Replaceable sacrificial anode well and its replacement method

A sacrificial anode technology to be replaced, applied in the field of sacrificial anode protection devices, can solve the problems of no economically feasible non-excavation replaceable sacrificial anode technology, laborious work, high cost, etc., achieve important social and economic benefits, and reduce replacement costs , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

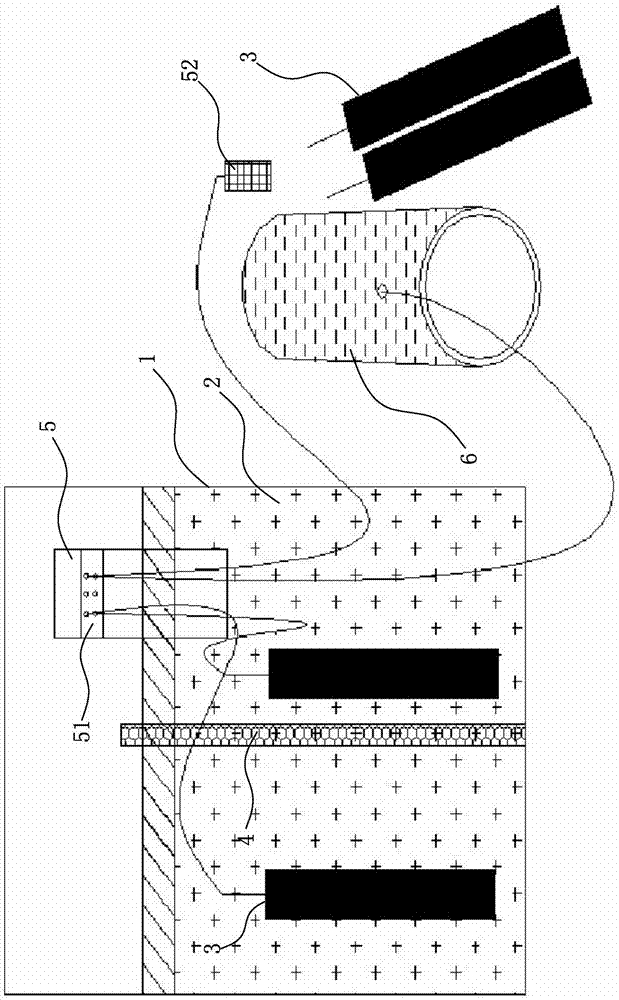

[0026] Such as figure 1 As shown, the replaceable sacrificial anode well of the present invention includes a well body 1 , packing material 2 , two sacrificial anodes 3 and an insulating plate 4 . The well body 1 communicates with the pipeline, and an insulating plate 4 is axially arranged in the well body 1 . The insulating plate 4 divides the well body into two cavities, both cavities are filled with packing material 2, and a sacrificial anode 3 is arranged on the upper part of the two cavities. Each sacrificial anode 3 is connected to the pipeline through wires. The bottoms of the two cavities lead to the pipeline 6, the pipeline 6 is filled with ordinary loess, and the resistivity of the packing material 2 is lower than that of the ordinary loess. The top of the packing material 2 in the well body 1 is covered with floating soil.

[0027] The wires of each sacrificial anode are connected to the pipeline 6 through the test pile 5 .

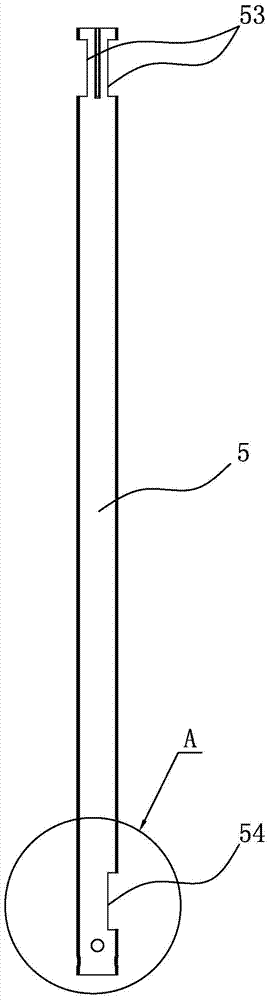

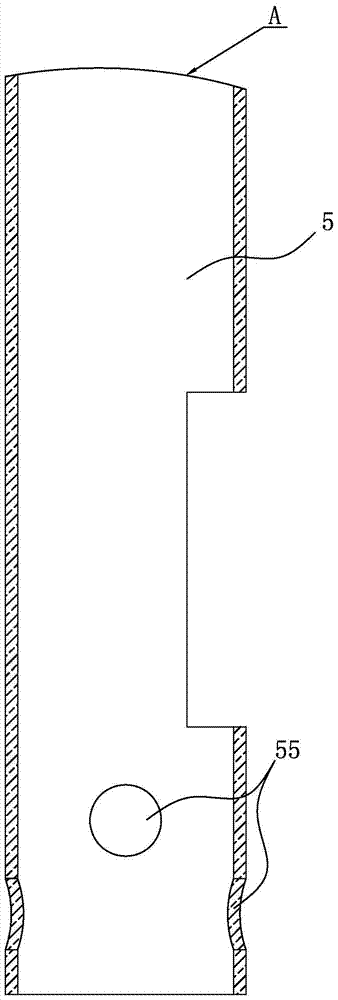

[0028] Such as figure 2 and imag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com