Patents

Literature

33results about How to "Large bend" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

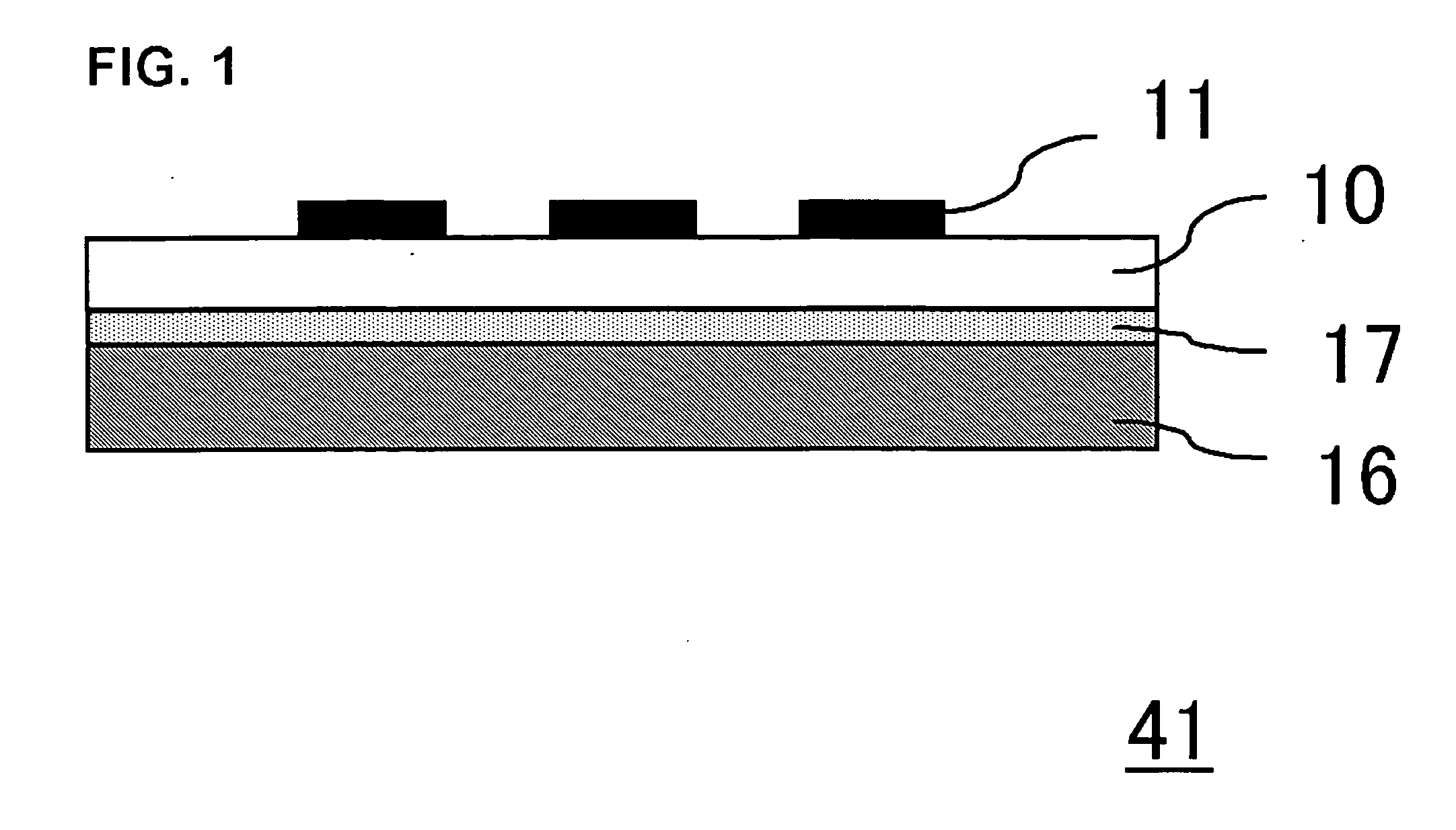

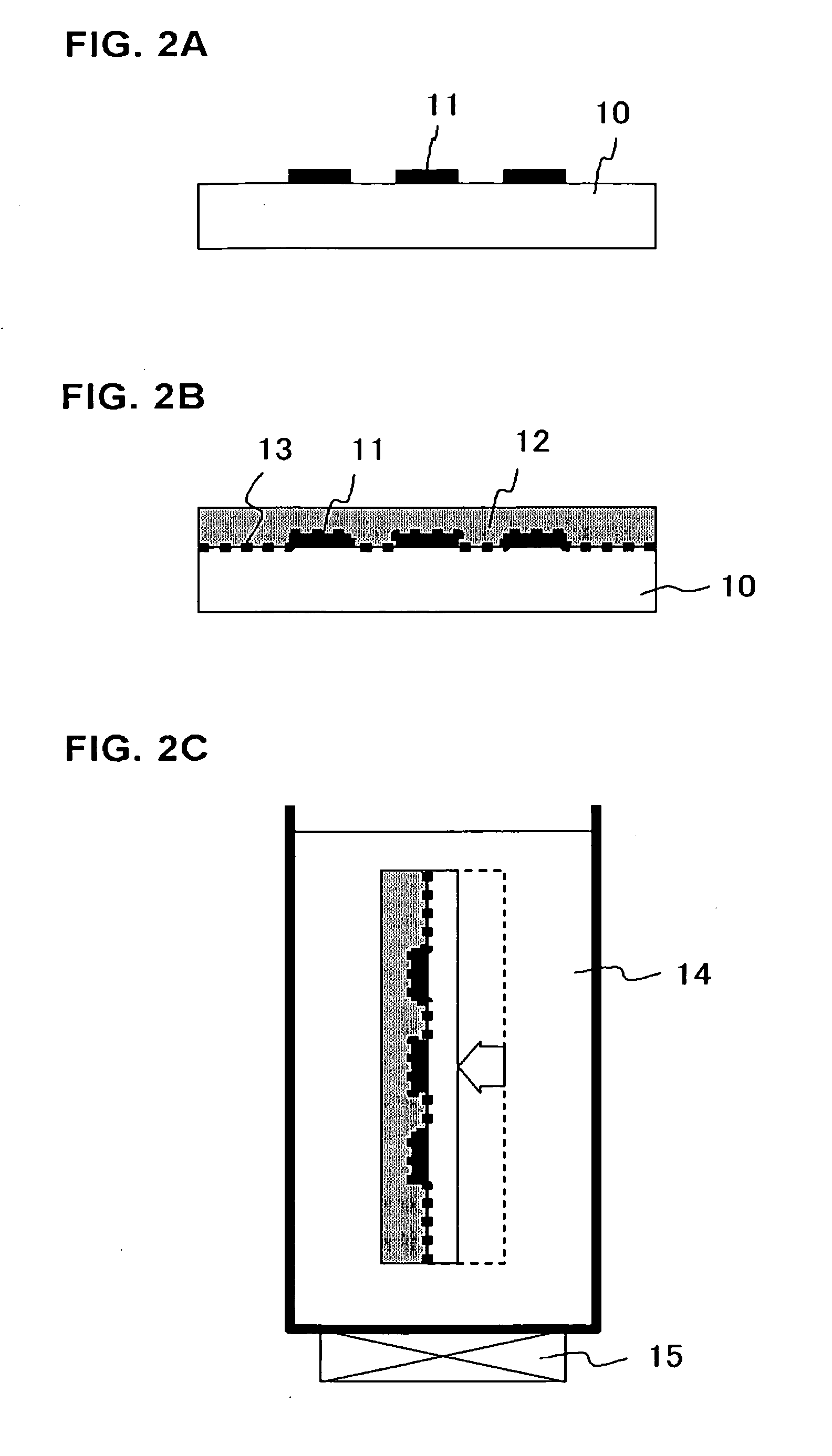

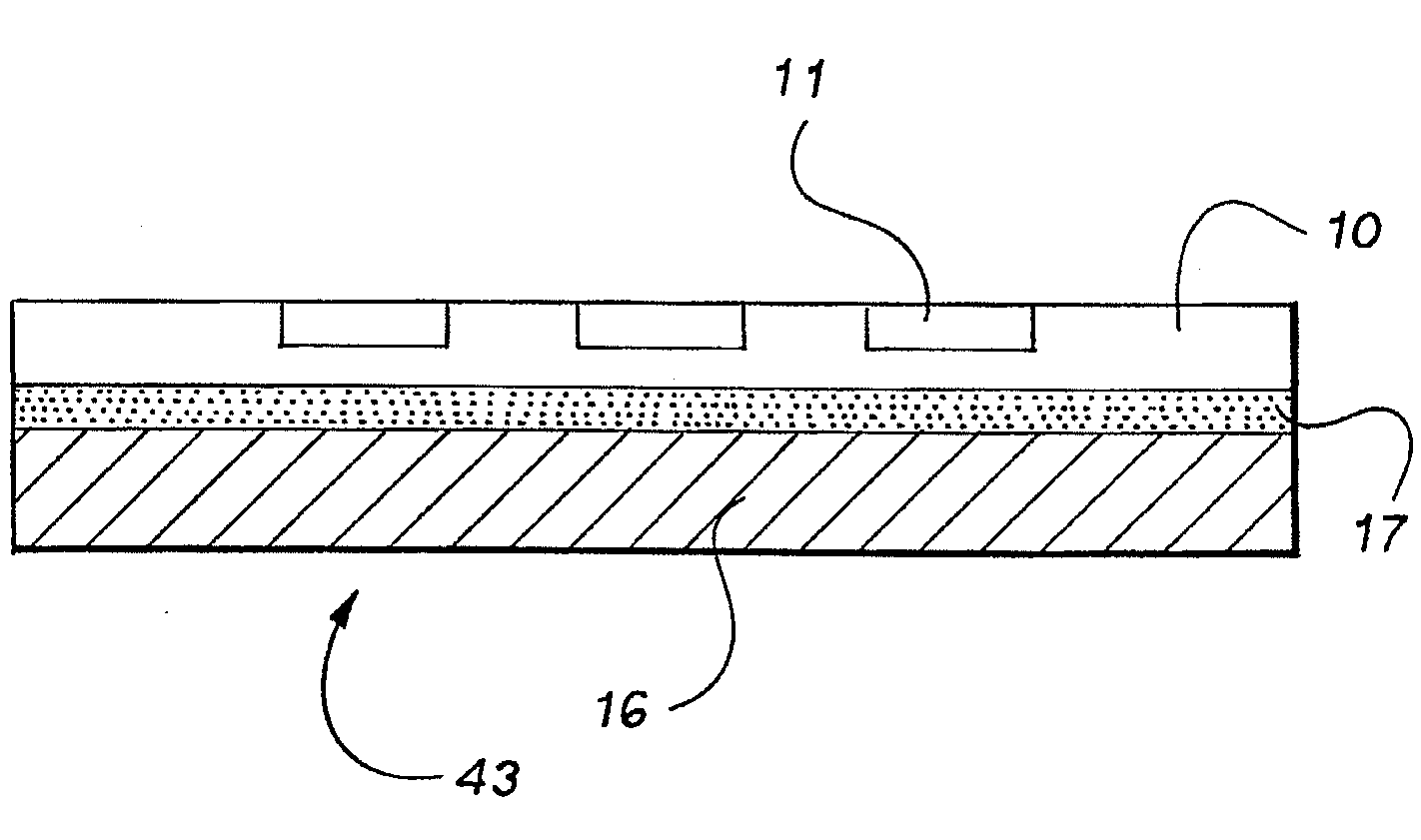

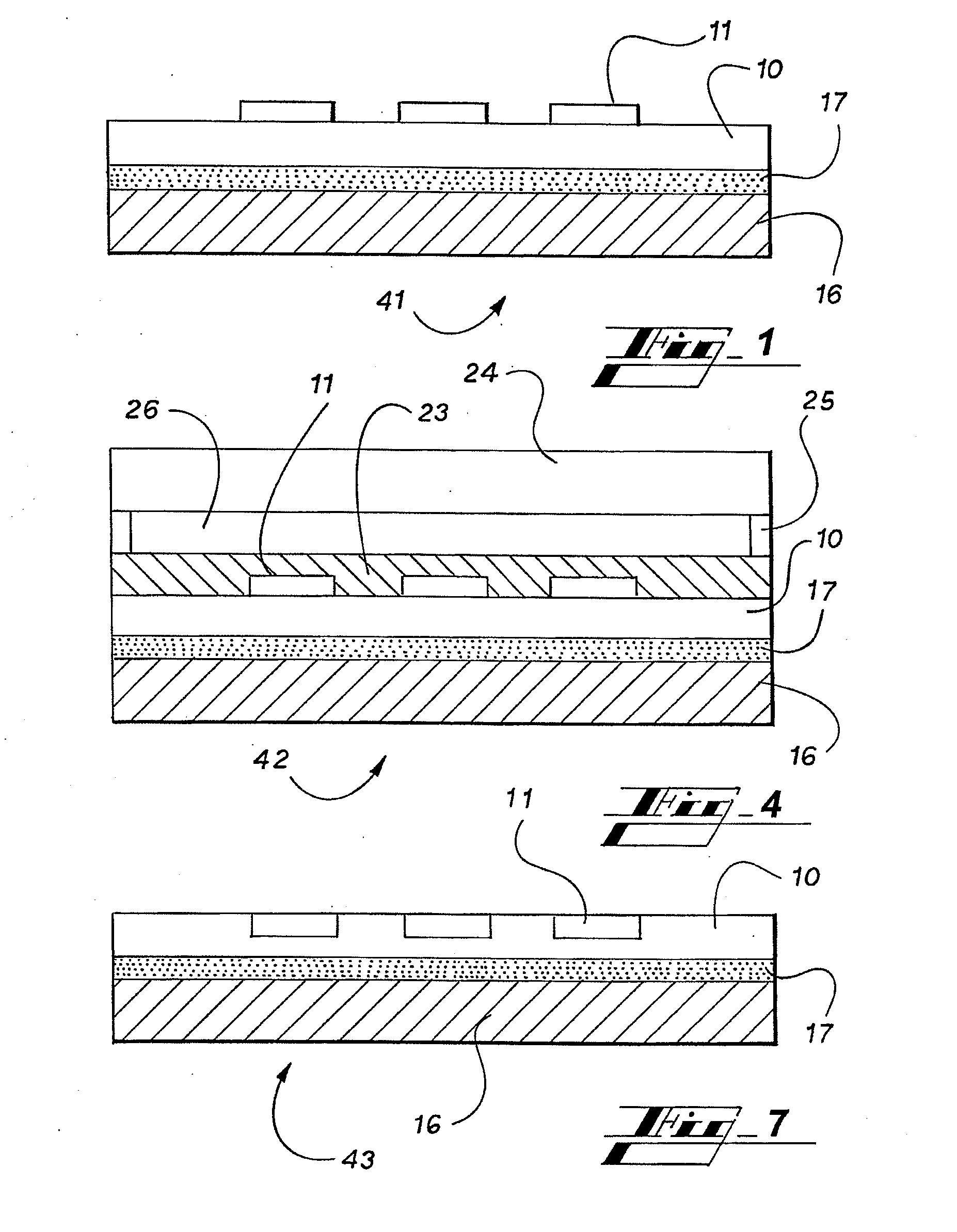

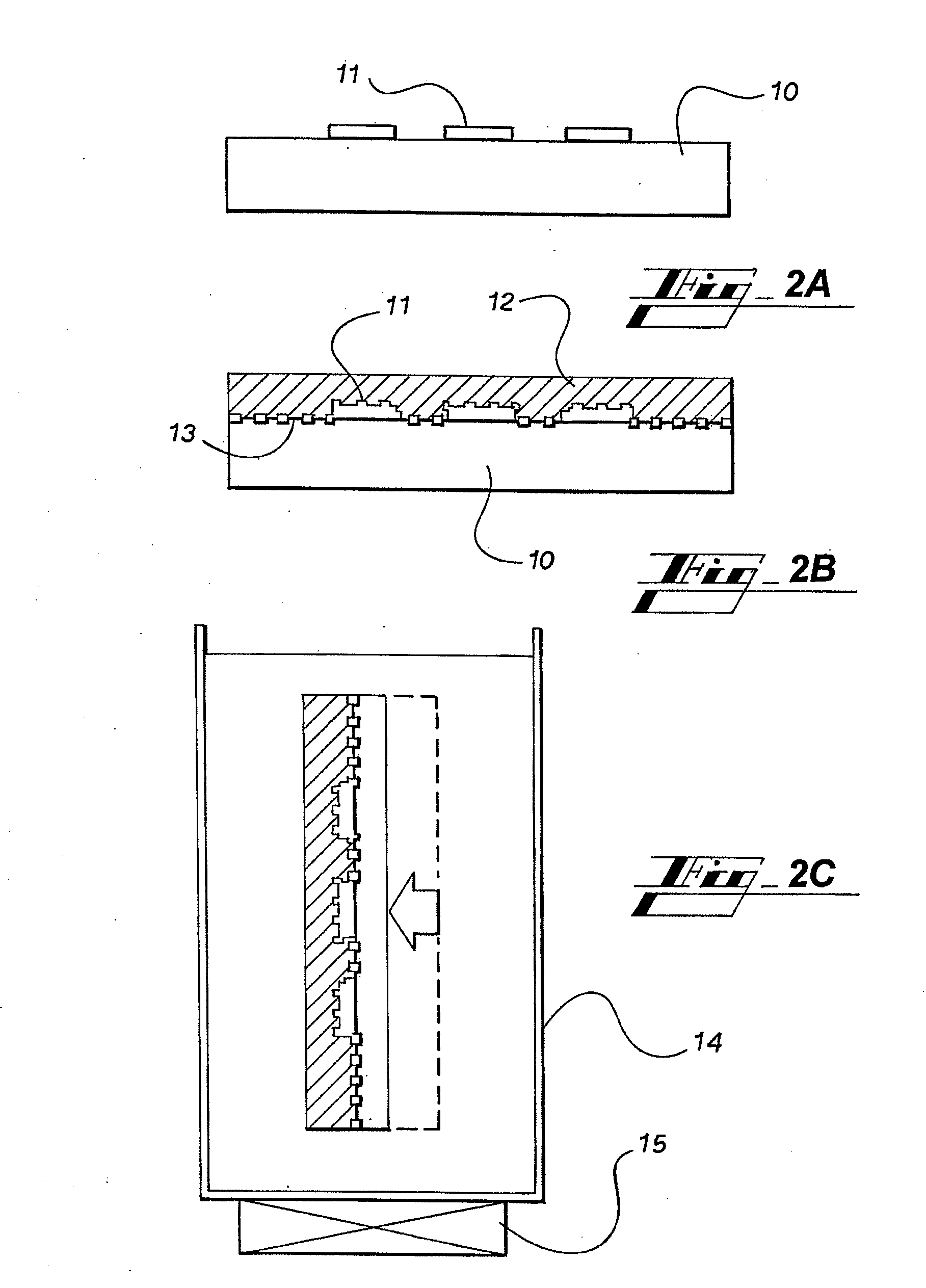

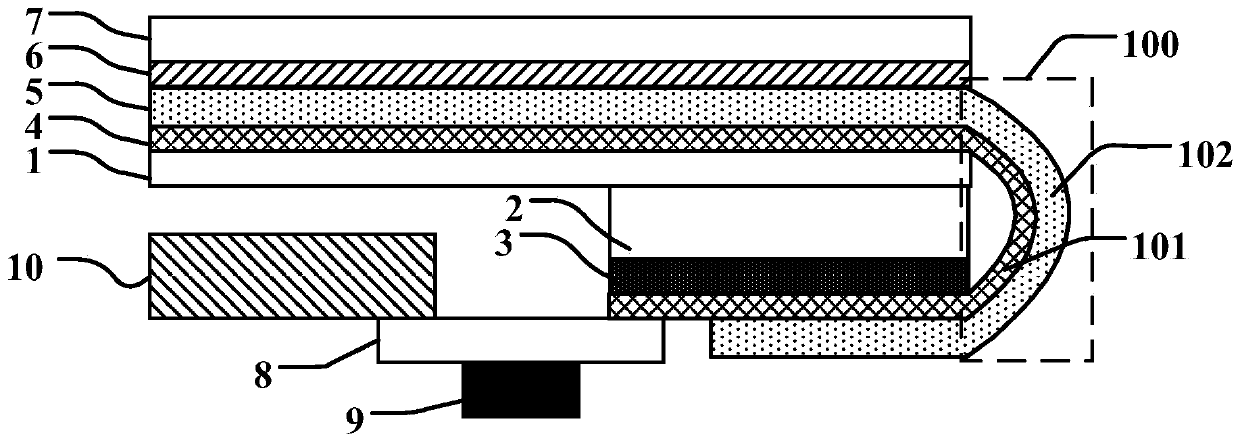

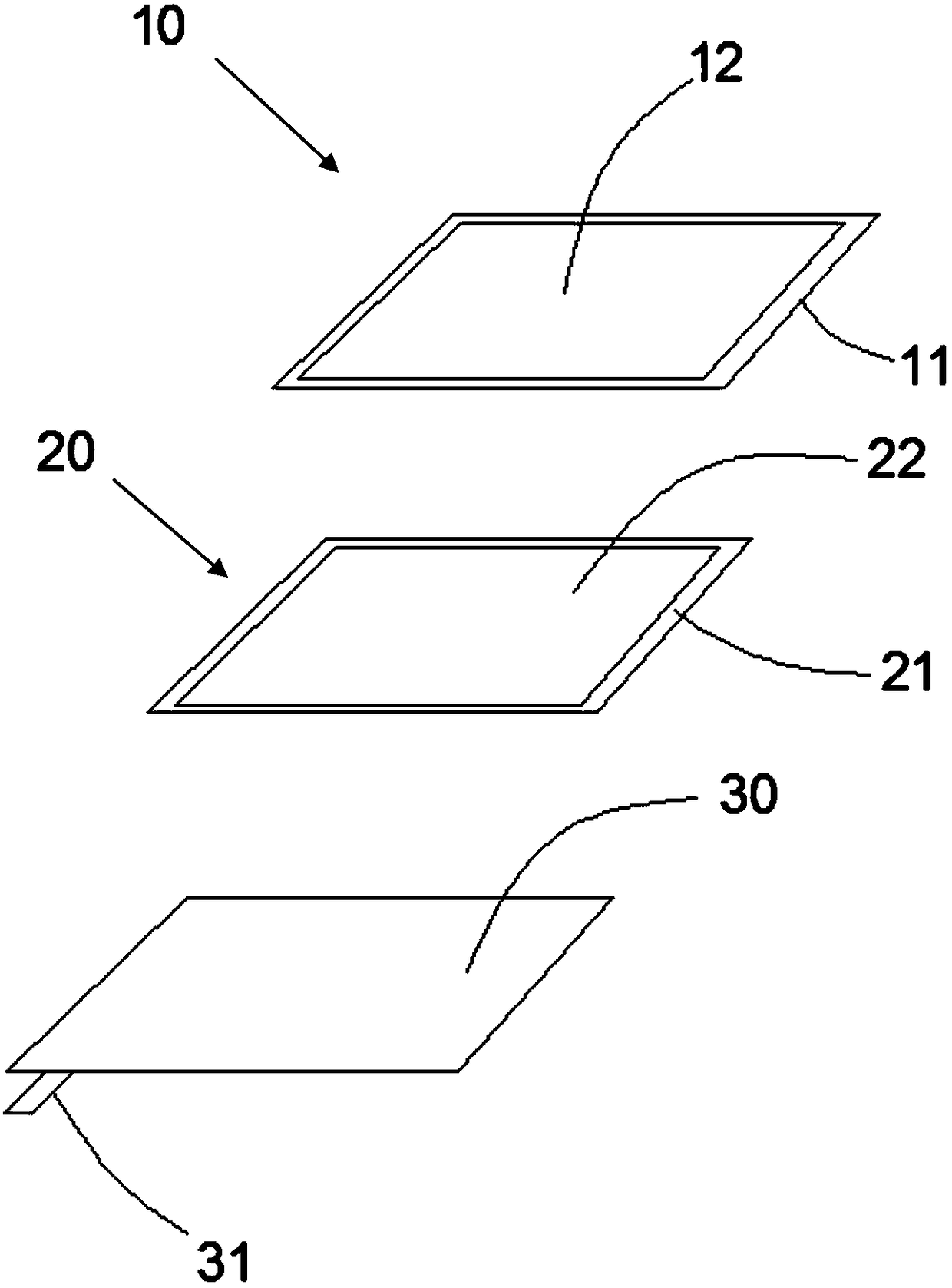

Semiconductor device and method for manufacturing same

InactiveUS20060017154A1Large bendLarge warpageSemiconductor/solid-state device detailsPrinted circuit aspectsDevice materialEngineering

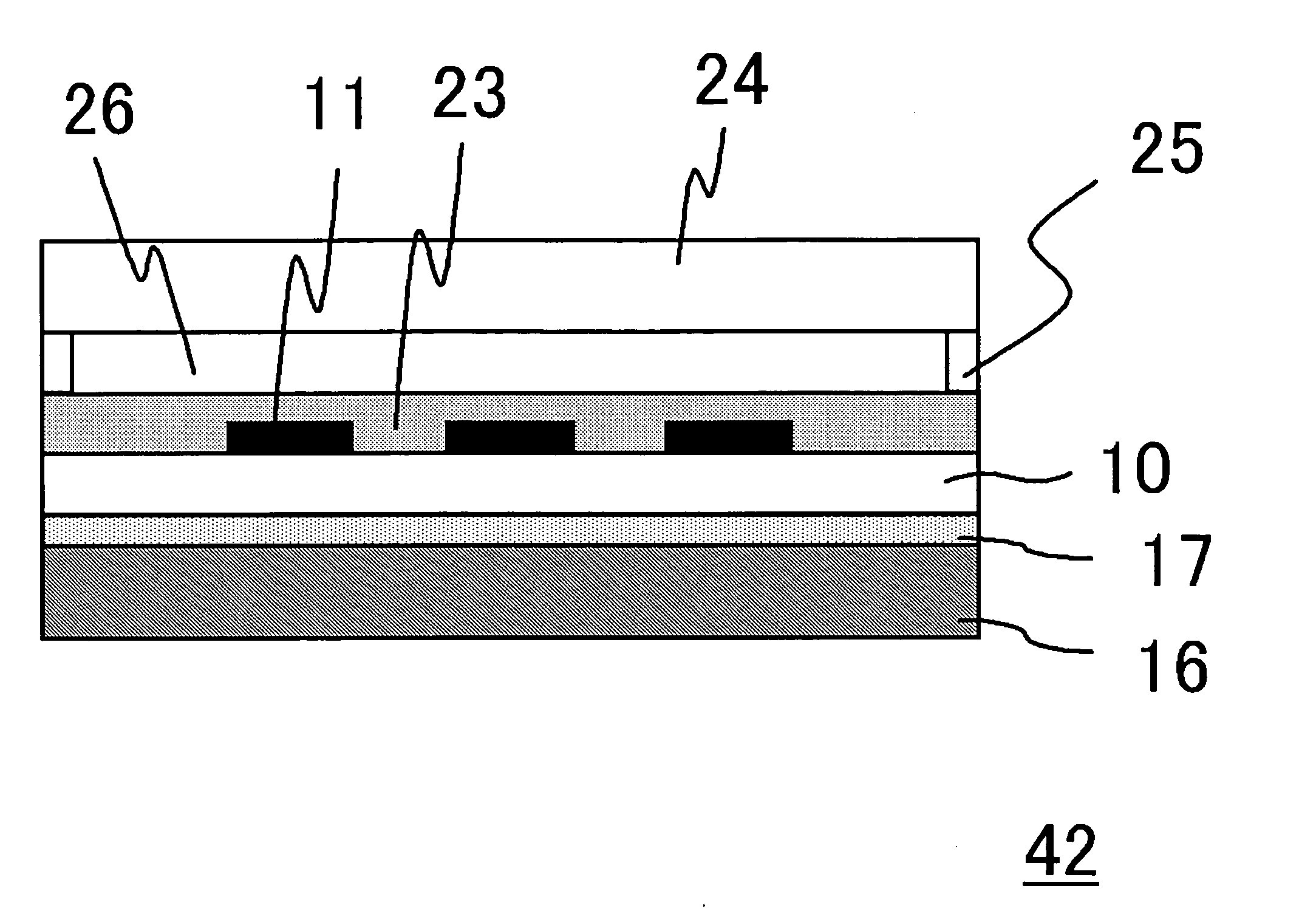

A method to provide an improved production yield of electronic devices. A thin film device 41 is manufactured by the following method. Semiconductor elements 11 are formed on the substrate 10. Then, a protective film is adhered onto the upper portions of the semiconductor elements 11 using an adhesive agent. Then, the substrate 10 is removed along the thickness direction from the surface thereof opposite to the surface having the semiconductor elements 11 provided thereon. Subsequently, a film 16 is adhered onto the surface of the removal-processed substrate 10. Subsequently, the protective film is removed. The obtained thin film device 41 is heat-treated.

Owner:SUMITOMO BAKELITE CO LTD +1

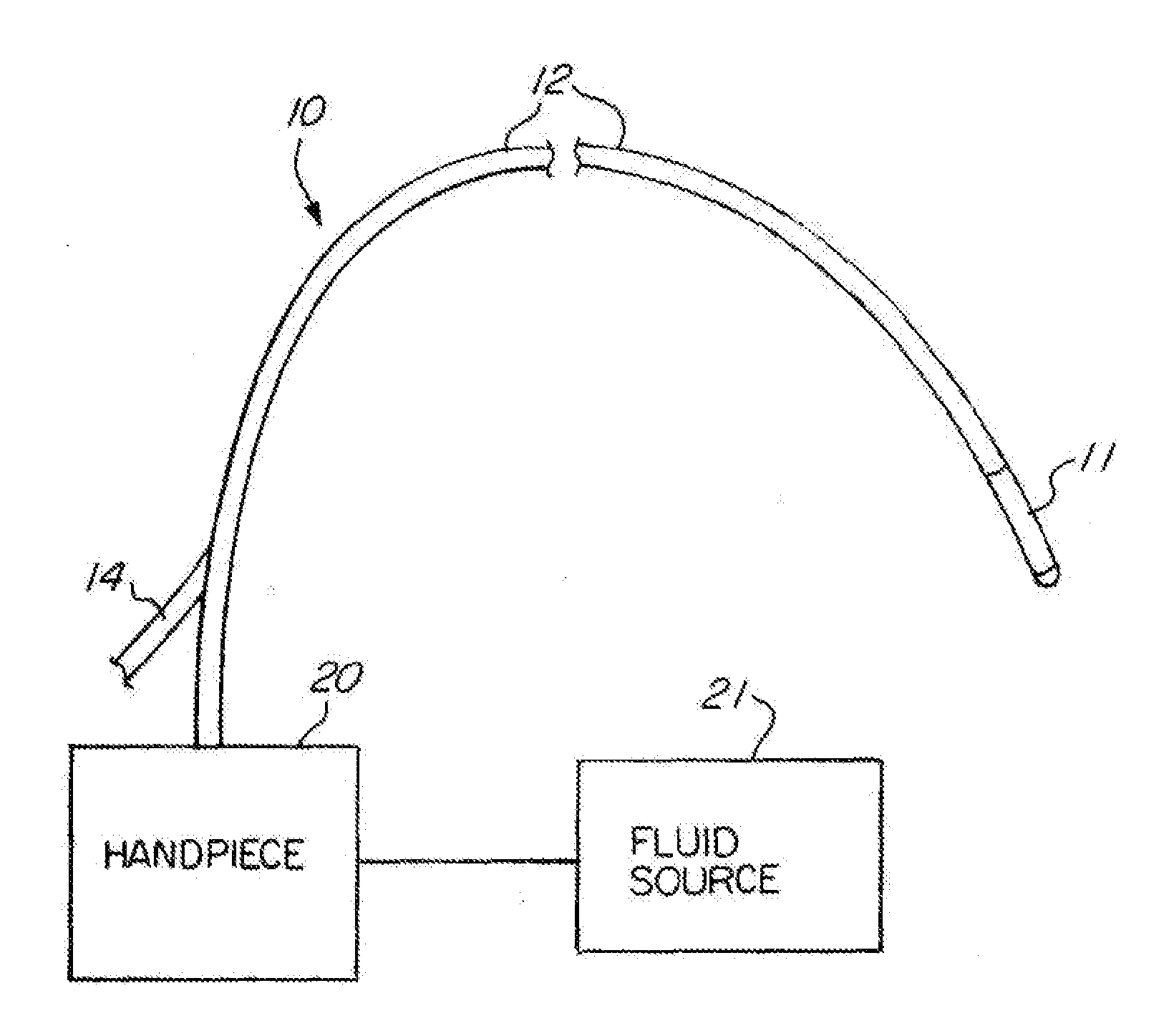

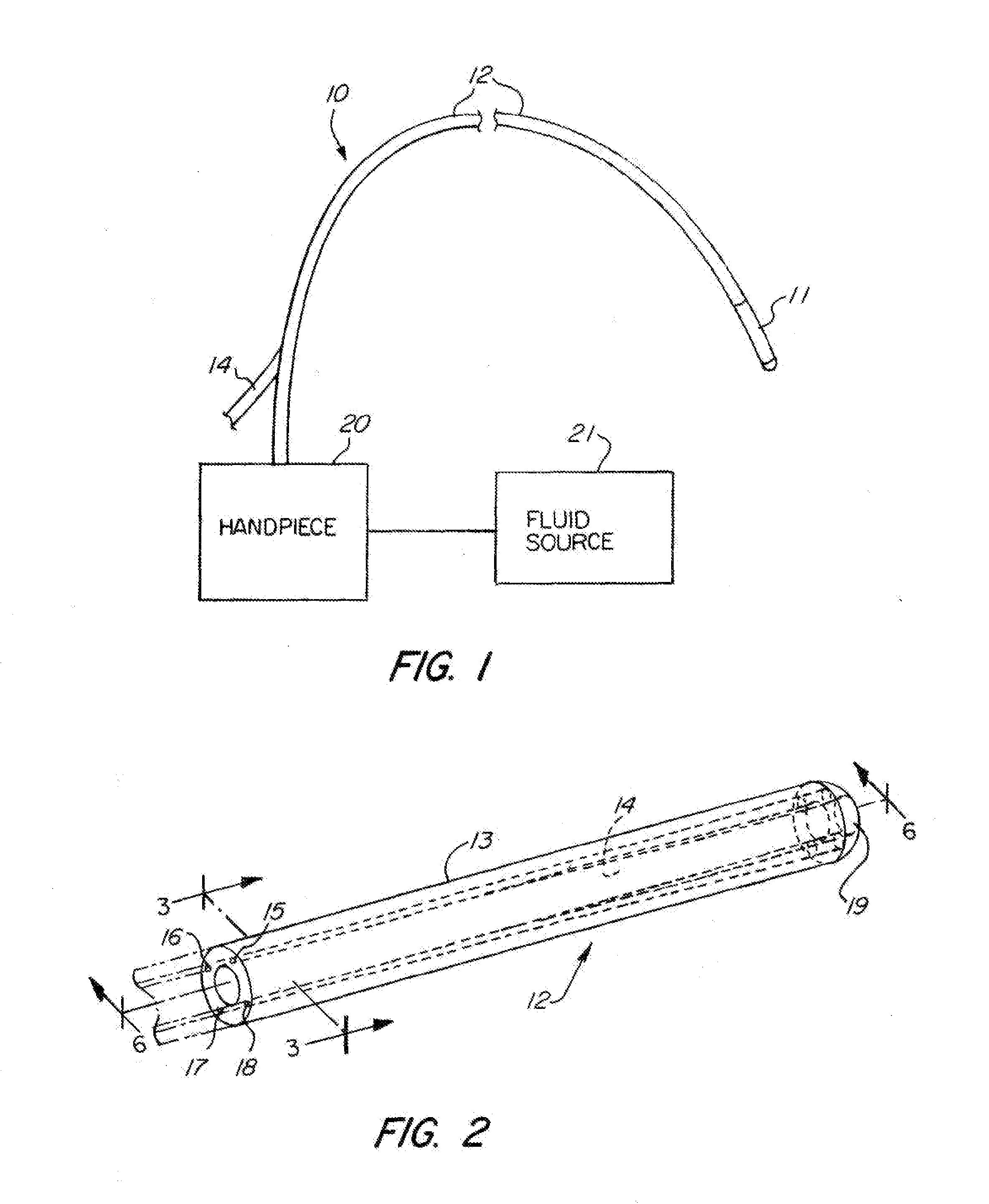

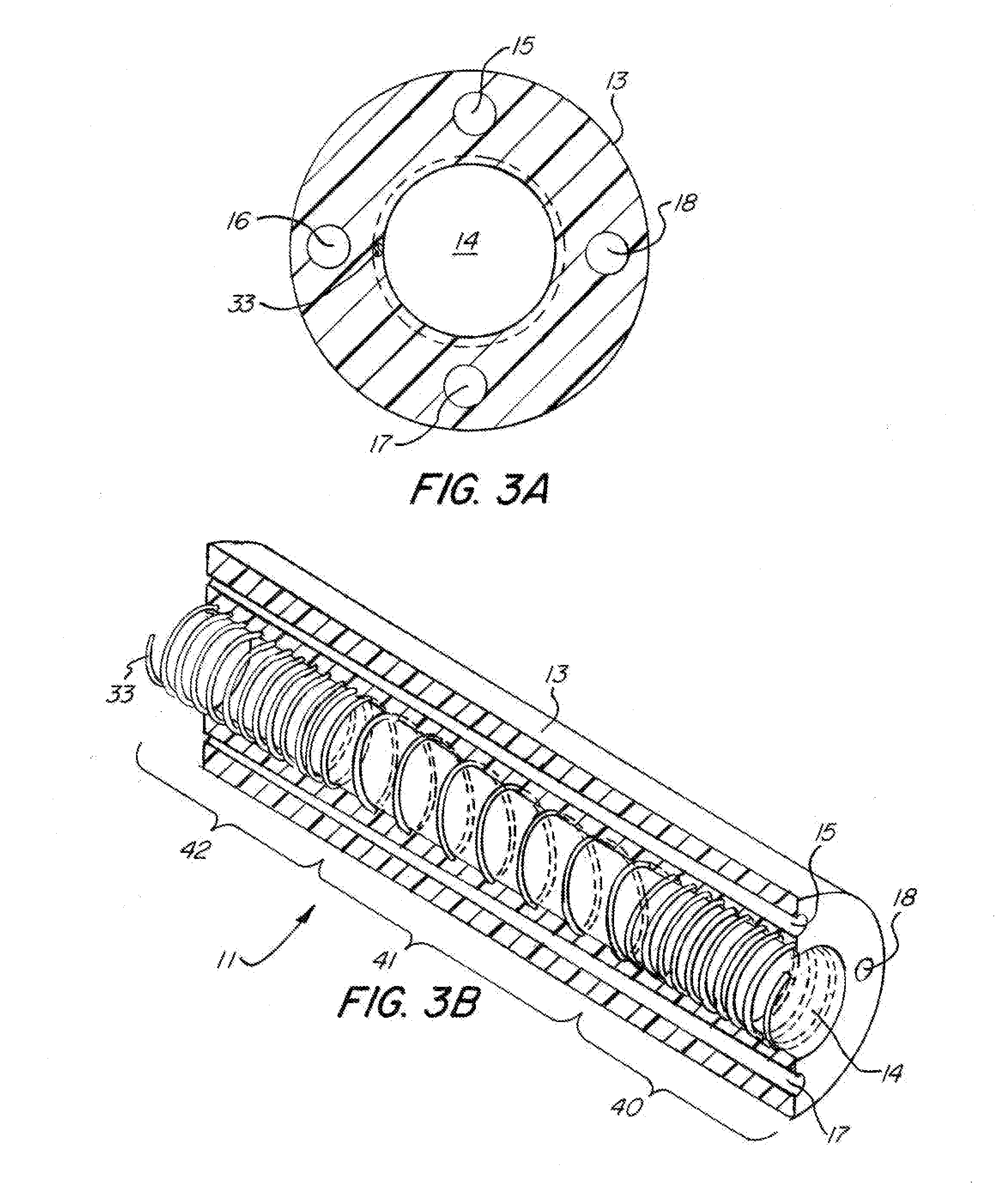

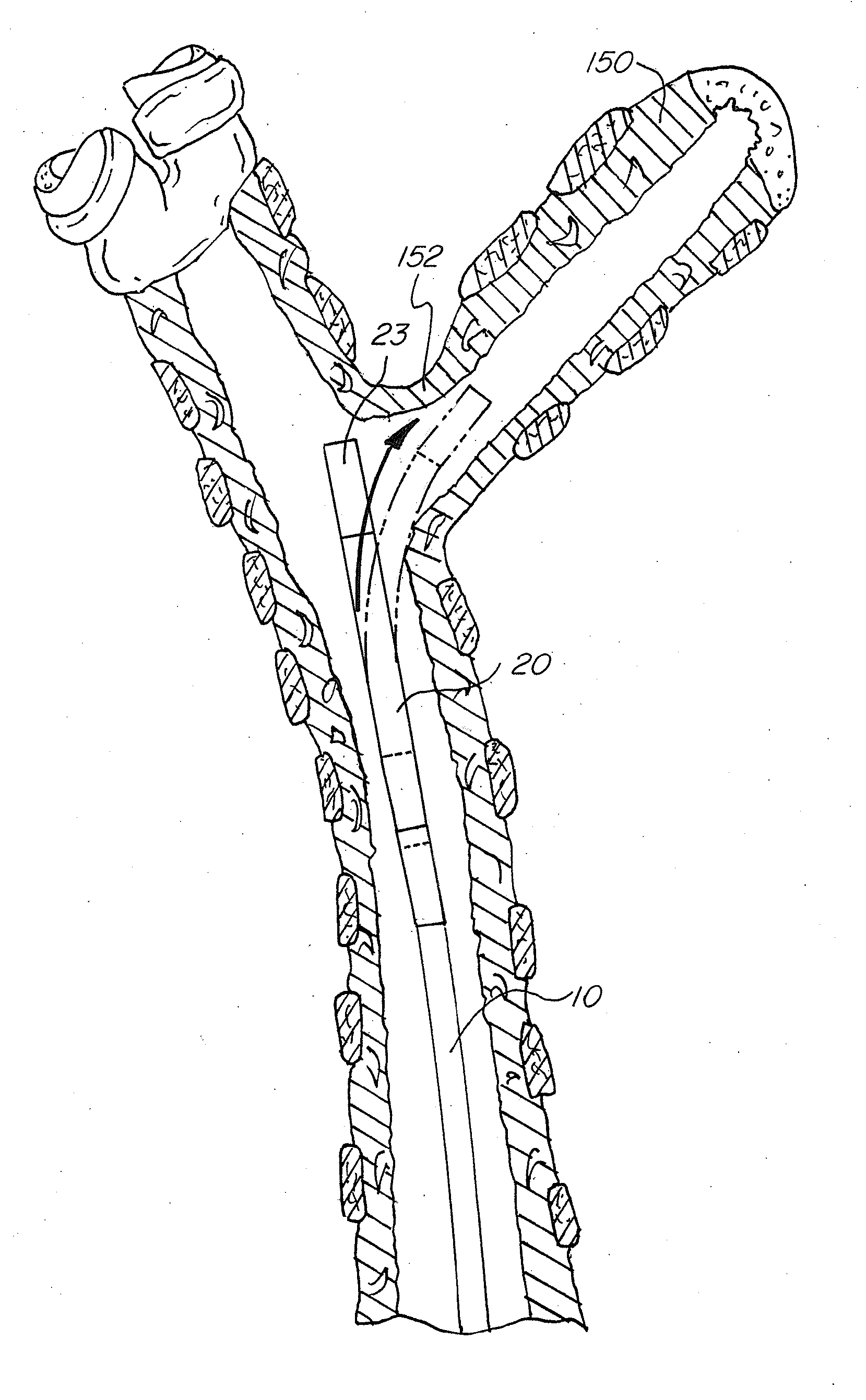

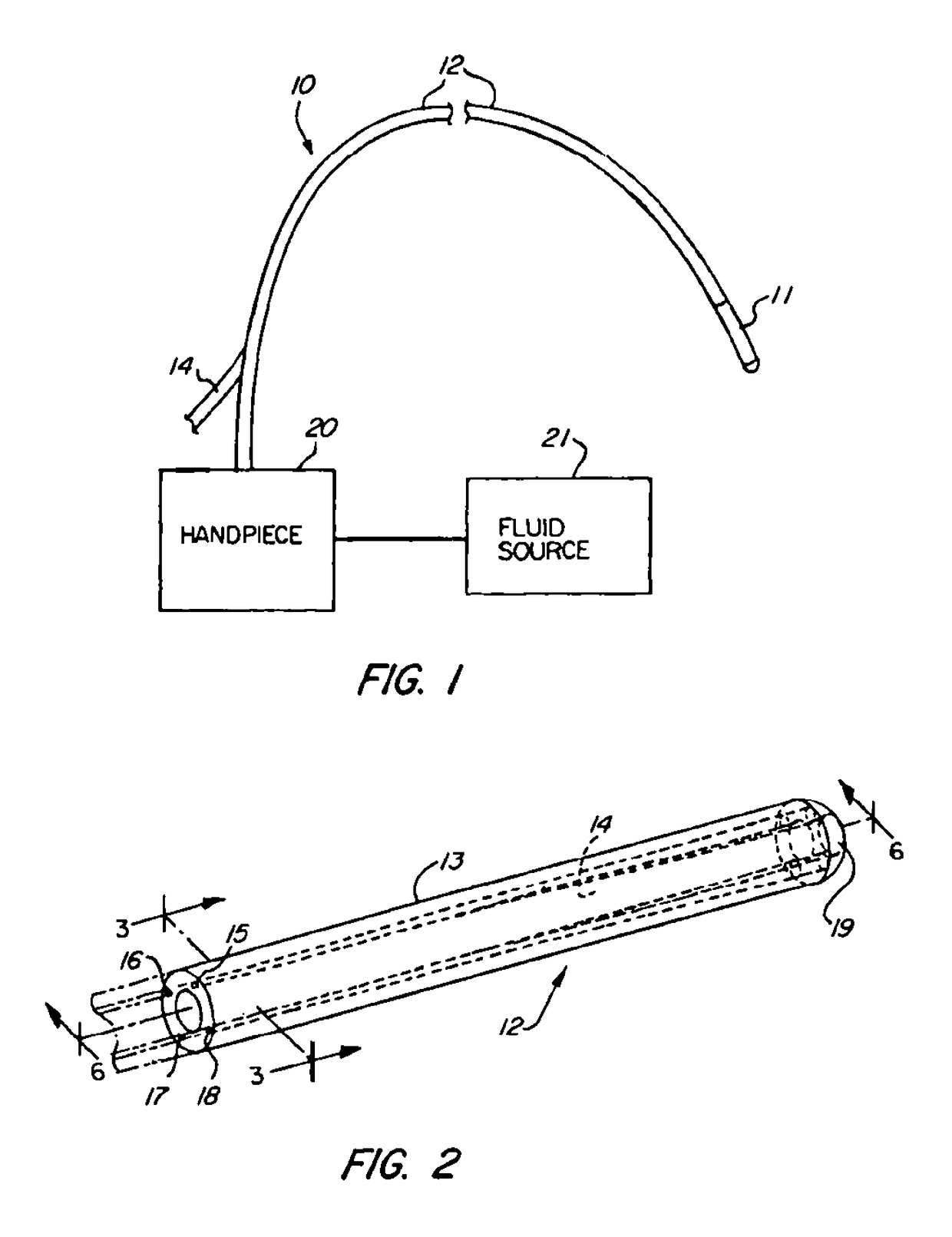

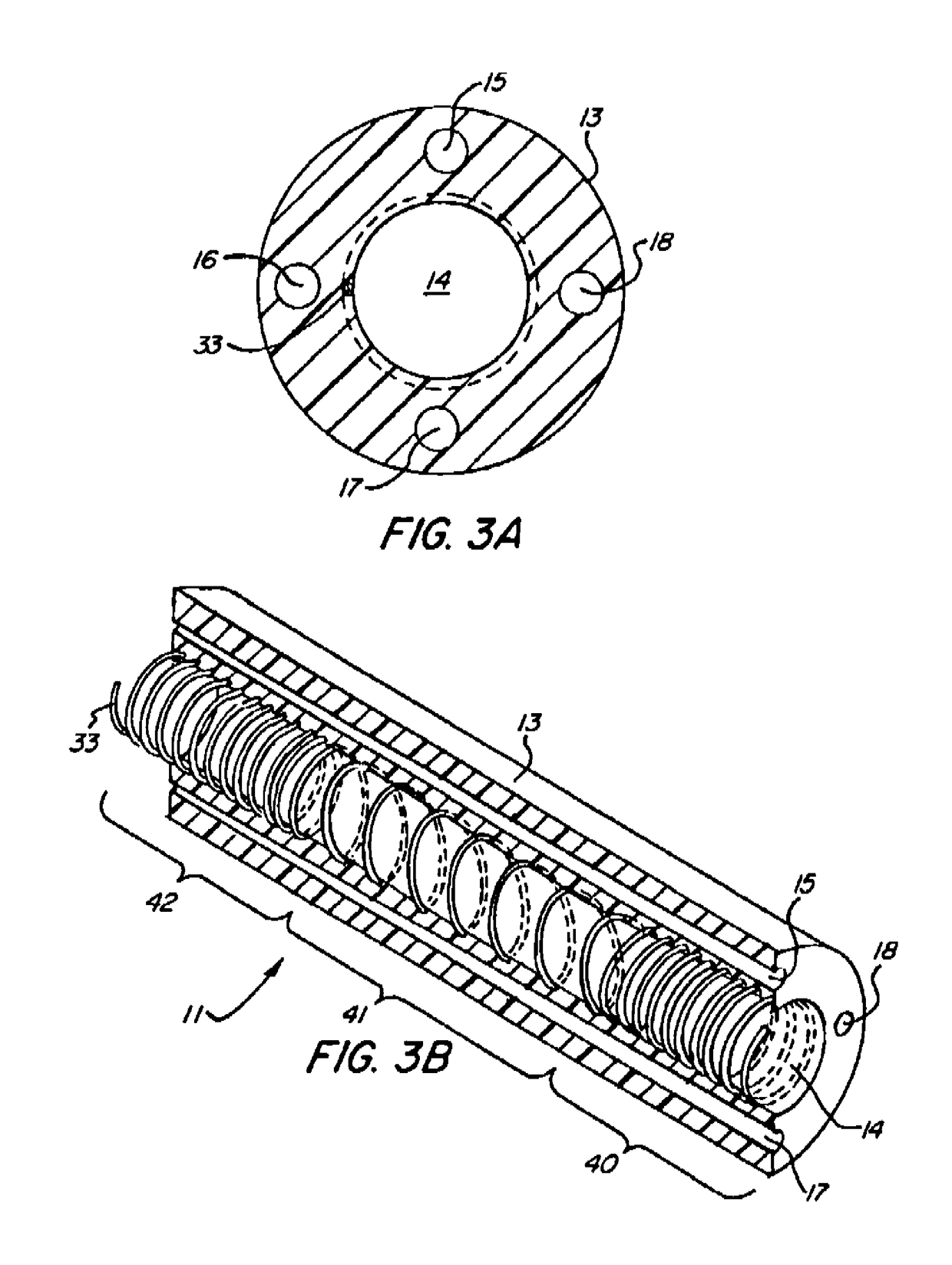

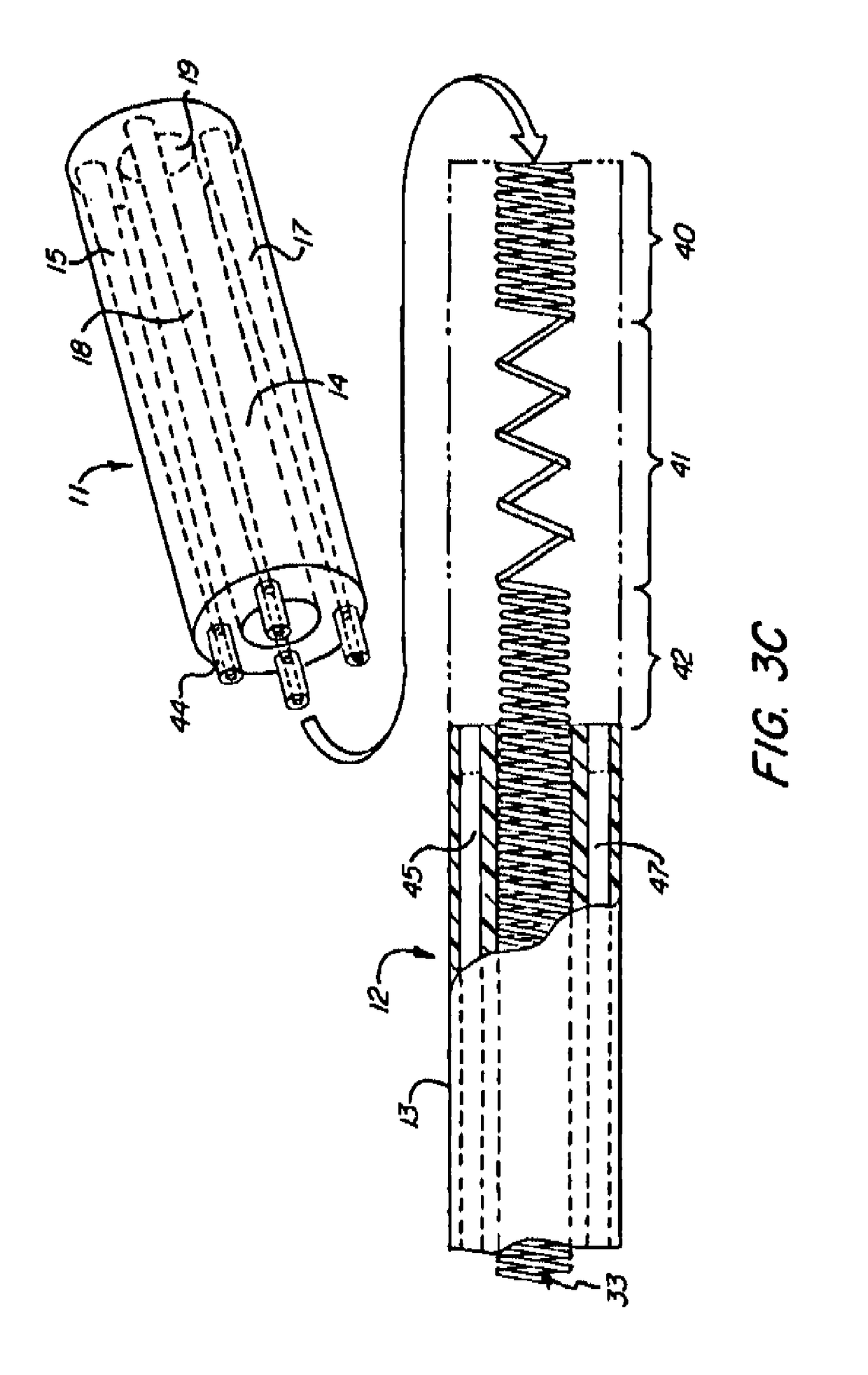

Steerable Catheter

The present invention relates to a steerable catheter device and method of using the same comprising a catheter body having a distal section. The distal section of the catheter body has an inner lumen, and one or more steering lumen radially offset from the inner lumen. The steering lumen comprise a first end having a first diameter and a second end having a second diameter smaller than the first diameter. A fluid source is in fluid communication with the steering lumen for supplying fluid thereto to radially distend the first end of the steering lumen such that the catheter body bends away from the steering lumen. In some cases, a vacuum is supplied to an opposite lumen to further assist bending of the catheter body. The inner lumen may include a porous material that is utilized to clean an instrument, such as an imaging device, movably disposed in the inner lumen.

Owner:SANOVAS

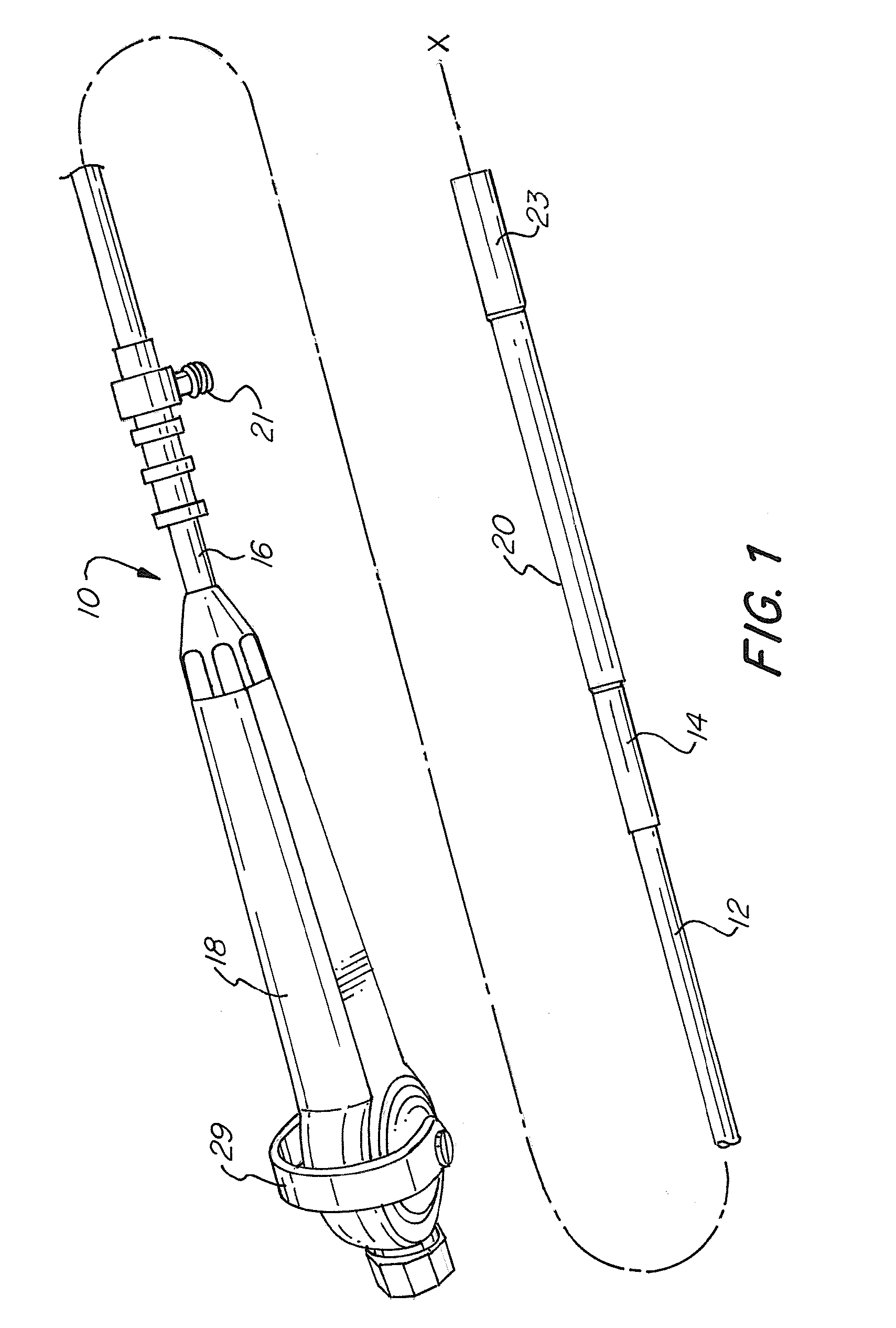

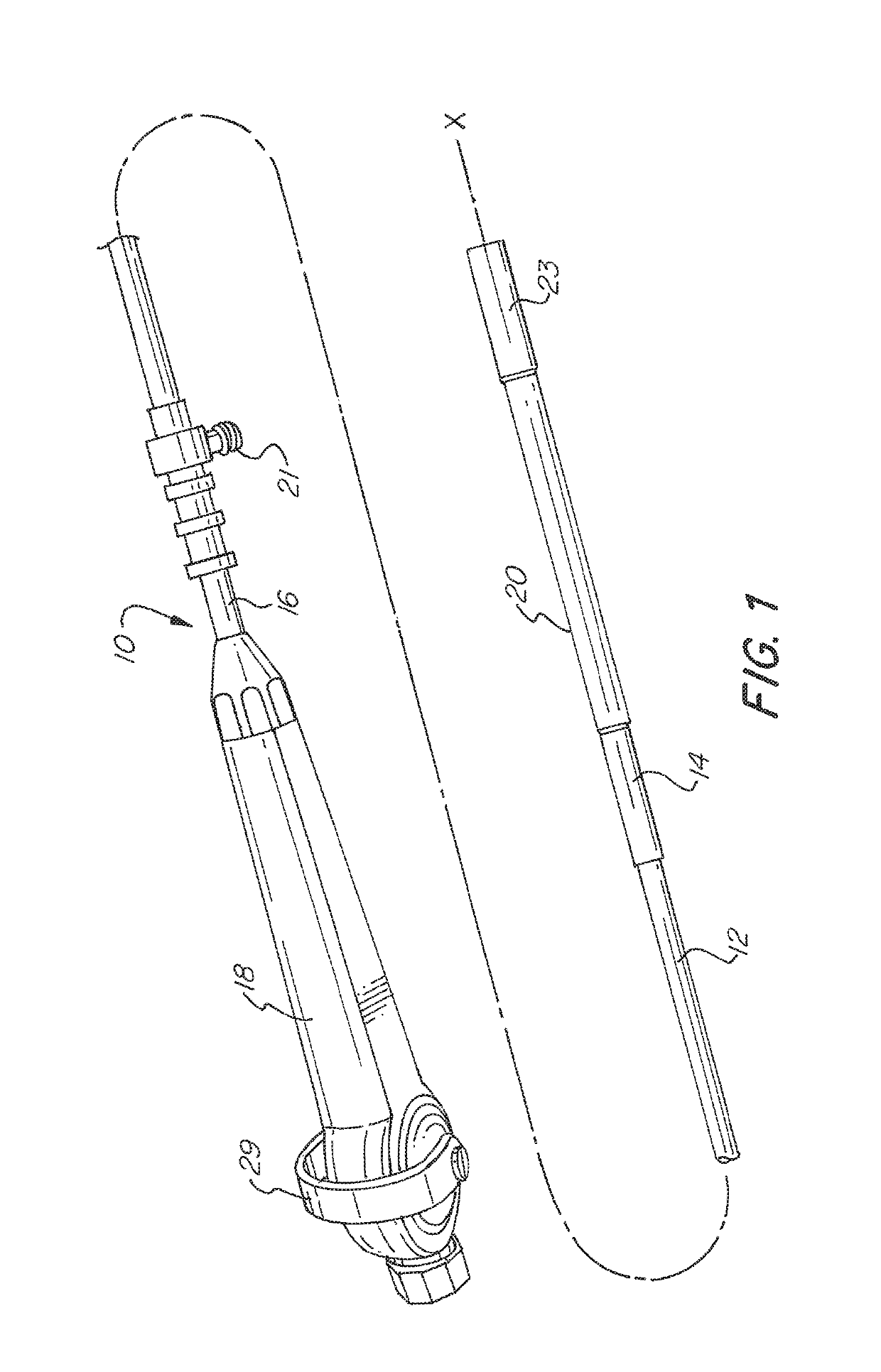

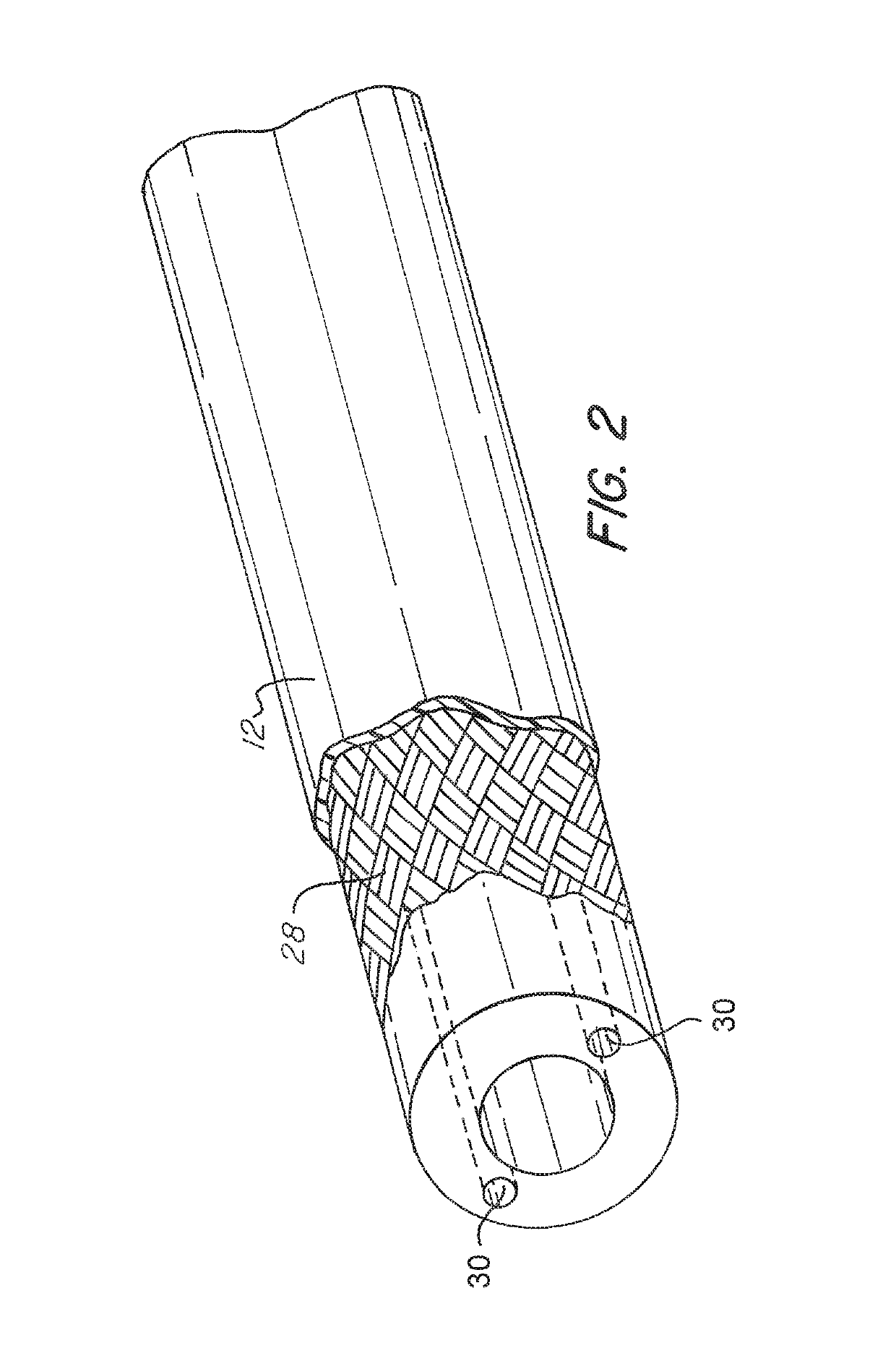

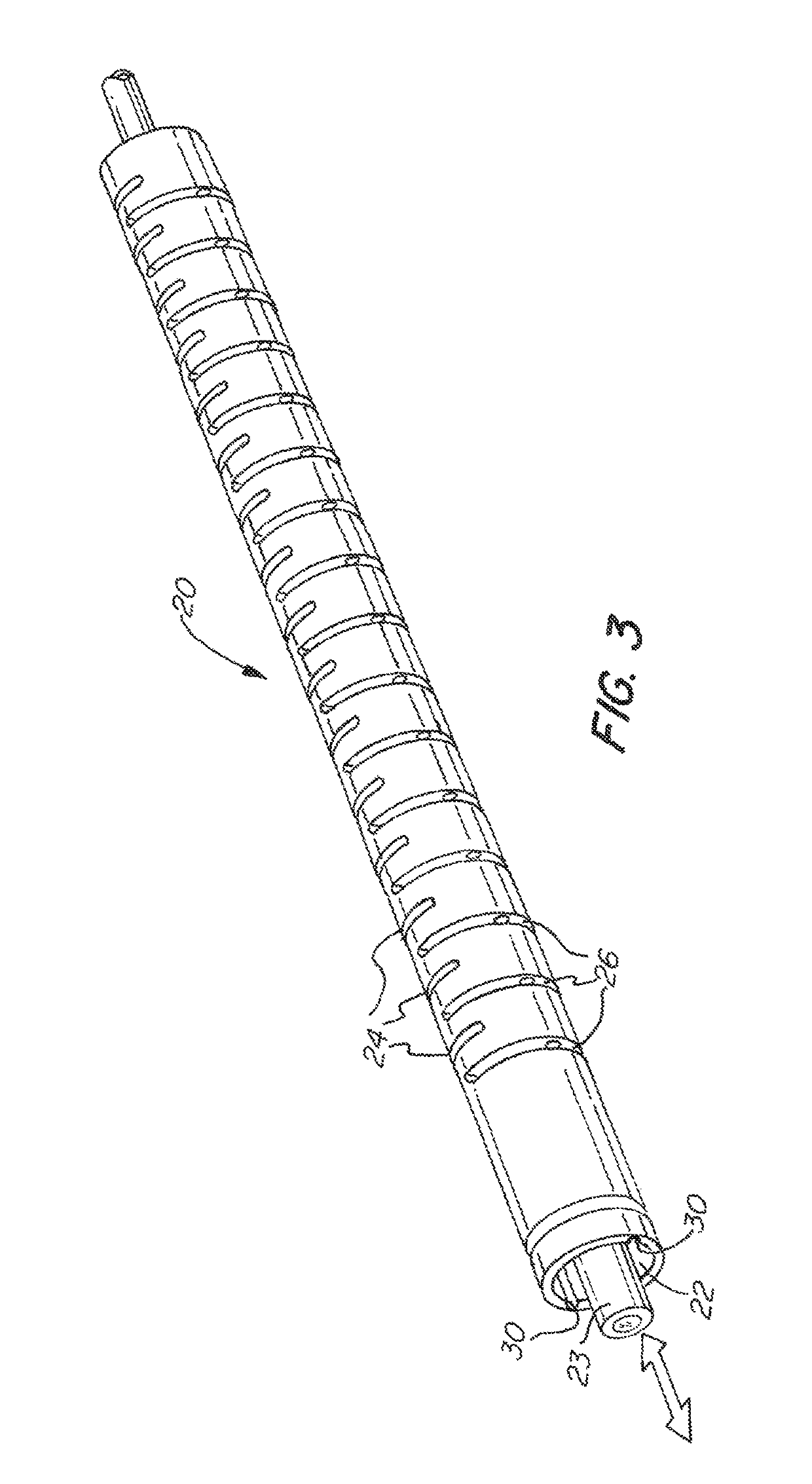

Steerable Catheter With Flexing Tip Member

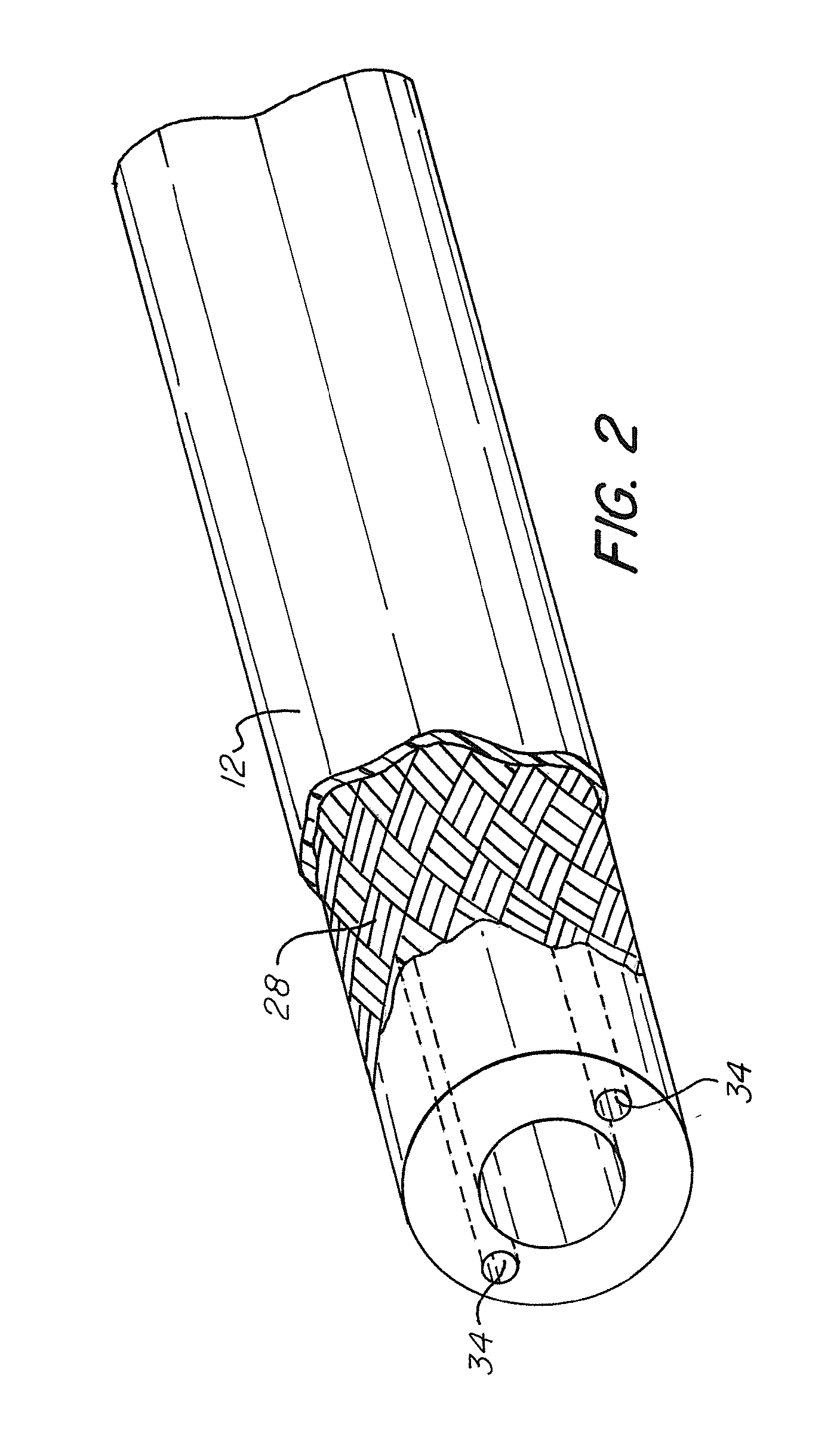

A steerable catheter device includes a catheter body, a flexing tip member coupled to a distal end of the catheter body and having a wall with a first plurality of arcuate slits and a second plurality of arcuate slits, the first and second plurality of slits being diametrically opposed and alternating with each other, and an actuator that bends the flexing tip member, wherein at least a portion of the catheter body includes a braided sheath, and wherein each of the first and second plurality of slits has two ends and a center positioned midway between the two ends, and wherein all of the first plurality of slits have centers positioned along a first axis substantially parallel to the longitudinal axis of the catheter body and all of the second plurality of slits have centers positioned along a second axis substantially parallel to the longitudinal axis of the catheter body.

Owner:SANOVAS

Embolic filtering devices

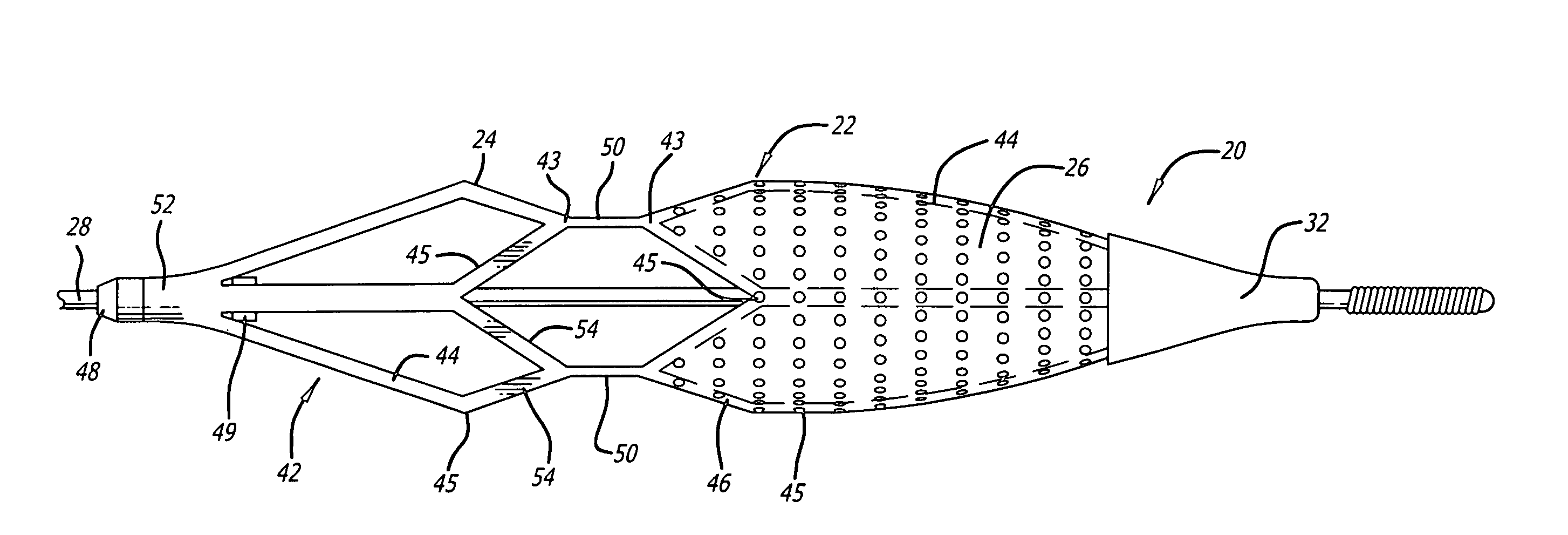

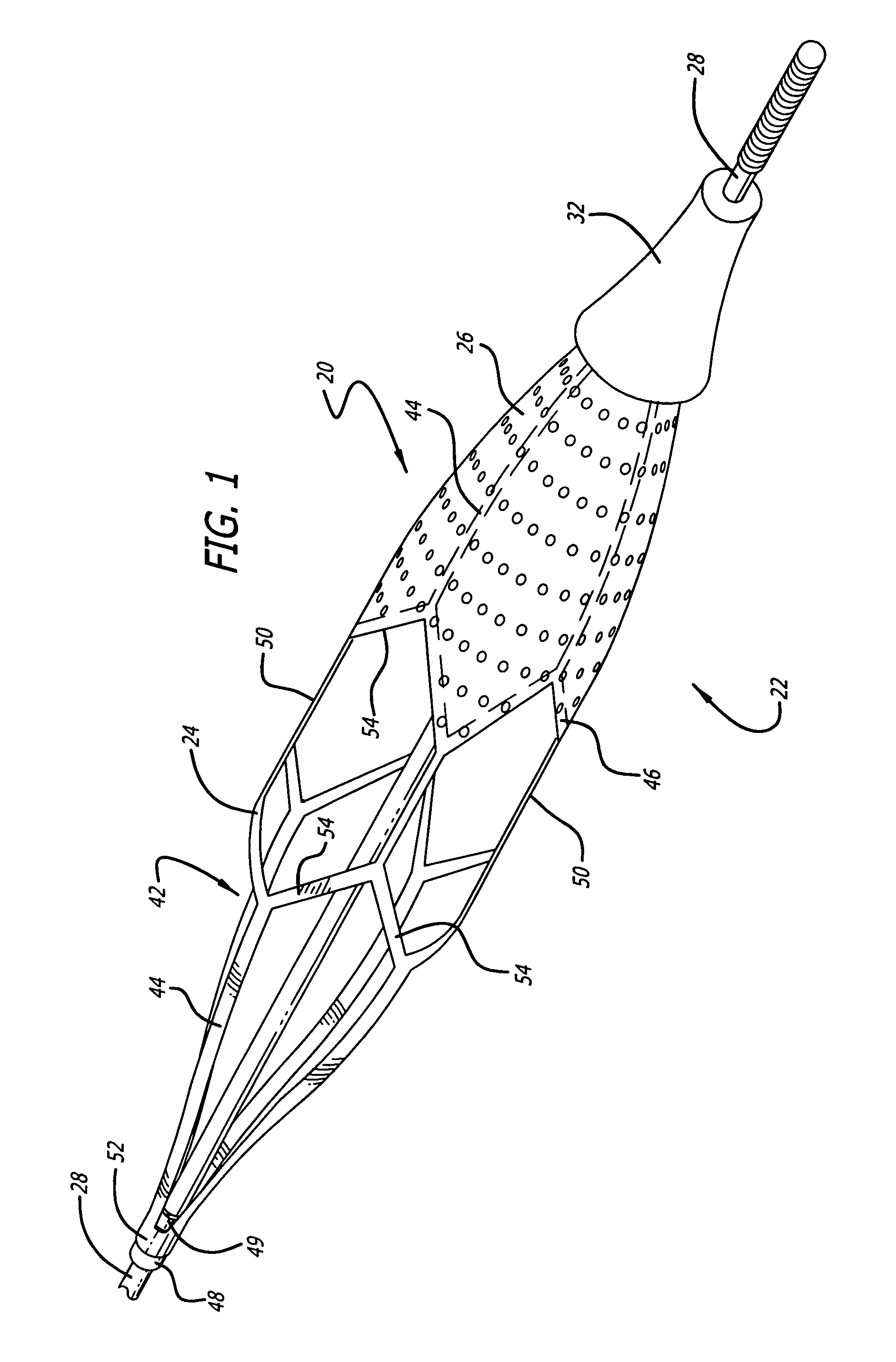

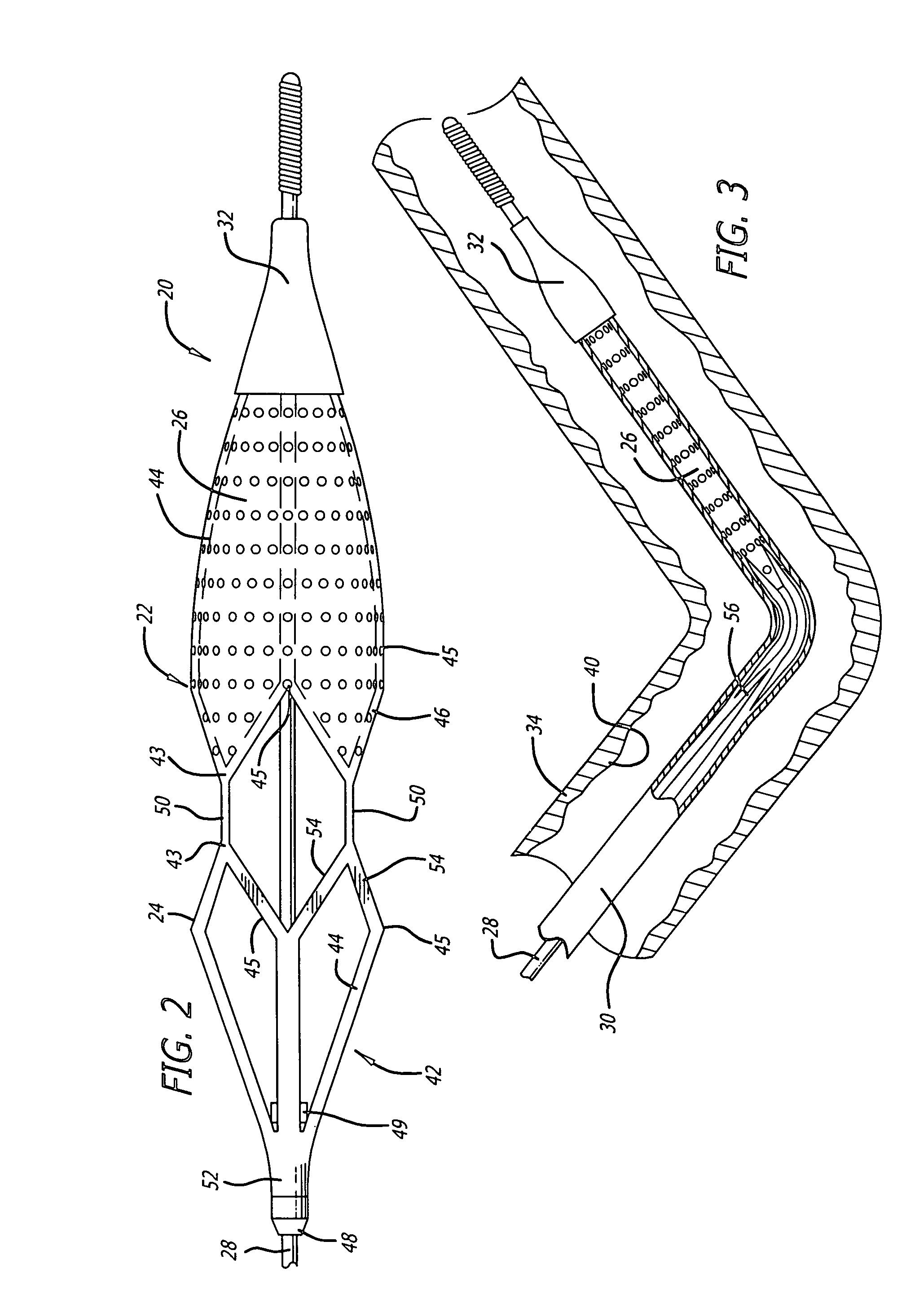

A self-expanding basket for use in conjunction with an embolic filtering device has a proximal set of struts which are connected to a distal set of struts by a bending region which provides enhanced bending characteristics to the basket. The bending region can be formed by intermediate links which are extremely flexible and bendable to allow the basket to be delivered through tortuous anatomy. The intermediate links are extremely flexible and create a mechanical hinge-like connection between the proximal and distal strut assemblies. The basket thus is capable of substantial bending when being delivered through the patient's vasculature and will bend and conform to the patient's anatomy once positioned for filtering purposes. The intermediate links can also lengthen, when needed, when positioned in a curved vessel in the patient's vasculature, when needed. As a result, the basket will easily conform to a curved body vessel to maintain proper wall apposition of the filtering element with the wall of the body vessel.

Owner:ABBOTT CARDIOVASCULAR

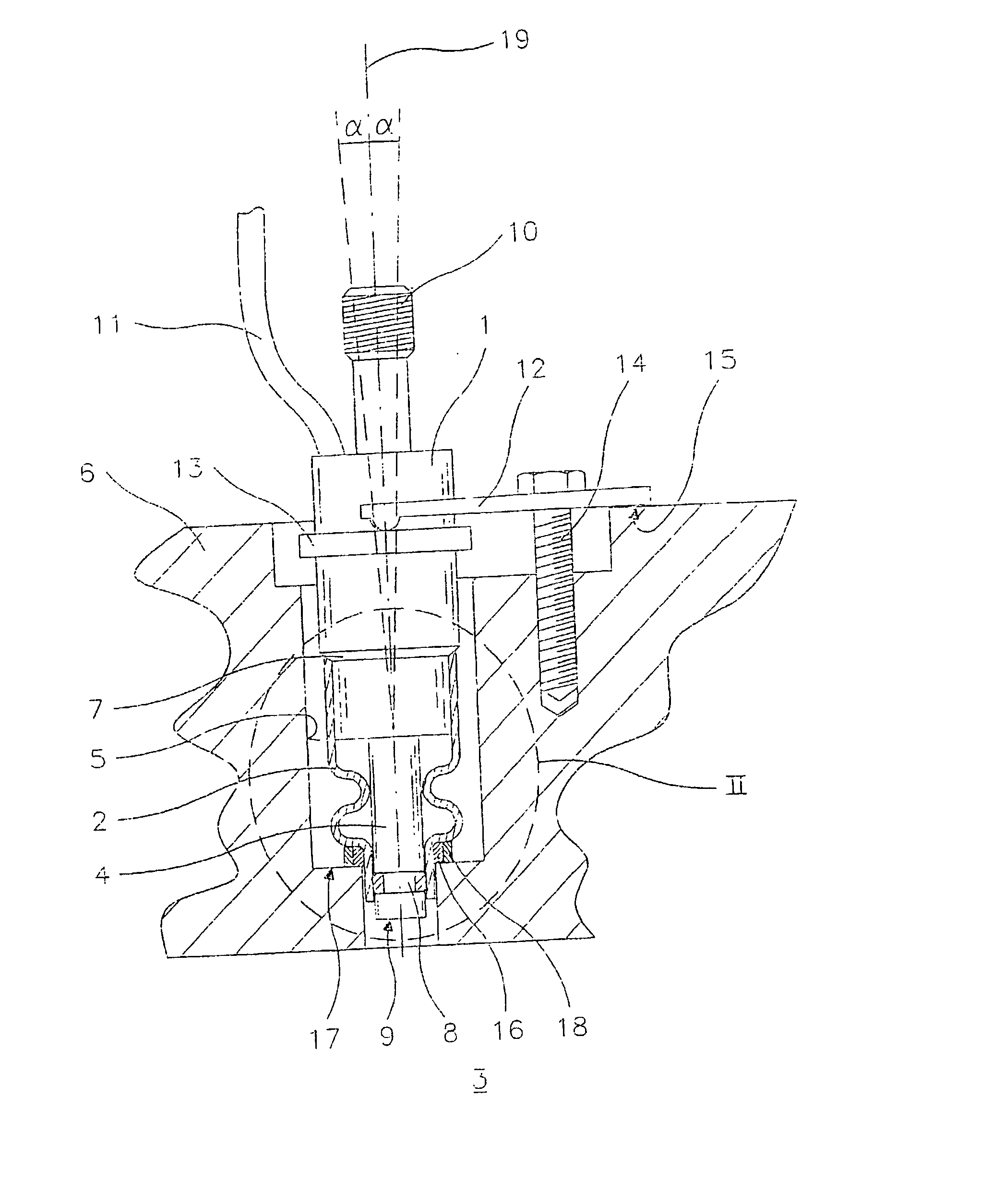

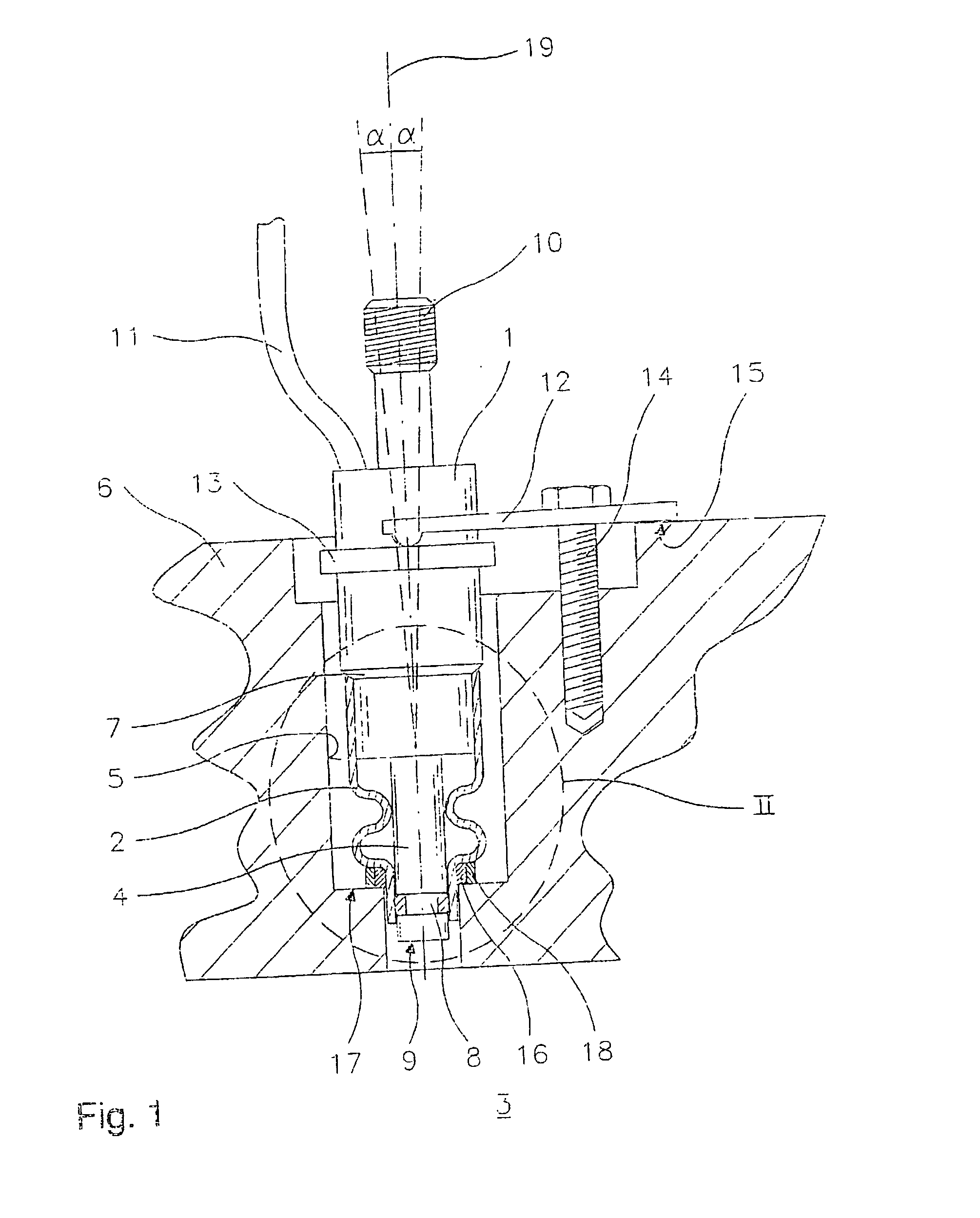

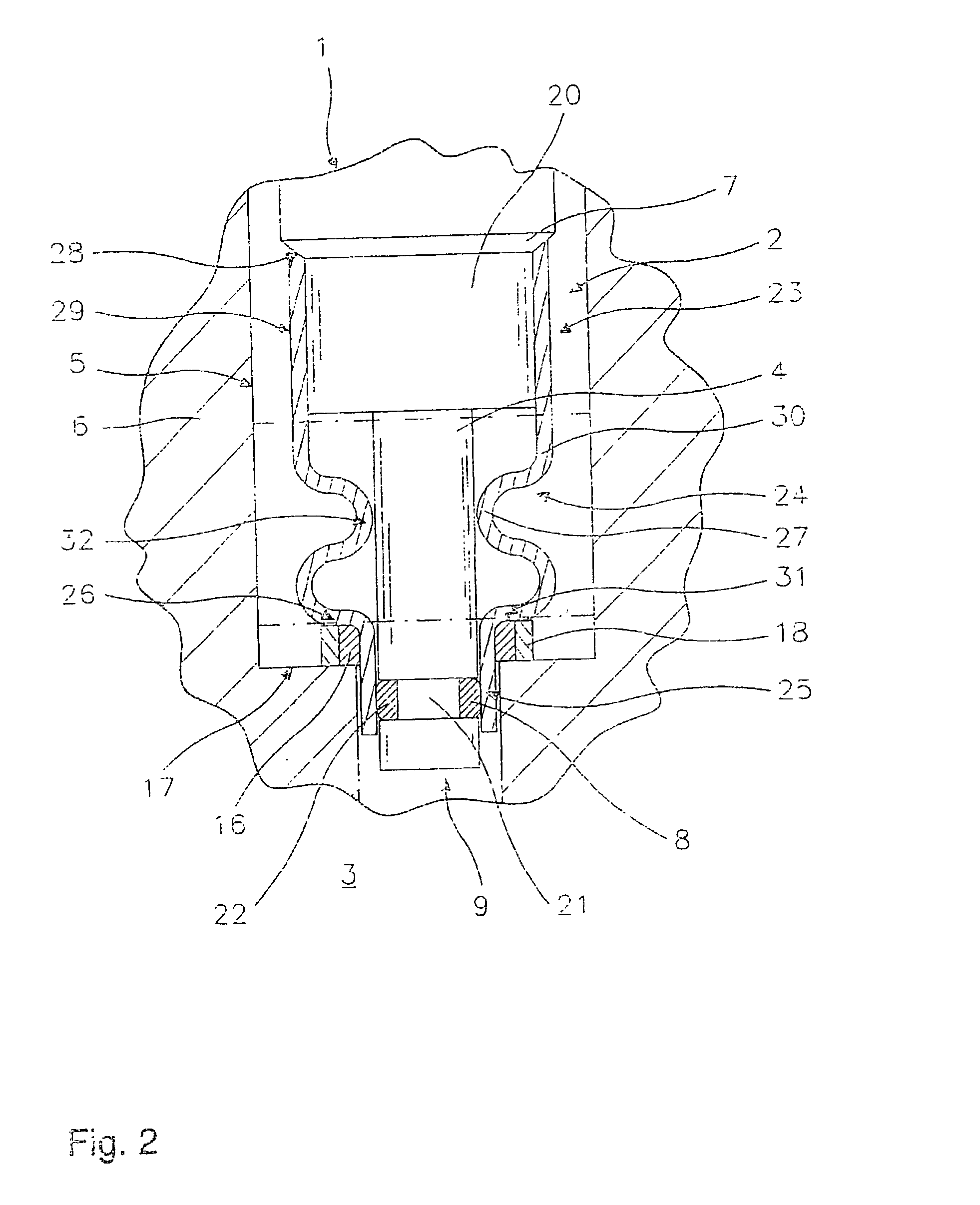

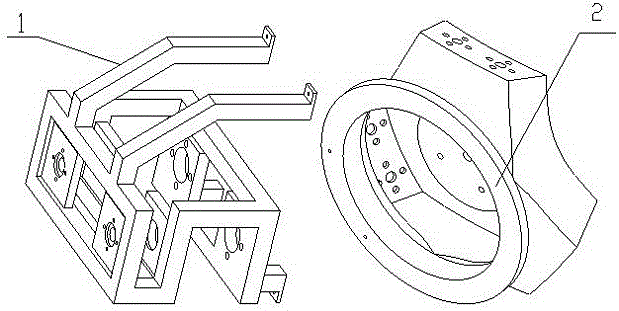

Compensating element

InactiveUS20020157648A1Easy to manufactureSignificant degreeCylinder headsCylindersCombustion chamberCylinder head

A compensating element (2) for a fuel injector (1), which can be inserted into a receiving borehole (5) of a cylinder head (6) of an internal combustion engine, in order to directly inject fuel into the combustion chamber (3) of the internal combustion engine, has a compensating sleeve (30); a connecting segment (23) of the compensating sleeve (30) being attachable to a housing segment (20) of the fuel injector (1). The compensating element (2) is supported in the receiving borehole (5) of the cylinder head (6), by a support segment (25) of the compensating sleeve (30); and a flexible segment (24) is provided between the connecting segment (23) and the support segment (25).

Owner:ROBERT BOSCH GMBH

Pneumatic soft mechanical hand with touch sensing function

The invention discloses a pneumatic type soft mechanical hand with a touch sensing function. The pneumatic soft mechanical hand is composed of an electric heating phase change actuator, a soft mechanical hand and a flexible touch sensing unit, wherein a flexible heating film and a liquid phase change material are arranged in the electric heating phase change actuator. According to the pneumatic type soft mechanical hand with the touch sensing function, the liquid phase change material is evaporated by electrifying and heating the flexible heating film, so that the pressure intensity of the cavity in the inner part of the electric heating phase change actuator is regulated, thus the bending state of the soft mechanical hand is dynamically adjusted so as to complete the grabbing operation; meanwhile, the flexible touch sensing unit is used for sensing time-varying information of grabbing force during the grabbing target process of the soft mechanical hand and taking the time-varying information as a feedback source for adjusting the bending state of the soft mechanical hand, so that closed-loop feedback control is formed; and the structure of the pneumatic type soft mechanical hand is flexible, a feasibility scheme is provided for safely and intelligently grabbing for the robot dexterous hand.

Owner:ANHUI UNIVERSITY

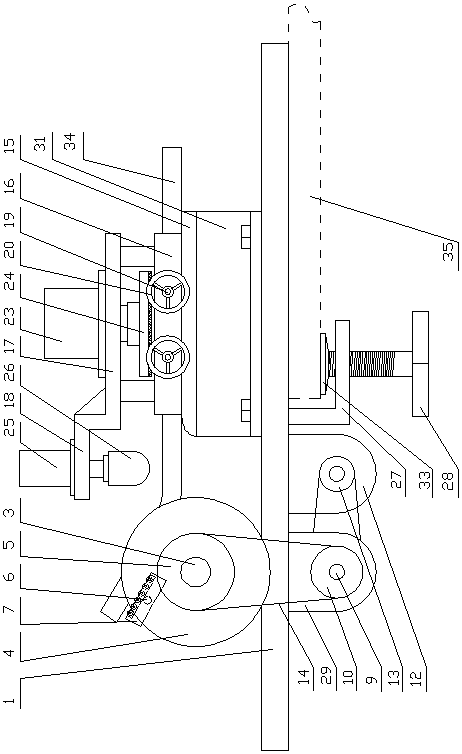

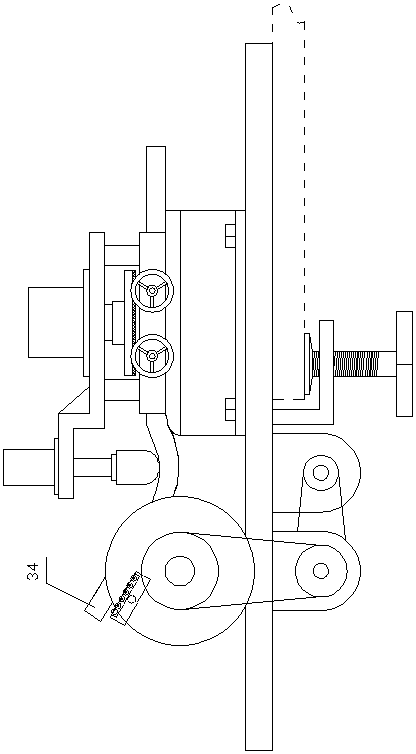

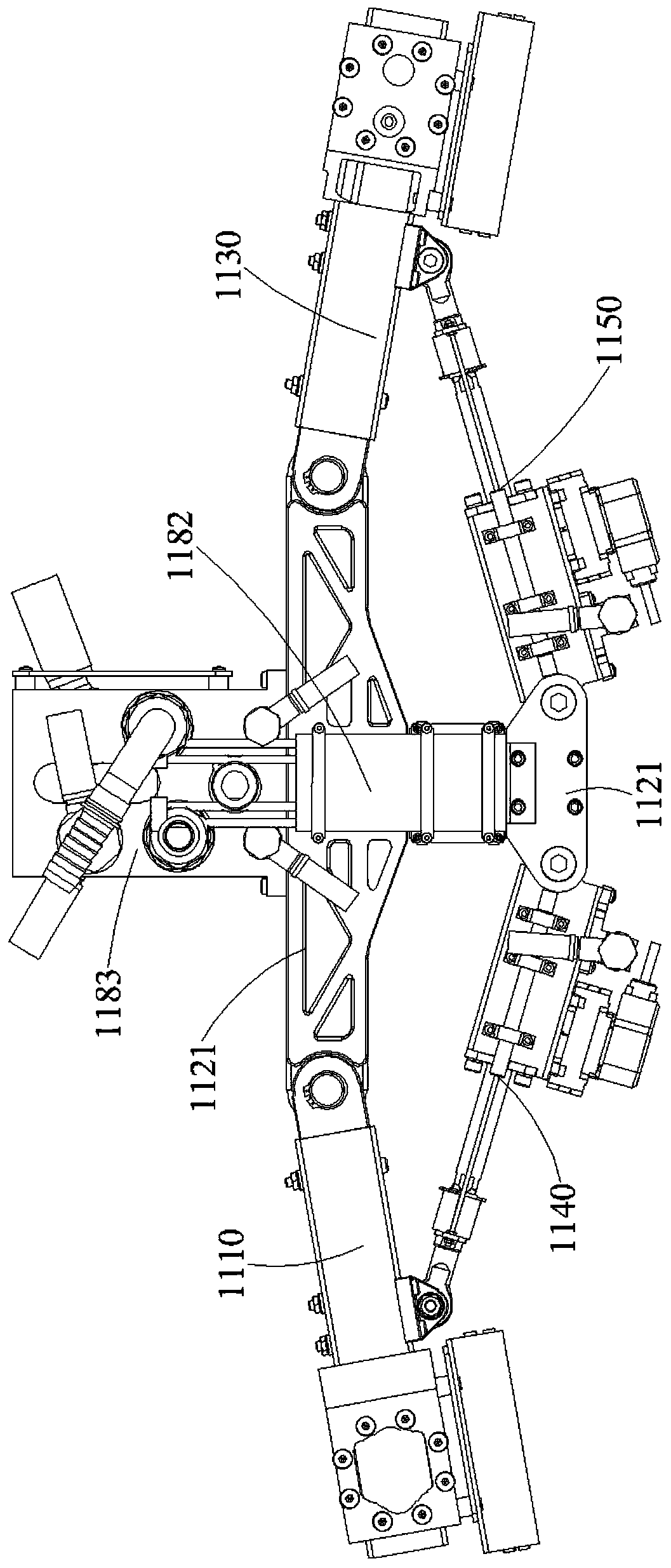

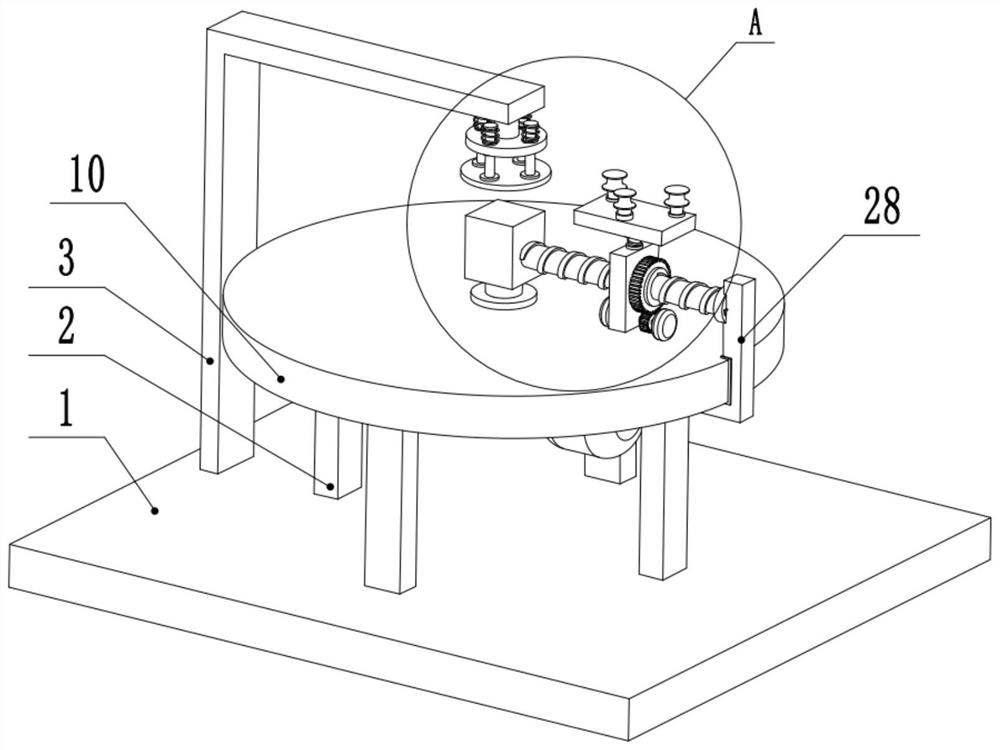

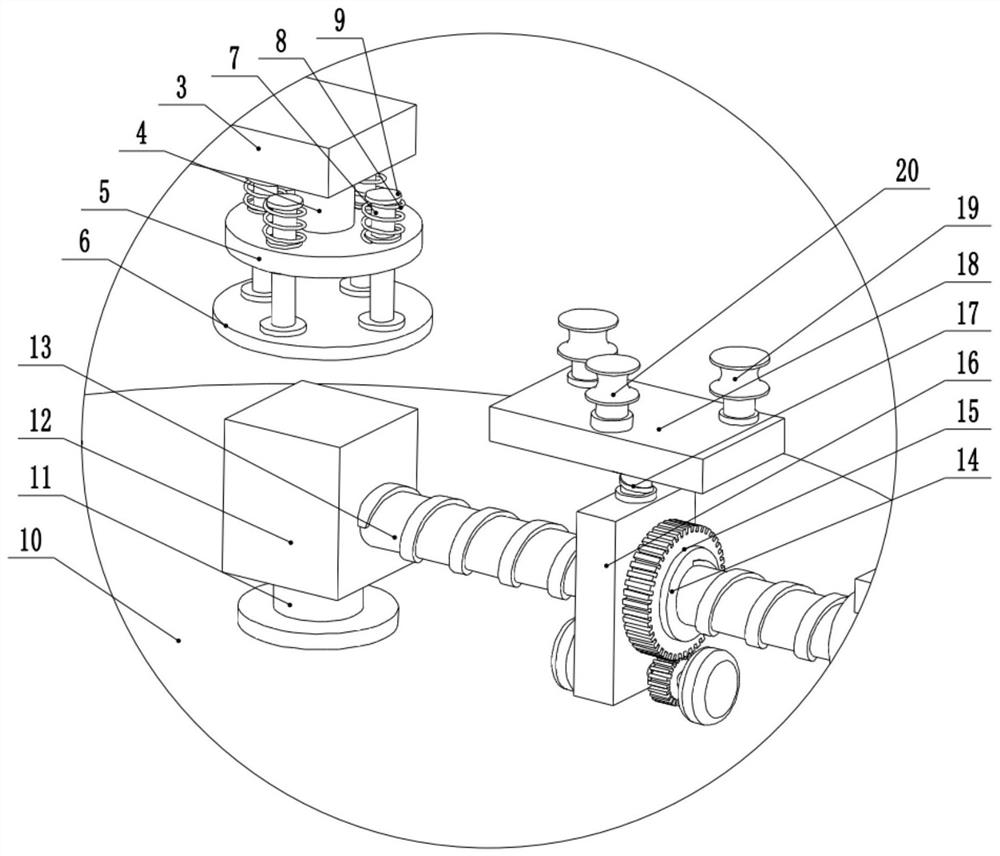

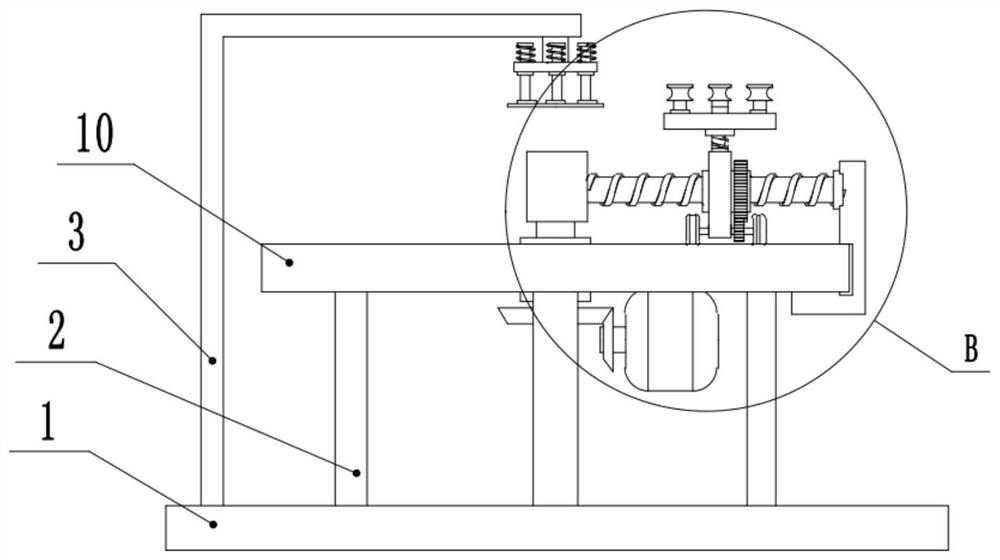

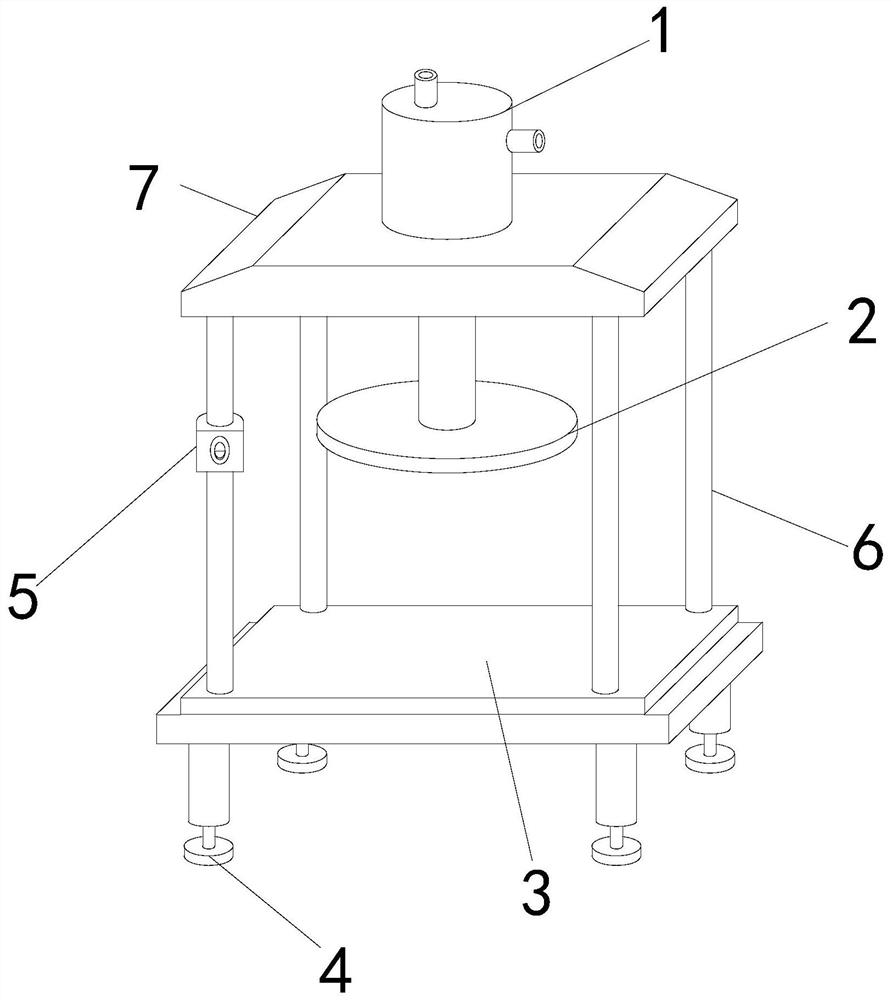

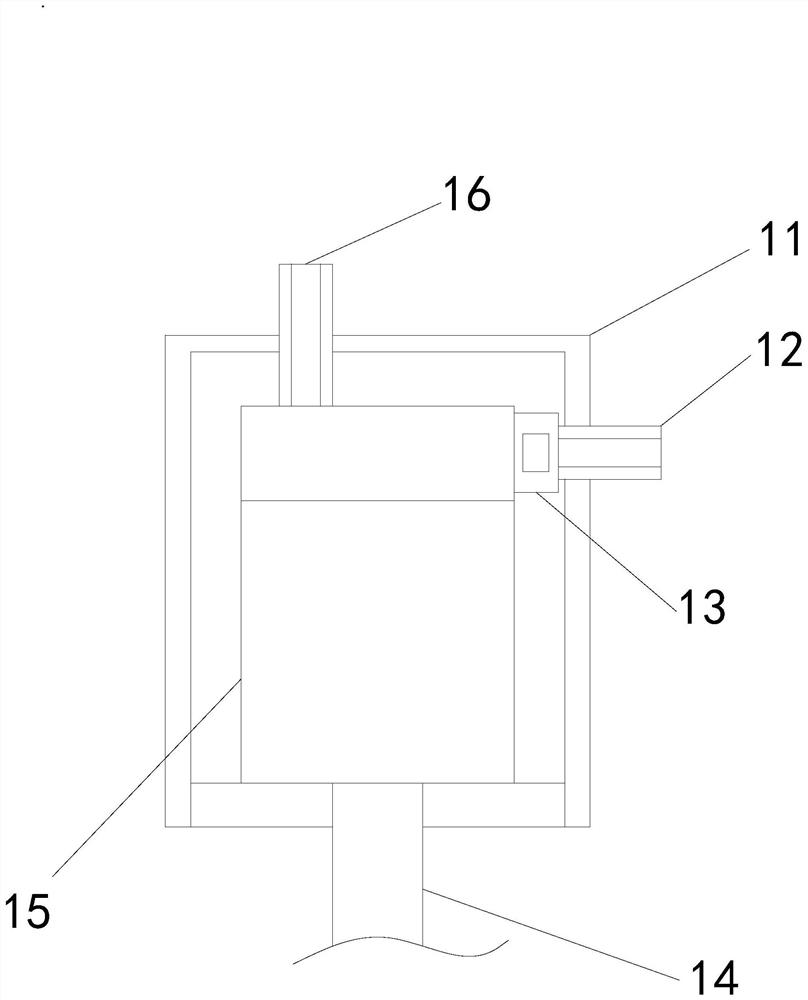

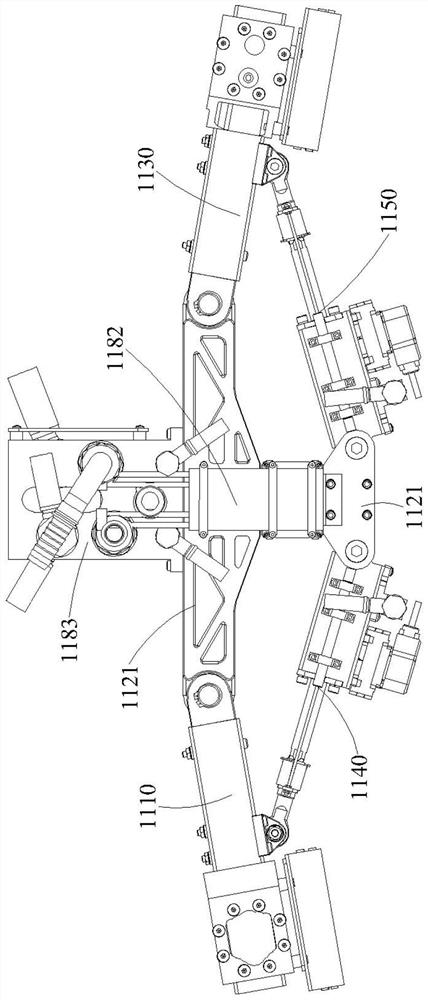

Clamping type pipe bending equipment

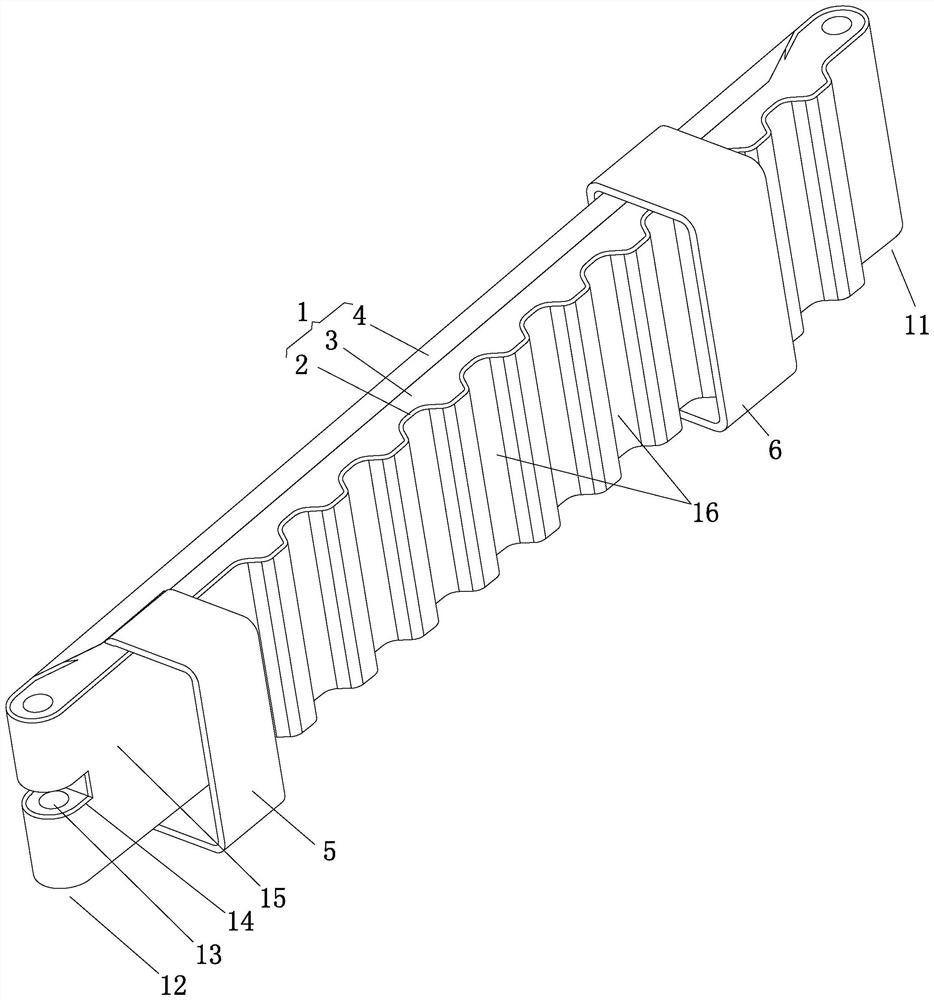

InactiveCN108057747ALarge bendRealize the second bendMetal-working feeding devicesPositioning devicesEngineeringMechanical engineering

The invention discloses clamping type pipe bending equipment. The equipment comprises a device main frame; a spindle base is welded to the upper part of the device main frame and is matched with the spindle in a rotating mode; a rotating wheel and a driven chain wheel are connected to the spindle in a key mode; a push shaft is connected to the rotating wheel; a pipe push support is arranged on thepush shaft in a rotating mode; the driven chain wheel is matched with transfer chain wheels on a transfer shaft; a supporting plate frame is further detachably connected to the device main frame; supporting frames are welded to the two sides of the upper part of the supporting plate frame; a top plate frame is connected to the upper parts of the supporting frames; a lower pressing plate frame iswelded to one end of the top plate frame; a plurality of limiting bolts are connected to the supporting frames in a screwed mode; a fixed oil cylinder is arranged on the top plate frame; a lower pressing oil cylinder is arranged on the lower pressing plate frame; a right-angled frame is welded to the lower part of the device main frame; and a clamping bolt is connected to the right-angled frame ina screwed mode. The clamping type pipe bending equipment is clamped on a workbench, pipes can be bent in batches, the working efficiency is high, the uniformity of the bending angles of the pipes isgood, the operation is labor-saving and simple, and the application range is wide.

Owner:ANHUI TECHN COLLEGE OF MECHANICAL & ELECTRICAL ENG

Steerable catheter with flexing tip member

A steerable catheter device includes a catheter body, a flexing tip member coupled to a distal end of the catheter body and having a wall with a first plurality of arcuate slits and a second plurality of arcuate slits, the first and second plurality of slits being diametrically opposed and alternating with each other, and an actuator that bends the flexing tip member, wherein at least a portion of the catheter body includes a braided sheath, and wherein each of the first and second plurality of slits has two ends and a center positioned midway between the two ends, and wherein all of the first plurality of slits have centers positioned along a first axis substantially parallel to the longitudinal axis of the catheter body and all of the second plurality of slits have centers positioned along a second axis substantially parallel to the longitudinal axis of the catheter body.

Owner:SANOVAS

Electronic Device and Method for Manufacturing Same

InactiveUS20100003804A1Large bendLarge warpageSemiconductor/solid-state device detailsPrinted circuit aspectsEngineeringSemiconductor

Owner:EGUCHI TOSHIMASA +1

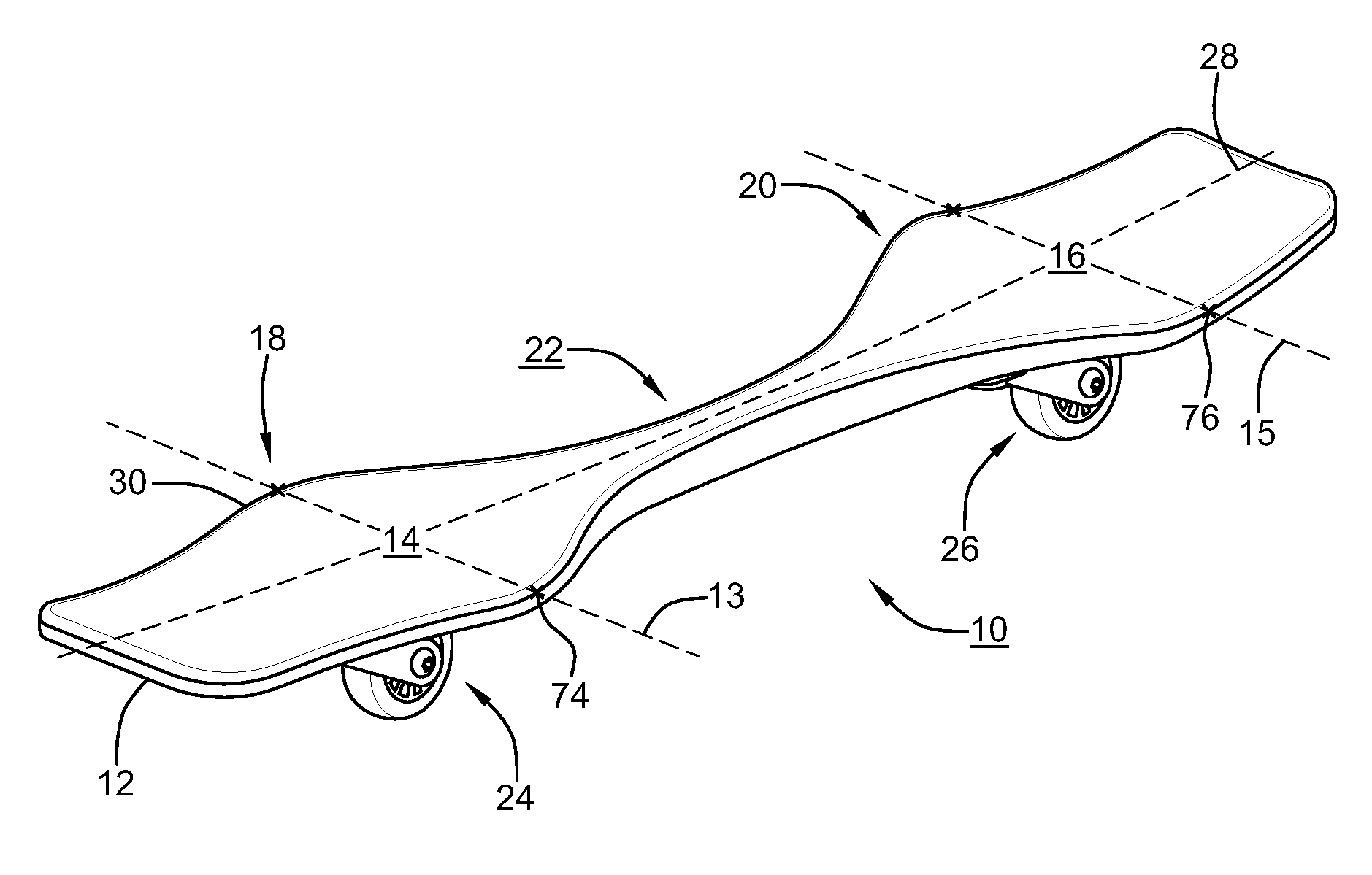

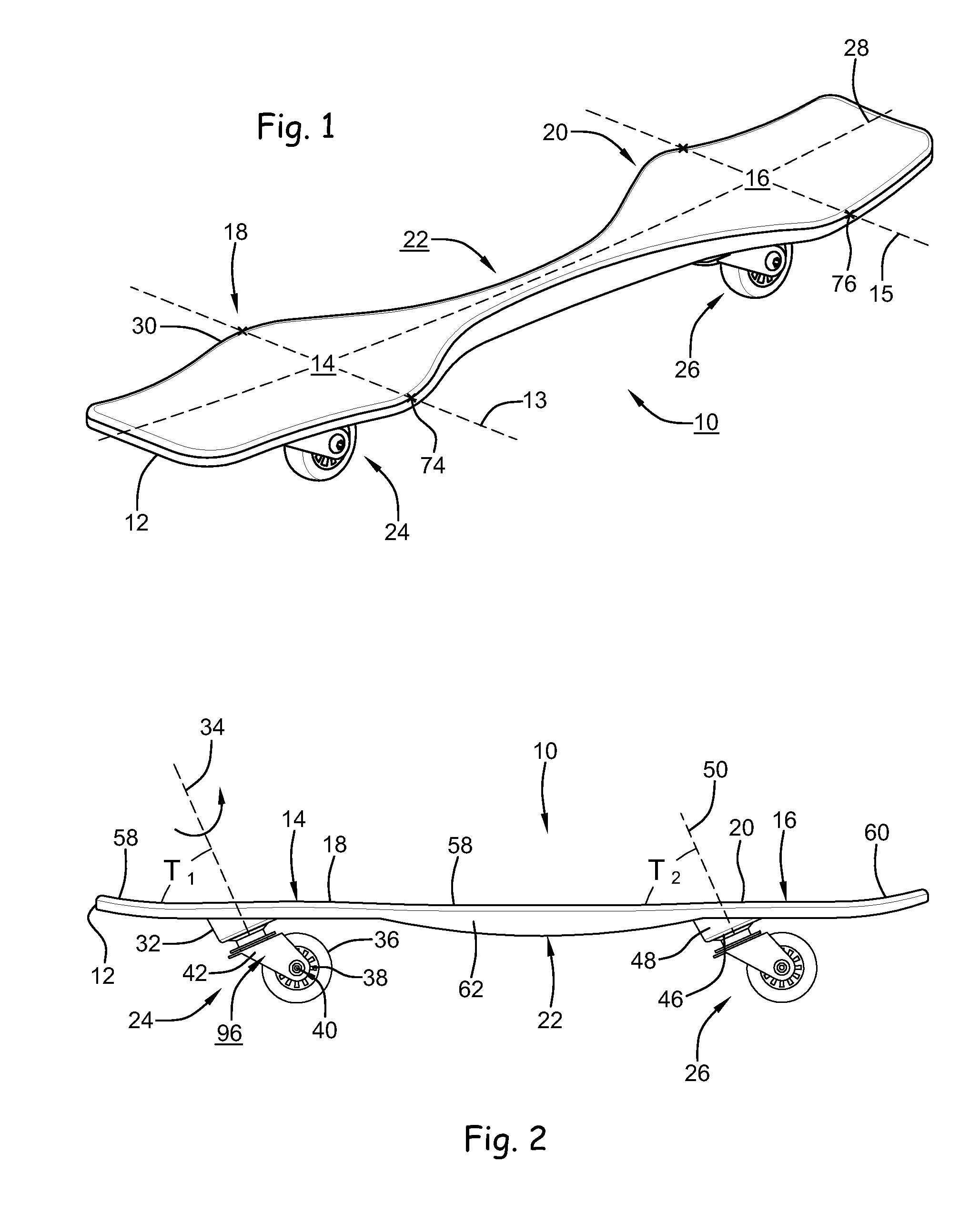

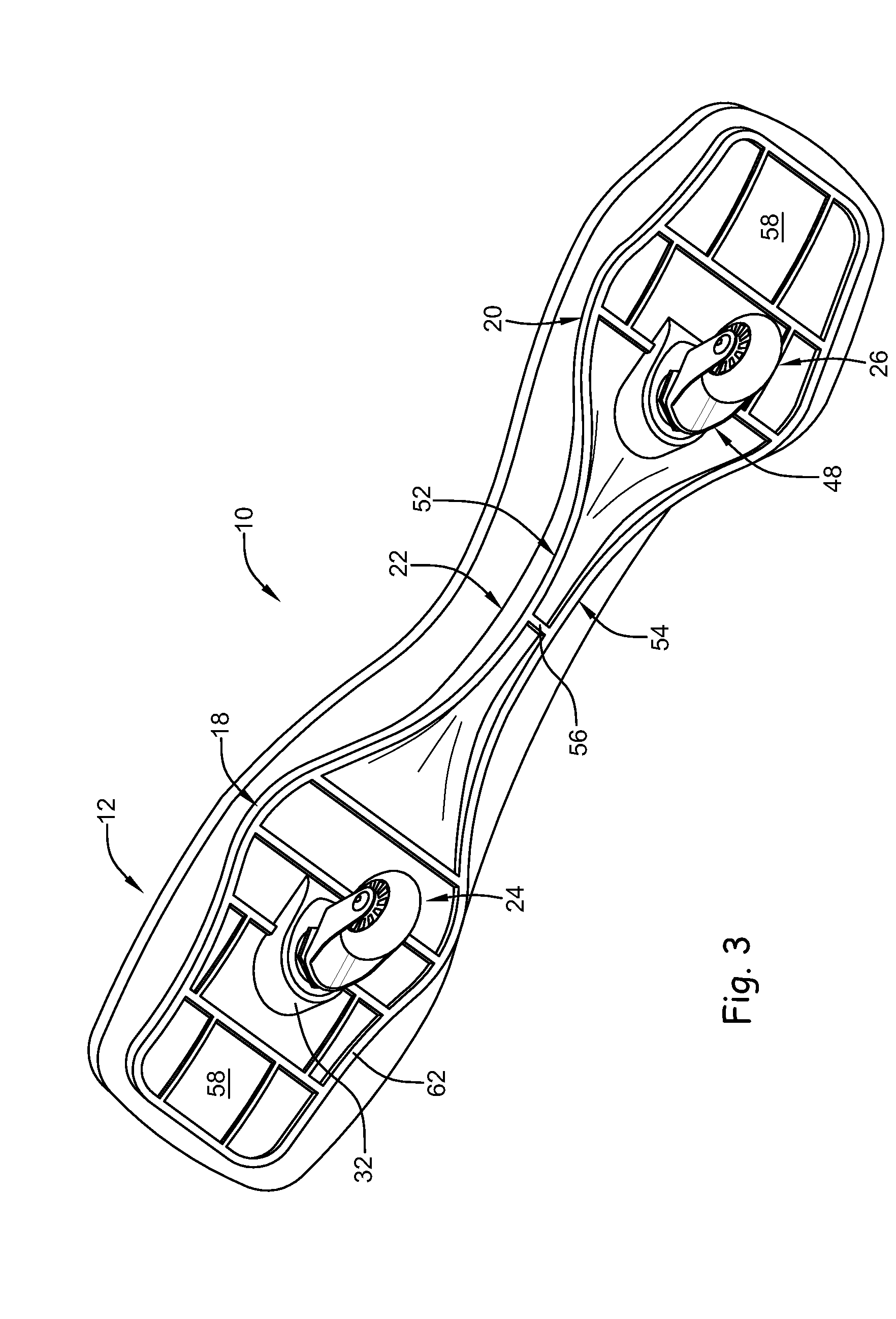

One piece flexible skateboard

ActiveUS20070252354A1Large bendImproved resistance to twistingSkatesGuiding agricultural machinesEngineeringSlide plate

Owner:RAZOR USA

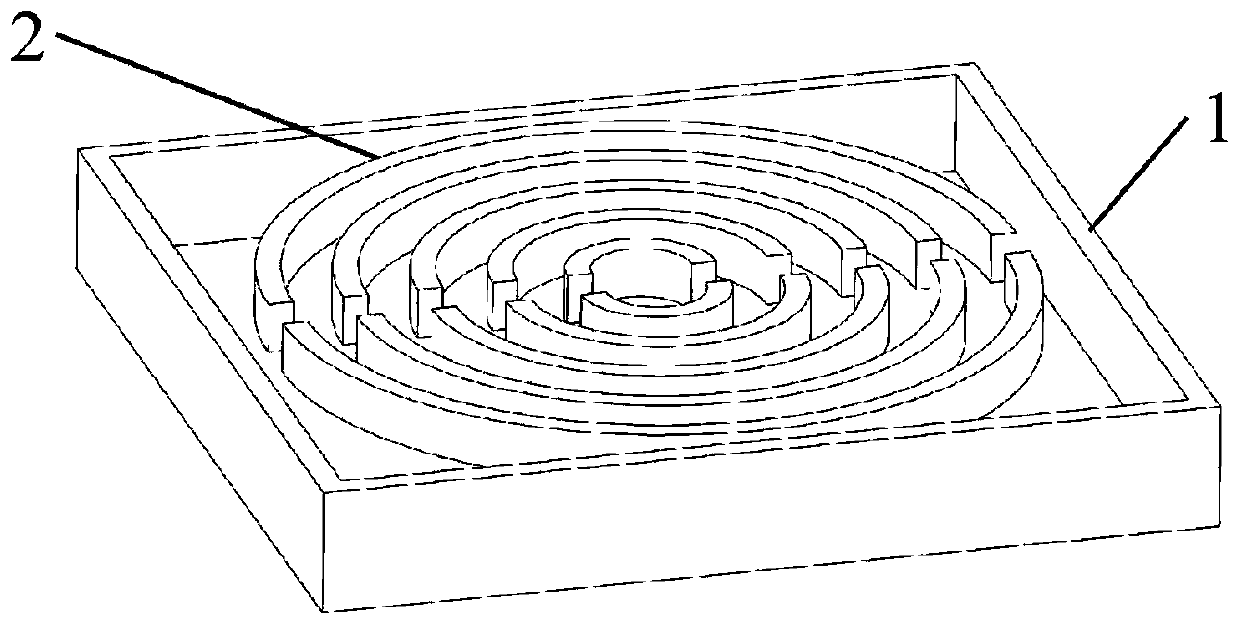

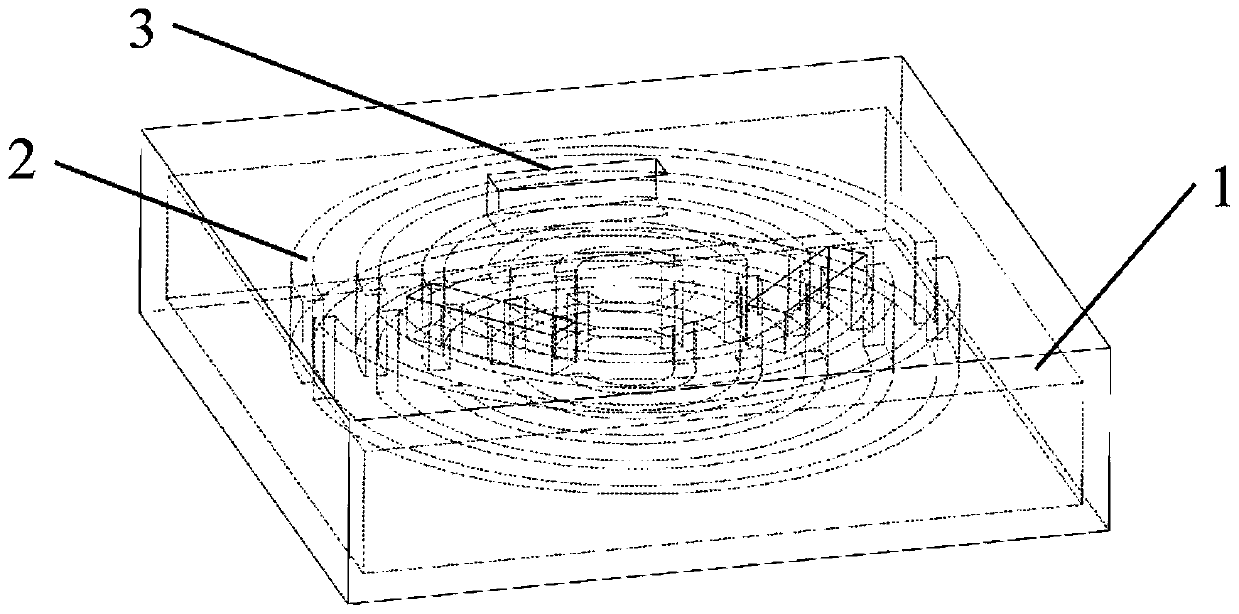

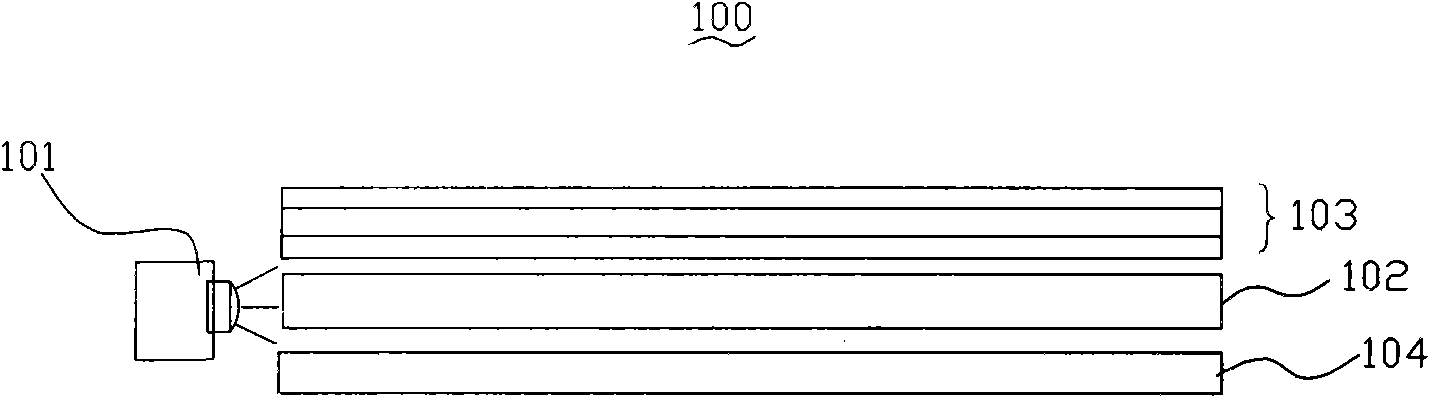

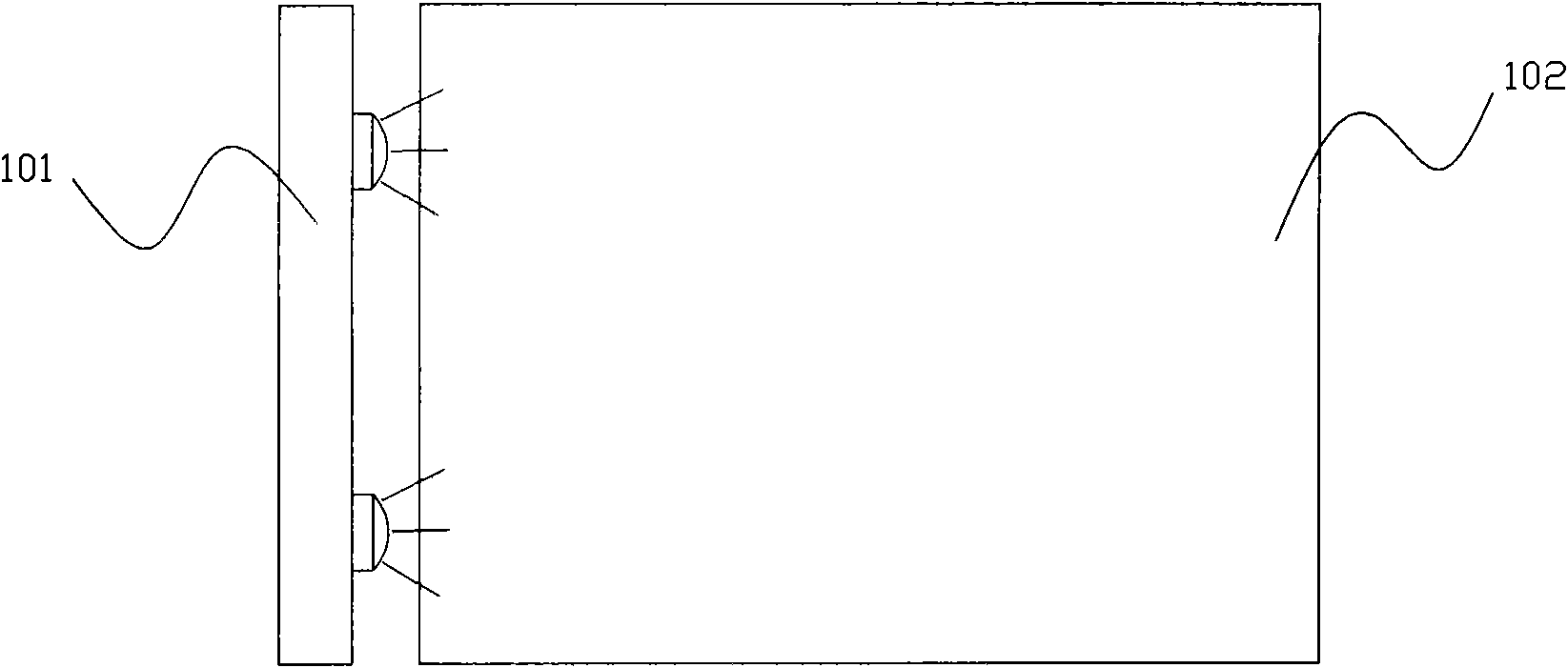

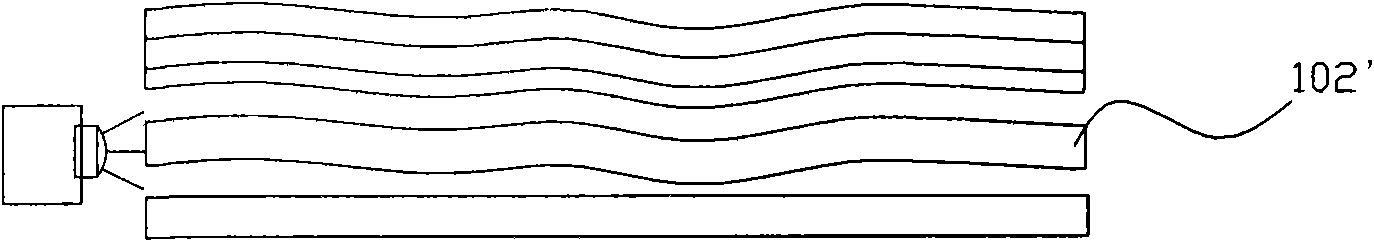

Light guide plate and back light module

InactiveCN101818882ALarge bendMechanical apparatusLight guides for lighting systemsLight guideEngineering

The invention provides a light guide plate and a back light module using the same. The light guide plate is formed by the connection of multiple sub-light guide plates by hinge structures, wherein the contact surface of each sub-light guide plate is designed into a concave-convex matching cambered surface structure to enable the whole light guide plate to be bent to a certain extent along the cambered surfaces. Therefore, the light guide plate and the back light module have the advantage of large bending amplitude and are not influenced by the dimension.

Owner:AU OPTRONICS (XIAMEN) CORP +1

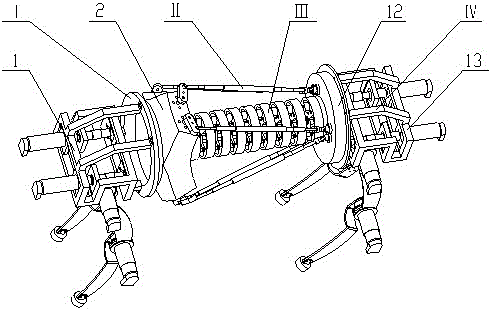

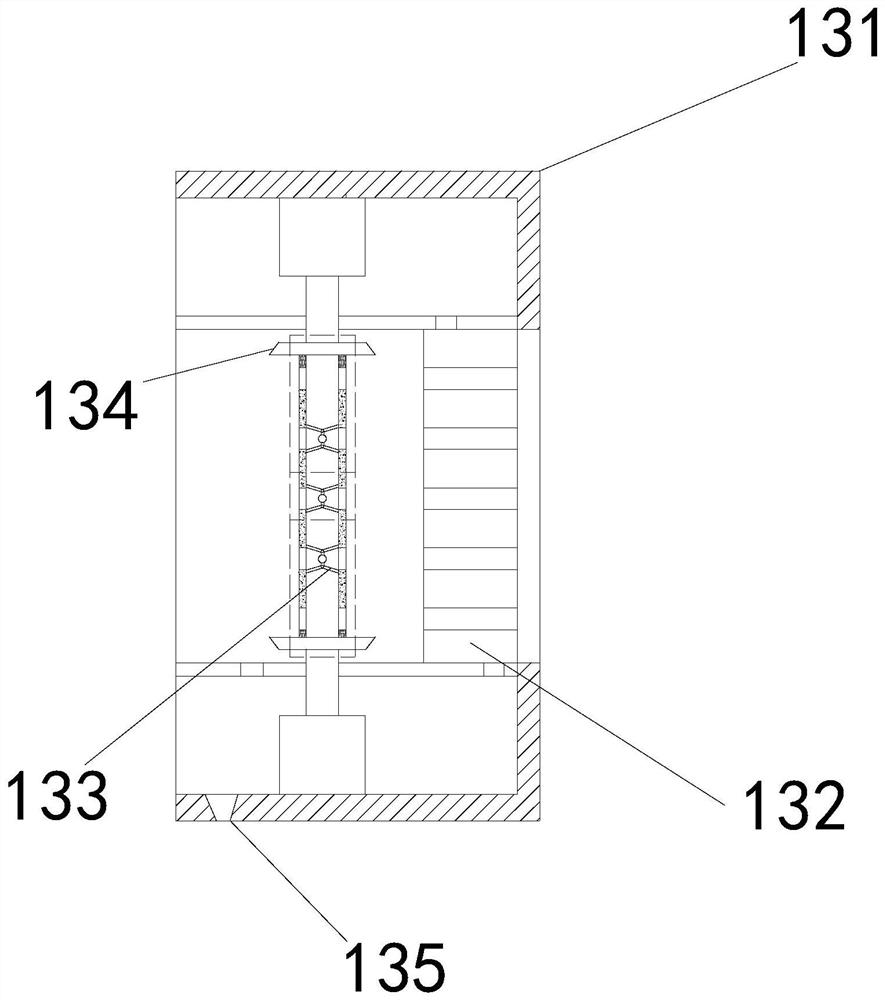

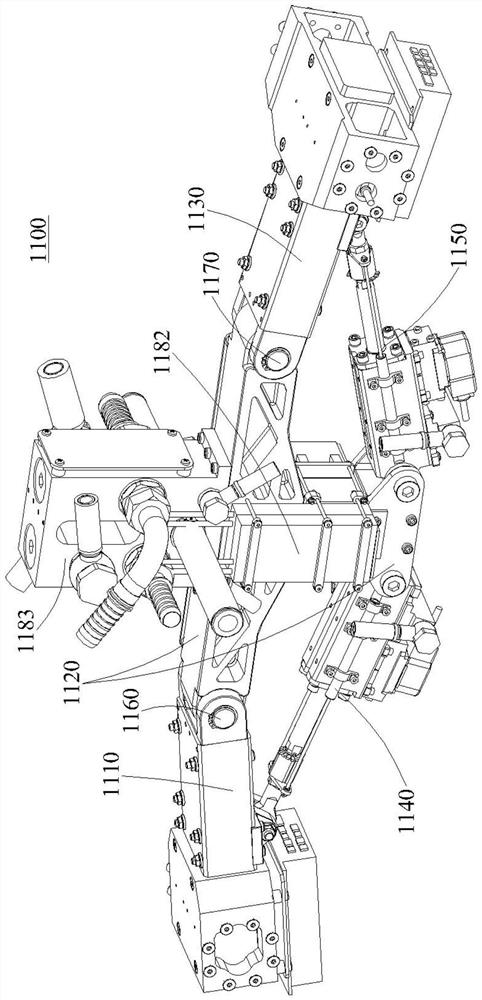

Bionic body mechanism capable of realizing multi-directional bending

The invention relates to a bionic body mechanism capable of realizing multi-directional bending. The bionic body mechanism comprises a front body assembly, a driving assembly, a bionic spine assembly and a back body assembly, wherein the front body assembly and the back body assembly adopt frame structures; the driving assembly comprises six motors which drive six fixed-length connecting rods respectively and are circumferentially distributed around the bionic spine assembly, and the driving assembly is fixedly connected with the front body assembly and the back body assembly through screws; the two ends of the bionic spine assembly are fixedly connected with the front body assembly and the back body assembly through screws respectively. The bionic body mechanism capable of realizing multi-directional bending simulates the body structure of four-footed organisms, can realize lateral bending and vertical bending, has a good bionic property and bending flexibility and overcomes the defect that traditional robot body structures cannot realize flexible and dynamic bending.

Owner:SHANGHAI UNIV

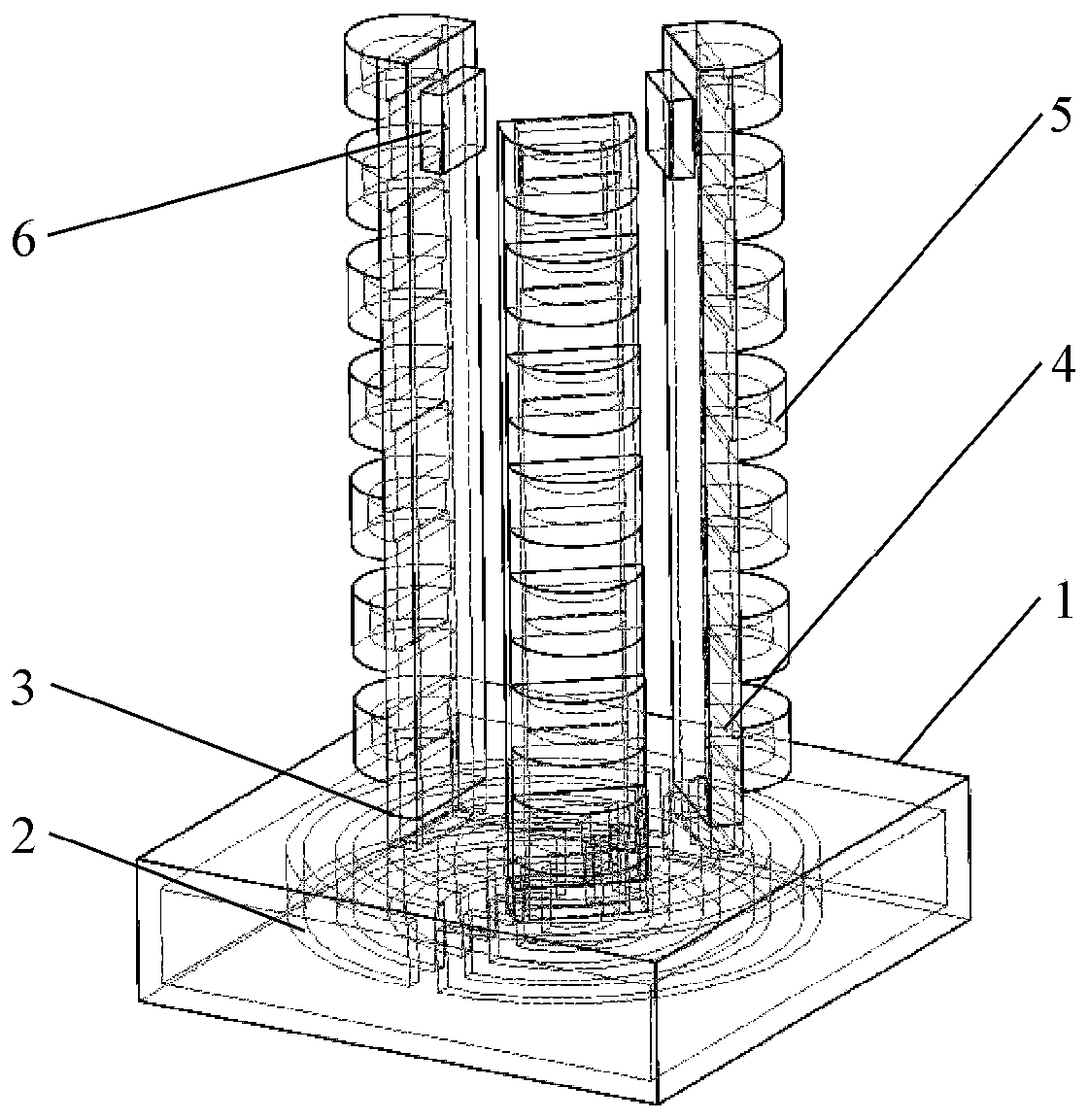

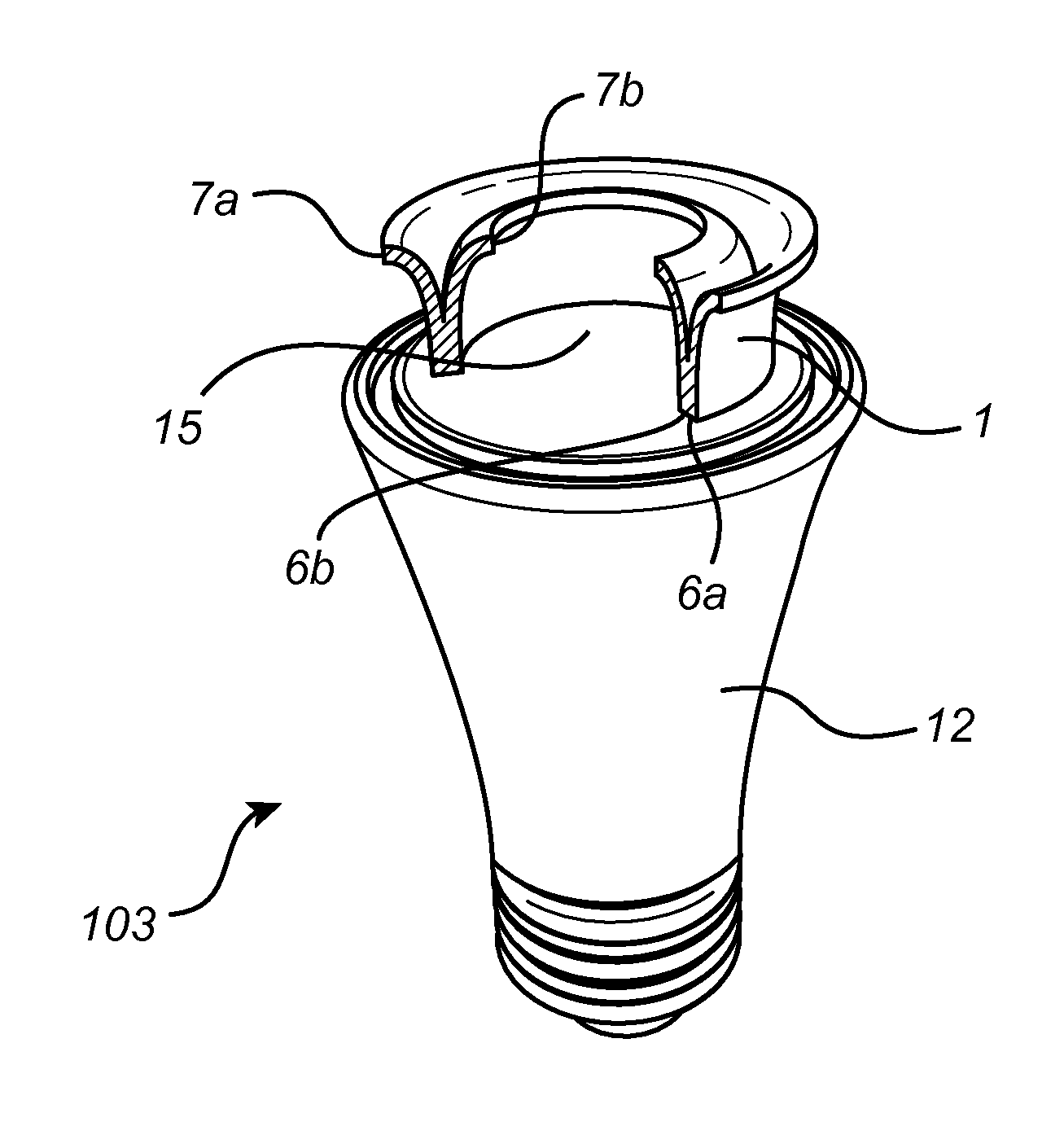

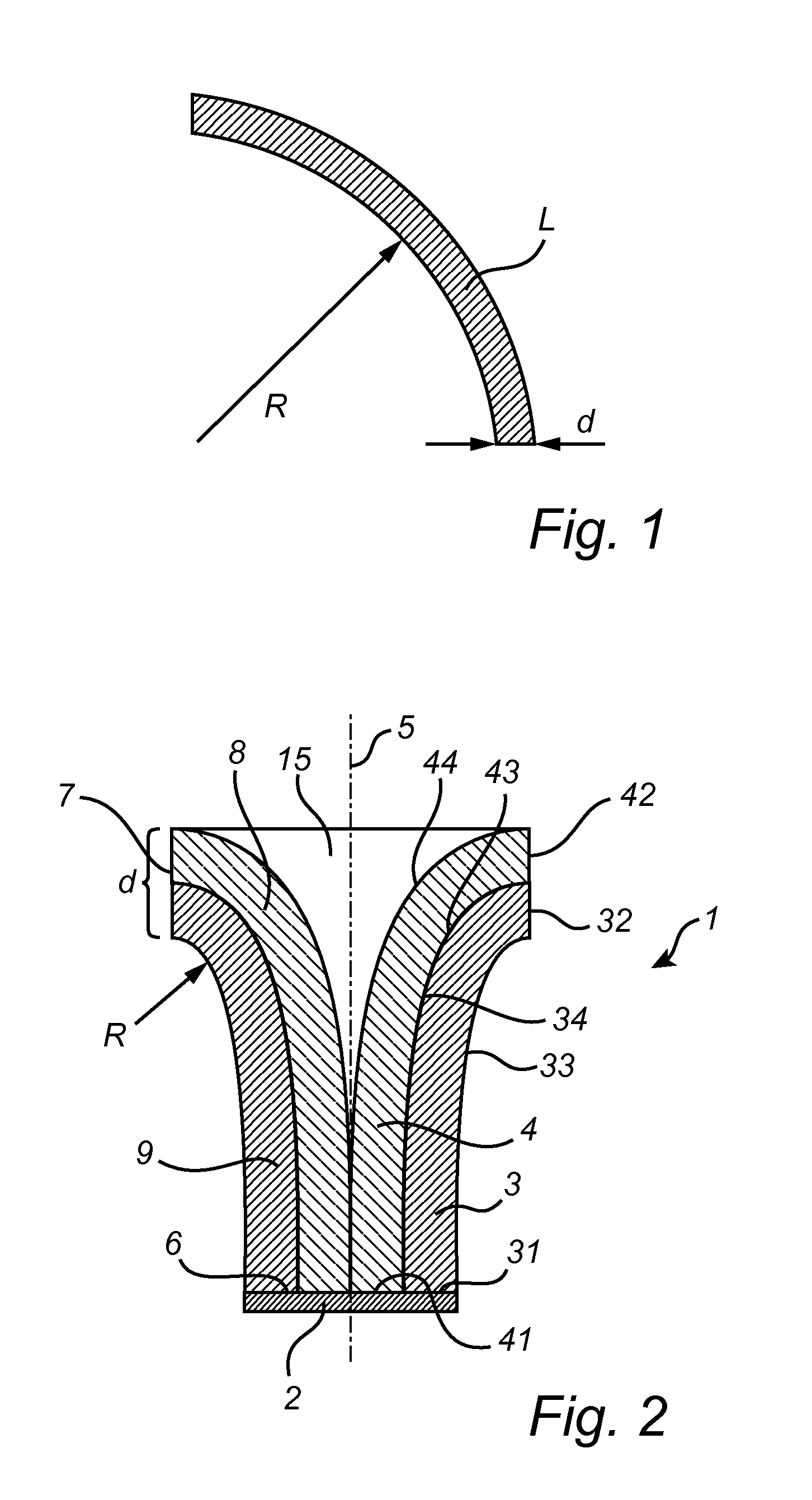

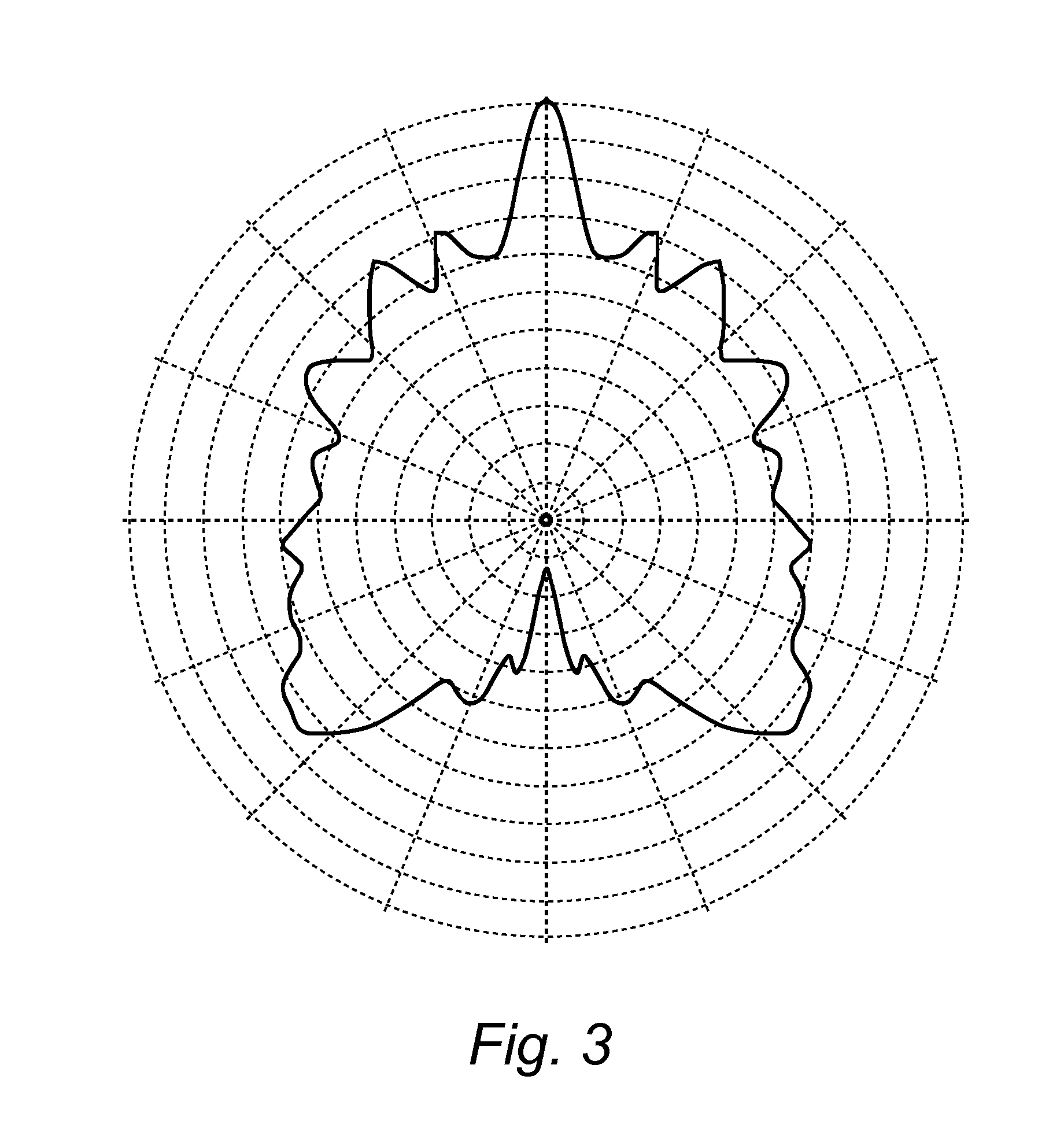

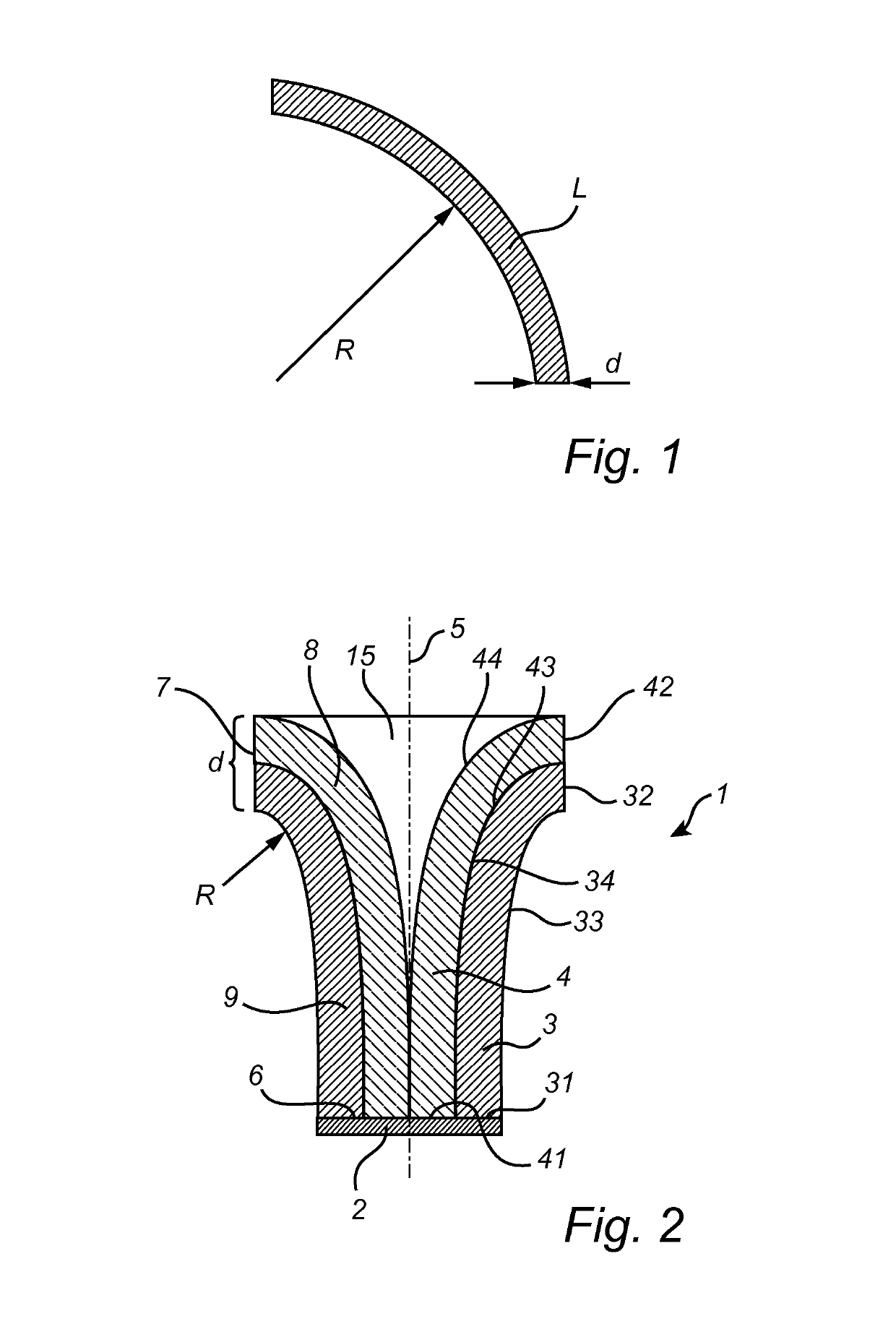

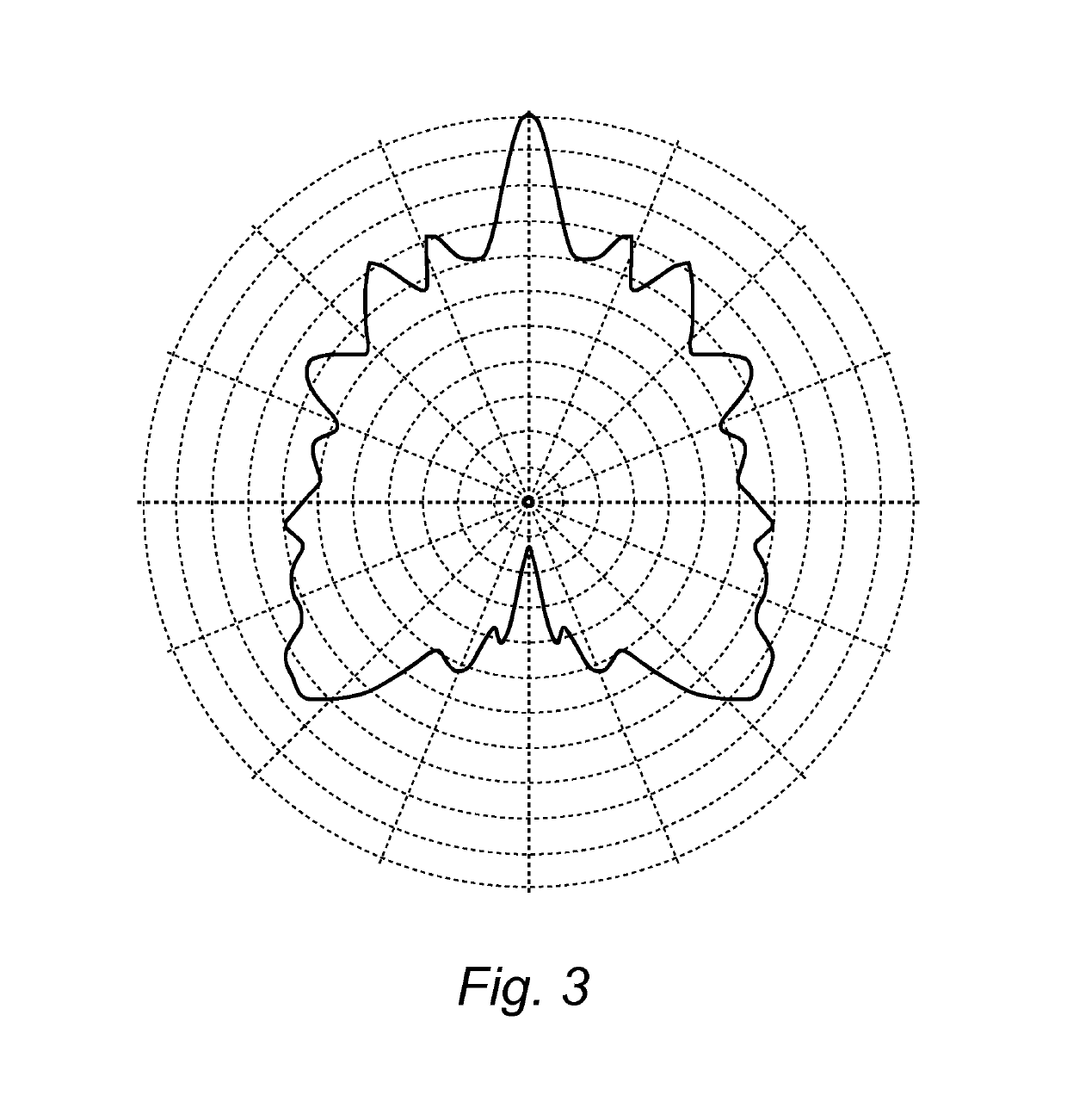

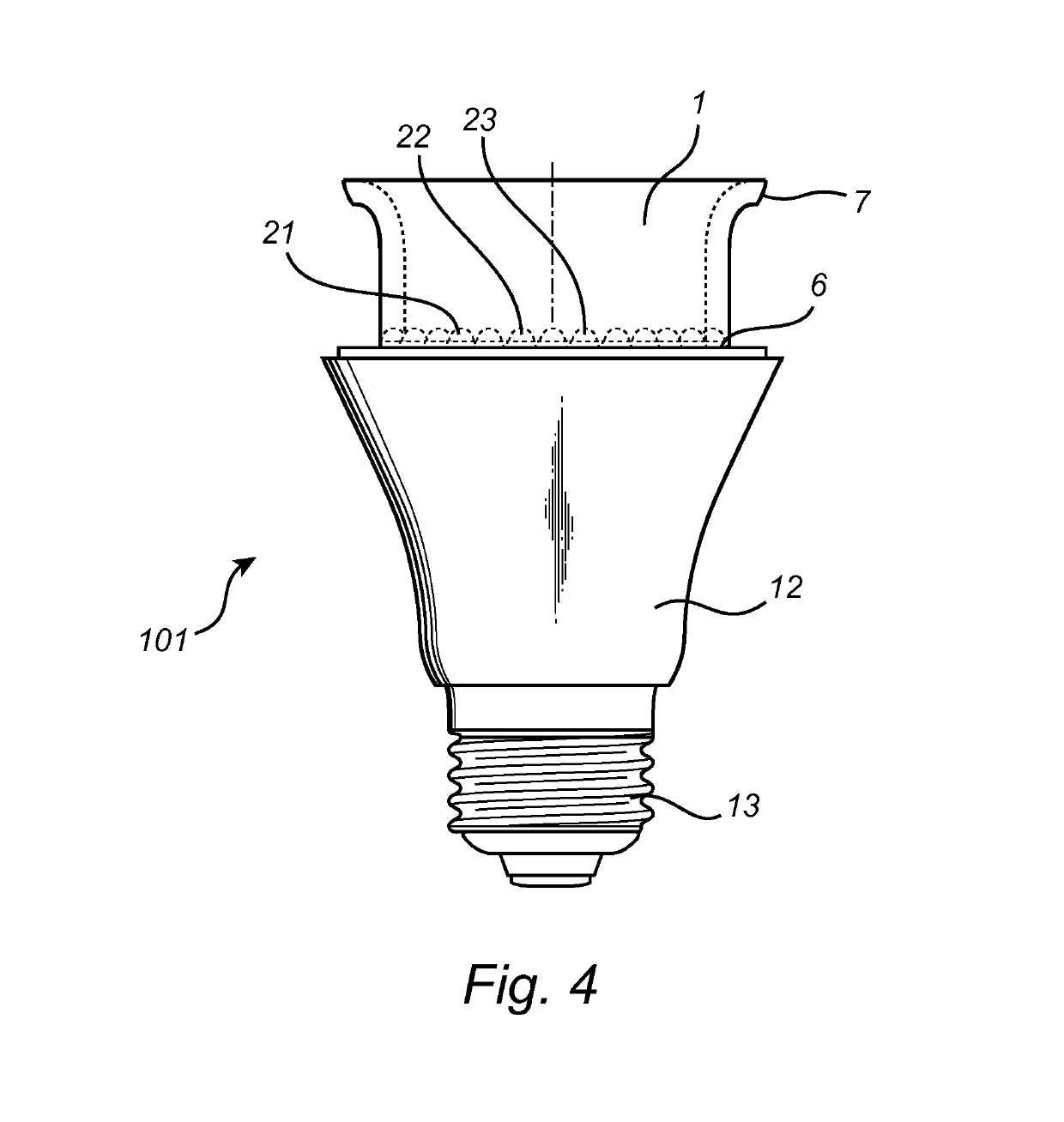

Light emitting device

A light emitting device (1) comprising at least one light source (2), and a light guide unit comprising at least a first light guide (3) and a second light guide (4) each comprising a light input end surface (6, 31, 41) arranged to, when in operation, receive light emitted from the at least one light source and a light output surface (7, 32, 42), at least a part (8) of the first light guide and the second light guide near the light output end surface being bent in a bending radius (R), at least the first light guide of the light guide unit being ring-shaped in cross section, and the first light guide and the second light guide of the light guide unit being arranged in a nested relationship.

Owner:SIGNIFY HLDG BV

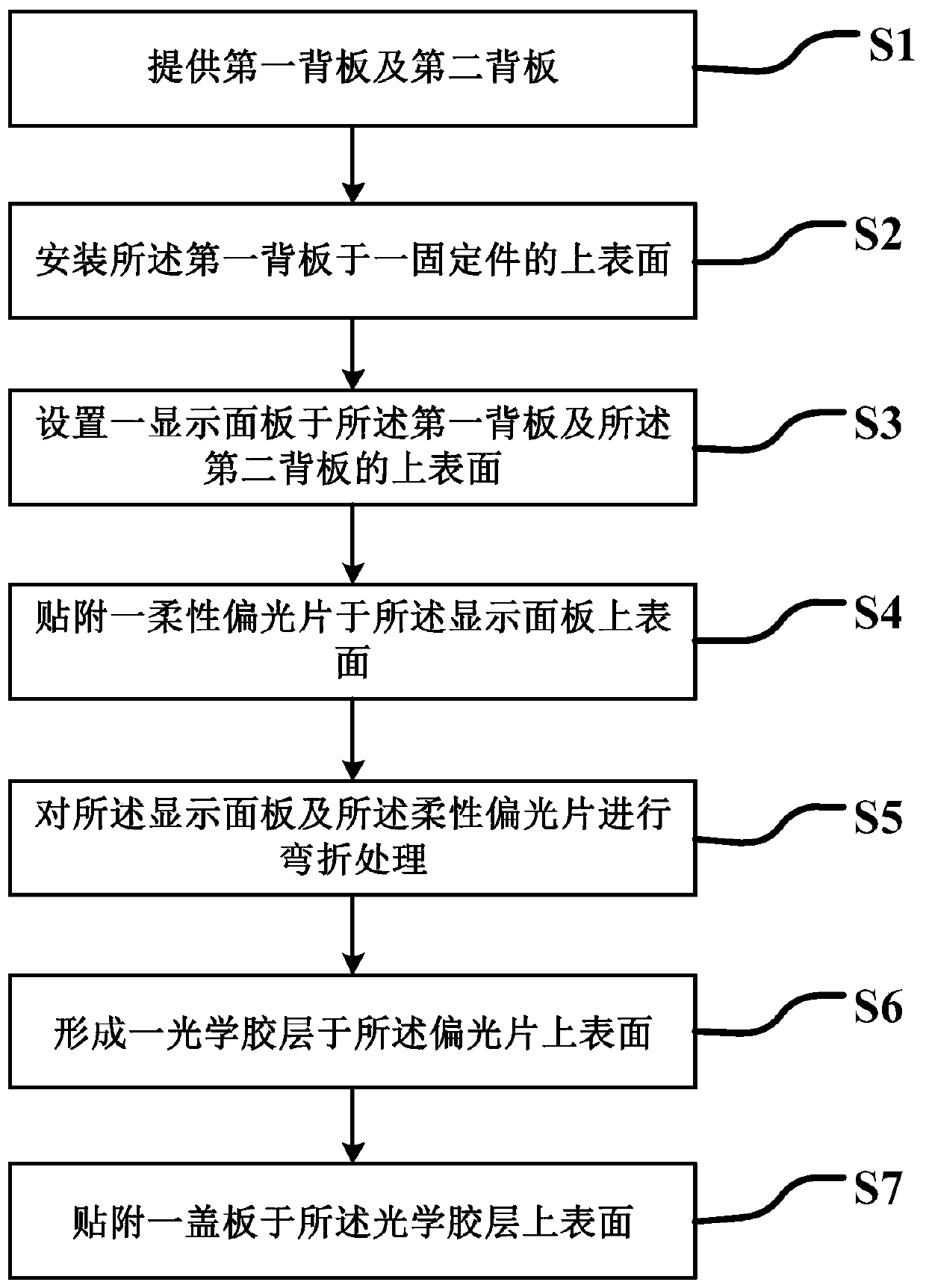

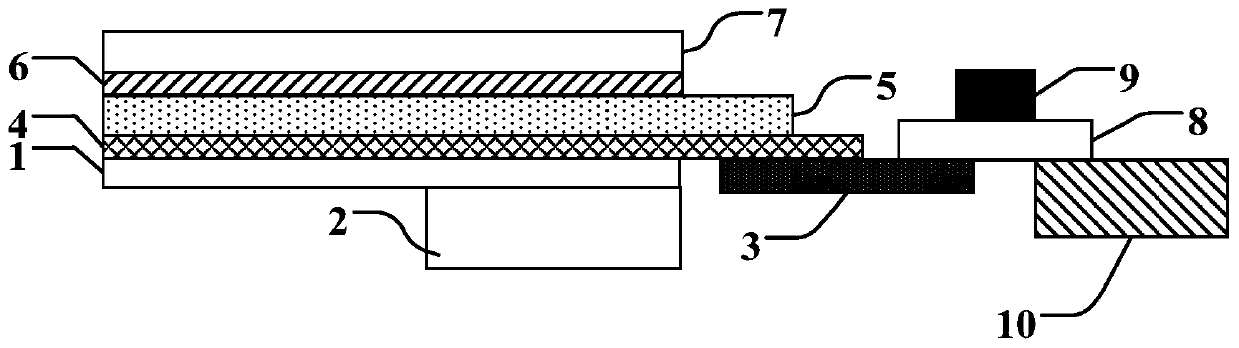

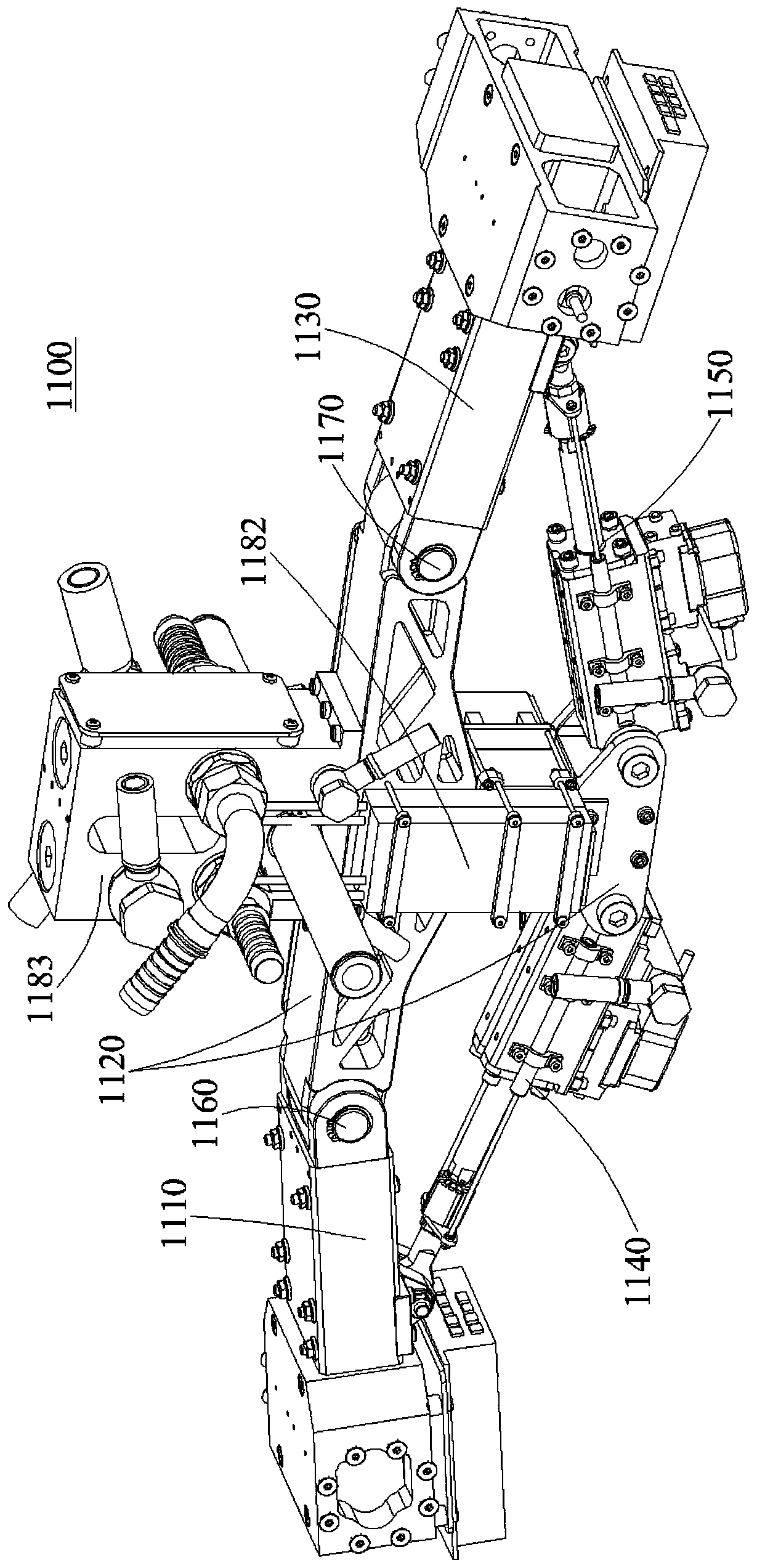

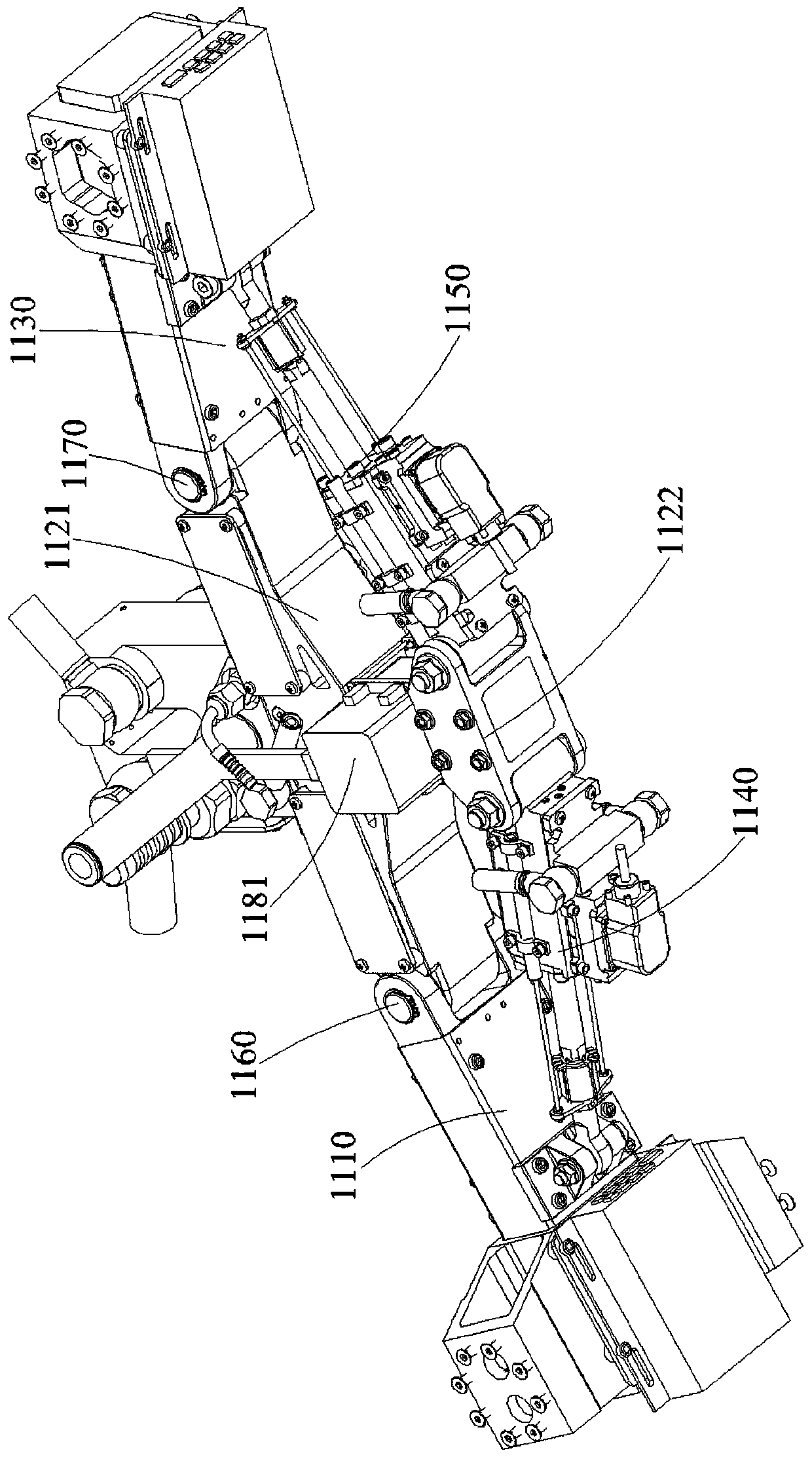

OLED display screen and preparation method thereof and display device

PendingCN111524944AImprove qualityLarge bendSolid-state devicesIdentification meansDisplay deviceEngineering

The invention provides an OLED display screen and a preparation method thereof and a display device. The OLED display screen comprises a first back plate, a fixing piece, a second back plate, a display panel and a flexible polaroid. The flexible polaroid and the display panel extend from the face, away from the fixing piece, of the first back plate and are bent to the face, away from the fixing piece, of the second back plate, and a gap without filler exists between the display panel and the fixing piece. According to the invention, the existing MLC dispensing process is removed; the flexibility and the ductility of the flexible polaroid are utilized; the length of the flexible polaroid is increased, so that the flexible polaroid is bent from the upper surface of the first back plate and extends to the lower surface of the second back plate, the problems that colloid interferes with other parts in the bending area and wave warping occurs in the bending area can be effectively avoided,and the quality of the OLED display screen is improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

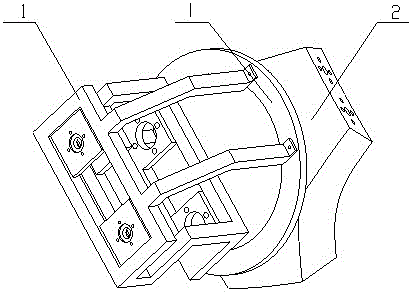

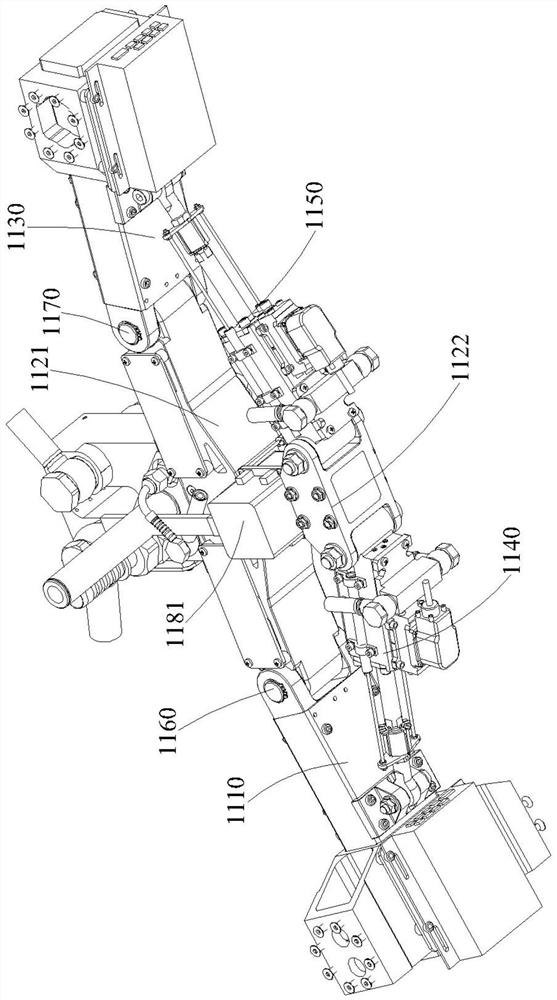

Multi-joint spine and spine four-foot robot

ActiveCN109940586AAchieve independent driveGuaranteed Motion Control IndependenceProgramme-controlled manipulatorJointsEngineeringSacroiliac joint

The invention discloses a multi-joint spine. The multi-joint spine comprises a first chine, a second chine and a third chine hinged in sequence; the first chine and the third chine are used for mounting robot lower limbs; the first chine is connected with a first driving unit for driving the first chine to rotate around the hinged shaft; the third chine is connected with a second driving unit fordriving the third chine to rotate around the hinged shaft; and the first driving unit and the second driving unit are mounted on the second chine. The invention further discloses a spine four-foot robot; the spine four-foot robot comprises the multi-joint spine and the robot lower limbs; and the robot lower limbs are mounted on the first chine and the third chine. The multi-joint spine and the spine four-foot robot; and the robot has the multi-joint spine structure to simulate spine bending actions of four-foot organisms, so that the spine bending amplitude is wide, the motion independence andoperability of front and back limbs are improved, and the motion speed and the motion flexibility of the four-foot robot are improved.

Owner:HARBIN INST OF TECH

Light emitting device

A light emitting device (1) comprising at least one light source (2), and a light guide unit comprising at least a first light guide (3) and a second light guide (4) each comprising a light input end surface (6, 31, 41) arranged to, when in operation, receive light emitted from the at least one light source and a light output surface (7, 32, 42), at least a part (8) of the first light guide and the second light guide near the light output end surface being bent in a bending radius (R), at least the first light guide of the light guide unit being ring-shaped in cross section, and the first light guide and the second light guide of the light guide unit being arranged in a nested relationship.

Owner:SIGNIFY HLDG BV

Steerable catheter

The present invention relates to a steerable catheter device and method of using the same comprising a catheter body having a distal section. The distal section of the catheter body has an inner lumen, and one or more steering lumen radially offset from the inner lumen. The steering lumen comprise a first end having a first diameter and a second end having a second diameter smaller than the first diameter. A fluid source is in fluid communication with the steering lumen for supplying fluid thereto to radially distend the first end of the steering lumen such that the catheter body bends away from the steering lumen. In some cases, a vacuum is supplied to an opposite lumen to further assist bending of the catheter body. The inner lumen may include a porous material that is utilized to clean an instrument, such as an imaging device, movably disposed in the inner lumen.

Owner:SANOVAS

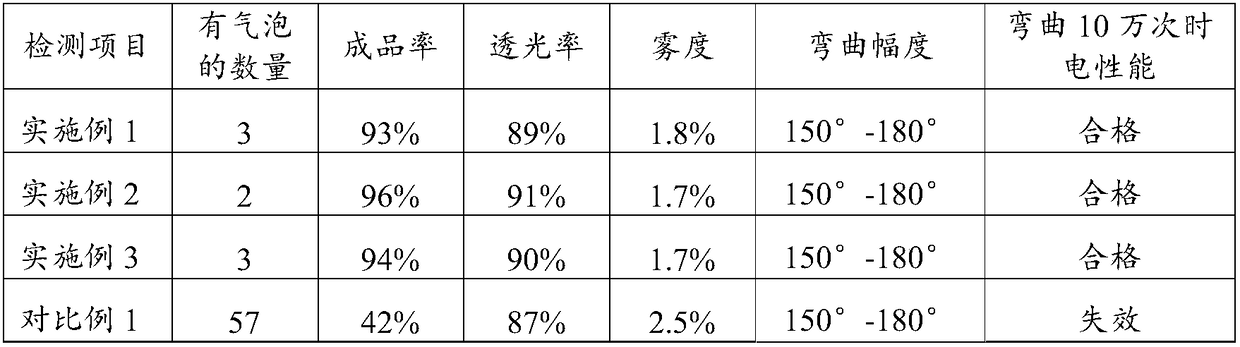

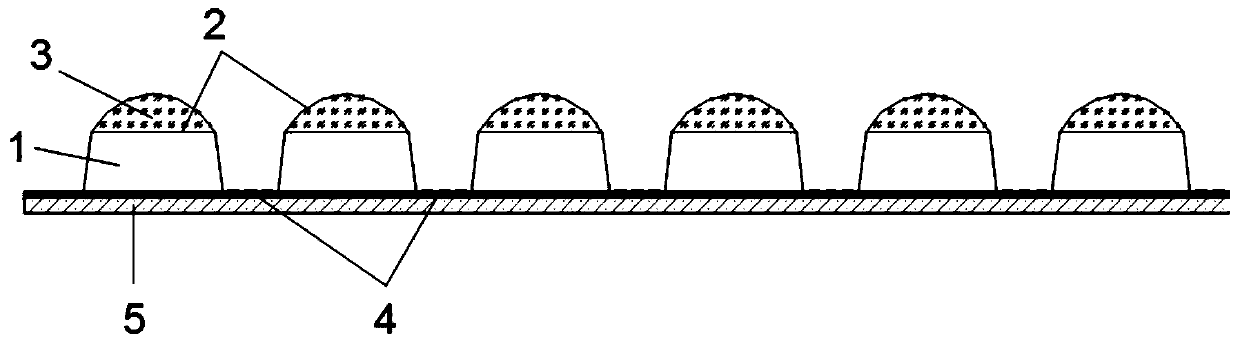

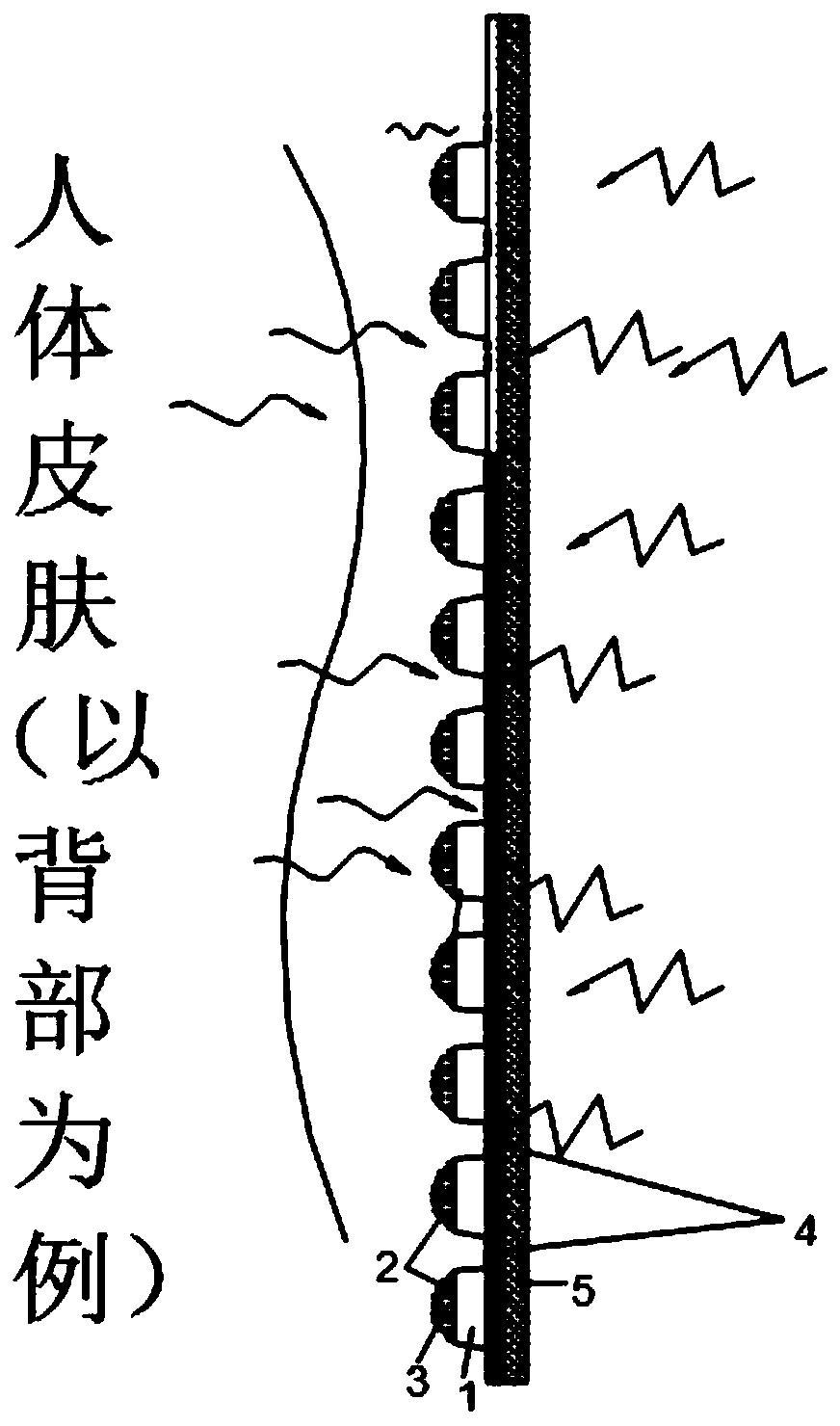

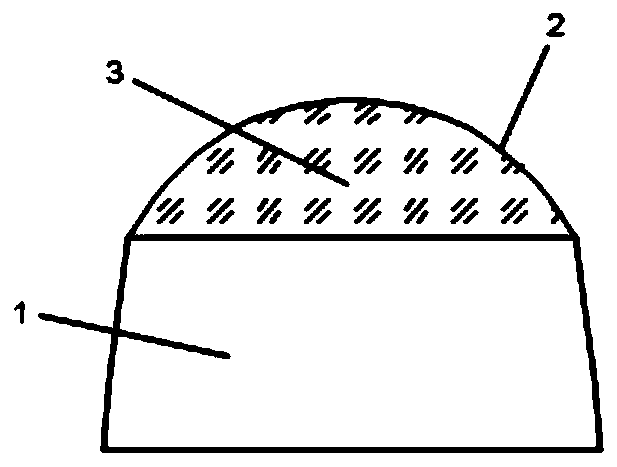

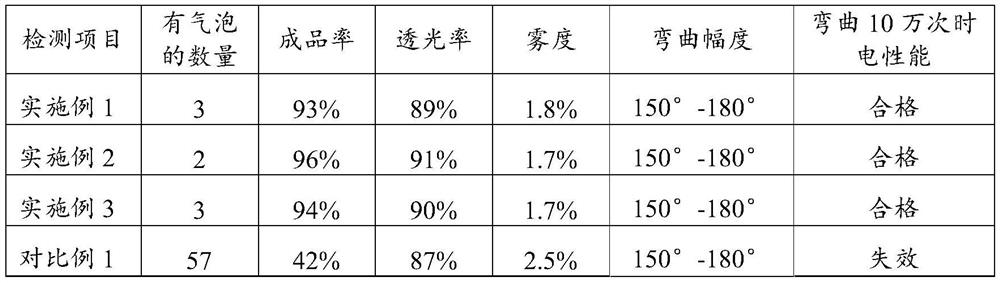

Flexible touch control panel, and preparation method and touch control device thereof

ActiveCN108664159ALarge bendExtended service lifeLamination ancillary operationsSynthetic resin layered productsTouch panelEngineering

The invention provides a flexible touch control panel, and a preparation method and a touch control device thereof, which relate to the field of electronic device preparation. The flexible touch control panel comprises a flexible transparent cover plate, a flexible transparent decorative plate and a sensor film layer for connecting a circuit board stacked in sequence. The flexible touch panel solves the technical problems of small bending amplitude and short service life of the flexible touch panel in the prior art. Compared with the traditional touch panel, the flexible touch panel has largerbending amplitude and longer service life, expands the application range of the flexible touch panel, and improves the market competitiveness of the flexible touch panel.

Owner:LENS TECH CHANGSHA

Lining capable of adjusting space temperature in firefighter uniform and manufacturing method of lining

ActiveCN111097113AReduce usagePlay a buffer roleChemical protectionHeat protectionFood gradeAfter treatment

The invention discloses a lining capable of adjusting the space temperature in a firefighter uniform and a manufacturing method of the lining. A fabric layer and a plurality of buffering temperature adjusting protrusions are included. The multiple buffering temperature adjusting protrusions are fixed to the side face of the fabric layer at equal intervals, and the part, between every two adjacentbuffering temperature adjusting protrusions, of the fabric layer is provided with ventilation holes. Each buffering temperature adjusting protrusion is internally provided with an inert gas containingcavity and a phase change material containing cavity. After food-grade silica gel is subjected to extrusion molding and fusion through an extruder, a membrane is formed in a forming mold and extruded; the buffering temperature adjusting protrusions are formed after treatment, the inert gas containing cavities are inflated with nitrogen, and the phase change material containing cavities are filledwith phase change materials; and finally, the buffering temperature adjusting protrusions are sewn to the side face of the fabric layer, the ventilation holes are punched through a mechanical punching device, and the lining is manufactured. On the premise that a good cooling effect is guaranteed, the lining is light in structure and convenient to wear and use, and meanwhile the lining has good buffering capability; and accordingly the personal safety and work efficiency of firemen in the high temperature environment are improved.

Owner:HUNAN UNIV OF SCI & TECH

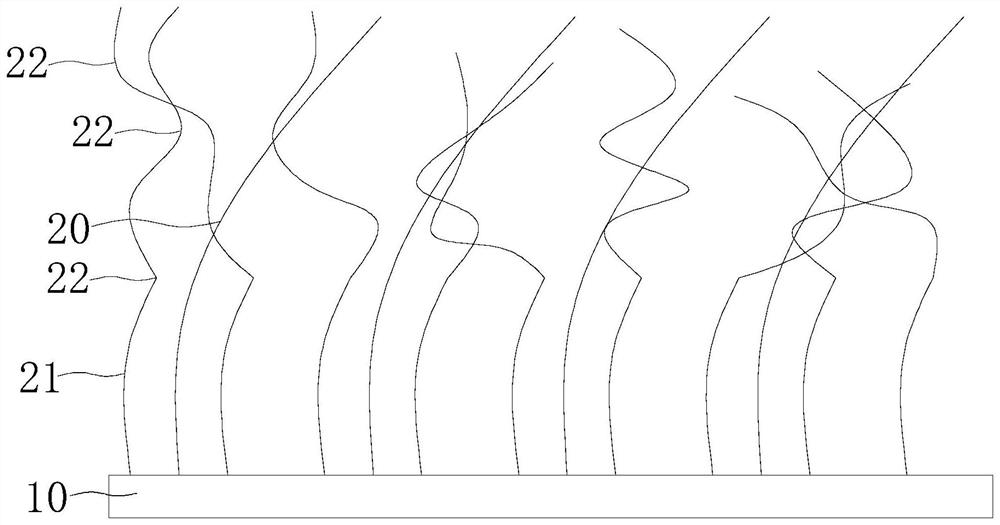

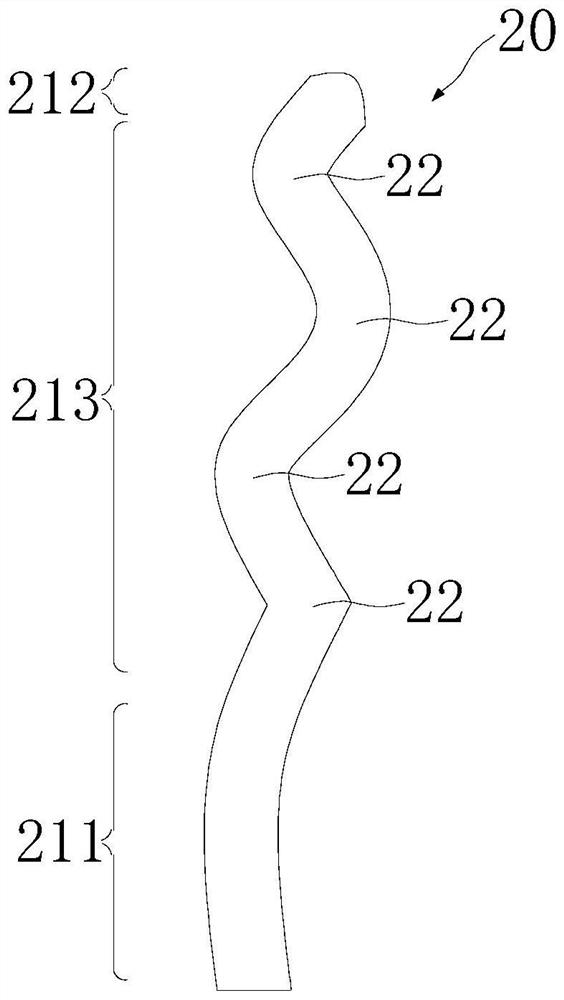

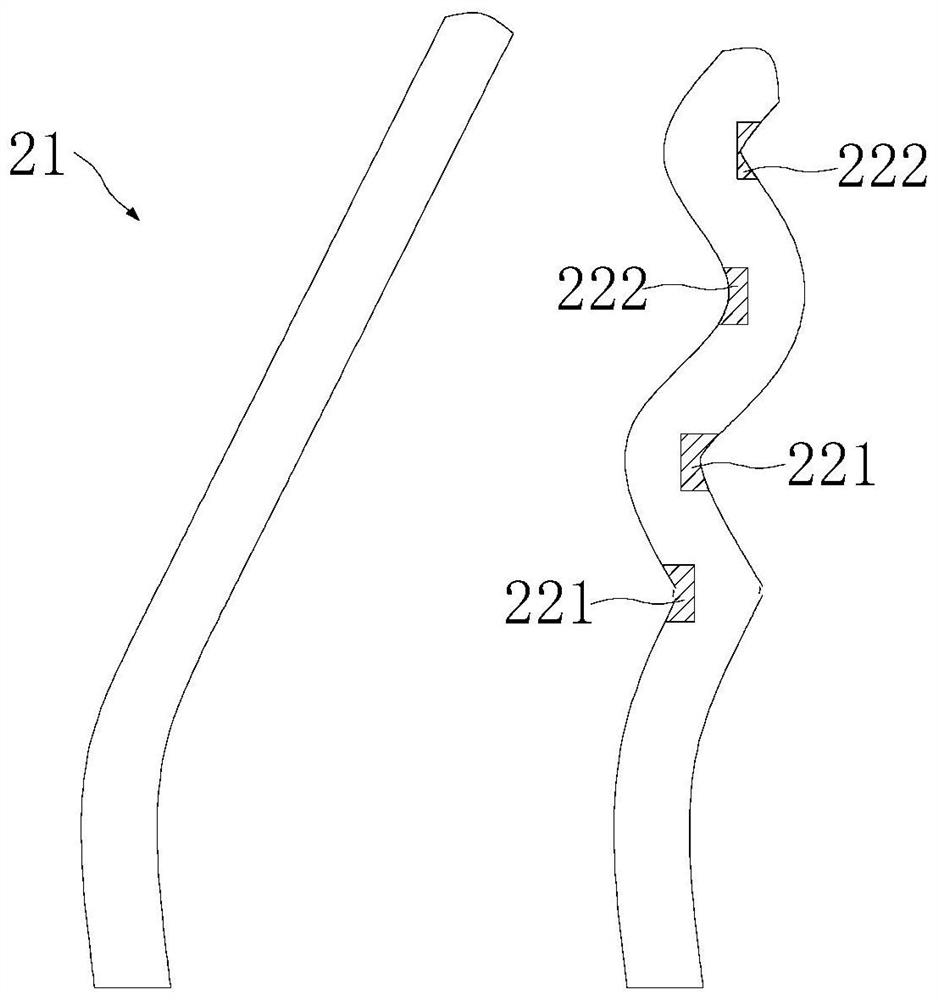

False eyelash

The false eyelash comprises an eyelash stem and a plurality of eyelash bodies, at least part of the eyelash bodies are simulation bodies, each simulation body comprises a root portion, a tail portion and a deformation section located between the root portion and the tail portion, the root portions are connected and fixed to the eyelash stem, the deformation sections are provided with bending points, and the bending points are connected with the tail portions. And after the simulation bodies are deformed and bent at the bending points, the extension paths of the deformation sections of the two adjacent simulation bodies are different. The false eyelashes can be more stereoscopic and can be prevented from hurting a human body.

Owner:于子轩

Paper watchband and manufacturing process thereof

PendingCN114376308ALarge bendWon't tearFibre typesStarch coatingsComposite materialManufacturing engineering

The invention relates to a paper watchband and a manufacturing process thereof, the paper watchband comprises a band body, a fixed band ring and a movable band ring, the band body comprises a fabric, a core material and a backing material, the fabric comprises a paper material and a waterproof layer, and the waterproof layer is waterproof glue coated on the surface of the paper material; the belt body is divided into a first belt body and a second belt body, the fixed belt ring is fixed on the first belt body, and the movable belt ring movably sleeves the first belt body; one part of the fixing belt ring is adhered and fixed between the core material and the bottom material of the first belt body, and the other part of the fixing belt ring is exposed outside the first belt body; the paper material is recycled newspaper, printed characters and patterns on the newspaper form a decorative layer, and the waterproof layer is a transparent waterproof layer through which the decorative layer of the paper material can be observed. The paper watchband is made of paper, and printed characters and patterns on newspaper are recycled to form a decorative layer of the watchband, so that the watchband is more environment-friendly to manufacture, and the appearance of the watchband is more personalized; the core material and the bottom material which are made of leather provide enough toughness for the watchband, so that the watchband is not easy to break.

Owner:DONGGUAN DELI CLOCK CO LTD

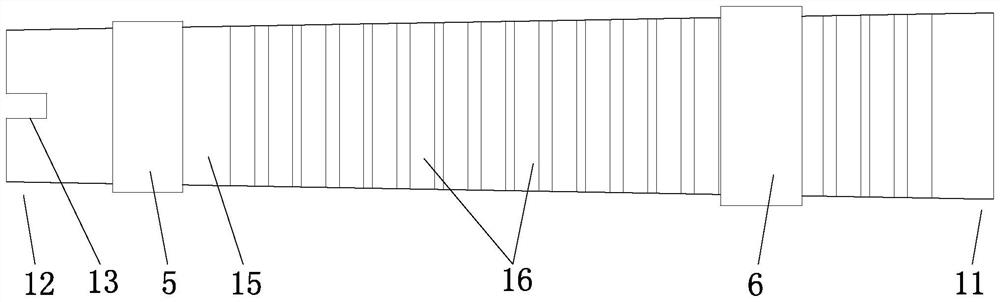

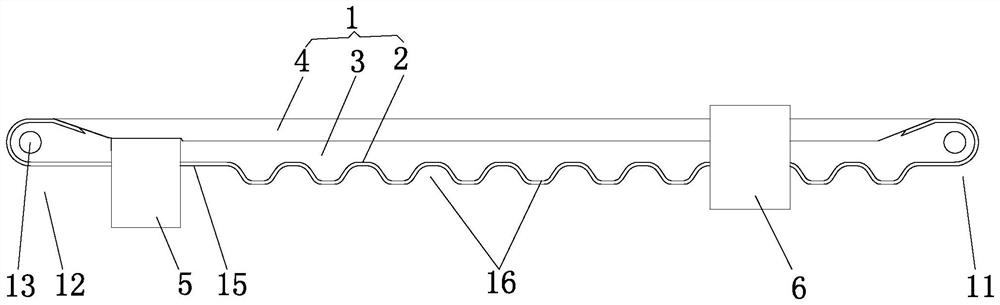

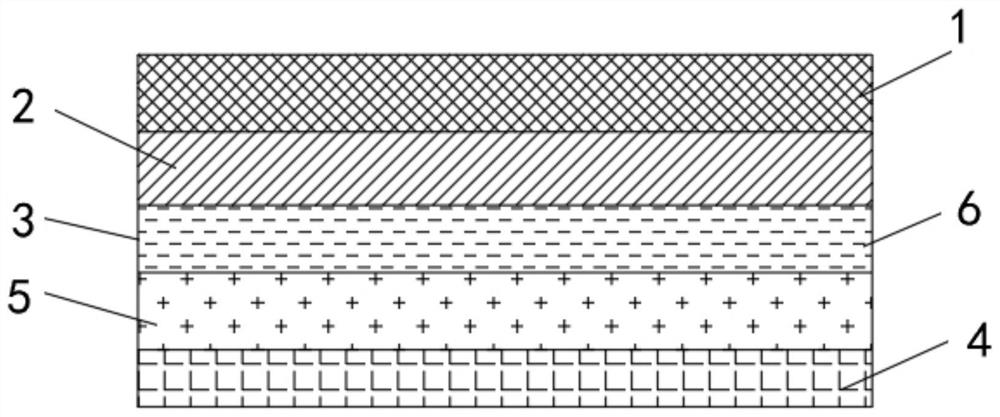

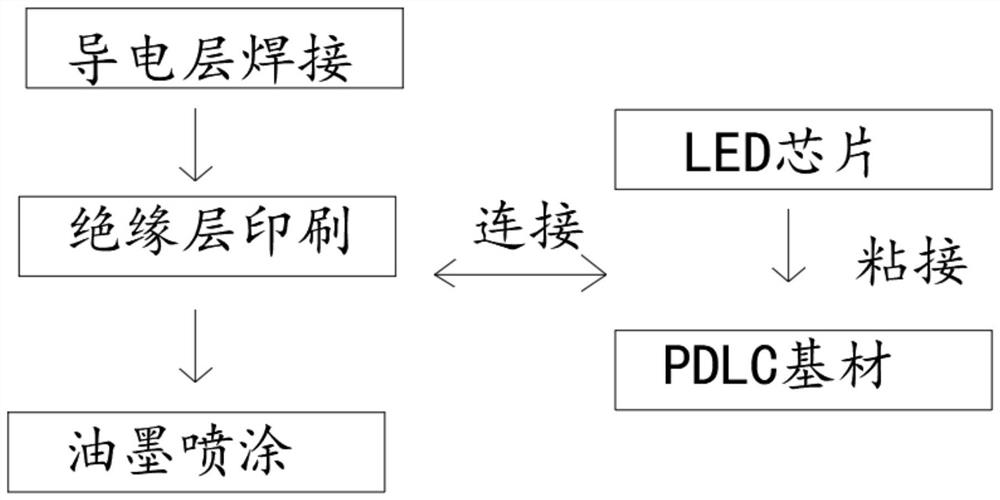

Flexible electronic paper electronic display equipment and manufacturing method thereof

The invention provides flexible electronic paper electronic display equipment and a manufacturing method thereof, and relates to the technical field of road and bridge technologies. The flexible electronic paper electronic display equipment comprises a flexible base layer, an LED chip is adhered to the bottom of the flexible base layer, a circuit layer is arranged at the bottom of the LED chip, the circuit layer comprises a conductive layer and an insulating layer, the insulating layer is arranged at the top of the conductive layer, and an ink layer is arranged on the top surface of the insulating layer. The top face of the ink layer is electrically connected with the LED chip, the flexible base layer is a PDLC base material, the PDLC base material is adopted as a flexible base material of electronic paper, the flexible electronic paper is prepared through three-layer overprinting through ink-jet printing, and the flexible display device which is passively displayed and can be bent is achieved. Compared with a traditional glass or metal display substrate, the PDLC used as the base material can be bent in any direction to a certain extent, the weight of the electronic paper is reduced, the bending degree is larger, resources are saved, use is convenient, conductive spraying is conducted on the surface of the electronic paper through the ink jet technology, forming is simpler, cost is low, the forming efficiency and speed are both improved, and the use performance of the electronic paper is improved.

Owner:深圳市蔚来芯科技有限公司

Hardware strip bending device

The invention relates to the technical field of hardware processing, and discloses a hardware strip bending device. The hardware strip bending device comprises a bottom plate, wherein a fixing frame is arranged on the left side of the upper surface of the bottom plate; a fixing rod is arranged at the right end of the fixing frame; a fixing block is arranged at the lower part of the fixing rod; a supporting column is arranged on the right side of the upper surface of the bottom plate; a workbench is arranged at the upper end of the supporting column; the middle of the workbench is rotationallyconnected with the middle of a rotating shaft; the upper part of the rotating shaft is provided with a rotating block; the left side of the rotating block is provided with a lead screw; the middle ofthe lead screw is connected with a driving nut in a threaded mode; the left side of the driving nut is rotationally connected with the middle of a fixing plate; the lower part of the fixing plate is rotationally connected with a rotating rod; and the left end and the right end of the rotating rod are provided with driving wheels. According to the hardware strip bending device, the rotating shaft is arranged to drive the fixing plate to rotate, and in the rotating process, the driving nut moves along the lead screw, so that the fixing plate finally moves along the track of a spiral involute, and consequently, a hardware strip is bent.

Owner:马国庆

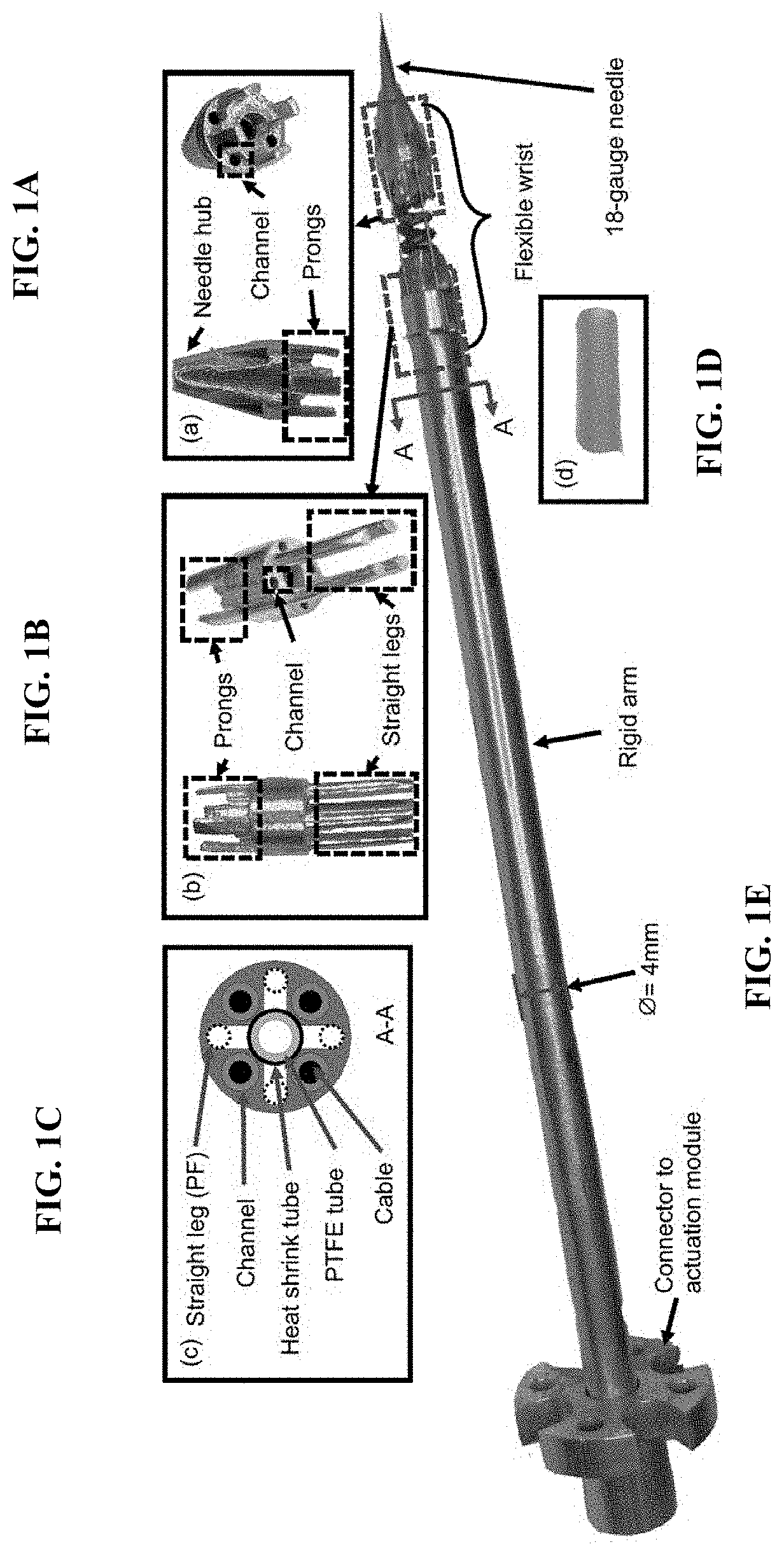

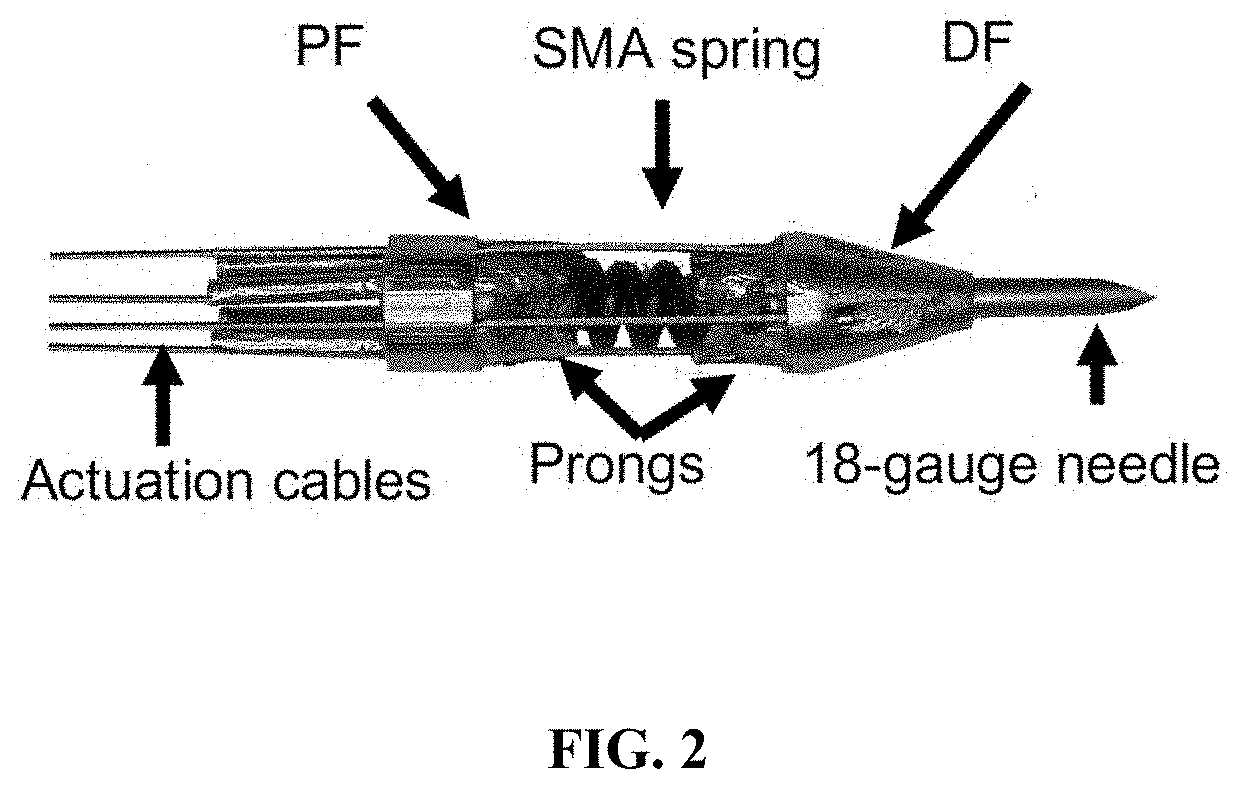

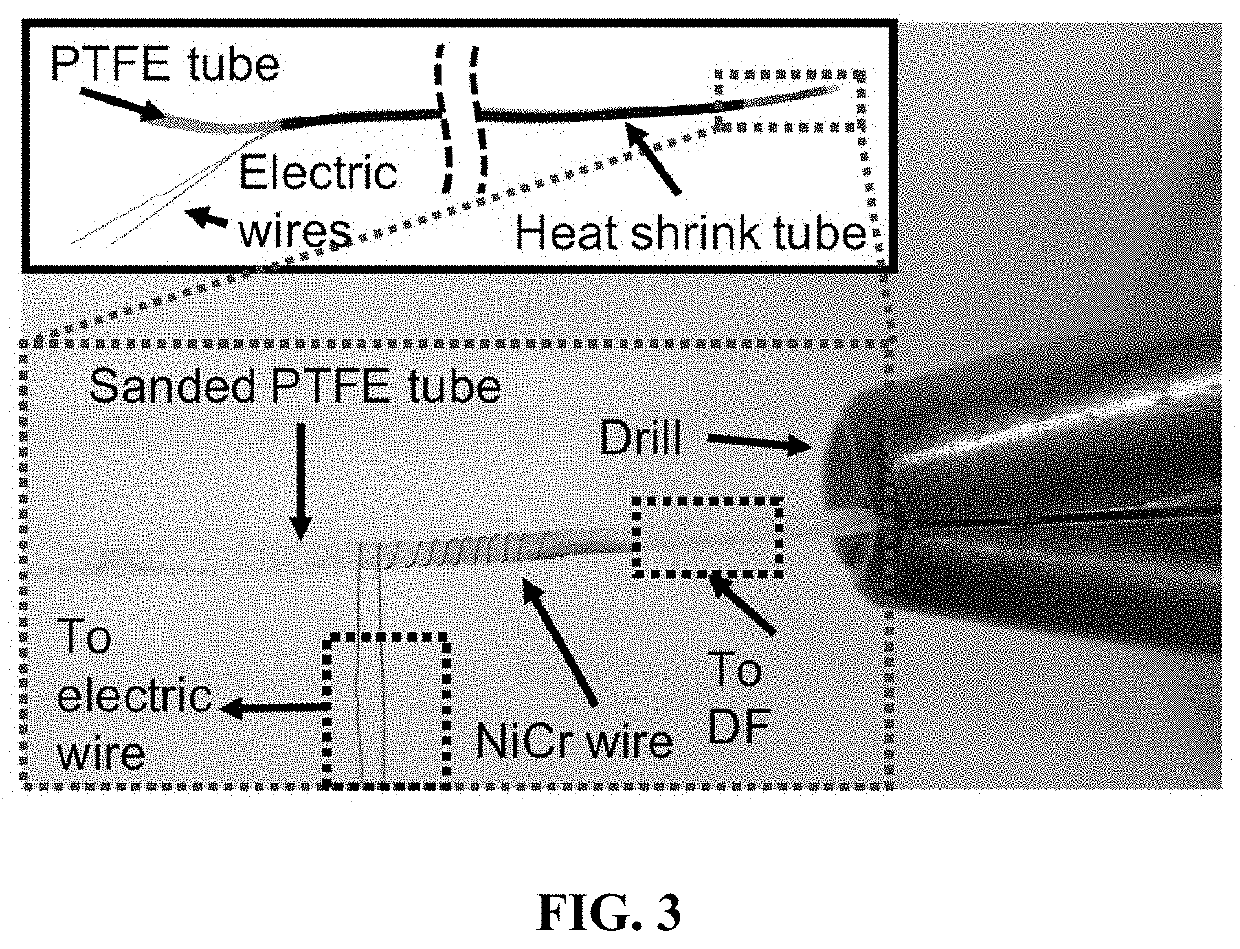

Flexible surgical instruments for percutaneous and neurosurgical applications

PendingUS20220225973A1Minimizing chance of damageMinimizes mechanical stressSurgical needlesSurgical scissorsParacentesisThird ventriculostomy

The subject invention pertains to percutaneous surgical device with variable stiffness for percutaneous procedures, including but not limited to pericardiocentesis, and flexible neurosurgical devices for procedures, including but not limited to intracerebral hemorrhage evacuation and third ventriculostomy and brain tumor biopsy, and methods of making and using them.

Owner:THE CHINESE UNIVERSITY OF HONG KONG

Dried bean curd air pressure equipment

InactiveCN112715855ALarge bendRemove moistureDispersed particle separationCheese manufactureAgricultural engineeringDry bean

The invention discloses dried bean curd air pressure equipment which is structurally provided with an air pressure device, a pressing plate, a placing table, a buffer base, a starter, a connecting column and a top cover, and the bottom surface of the air pressure device is detachably mounted in the center of the top surface of the top cover; the top surface of a placement table is in threaded connection with the bottom surface of the top cover through a connecting column, the bottom of the placement table is movably connected with a buffer base, and the heating ring in the dehumidification device mounted at the left end of the air inlet is used for heating incoming humid air, so that moisture in some air is eliminated; a sponge plate in an extrusion device is used for absorbing residual moisture in air, moisture entering an inner cavity is reduced, the situation that dried bean curd is broken due to the fact that the pressure of the inner cavity of the pneumatic pump is too large and the compressive strength of a product is too high is prevented, and the bending amplitude of the sponge plate cannot be increased when the sponge plate is extruded through cooperation of a limiting mechanism; therefore, water remains on the sponge plate.

Owner:陈富荣

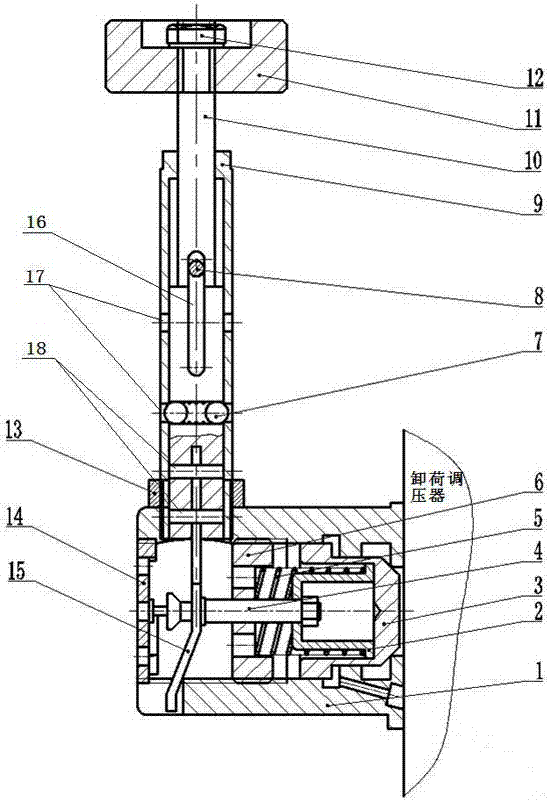

A kind of anti-load pressure regulator pre-charging mechanism with selection function

ActiveCN105114676BEasy to operate manuallyAchieve openOperating means/releasing devices for valvesAeration devicesEngineeringPressure regulator

The invention relates to an anti-load pressure regulator pre-pressurizing mechanism with a selecting function. The anti-load pressure regulator pre-pressurizing mechanism with the selecting function comprises a pre-pressurizing shell, a baffle, a pre-pressurizing spring and a valve. A longitudinal supporting pipe frame is fixed to the top surface of the pre-pressurizing shell. An operating rod is arranged in the supporting pipe frame. The top of the operating rod penetrates upwards out of the supporting pipe frame and is provided with an operating head. The bottom of the operating rod extends downwards into the pre-pressurizing shell, and a shifting piece is fixed to the bottom of the operating rod. The upper portion of the shifting piece is vertical, and the lower portion of the shifting piece deflects towards the side away from the valve. A seam is formed in the middle of the shifting rod in the direction of the shifting piece. A sliding block is arranged between the pre-pressurizing spring and the valve. One end of a pull rod is fixed to the sliding block. The other end of the pull rod sequentially penetrates through the pre-pressurizing spring, the baffle and the seam. A protruding block is arranged on the pull rod and located near the side, away from the valve, of the shifting piece. The coarse motion of loosening or tensioning the pre-pressurizing spring is converted into the longitudinal motion of lifting or pressing the operating rod, the overall arrangement is reasonable, operation of aviators is facilitated, and the aviators can autonomously choose to start the pre-pressurizing function or stop the pre-pressurizing function.

Owner:AEROSPACE LIFE SUPPORT IND LTD

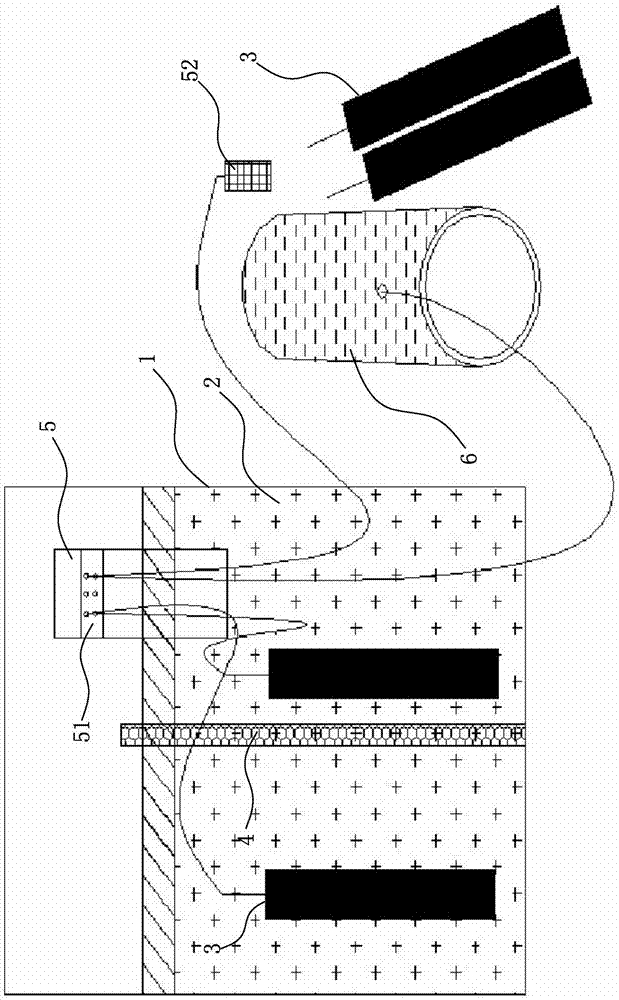

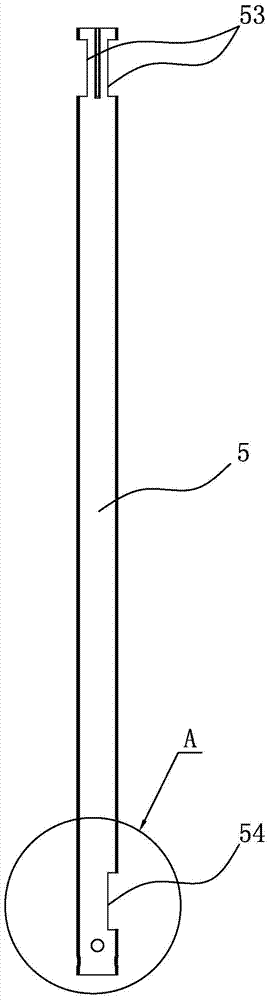

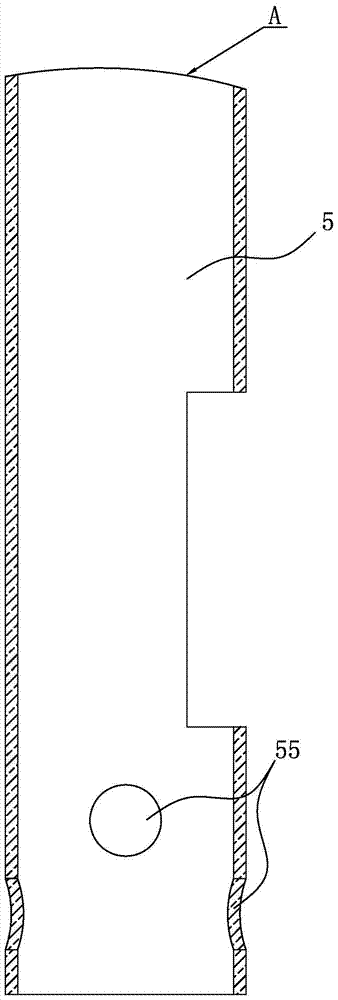

Replaceable sacrificial anode well and its replacement method

The replaceable sacrificial anode well of the present invention relates to a sacrificial anode protection device, in particular to a sacrificial anode well for protecting underground pipelines and a replacement method thereof. The purpose is to provide a replaceable sacrificial anode well and its replacement method with simple structure, time-saving and labor-saving, low cost, easy operation, low excavation difficulty and long service life. The replaceable sacrificial anode well of the present invention comprises a well body (1), packing material (2), two sacrificial anodes (3) and an insulating plate (4), the well body (1) communicates with the pipeline, and the well body (1) ) is axially provided with an insulating plate (4), which divides the well body into two cavities, both cavities are filled with packing material (2), and the upper part of the two cavities Each is provided with a sacrificial anode (3), and each of the sacrificial anodes (3) is connected to the pipeline through wires.

Owner:北京永逸舒克防腐蚀技术有限公司

Multi-joint spine and spine-type quadruped robot

ActiveCN109940586BLarge bendGood exercise flexibilityProgramme-controlled manipulatorJointsSpinal columnPhysical medicine and rehabilitation

The invention discloses a multi-joint spine, which comprises a first spine, a second spine and a third spine hinged in sequence, and the first spine and the third spine are respectively used for installing the lower limbs of a robot. The first spine is connected with a first drive unit for driving it to rotate around the hinge axis, the third spine is connected with a second drive unit for driving it to rotate around the hinge axis, the first drive unit and the The second driving unit is respectively installed on the second spine; the invention also discloses a spine-type quadruped robot, which includes the multi-joint spine and robot lower limbs, and the robot lower limbs are respectively installed on the first spine bone with the third vertebra. The multi-joint spine and spine-type quadruped robot has a multi-joint spine structure and can simulate the spine bending action of a quadruped creature. The spine bending range is wide, and the movement independence and operability of the front and rear limbs are increased, and the movement of the quadruped robot is improved. Speed and flexibility of movement.

Owner:HARBIN INST OF TECH

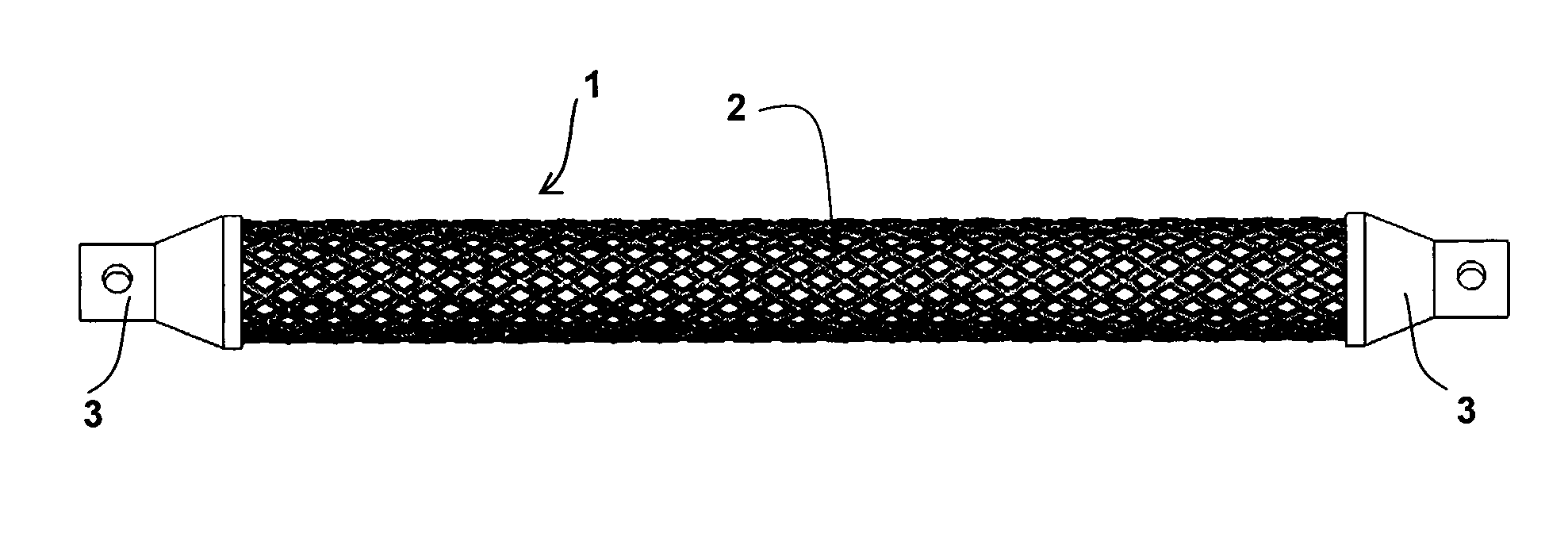

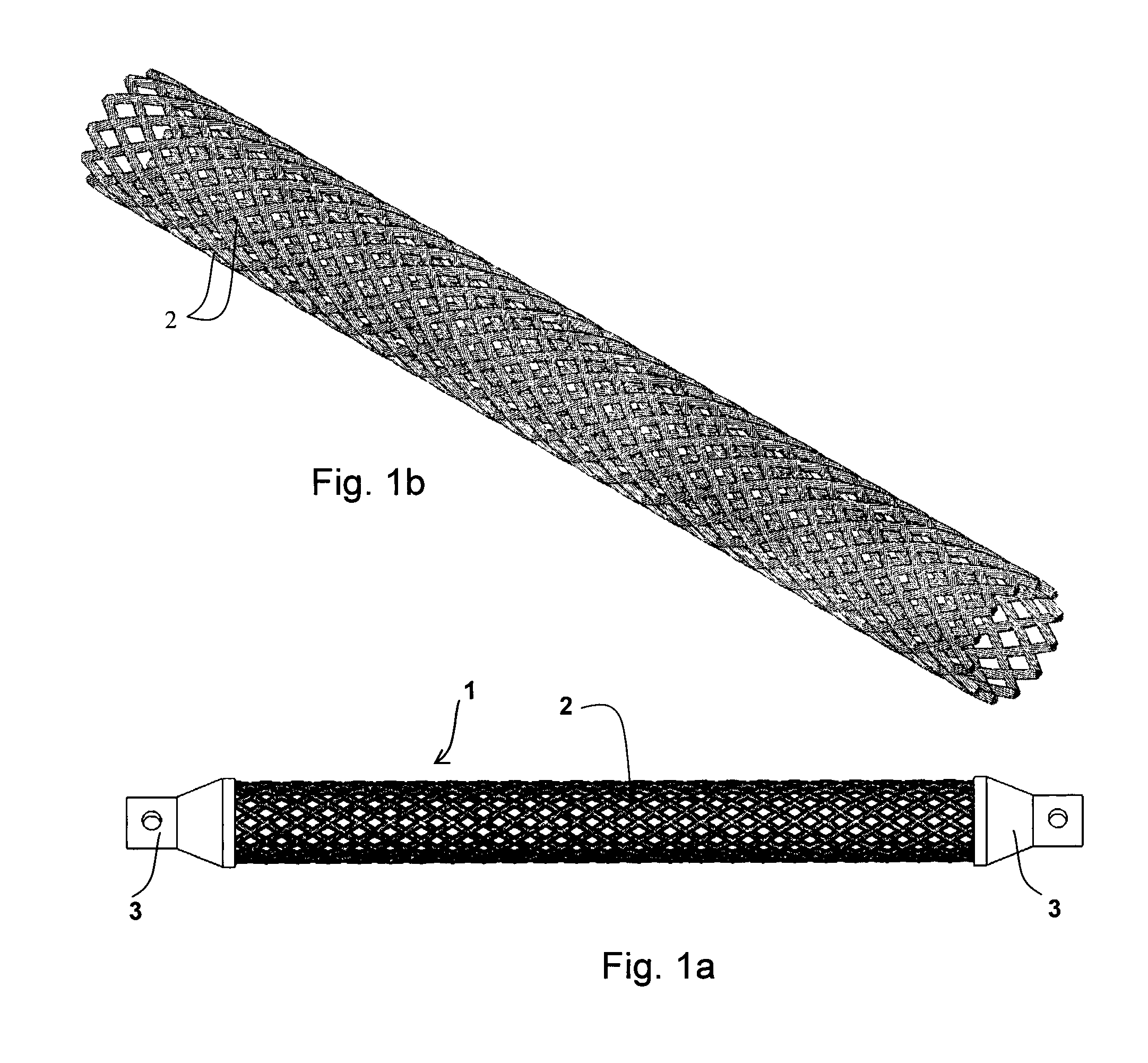

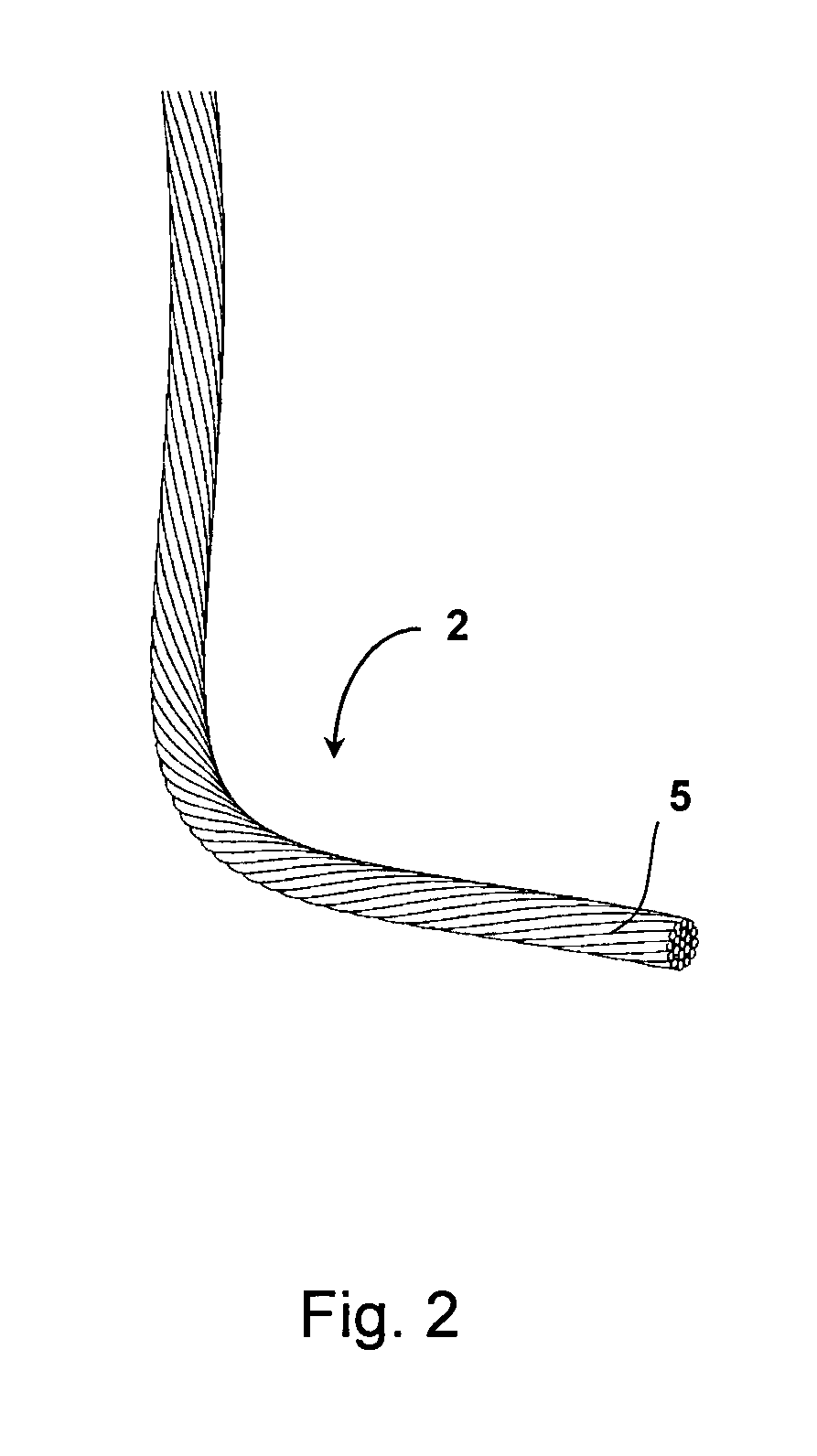

Ligament and tendon prosthesis made from cables of filaments

The invention provides a ligament or tendon prosthesis made from two or more of cables braided into a helical structure, where each cable is made from two or more strands. The strands may be made from an alloy exhibiting pseudoelastic properties at body temperature, and may be twisted into a helical structure in the cables.

Owner:TAVOR I T N LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com