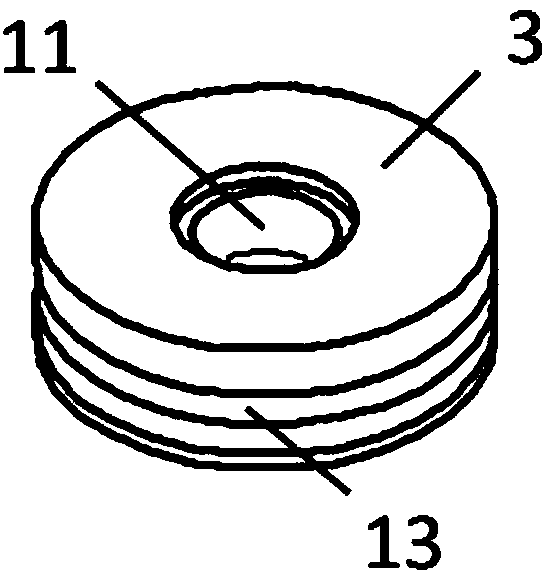

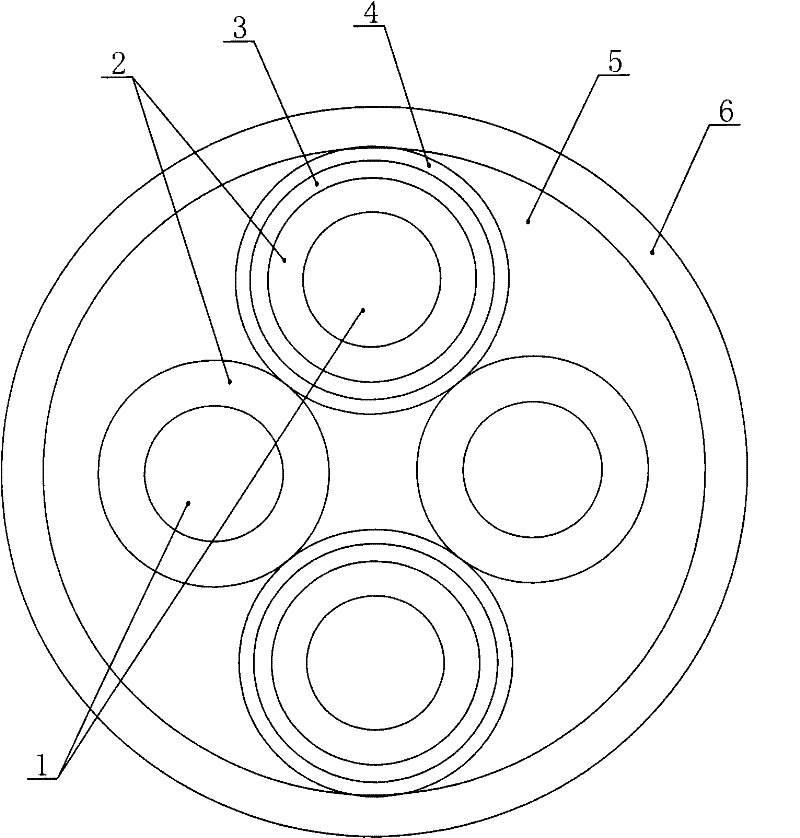

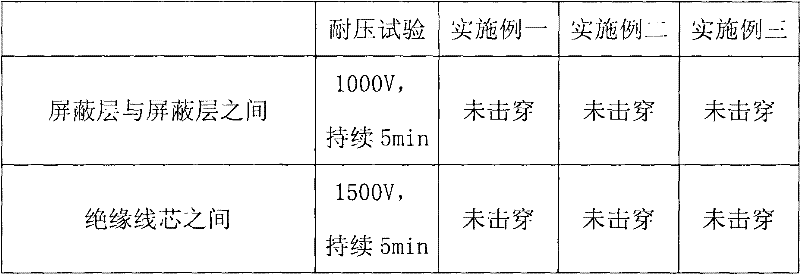

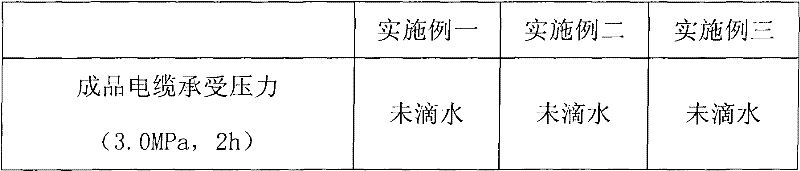

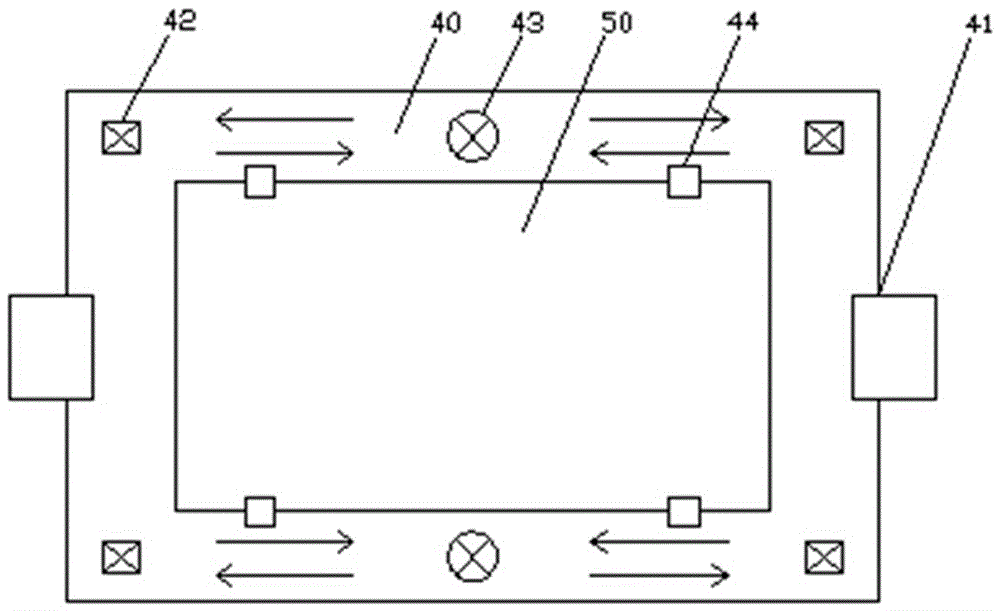

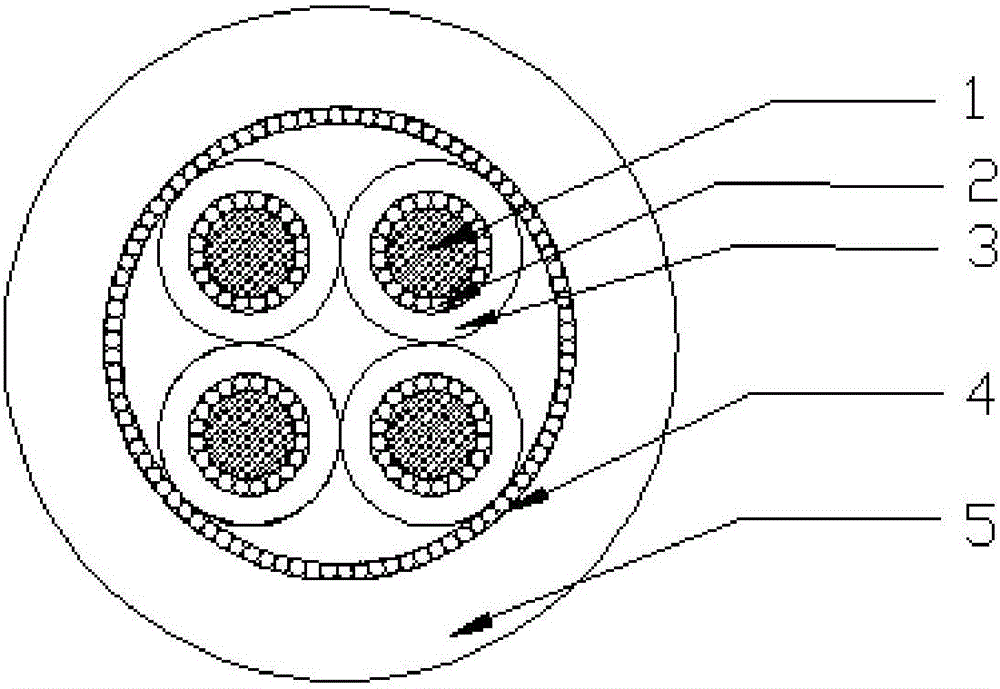

High-elasticity anti-twist wind energy cable with nominal voltage of six to thirty-five kilowatts and manufacturing method

ActiveCN103871615AHigh tensile strengthImprove electrical performanceNon-insulated conductorsClimate change adaptationPolyesterAlkali free

The invention discloses a high-elasticity anti-twist wind energy cable with the nominal voltage of six to thirty-five kilowatts. Three power insulated wire cores and three grounding insulation wire cores form a cable core in a twisted mode, the outer side of the cable core is sequentially provided with a two-layer alkali-free glass fiber band in an overlapped wrapping mode and a thermoplastic elastic outer jacket in an extruded wrapping mode, the outermost layer of the cable is a stainless steel wire, polyamide or polyester synthetic fiber yarn woven layer; each power insulated wire core forms a conductor by twisting tin-plated non-oxygen copper wires and stainless steel wires, each conductor is wrapped with a single-layer semi-conductive cotton tape wrapping layer in an overlapped wrapping mode, and a conduct shielding layer, an ethylene-propylene-diene monomer insulated layer and an insulated shielding layer form one power insulated wire core in an extruded wrapping mode; a semi-conductive rubber shielding layer is arranged on the outer side of each grounding insulation wire core conductor in an extruded wrapping mode. The high-elasticity anti-twist wind energy cable has the advantages of being high in extension strength, high in flexibility and abrasion resistance, resistant to oil, aging and outer environment weather and the like, and is suitable for connection portions of a turbine and a tower in a high-power wind power generation device and similar occasions.

Owner:新亚特电缆股份有限公司

Support member for a bed frame

A T-shaped support member that can be used with a bed frame or bed rails to provide support for a box spring and mattress. A leg assembly is affixed to the support member and is used to support the cross member. The leg assembly includes a housing having a leg that extends downwardly from the support member to contact the floor on which the bed frame or bed rails are located. The length the leg is extendable from the support member is self adjusting by a mechanism that can be twisted to an unlocked position to drop the leg downwardly quickly to contact the floor and then twisted back to lock the leg in that extended length.

Owner:FINGER LAKES INTPROP

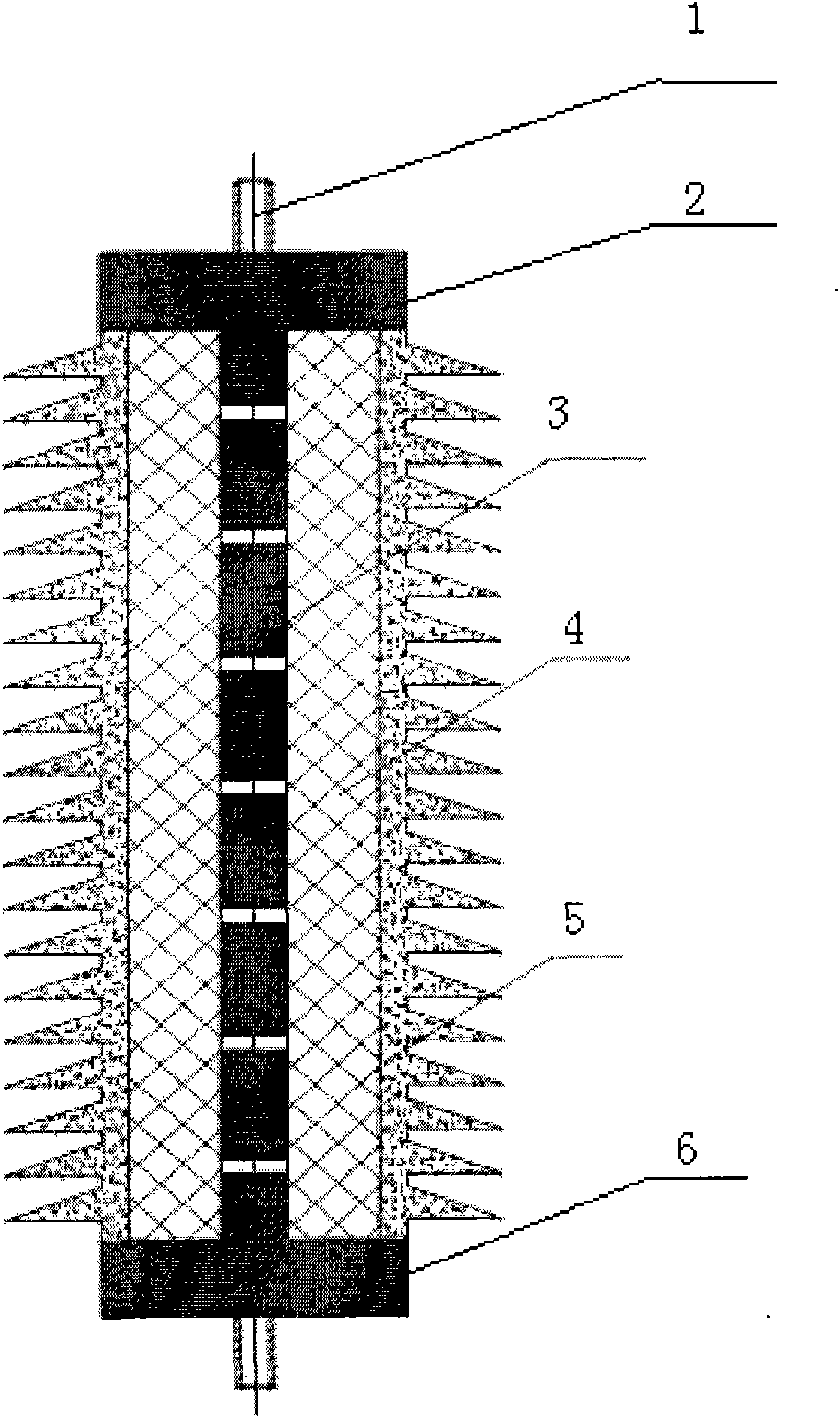

Polymeric housed arrester and method for preparing no-local-discharge compound-glass fiber winding pipe

InactiveCN101866731AImprove impact resistanceReduce weightSparking plugsRigid pipesEpoxyNumerical control

The invention discloses a method for preparing a no-local-discharge compound-glass fiber winding pipe. The preparation method comprises the following steps of: coating a release agent on the surface of a core module; arranging the core module on a numerical-control winding machine; automatically completing a winding process controlled by a microcomputer; winding fiber or alkali-free Worland clothes on the core module; preparing a resin adhesive, wherein the resin adhesive comprises epoxide resin, a curing agent, a toughener, silicon dioxide and a defoaming agent; injecting the resin adhesive in vacuum, stopping injecting the resin adhesive, closing a valve ladder and heating for solidifying and molding. The polymeric housed arrester has simple structure, light weight, good toughness, strong shock resistance capability, high tensile strength, high bending resistance, high twist resistance and more precise fiber distribution and is widely used for a power electric network, a transformer station and a communication device.

Owner:陕西泰普瑞电工技术有限公司

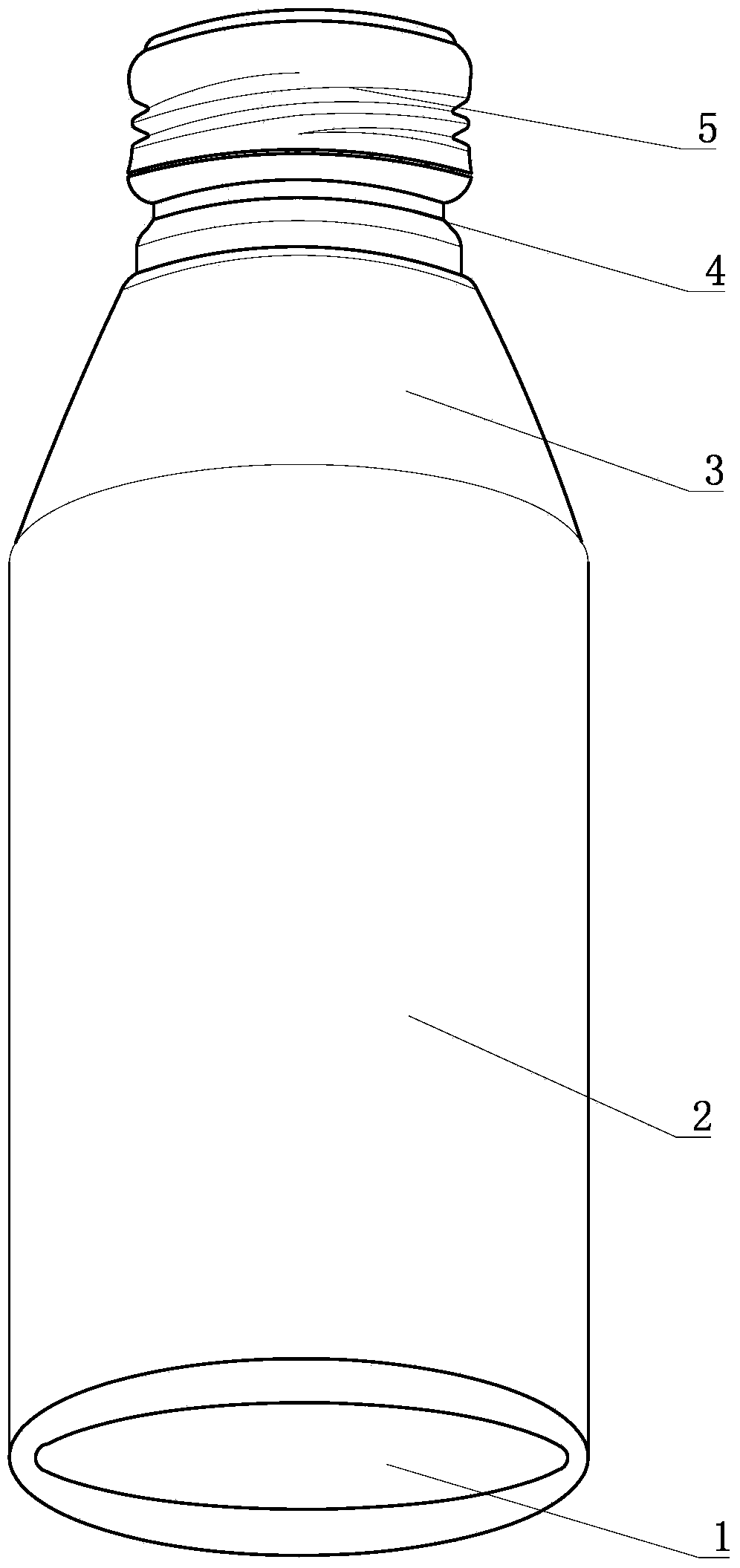

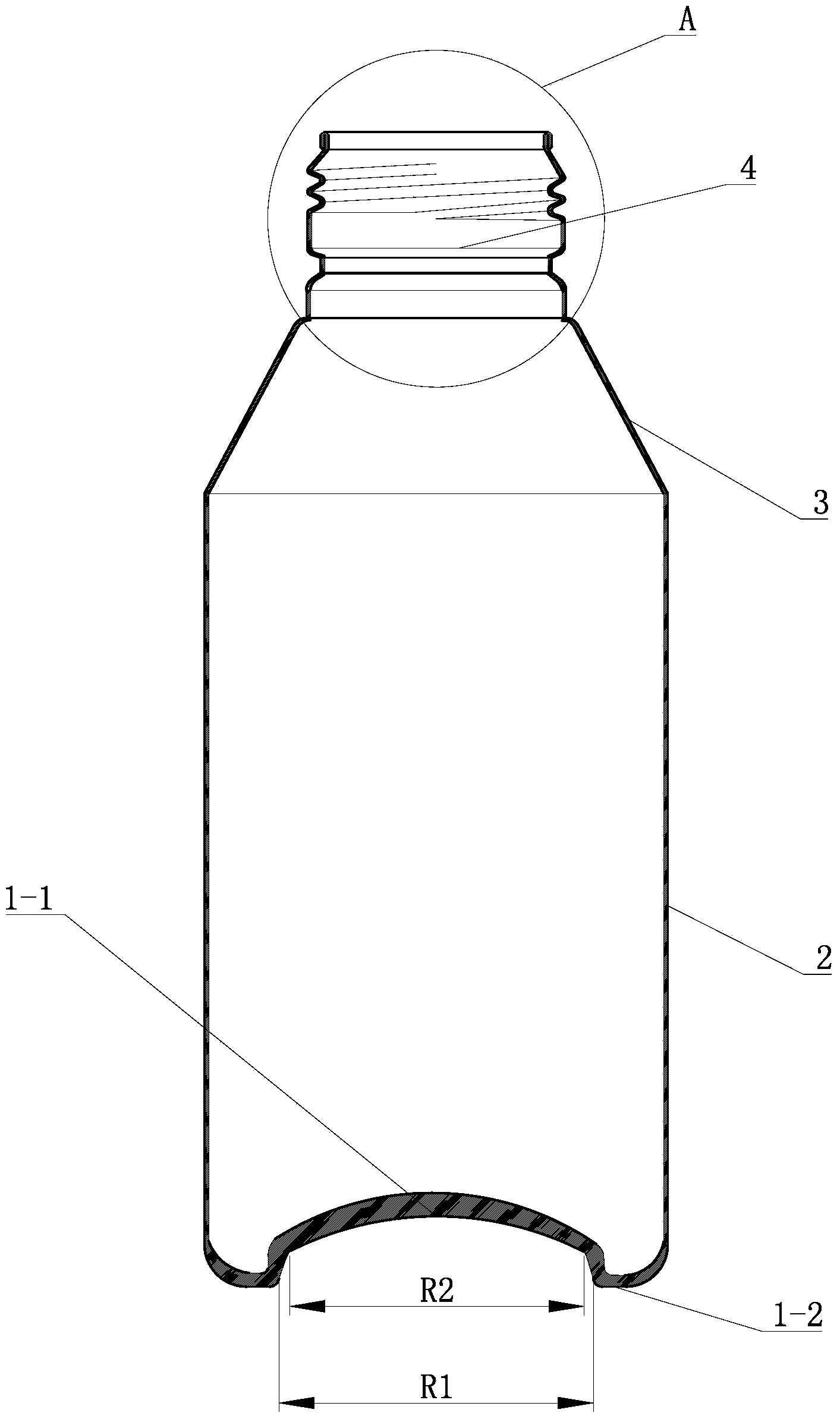

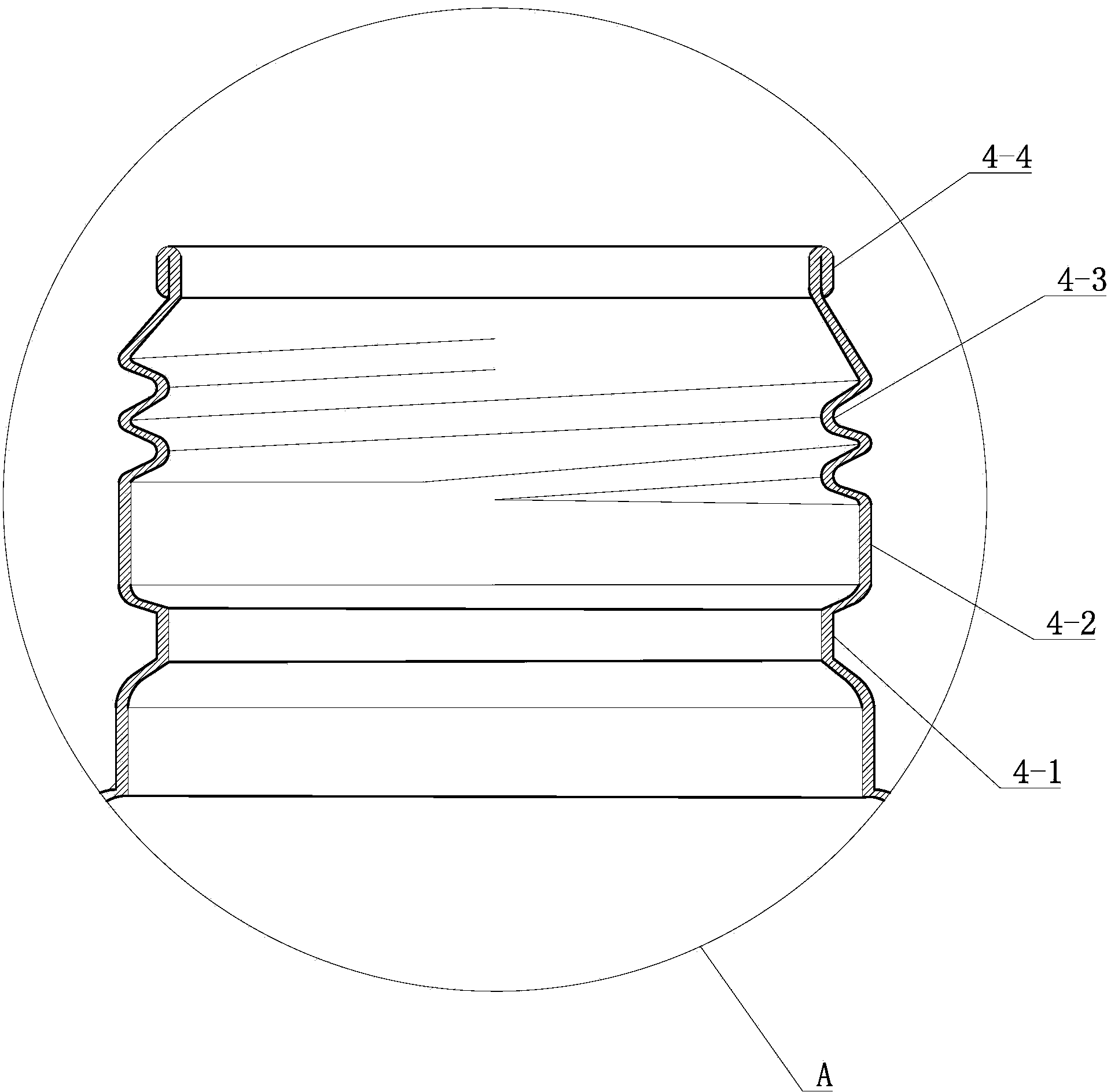

Aluminum thin-wall screw beverage bottle and manufacturing method thereof

InactiveCN103818601AChange the disadvantage of having more residuesDry fastBottlesBottle neckThin walled

The invention discloses an aluminum thin-wall screw beverage bottle. The aluminum thin-wall screw beverage bottle comprises a bottle bottom (1), a bottle cylinder (2), a bottle shoulder (3), a bottle neck (4) and a bottle cover (5), wherein the bottle bottom (1) comprises a recess part (1-1) and a supporting part (1-2); the recess part (1-1) is recessed into the bottle; the supporting part (1-2) is used for supporting a bottle body; the first diameter (R1) of the bottom of the recess part (1-1) is greater than the second diameter (R2) of the top of the recess part (1-1); the supporting part (1-2) encircles the bottle bottom for a circle to form an annular shape; the thickness of the bottle bottom (1) is 0.25-0.70mm; the thickness of each of the bottle cylinder (2), the bottle shoulder (3) and the bottle neck (4) is 0.02-0.08m; an annular groove (4-1), an annular convex edge (4-2) and an external thread (4-3) are sequentially formed in the bottle neck (4) from bottom to top; a bottle opening (4-4) is formed in the top of the bottle neck (4) by folded edges.

Owner:GUANGDONG EURO ASIA PACKAGING

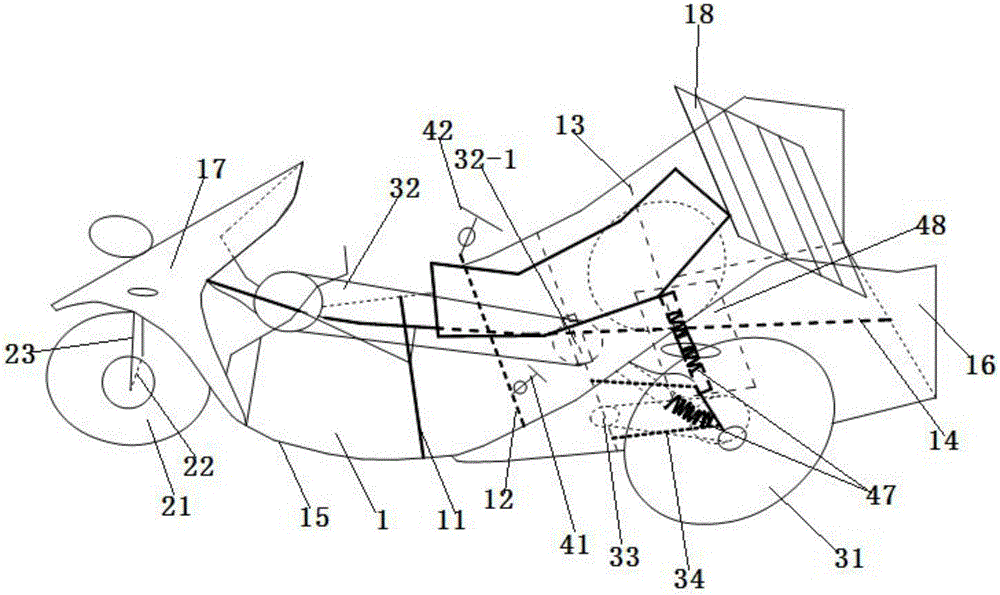

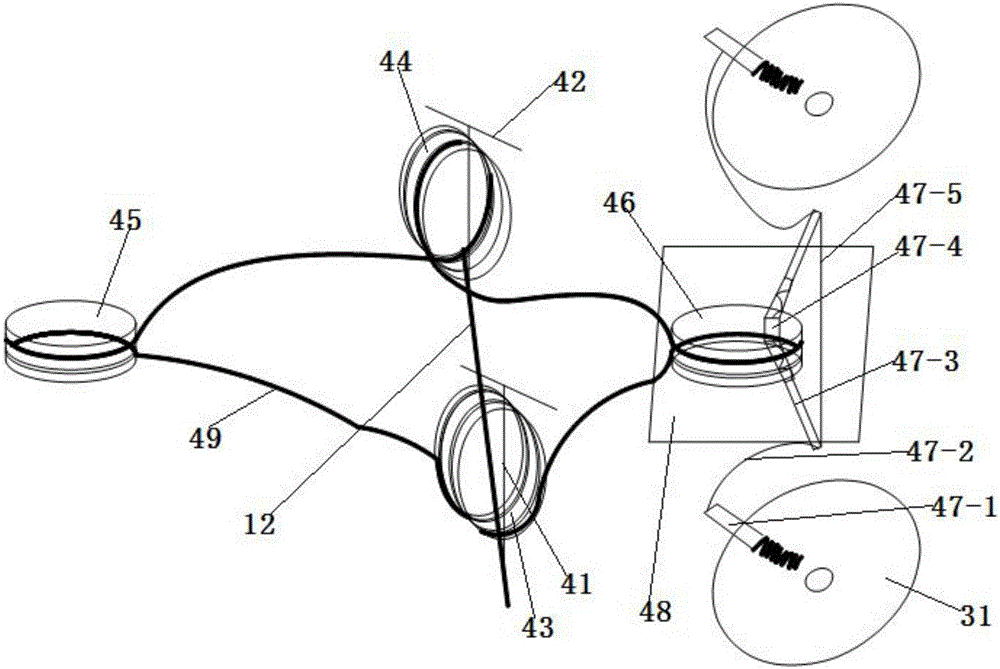

Recreational lying type bicycle for all road conditions

InactiveCN105857472AReduce bumpsImprove bending resistanceFoldable cyclesWeather guardsVehicle frameShock resistance

The invention discloses a recreational lying type bicycle for all road conditions, and belongs to the technical field of transportation means. The recreational lying type bicycle comprises a frame and a rear wheel hanging mechanism. The frame is of a foldable three-longitudinal-beam type structure. The rear wheel hanging mechanism comprises two rear wheels, a rear transmission device, two transmission shaft assemblies and two swing arms. Each transmission shaft assembly comprises a left half shaft and a right half shaft. The rear wheels can be independently hung and can be driven when damping is achieved, the bending resistance, torque resistance and shock resistance of the frame are greatly improved, shock is reduced, and the bicycle is comfortable to ride and suitable for being ridden in various road conditions; the bicycle is controlled to make a turn by driving a pull wire through a handlebar; meanwhile, by adjusting the hanging heights of the left rear wheel and the right rear wheel and making the bicycle incline in the turning direction, the safety is ensured when the lying type bicycle makes a turn at high speed; by means of alternating electric and manpower dual-drive hybrid, different use requirements are met; the bicycle is reasonable in structure, ingenious in design, high in stability, suitable for long-distance riding and high in practical value.

Owner:刘矿成

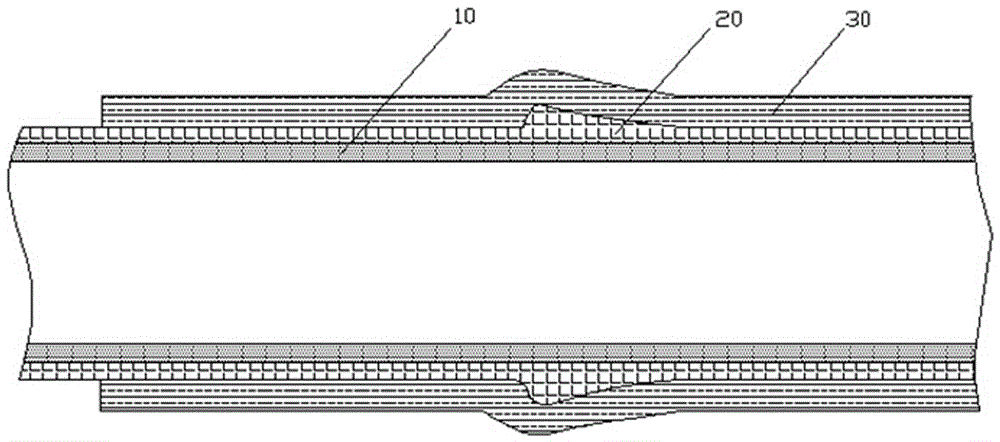

Wear-resistant waterproof rubber flexible cable of suspender

InactiveCN107086076AGood flexibilityImprove ductilityNon-insulated conductorsConductive materialAviationWear resistant

The invention provides a wear-resistant waterproof rubber flexible cable of a suspender. The cable comprises a cable body and projections arranged symmetrically at the upper and lower ends of the cable body, and the cable body is composed of a cable core, an inner sheath, a bearing reinforced layer and an oversheath; the cable core is composed of a water-blocking tape wrapping layer and an internal core; the cable core is internally provided with three power cores and a grounding core; the water-blocking tape wrapping layer is extruded outside the power cores and the grounding core; the inner sheath is extruded outside the cable core; the bearing reinforced layer is extruded outside the inner sheath; the oversheath is extruded outside the bearing reinforced layer; and bearing steel ropes are arranged in the projections respectively. According to the structure of the cable, two high-intensity aviation steel ropes are added symmetrically and serve as bearing carriers when the oversheath is extruded, the cable has a large bearing capability as well as high mechanical, wear-resistant, corrosion-resistant, cold-resistant and waterproof performances, and the cable is especially suitable for suspenders of hoisting equipment.

Owner:ANHUI LINGYU CABLE TECH

Pipeline repairing method

The invention discloses a pipeline repairing method. During a pipeline repairing process, a steel bar is inserted into a first liner in a penetrating mode after a pipeline is cleaned, then the first liner with the inserted steel bar is placed in the pipeline to be repaired, the first liner and the inner wall of the pipeline are attached through an air bag, then grouting materials are injected into a gap formed between the inner wall of the pipeline and a liner plate of the first liner, and after the grouting materials are condensed, pipeline repairing is completed. According to the pipeline repairing method, the condensed grouting materials are grabbed through a supporting piece, the steel bar is inserted between the grouting materials in a penetrating mode, so that the intensity of the grouting materials is greatly improved, and the pressure-resisting capacity, the shock-resisting capacity, the distorting-resisting capacity, the impact-resisting capacity and the like of the repaired pipeline are improved as a whole substantially.

Owner:SHENZHEN VICQUICK ENG TECH

Power cable for marine engineering equipment and preparation technology thereof

InactiveCN104795161ASmall sizeHigh mechanical strengthClimate change adaptationInsulated cablesElectrical conductorCopper wire

The invention relates to the technical field of manufacture of cables for marine engineering equipment, and specifically refers to a power cable for marine engineering equipment and a preparation technology thereof. The cable comprises a cabling wire core which is formed by stranding a plurality of insulated wire cores. Each insulated wire core comprises a cable conductor formed by stranding a plurality of tinned copper wires, the cable conductor is wrapped with a fireproof layer, and the fireproof layer is wrapped with an insulating layer. The outer layer of the cabling wire core is provided with an oil-resistant inner sheath layer, and a filling rope is arranged between the oil-resistant inner sheath layer and the insulated wire cores. The outer layer of the oil-resistant inner sheath layer is provided with a braided armoring layer, and an oil-resistant outer sheath layer is arranged outside the braided armoring layer in an extruding manner. The power cable for marine engineering equipment disclosed by the invention has the characteristics of compact structure, high mechanical strength, flame retardancy, ultraviolet resistance, fireproofing, high oil resistance, and no pollution after combustion. Because of the improvement of the preparation technology, the overall mass of the cable is reduced and optimized obviously, and the distortion resistance of the cable is improved greatly.

Owner:ANHUI STAR CABLE

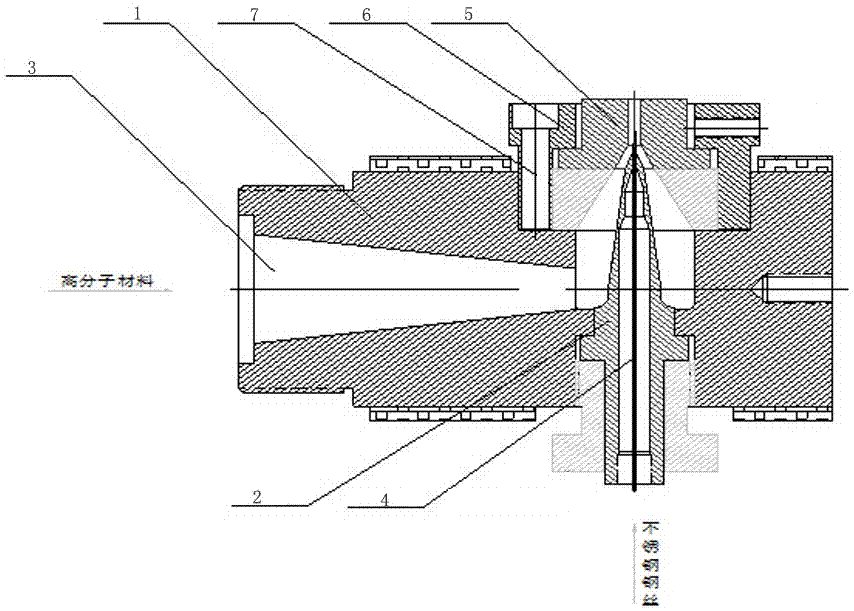

Machining method of micropore catheter

ActiveCN107031006AImprove bending resistanceImproved resistance to twistingDomestic articlesCoatingsCatheterDiameter control

The invention relates to the technical field of medical instruments, in particular to a forming process of a micropore catheter, and aims at providing a machining method of the micropore catheter. According to the machining method, a micropore structure can be formed, micropores are uniform in size, and the micropores are not likely to be blocked. A steel wire and a polymer material are subjected to joint extrusion forming, the surface of the steel wire is coated with the polymer material, in other words, the steel wire is implanted in the center of the catheter, the micropores are formed after the steel wire is drawn out, the sizes of the micropores are controlled by controlling the diameter of the steel wire, meanwhile, the surface of the steel wire is spray-coated or soaked with medical silicon oil, the problems that due to the characteristics of materials, after the surface of a steel wire is wrapped by the materials, the materials easily adhere to the steel wire, and the steel wire cannot be drawn out are solved, the micropore structure can be formed in the catheter, the micropores are uniform in size, and the walls of the micropores are smooth and free of adhesion.

Owner:ZHEJIANG FERT MEDICAL DEVICE

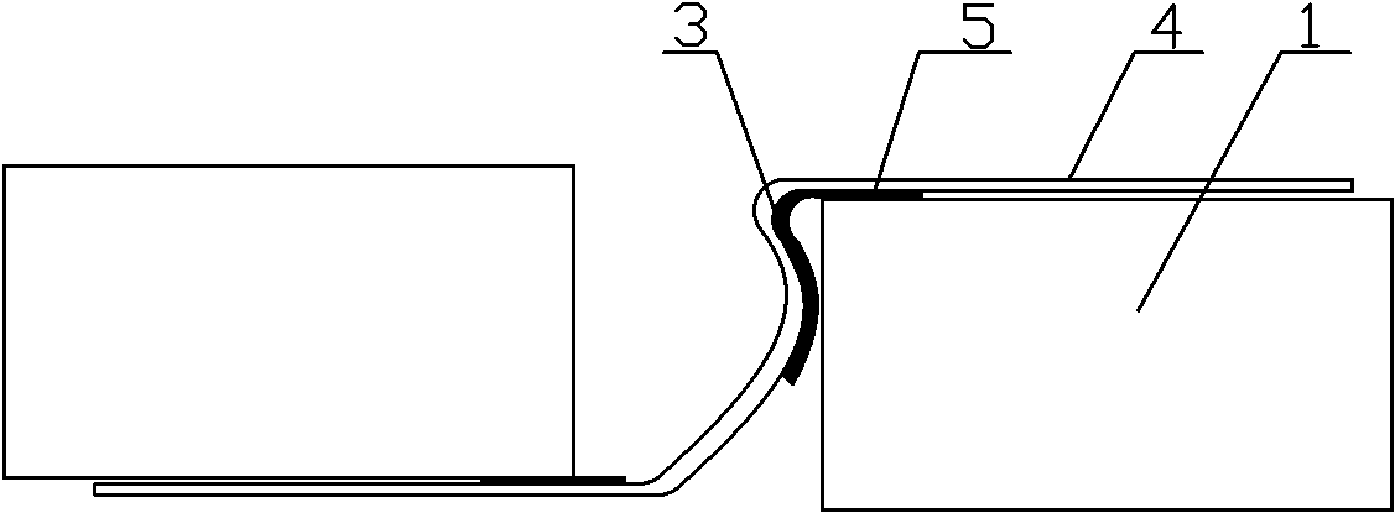

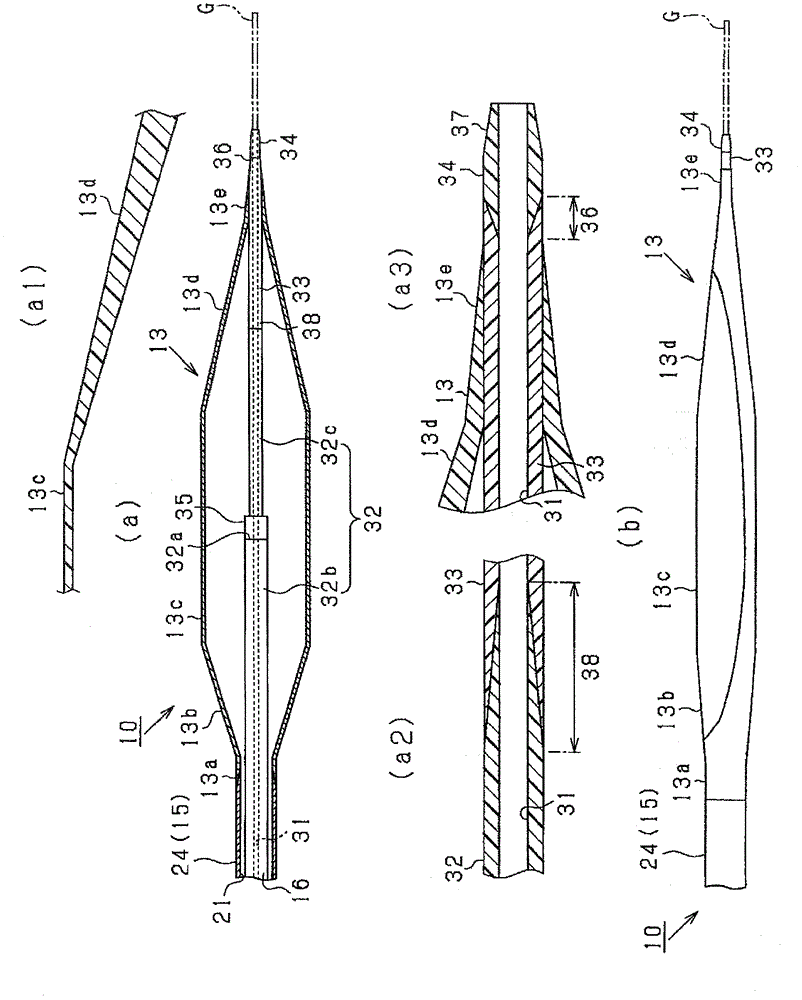

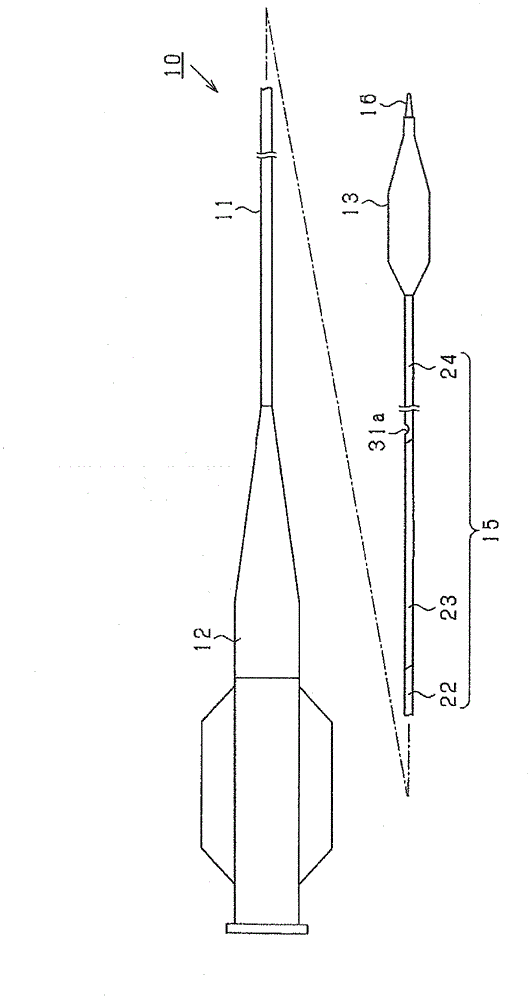

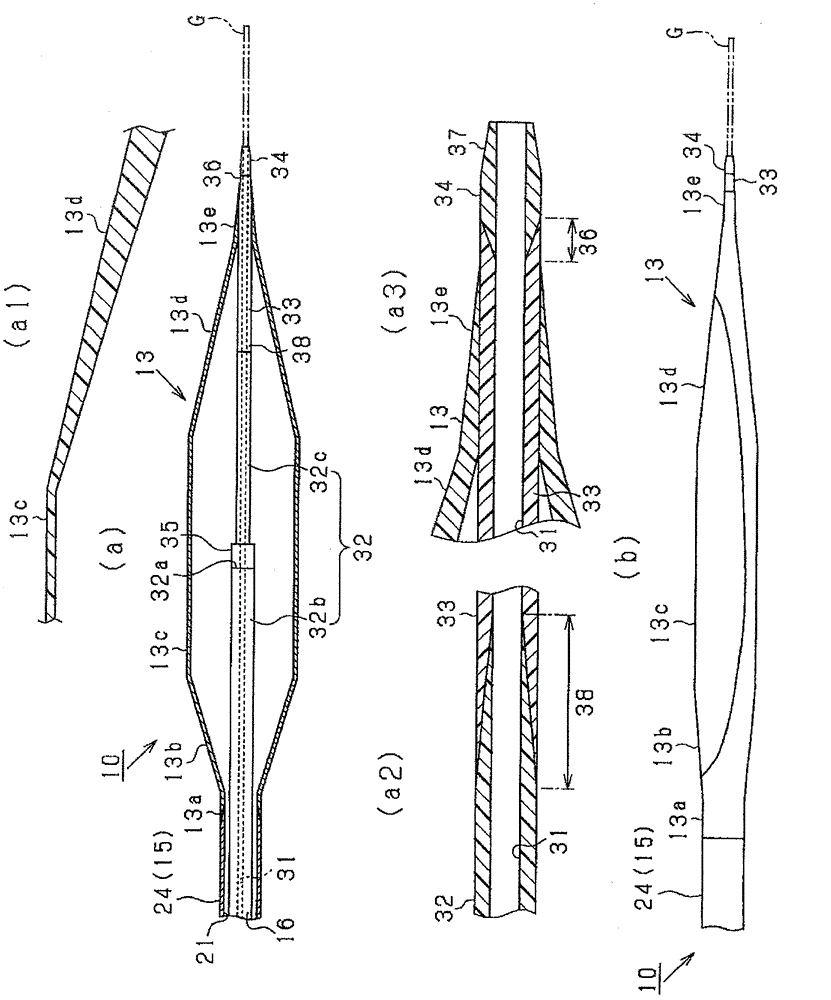

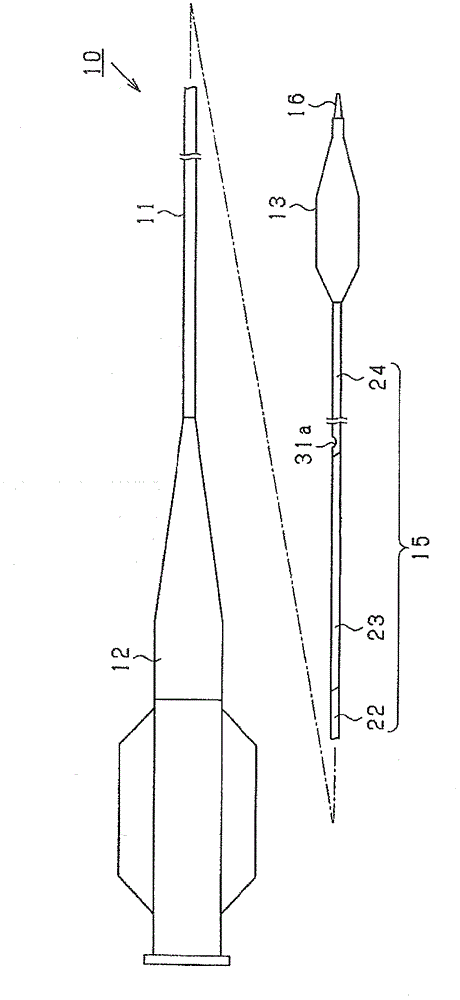

Balloon catheter

ActiveCN102793964AImproved resistance to twistingStentsBalloon catheterInsertion stentBalloon catheter

The invention relates to a balloon catheter, which enables the stability to be improved on the basis of supporting a balloon and enables the flexibility of a remote end part to be improved. The balloon catheter (10) comprises an outside pipe (15) and an inside pipe (16). The inside pipe (16) is extended to a position further than the outside pipe (15), and the balloon is arranged in a manner of covering from the outside and extended out of the region. The inside pipe (16) possesses an inside intermediate pipe (33) and an inside remote pipe (34) of which the rigidity is lower than that of the inside intermediate pipe (33). On the condition, the joint position of the inside intermediate pipe (33) and the inside remote pipe (34) exists a position further than the remote side bracket region (13e) of the balloon (13).

Owner:GOODMAN & COMPANY

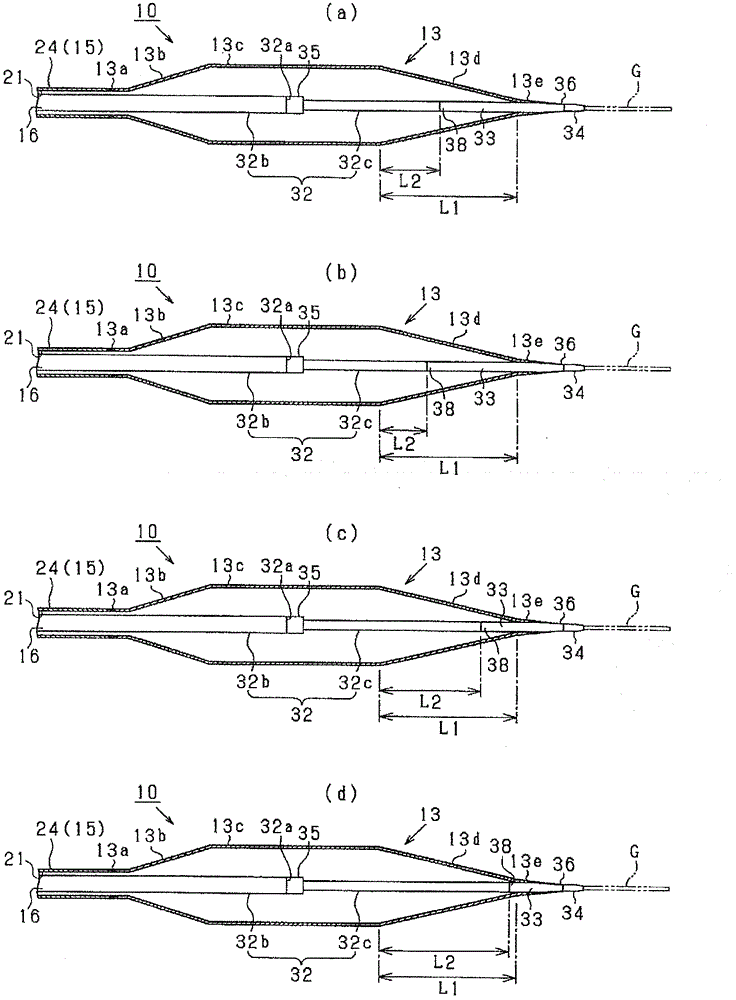

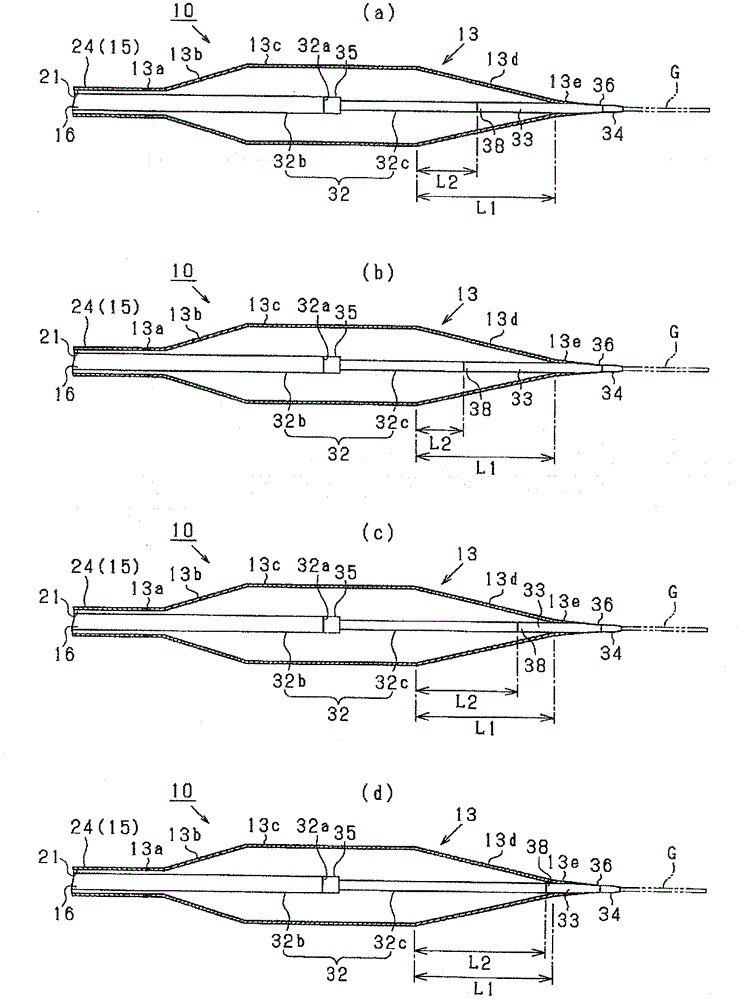

Air bag catheter

ActiveCN102743814AImprove support stabilityGood flexibilityStentsBalloon catheterInsertion stentEngineering

The present invention provides an air bag catheter increasing the flexibility of a far position end portion, wherein inside the air bag catheter, the rigid optimization of an area provided with the air bag is realized. The air bag catheter (10) is provided with an outer side pipe (15) and an inner side pipe (16), wherein the inner side pipe (16) is arranged to extend to the position of a far position side compared with the outer side pipe (15) and provided with an air bag (13) in a manner of covering the extended area from the outer side, and the inner side pipe (16) is provided with an inner side near position pipe (32) and an inner side middle pipe with a lower rigidity than the inner side near position pipe (32). Under such conditions, the far position end portion of the inner side near position pipe (32) is arranged at a position where the boundary of a far position side cone-shaped area (13d) and the far position side support area (13e) is near the near position side and the boundary of the straight pipe area (13c) of the air bag and the far position side cone-shaped area (13d) is near the far position side in the axial direction.

Owner:GOODMAN & COMPANY

Rated-voltage 6-35kV high-elasticity distortion-resistant wind power cable and manufacture method

ActiveCN105321627AHigh tensile strengthImprove electrical performanceClimate change adaptationInsulated cablesPolyesterYarn

The invention discloses a rated-voltage 6-35kV high-elasticity distortion-resistant wind power cable. The rated-voltage 6-35kV high-elasticity distortion-resistant wind power cable is characterized in that a cable core is formed by stranding three power insulation cores and three grounding insulation cores, a dual-layer alkali-free glass-fiber strip and a thermoplastic elastomer are sequentially arranged outside the cable core respectively in a wrapping manner and in an extruding manner, and an outermost layer of the cable is a braid layer consisting of stainless steel wires and polyester synthetic fiber yarns; each power insulation core adopts a tinned oxygen-free copper wire and a stainless steel wire to form a conductor in a stranding manner, a single layer of semiconductor cotton-cloth strip is wrapped outside the conductor, and a conductor shielding layer, an EPDM rubber insulation layer and an insulation shielding layer are co-extruded to form the power insulation core; a conductor of each grounding insulation core is provided with a semiconductor rubber shielding layer in an extruding manner. The cable has characteristic of high tensile strength, high flexibility, high wearability, oil resistance, aging resistance, external environmental weather resistance and the like and is applicable to the junction between a turbine motor and a tower barrel in a high-power wind power generating device or other similar fields.

Owner:新亚特电缆股份有限公司

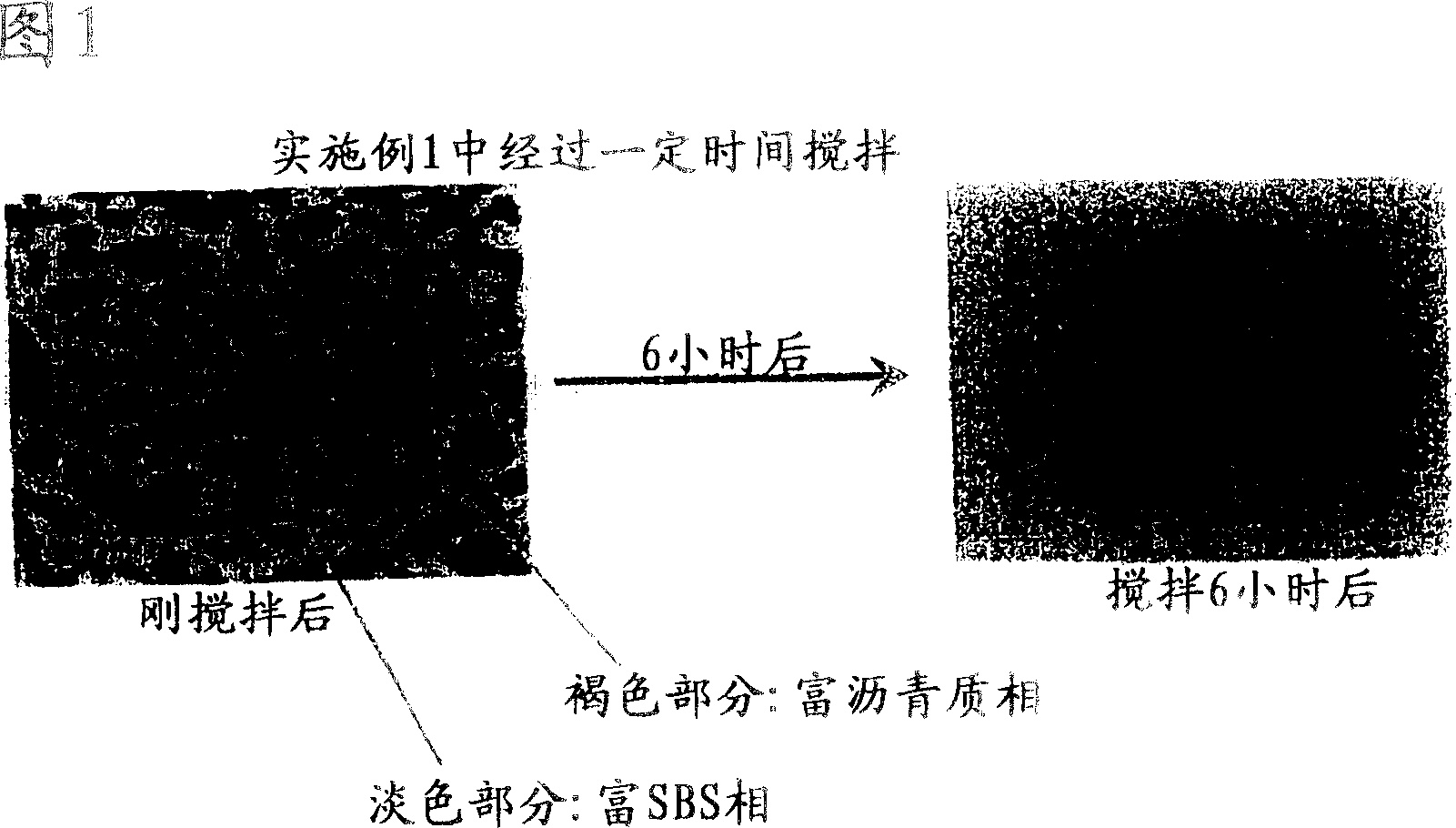

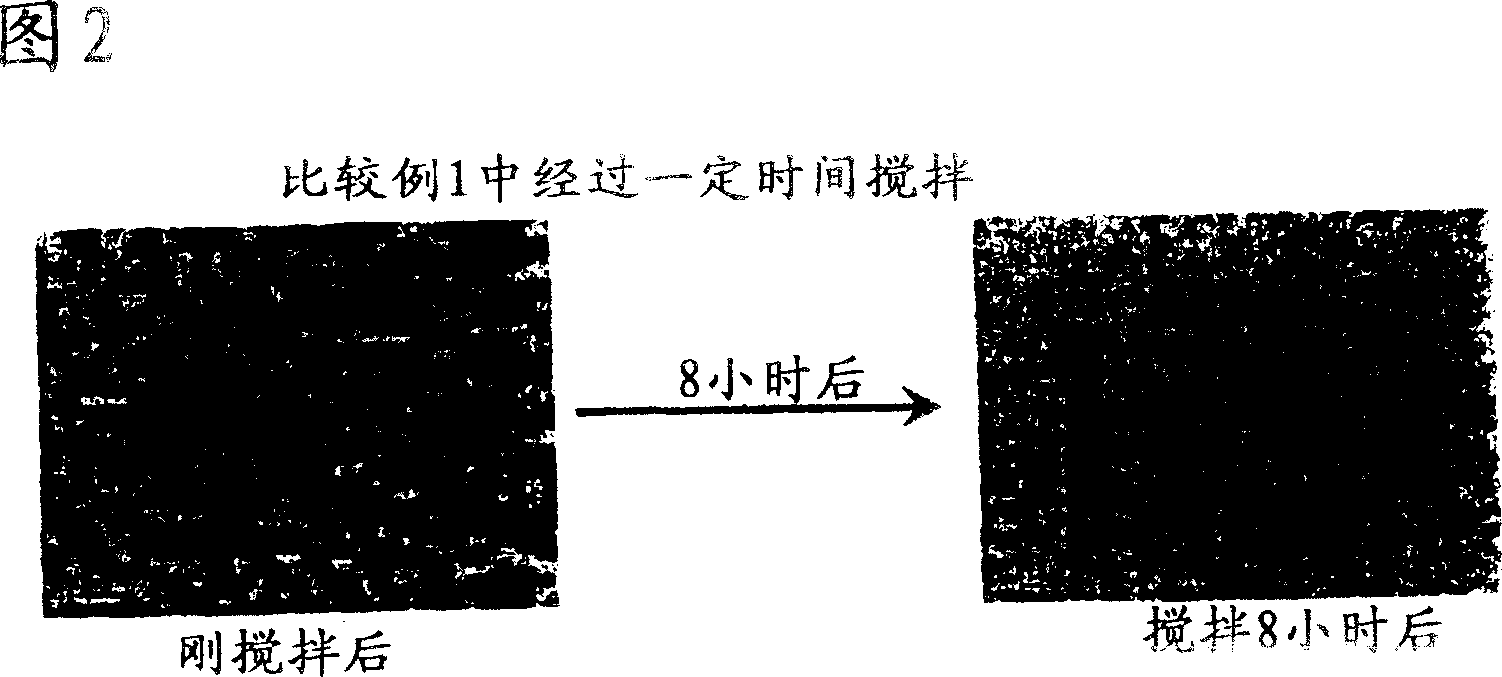

Block copolymer composition for asphalt modification, process for producing the same, and asphalt composition

InactiveCN1969011AImprove solubilityExcellent toughness and elasticityBuilding insulationsHigh temperature storageSolubility

A block copolymer composition for asphalt modification which is excellent in solubility in asphalt and high-temperature storage stability, has a low melt viscosity, and attains excellent asphalt properties, especially torsion resistance; and an asphalt composition. The block copolymer composition for asphalt modification comprises (i) a block copolymer comprising at least two polymer blocks formed mainly from an aromatic vinyl compound and at least one polymer block formed mainly from a conjugated diene and (ii) a block (co)polymer which comprises one or more aromatic vinyl polymer blocks as an essential component and optionally further contains one or more polymer blocks formed mainly from a conjugated diene and in which the peak molecular weight thereof in terms of standard polystyrene, as measured by gel permeation chromatography (GPC), is less than 1 / 3 the peak molecular weight of the block copolymer (i), the (i) / (ii) proportion being (95-70) / (5-30) (by weight). The asphalt composition is obtained by adding the modifying composition to asphalt.

Owner:KRATON JSR ELASTOMERS KK

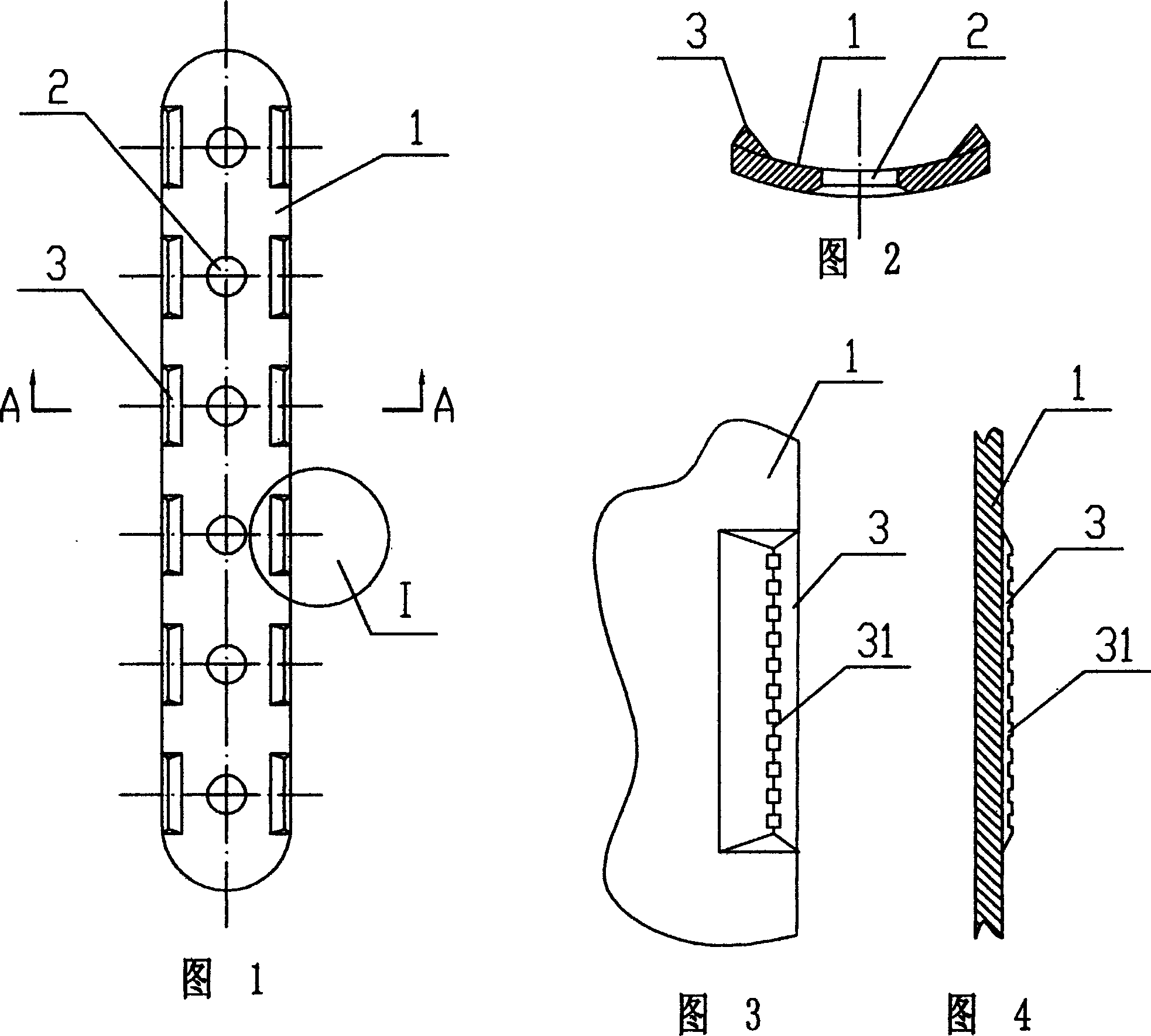

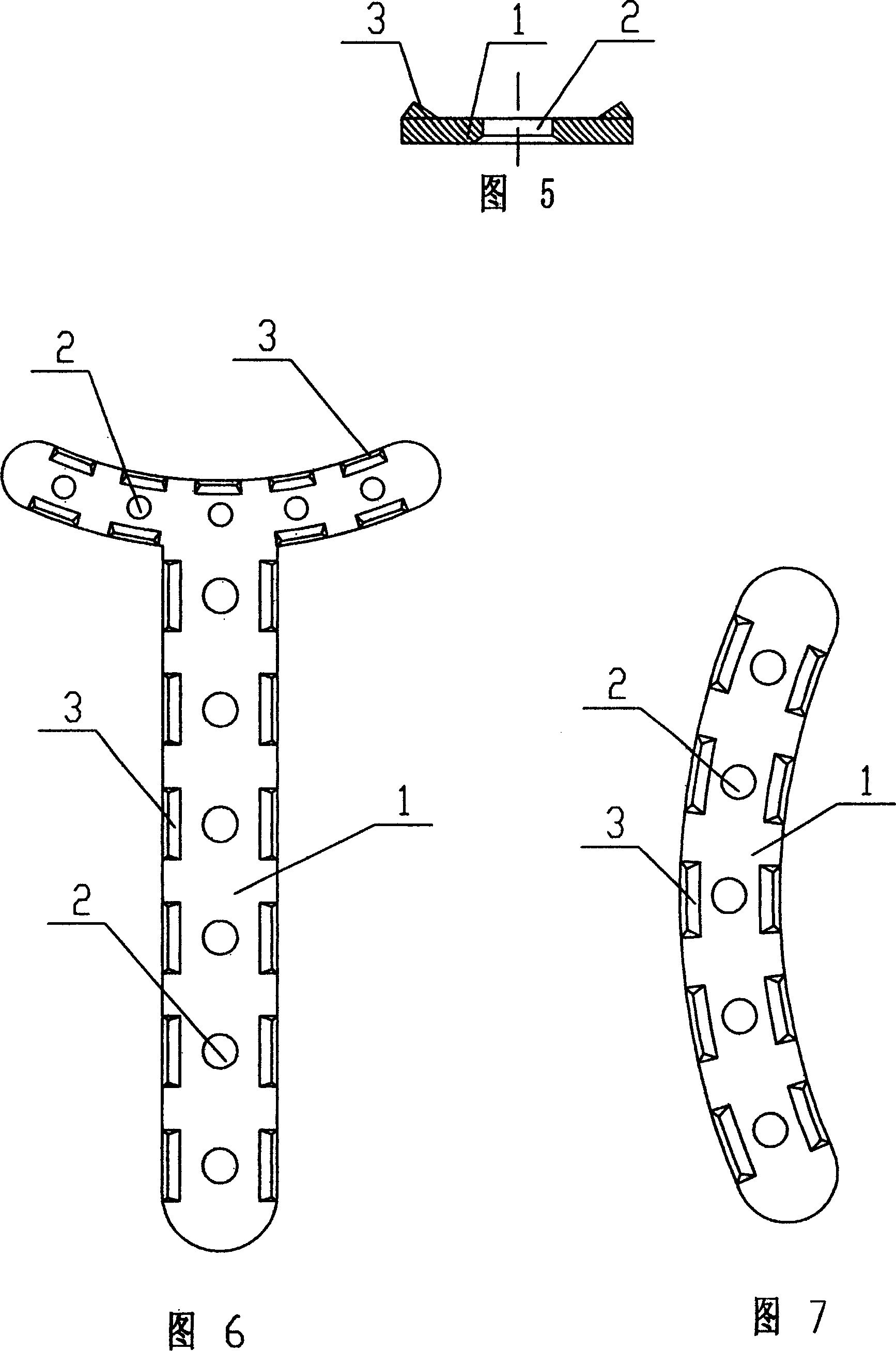

Breakage-proof bone-setting plate

InactiveCN1935094AAvoid Strength DefectsImprove fatigue resistanceBone platesBone screwsBone fracture

The present invention discloses an anti-breaking bone fracture plate. It includes an arched or plate-shaped bone fracture plate self-body, on the described bone fracture plate self-body several screw holes through which the bone screws can be respectively passed are set, the side surface of the described bone fracture plate close to bone and the bone fracture plate self-body edge close to screw hole are respectively equipped with long-strip projections, said long-strip projections are correspondent to their respective screw holes, so that these long-strip projections can raise strength of screw holes, and can prevent said bone fracture plate from breaking.

Owner:张庆宜

Elevator mounting device assembly capable of being used for shaft-free building and elevator mounting method

The invention discloses an elevator mounting device assembly capable of being used for a shaft-free building and an elevator mounting method. The elevator mounting method comprises the following steps that 1), bottom steel plates are laid; 2) a first set of supports and a degree-of-parallelism guiding rule are mounted; 3), a second set of supports and a degree-of-parallelism guiding rule are further mounted; 4), a third set of supports and a degree-of-parallelism guiding rule are further mounted; 5), fixed mounting of later support sets and top supports is further completed; 6), the top supports and the top floor are fixedly connected; 7), elevator guide rails are mounted on box iron; 8), mounting of an elevator car and a counterweight device is completed; 9), support fixing pull rods are mounted; and 10), a traction machine platform is mounted, and system debug is conducted. By means of the elevator mounting device assembly and the elevator mounting method, the elevator transformation mounting of the shaft-free building in an old type community can be completed, and the elevator mounting device assembly and the elevator mounting method have the beneficial effects that on the premise of guaranteeing the operating stability and safety of an elevator, the structure is simple and practical, the occupied space is small, and mounting is convenient and accurate, and the safety factor in the mounting process is higher.

Owner:FUJI ELEVATOR SICHUAN CO LTD

One piece flexible skateboard

ActiveUS20070252354A1Large bendImproved resistance to twistingSkatesGuiding agricultural machinesEngineeringSlide plate

Owner:RAZOR USA

Pipeline fixing support

InactiveCN104057895AImprove sealingExtended service lifeElectric/fluid circuitVehicle frameVibration treatment

The invention discloses a pipeline fixing support which comprises a support body and a bolt column arranged on the top end face of the support body. A first anti-vibration pad is arranged on the straightness edge of the left side of the support body, and a second anti-vibration pad is arranged on the straightness edge of the right side of the support body. The bolt column is provided with a third anti-vibration pad. The third anti-vibration pad is of a structure that the two ends shrink towards the middle in the bolt column direction. According to the pipeline fixing support, two layers of anti-vibration pads are additionally arranged based on an existing fixing support, the anti-vibration treatment is conducted on the fixing position of a pipeline and a vehicle frame through the two layers of the anti-vibration pads, vibration generated by a vehicle body and an engine can be further buffered and reduced, the anti-bending capacity and anti-twist capacity of the fixing support are enhanced, the strength of the support body is enhanced, the airtightness of the pipeline is improved, and the service life of the pipeline is prolonged.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Cable for ship hydrophone equipment and manufacturing method thereof

InactiveCN102176343AImprove insulation performanceGuaranteed waterproof performanceRubber insulatorsBraided wire conductorsHydrophoneElectrical conductor

Owner:JIANGSU YUANYANG DONGZE CABLE

Manufacturing method for novel rubber sleeve with steel wire therein

ActiveCN106313591AImprove bending resistanceImproved resistance to twistingTubular articlesRubber materialVulcanization

The invention discloses a manufacturing method for a novel rubber sleeve with a steel wire therein. The rubber sleeve comprises an inner tube rubber layer, a reinforcing wire layer and an outer-skin rubber layer; the reinforcing wire layer is woven on the outer surface of the inner tube rubber layer; and the outer-skin rubber layer covers the reinforcing wire layer. The manufacturing method comprises the following steps of: 1: straightening a spiral steel wire by a straightening mechanism, and cutting the spiral steel wire according to equal length; 2: carrying out impregnation treatment and heating curing treatment on the steel wire cut in the step 1; 3: putting the cured steel wire into a mould, adding a rubber material, and carrying out mould-pressing, hot-pressing and forming, thereby obtaining a semi-finished product; 4: thermally cooling the semi-finished product obtained in the step 3, and feeding the thermally cooled semi-finished product into an extruding mechanism to extrude and reinforce, thereby obtaining a crude finished product; 5: carrying out vulcanization treatment on the crude finished product obtained in the step 4; and 6: de-molding the crude finished product to obtain a finished product. According to the manufacturing method disclosed by the invention, process flow is simplified, production cost is reduced, bending resistance, torsion resistance, drawing force, compression resistance and the like of a guide tube are improved, and actual use requirements are met.

Owner:焦作恒荣科技有限公司

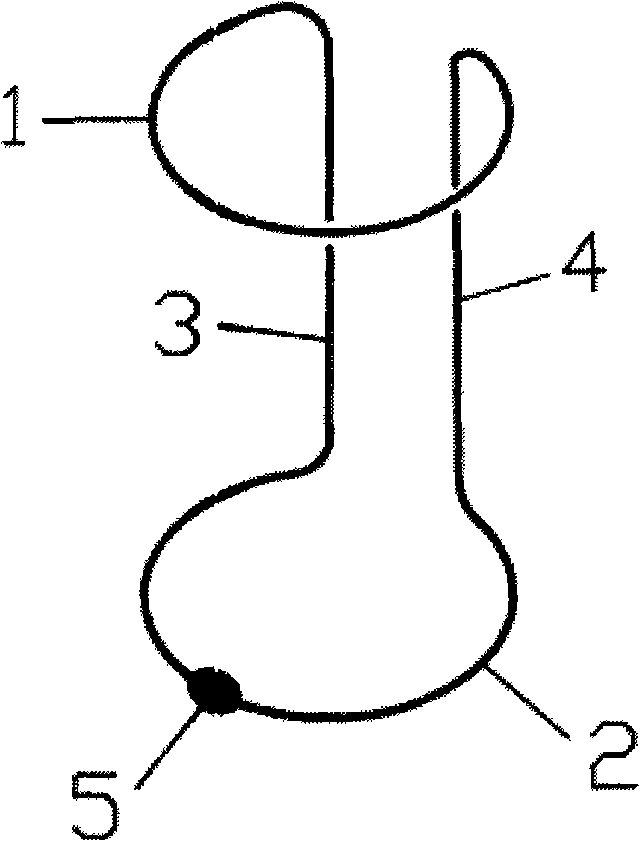

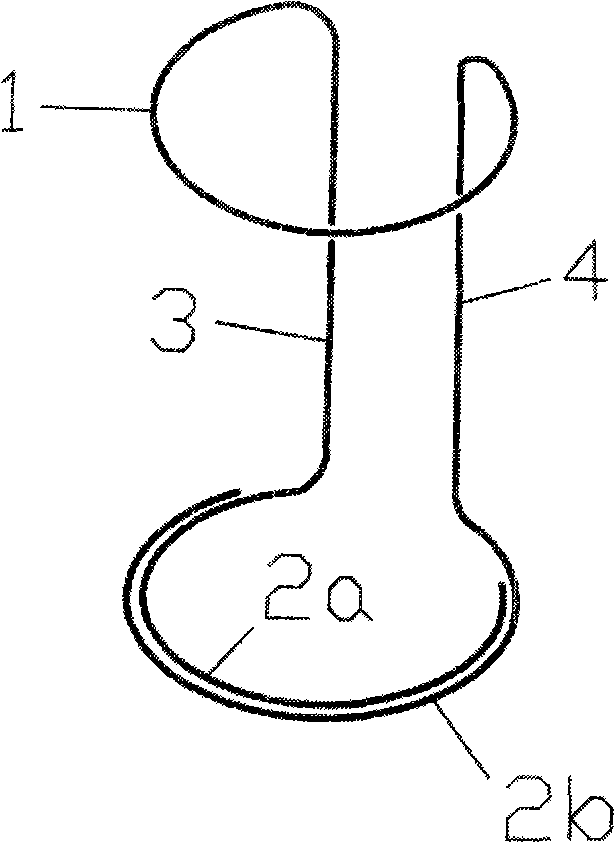

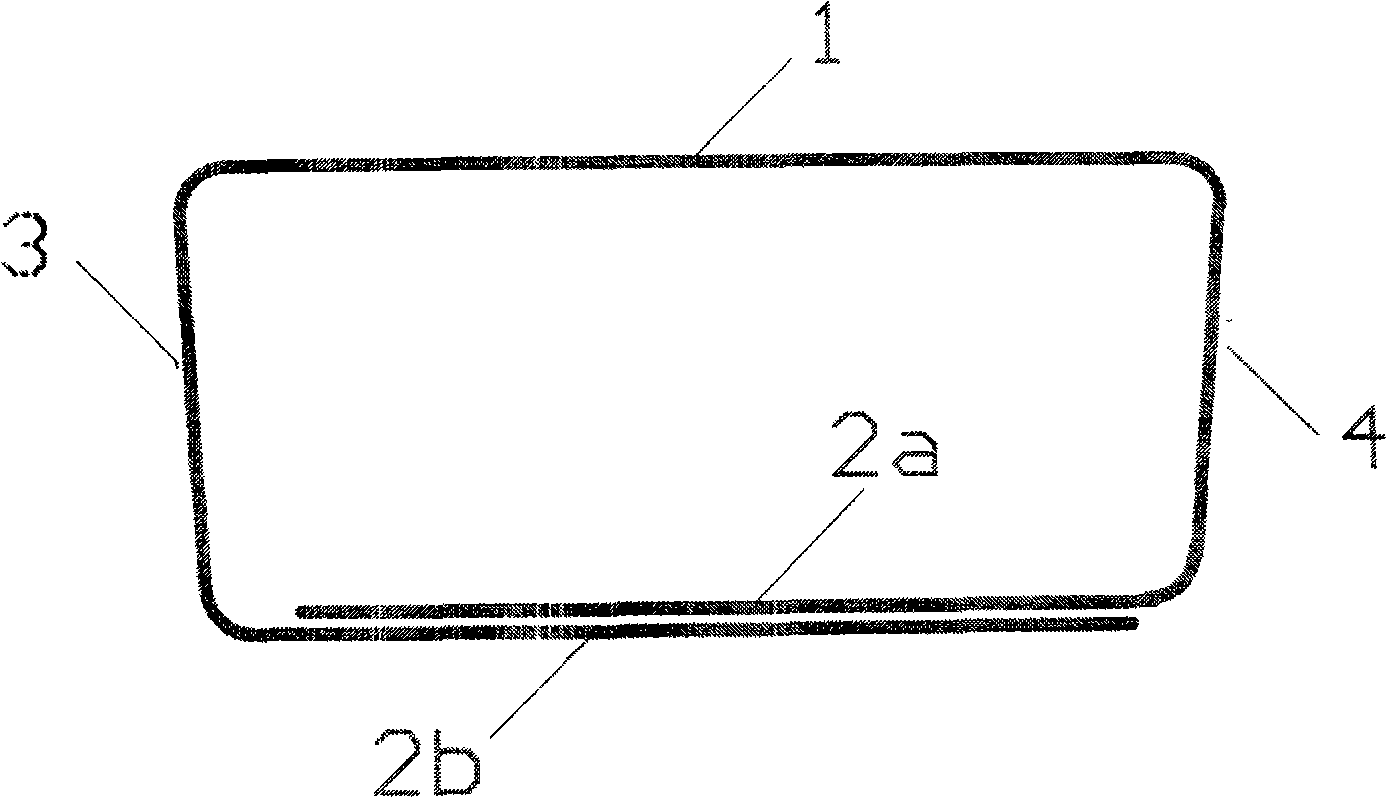

Saddle type penis holder

InactiveCN101513371AImprove fracture resistanceImproved resistance to twistingNon-surgical orthopedic devicesPenile TumescenceUrology

Disclosed is a saddle type penis holder to hold the penis for the impotence patient, maintain and increase the erection rigidity and improve the sexual potency of the patient. The saddle type penis holder is formed by a single metal wire, comprises an upper ring (1), a lower ring and two holding levers (3) and (4), and is characterized in that: the lower ring is a compound ring which is forming by the overlapping of two lower subrings (2a) and (2b). In addition, the compound ring is bound and fixed by two sleeve rings (6) and (7). The holder with the structure has better break resistance strength and racking resistance capability.

Owner:易明光

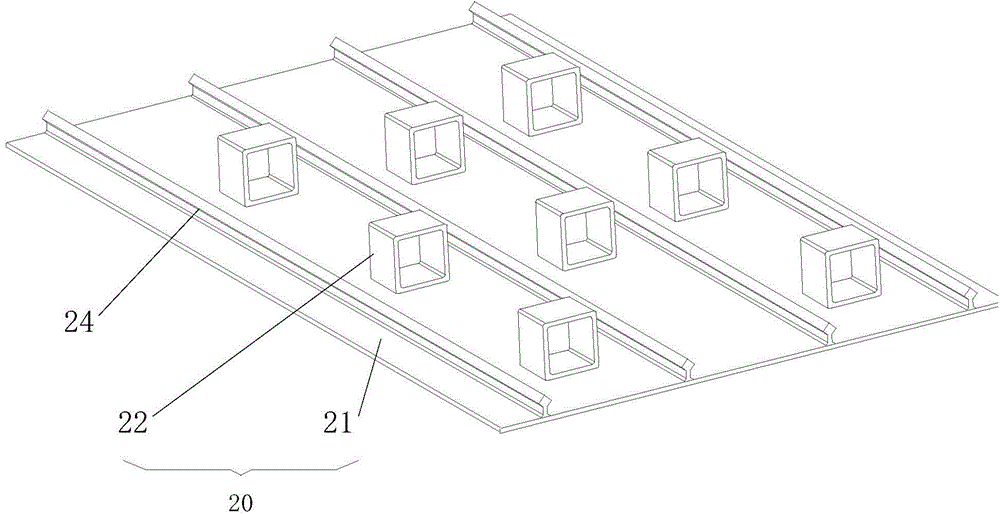

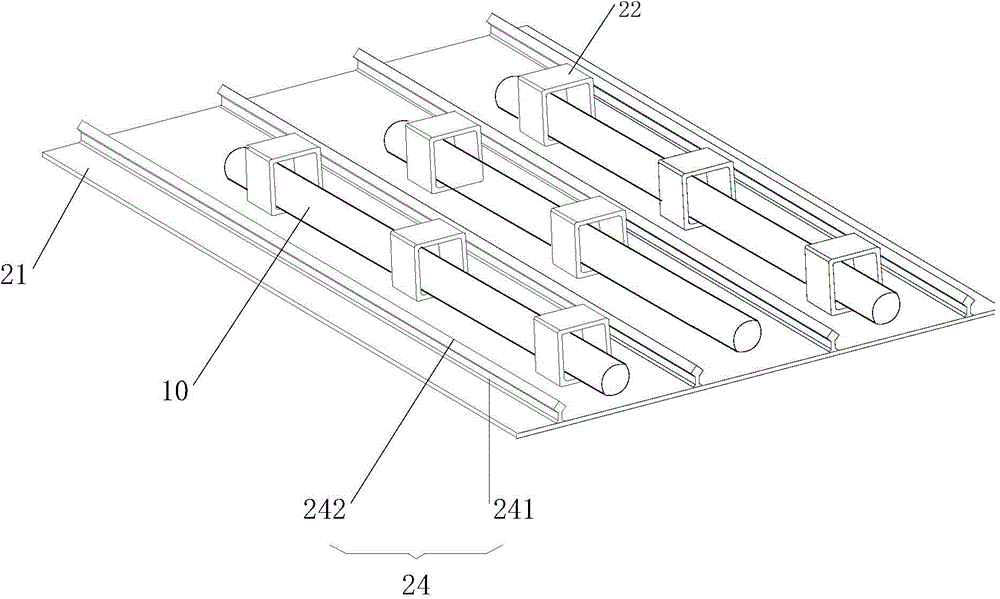

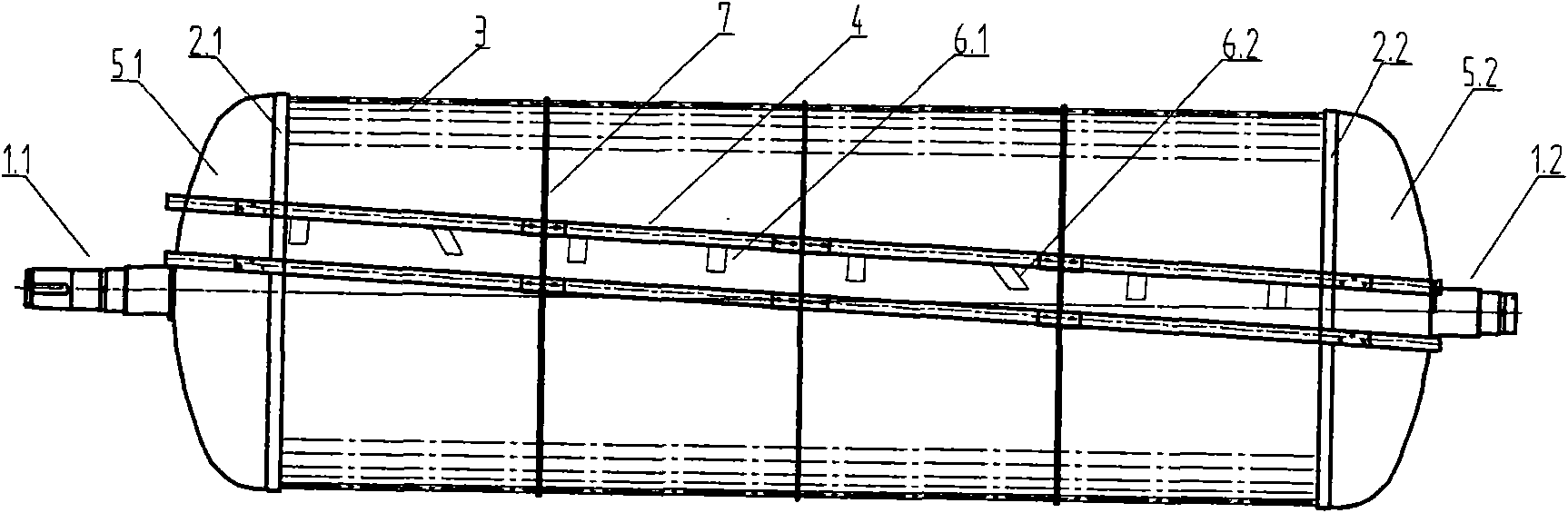

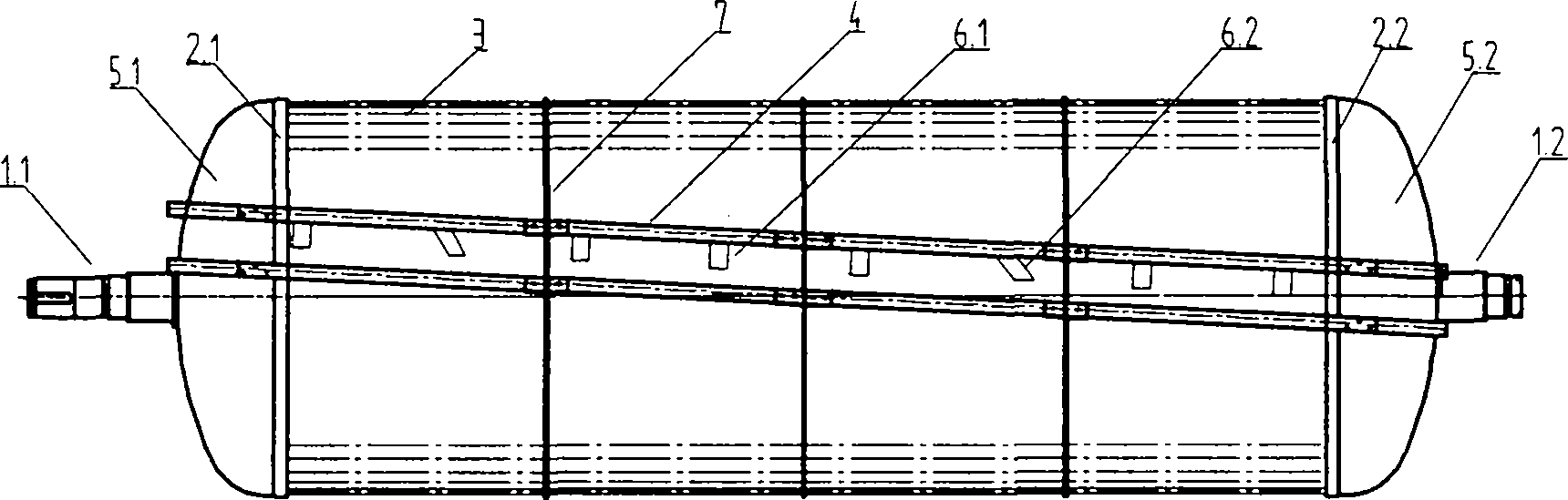

Improved tube bundle for tube bundle dryer

ActiveCN101782319AImproved resistance to twistingExtended service lifeDrying solid materialsHeating arrangementPulp and paper industryShovel

The invention provides an improved tube bundle for a tube bundle dryer, belonging to the field of chemical machinery and equipment. A transmission main shaft, a passive main shaft are weld with an end socket and a tube plate respectively at two ends into a whole; the two sides of a heating tubebank is in expanded joint with tube plates at the two ends, and the middle part is supported by a plurality of supporting tube plates; a material shovel angle iron provided with a straight material shovel and a tilted material shovel is welded and fixed on the circumferences of the tube plates at the two ends and the supporting tube plates; and the material shove angle iron is slantwise welded on the tube plates at the two ends and the supporting tube plates, i.e. an inclination angel is formed between the material shovel angle iron and the tubebank, thus improving the synchronism of the two ends of a main shaft and the torsion resistance of the material shovel angle iron, prolonging the service life of the material shovel angle iron and reducing the maintenance frequency of the tube bundle.

Owner:江苏纵横浓缩干燥设备有限公司

Cable for flexible robot and manufacturing method

InactiveCN105825925AHigh elongationImprove torsion resistancePower cables with screens/conductive layersFlexible cablesFiberElectrical conductor

The invention discloses a cable for a flexible robot, which comprises: a conductor braided by polyparaphenylene terephthalamide fibers and a plurality of oxygen-free copper wires; respectively covering each conductor to form each wire core Each polyvinyl chloride insulating layer; the copper wire shielding layer covering all the wire cores; the PUR sheath covering the copper wire shielding layer. The invention also discloses a method for manufacturing a cable for a flexible robot, including: placing poly-p-phenylene terephthalamide fibers in the center, placing a plurality of oxygen-free copper wires on the outer layer, and then braiding through a braiding machine A conductor with a density greater than 90% is formed into a conductor; a layer of PVC insulation is extruded outside the conductor by insulation extrusion equipment to form a core; a braiding machine is used to tightly weave the multi-strand core with a layer of braid density greater than 85% The copper wire shielding layer; outside the copper wire shielding layer, a PUR sheath is extruded by a sheath extruder. The invention is suitable for flexible robots with high stretching and twisting frequencies and many friction times.

Owner:SHANGHAI NANYANG FUJIKURA CABLE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com