Flexible touch panel and its preparation method and touch device

A touch panel and flexible technology, applied in chemical instruments and methods, other household appliances, instruments, etc., can solve the problems that the preparation process cannot realize batch production and low yield rate, so as to improve market competitiveness and improve the quality of finished products. The effect of improving the efficiency and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

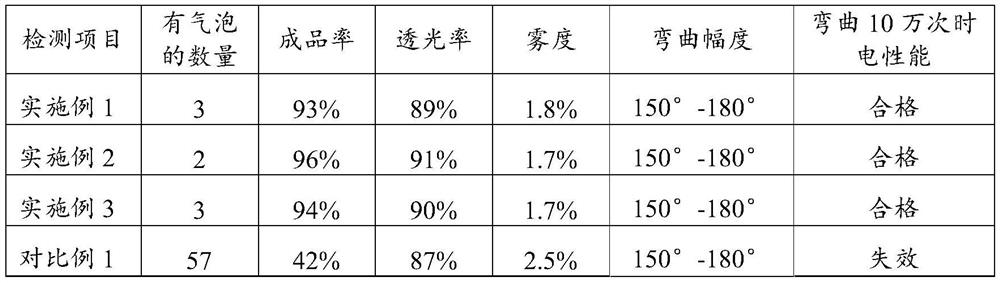

[0086] The mass production of flexible touch panels can be realized by using the preparation method provided by the present invention. In the current preparation process, the yield of the product is in the range of 40%-50%. The finished product rate can reach more than 90%, and the finished product rate has nearly doubled.

[0087] As a preferred embodiment of the present invention, the above-mentioned method for manufacturing a flexible touch panel, the step a) includes the following steps:

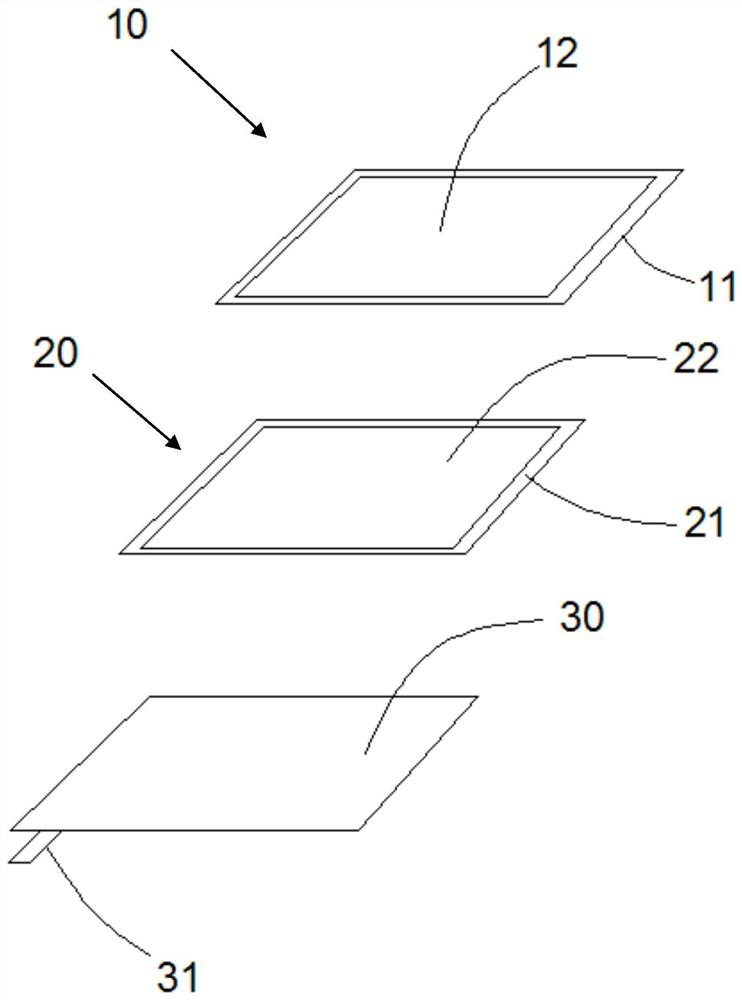

[0088] Step a1): preparing scratch-resistant coatings 12 on both surfaces of the first substrate 11 of the flexible transparent cover 10 to obtain the flexible transparent cover 10;

[0089] Step a2): preparing a decorative layer 22 on the surface of the second substrate 21 of the flexible transparent decorative plate 20 to obtain a flexible transparent decorative plate 20;

[0090] Step a3): laminating the flexible transparent cover plate 10 prepared in step a1) and the flexible transp...

Embodiment approach

[0130] As a further preferred embodiment of the present invention, the preparation method of the flexible touch panel comprises the following steps:

[0131] Step a): Laminating the flexible transparent cover 10 and the flexible transparent decorative plate 20 to obtain a flexible cover assembly;

[0132] Above-mentioned step a) comprises the following steps:

[0133] Step a1): Coat the film layer on the upper and lower sides of the first substrate 11 using the slot coating technology, the coating speed is less than 5m / s, and then bake, the baking temperature is 80-100°C, and the baking time is 10-20 minutes , then UV curing, UV wavelength 200-360nm, energy 500-550mJ / cm 2 , make the anti-scratch coating 12; the film thickness of the anti-scratch coating 12 is 5-60 microns, the adhesion level between the anti-scratch coating 12 and the first substrate 11 is greater than 4B, and a flexible transparent cover plate is obtained at this time 10;

[0134] Step a2): On the upper su...

Embodiment 1

[0143] This embodiment provides a flexible touch panel, the preparation method of which includes the following steps:

[0144] Step a): Laminating the flexible transparent cover 10 and the flexible transparent decorative plate 20 to obtain a flexible cover assembly;

[0145] Above-mentioned step a) comprises the following steps:

[0146] Step a1): coating the upper and lower sides of the PET-based film of the first substrate 11 with a film layer using a slot coating technique, wherein the thickness of the PET-based film of the first substrate 11 is 25 microns;

[0147] When coating, the coating speed is 1m / s, then bake, the baking temperature is 80°C, the baking time is 10min, and then UV curing, UV wavelength 200-360nm, energy 500mJ / cm 2 , make the anti-scratch coating 12; the film thickness of the anti-scratch coating 12 is 5 microns, the adhesion level between the anti-scratch coating 12 and the first substrate 11 is 4B, and now the flexible transparent cover plate 10 is o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com