Dried bean curd air pressure equipment

A technology of dried tofu and air pressure, which is applied in cheese substitutes, food science, applications, etc., and can solve problems such as excessive pressure, wall temperature exceeding the allowable value, and cracking of dried tofu

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

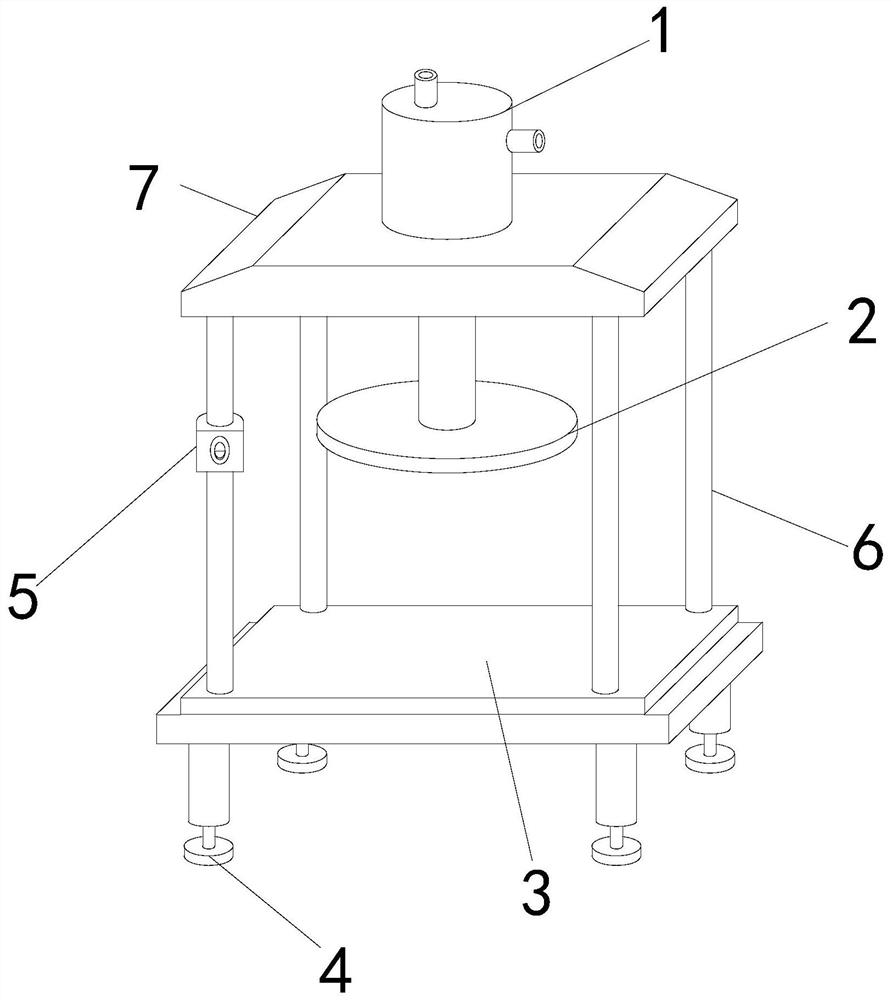

[0027] as attached figure 1 to the attached Figure 4 shown:

[0028] The invention discloses an air pressure equipment for dried tofu. It is installed at the center of the top surface of the top cover 7, the center of the top surface of the pressing plate 2 is threadedly connected to the bottom surface of the front end of the air pressure device 1, and the top surface of the placing table 3 is threadedly connected to the bottom surface of the top cover 7 through the connecting column 6. 3. The bottom is movably connected to the buffer base 4.

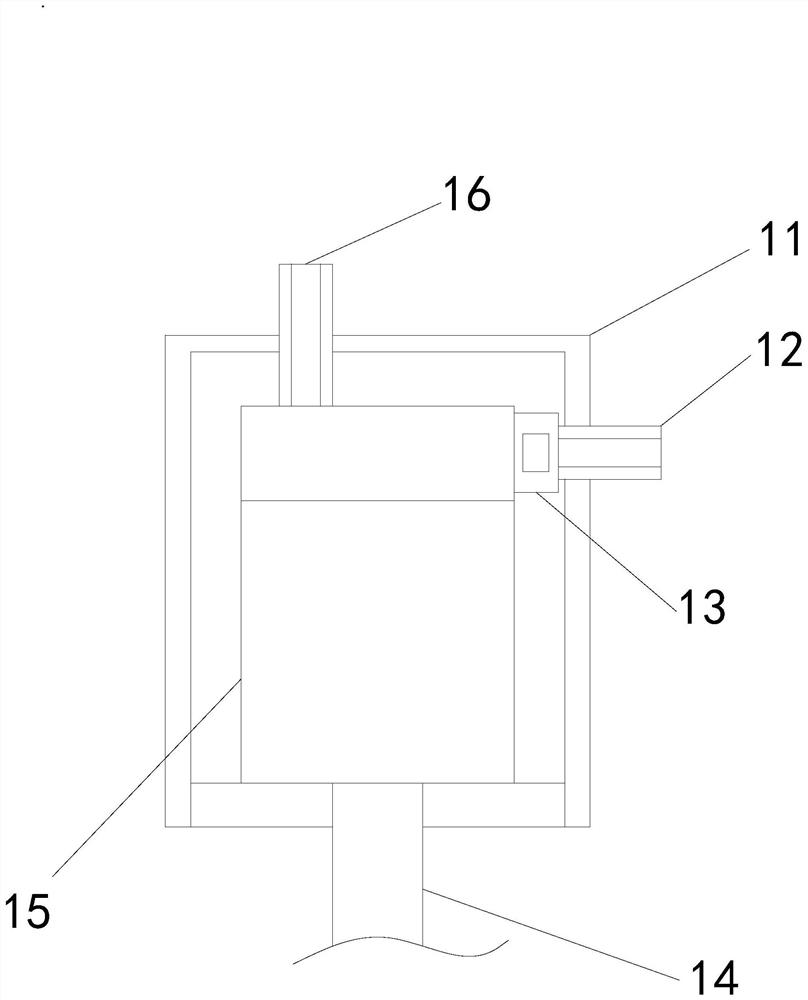

[0029] The air pressure device 1 is provided with a soundproof cover 11, an air inlet 12, a dehumidification device 13, a driven rod 14, an air pump 15, and an air outlet 16. The air inlet 12 is embedded and connected to the right end of the soundproof cover 11 and the dehumidifier. The device 13 is fixedly connected, the air outlet 16 is embedded and connected to the upper left of the soundproof cover 11 and is fixedly connected t...

Embodiment 2

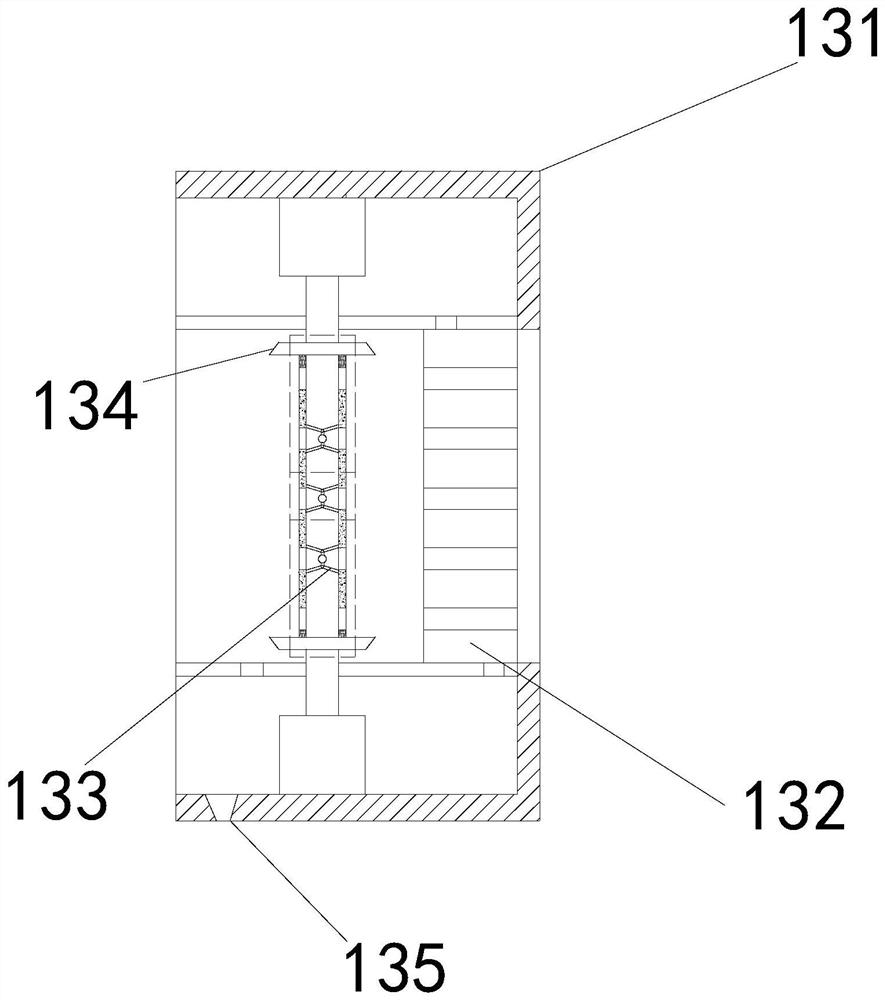

[0035] as attached Figure 5 to the attached Figure 7 shown:

[0036] The present invention discloses an air pressure equipment for dried tofu. The extrusion device 134 is provided with a push-pull rod A1, a fixed outer shell A2, a return force seat A3, a sponge plate A4, a driven block A5, and an extrusion ring A6. The ends are fixedly connected on both sides of the inner wall of the fixed housing A2, the outer wall of the sponge plate A4 is fixedly connected with the driven block A5, the driven block A5 is connected with the extrusion ring A6, and the front end of the return seat A3 is connected with the driven block A5 For fixed connection, there are two extruding rings A6 with the same structure, and are symmetrically installed inside the device, so that the force of the driven block A5 being extruded is average.

[0037] Wherein, the extrusion ring A6 includes a connector A61, a swing plate A62, and a pusher A63, the connector A61 is movably connected with the swing plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com