Paper watchband and manufacturing process thereof

A watch strap and strap body technology, which is applied in the field of watch production, can solve the problems such as the easy tearing of the waterproof watch strap, and achieve the effect of having a more individual appearance, ensuring the safety of use, and reducing the production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

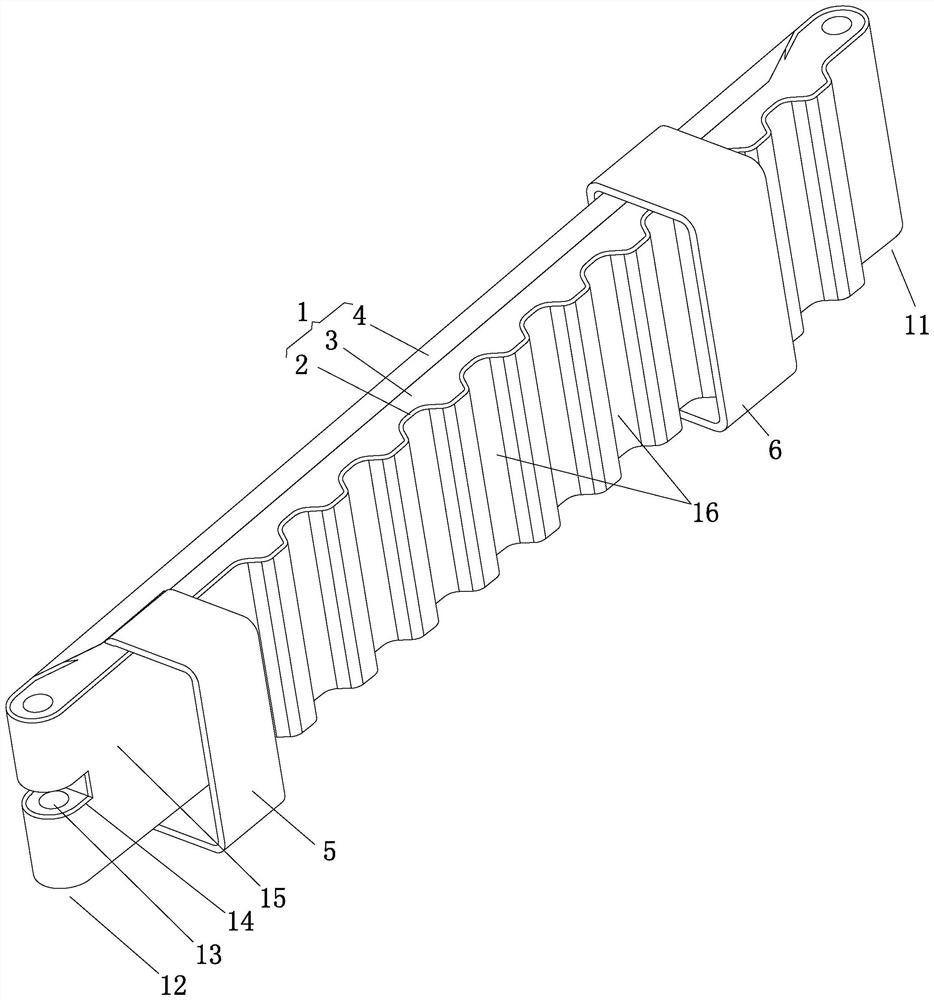

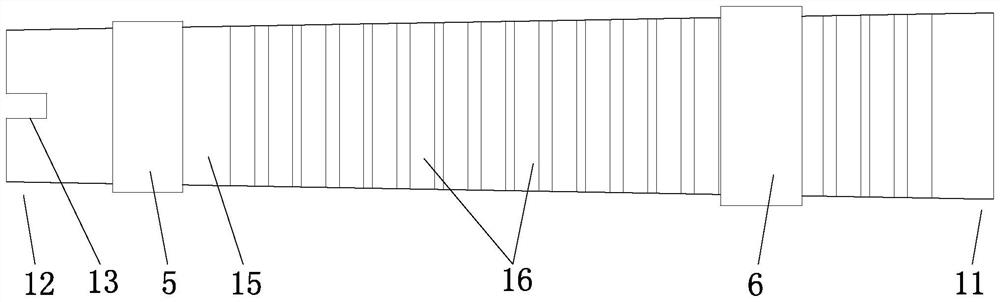

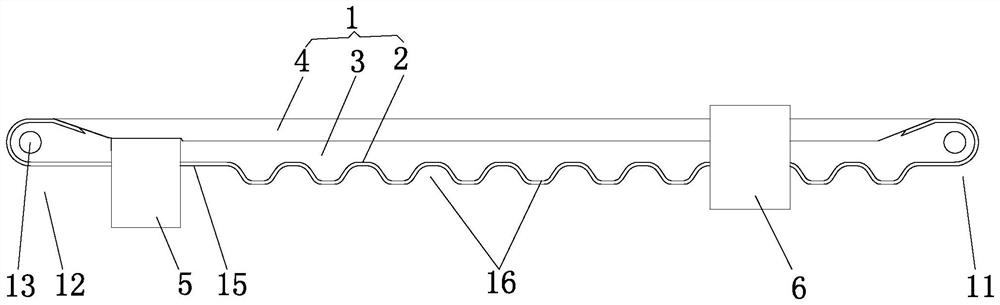

[0031] like figure 1 As shown, it is the first belt body of the watch, and the first belt body has a fixed band ring and a movable band ring, Figure 4The tongue of the second belt body is inserted in the fixed belt loop and the movable belt loop, the fabric 2 is made of paper, the core material 3 and the bottom material 4 are made of leather, and the paper fabric 2 can reduce the leather material and recycle The printed characters and patterns on the newspaper are the decorative layer of the watch strap, and there is no need to print the decorative layer on the strap, reducing the manufacturing process of the strap and making the strap more environmentally friendly. The core material 3 and the bottom material 4 made of leather provide sufficient toughness for the watch strap, so that the watch strap can be used normally and is not easy to break.

[0032] like Figure 1-4 As shown, a paper watchband includes a belt body, a fixed belt loop 5 and a movable belt loop 6. The bel...

Embodiment 2

[0044] A kind of craft of making above-mentioned paper watchband, comprises the following steps: Step 1, make fabric, the newspaper of sheet recycling is cut into a plurality of elongated paper strips of 5-10cm width, and a plurality of paper strips are sprayed on glue Spray the waterproof glue on the machine to form a waterproof layer. After drying at room temperature for 2 hours, place the paper strips in an ironing machine and iron them to make paper fabrics. The ironing temperature is 100 degrees Celsius;

[0045] Step 2, making the core material, cutting the base material into multiple long belts with a width of 5-10cm, and shoveling the belt on the shoveling machine. The thickness of the belt after shoveling is 0.3-0.6cm, and the thickness of the belt The belt is coated with water-based PU glue on the gluing machine, and after drying at room temperature for 6 hours, the belt is cut into a rectangular core material;

[0046] Step 3, make the base material, cut the base ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com